Manual Temperature Control FORD KUGA 2011 1.G Owner's Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1720 of 2057

Turbocharger – Overview

Turbocharger(s)

CAUTION: Do not switch off the engine

while it is running at high speed. If the

engine is switched off while it is running

at high speed, the turbocharger will

continue to run after the engine oil

pressure has already dropped to zero. This

will cause premature wear in the

turbocharger bearings.

A TC consists of an exhaust turbine located in the

exhaust gas flow, this turbine is connected to a

compressor by a shaft. The turbine is made to

rotate by the exhaust gas flow from the engine and

thus drives the compressor. The compressor

increases the pressure in the engine intake tract

so that a greater mass of air enters the cylinder

during the intake stroke.

The turbine housing of the TC is integrated into the

exhaust manifold. This construction offers

thermodynamic advantages compared with the

usual construction, the maximum exhaust

temperature is up to 1050°C.

The maximum boost pressure is 0.65 bar.

The exhaust manifold is secured to the exhaust

side of the cylinder head with 12 self-locking nuts.

The exhaust manifold gasket is a multi-layer steel

gasket and cannot be reused. In order to

compensate for the thermal expansion of the

exhaust manifold, the flange of the TC is provided

with two grooves.

The TC and the exhaust manifold are joined by a

hose clip. The hose clip must not be loosened or

removed. The TC and the exhaust manifold are

not available as separate replacement parts,

exchange is only possible as a complete unit.

The turbocharger heat shield is secured to the

exhaust manifold by four bolts. Two of the bolts

have spring washers underneath their heads.

During removal, make a note of the installation

location of the spring washers to refer to during

installation.

The recirculated air valve is built into the TC

housing and cannot be changed.

The Ford diagnostic unit can test the operation of

the wastegate control valve using actuator

diagnosis.

The boost pressure regulator is set in the factory.

Adjustments to the boost pressure regulator must never be attempted. A red colored seal is applied

to the adjustment nut of the operating rod, in order

to monitor the factory setting of the boost pressure.

The bearings of the TC are lubricated with engine

oil. The engine oil passes from the cylinder block

through the oil supply pipe to the TC. The oil is

returned to the oil pan through the oil return pipe,

The TC is cooled by the engine coolant circuit.

When installing hoses and lines, make certain that

their ends are free of oil residues and dirt.

G1032425en2008.50 Kuga8/2011

303-04B-

4

Fuel Charging and Controls - Turbocharger

—

2.5L Duratec (147kW/200PS) - VI5

303-04B- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1722 of 2057

Description

Item

PWM (pulse width modulation) signal

Comments:from PCM (powertrain control module)

5

Atmospheric pressure

6

Turbocharger boost pressure.

7

from air filter

8

Intake air

9Description

Item

Recirculated air valveRefertoComponentDescription:(page

7)

10

Vacuum line, recirculated air valve

11

to intake manifold

12

Throttle plate

13

Compressor

14

Turbine

15

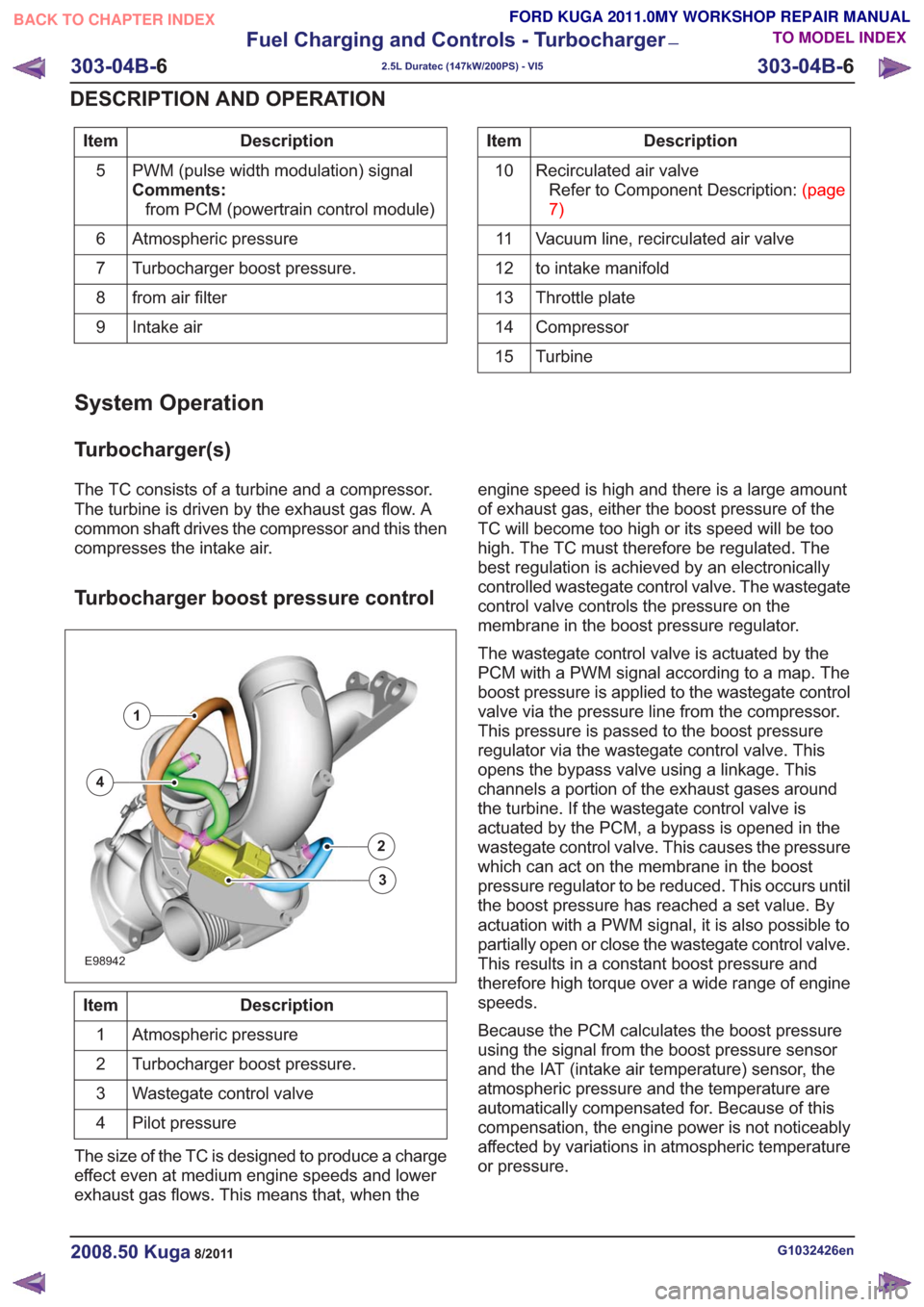

System Operation

Turbocharger(s)

The TC consists of a turbine and a compressor.

The turbine is driven by the exhaust gas flow. A

common shaft drives the compressor and this then

compresses the intake air.

Turbocharger boost pressure control

E98942

1

2

3

4

Description

Item

Atmospheric pressure

1

Turbocharger boost pressure.

2

Wastegate control valve

3

Pilot pressure

4

The size of the TC is designed to produce a charge

effect even at medium engine speeds and lower

exhaust gas flows. This means that, when the engine speed is high and there is a large amount

of exhaust gas, either the boost pressure of the

TC will become too high or its speed will be too

high. The TC must therefore be regulated. The

best regulation is achieved by an electronically

controlled wastegate control valve. The wastegate

control valve controls the pressure on the

membrane in the boost pressure regulator.

The wastegate control valve is actuated by the

PCM with a PWM signal according to a map. The

boost pressure is applied to the wastegate control

valve via the pressure line from the compressor.

This pressure is passed to the boost pressure

regulator via the wastegate control valve. This

opens the bypass valve using a linkage. This

channels a portion of the exhaust gases around

the turbine. If the wastegate control valve is

actuated by the PCM, a bypass is opened in the

wastegate control valve. This causes the pressure

which can act on the membrane in the boost

pressure regulator to be reduced. This occurs until

the boost pressure has reached a set value. By

actuation with a PWM signal, it is also possible to

partially open or close the wastegate control valve.

This results in a constant boost pressure and

therefore high torque over a wide range of engine

speeds.

Because the PCM calculates the boost pressure

using the signal from the boost pressure sensor

and the IAT (intake air temperature) sensor, the

atmospheric pressure and the temperature are

automatically compensated for. Because of this

compensation, the engine power is not noticeably

affected by variations in atmospheric temperature

or pressure.

G1032426en2008.50 Kuga8/2011

303-04B-

6

Fuel Charging and Controls - Turbocharger

—

2.5L Duratec (147kW/200PS) - VI5

303-04B- 6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1767 of 2057

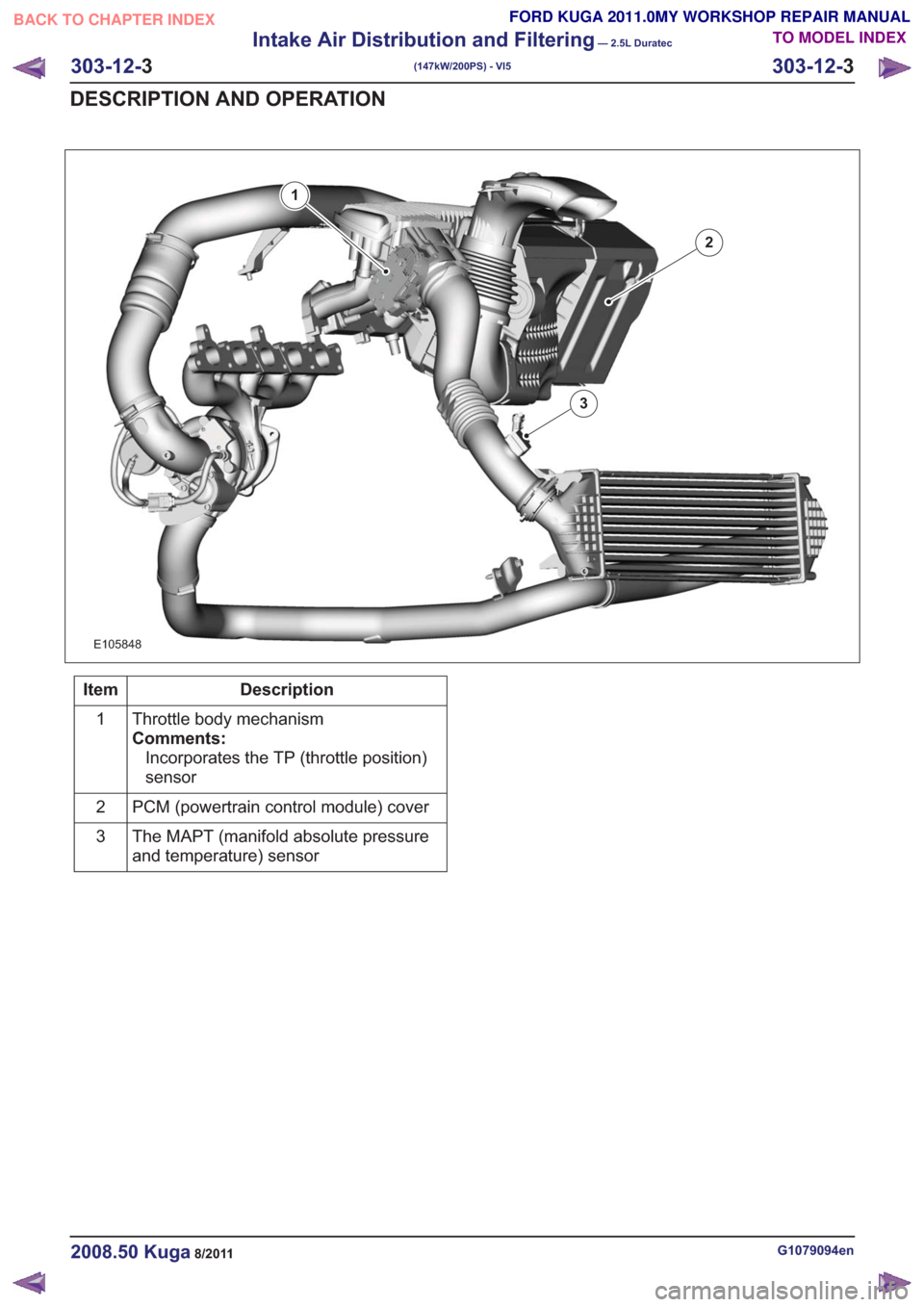

E105848

1

2

3

Description

Item

Throttle body mechanism

Comments:Incorporates the TP (throttle position)

sensor

1

PCM (powertrain control module) cover

2

The MAPT (manifold absolute pressure

and temperature) sensor

3

G1079094en2008.50 Kuga8/2011

303-12-

3

Intake Air Distribution and Filtering

— 2.5L Duratec

(147kW/200PS) - VI5

303-12- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1775 of 2057

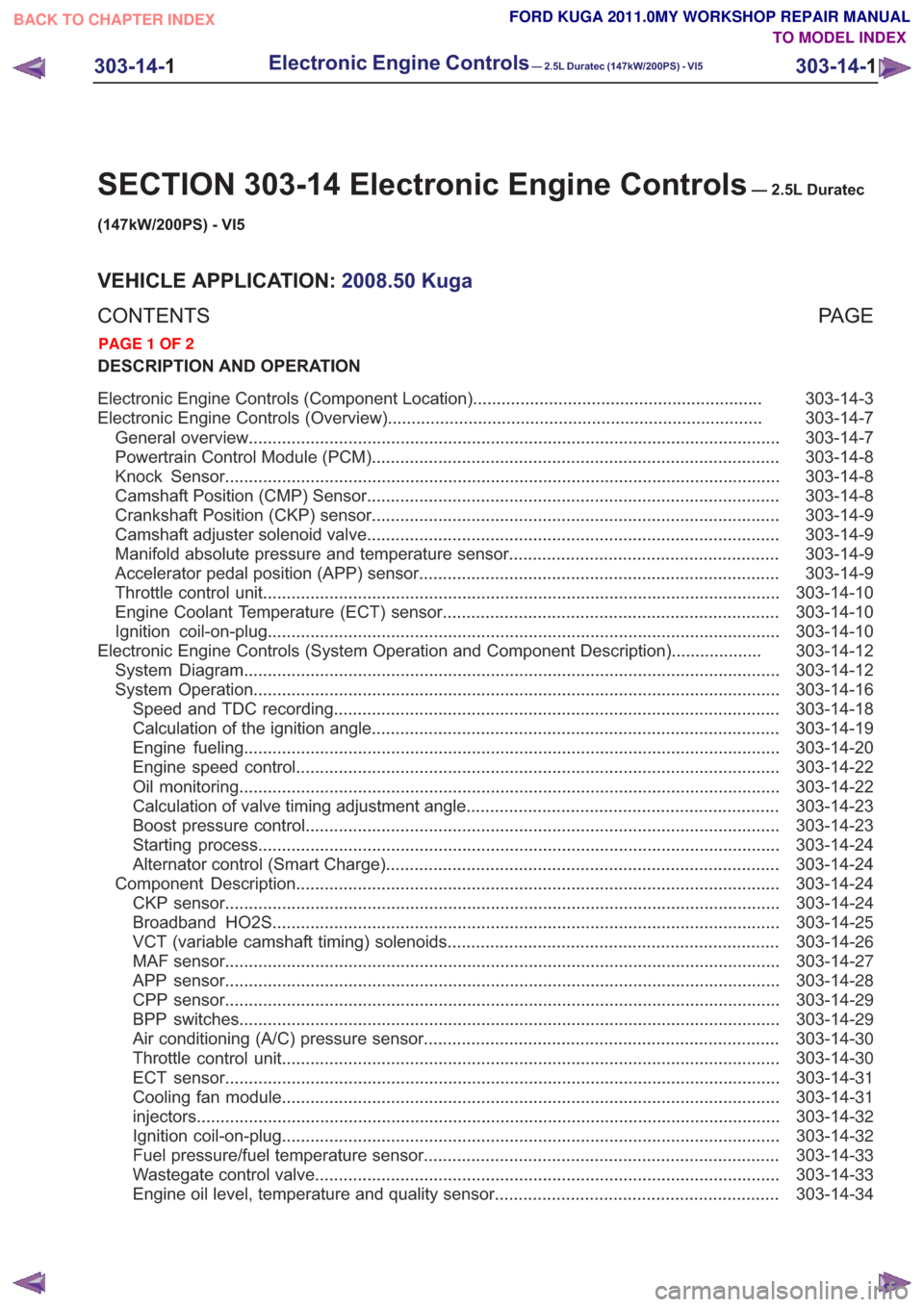

SECTION 303-14 Electronic Engine Controls— 2.5L Duratec

(147kW/200PS) - VI5

VEHICLE APPLICATION: 2008.50 Kuga

PA G E

CONTENTS

DESCRIPTION AND OPERATION

303-14-3

Electronic Engine Controls (Component Location) .............................................................

303-14-7

Electronic Engine Controls (Overview) ........................................................................\

.......

303-14-7

General overview ........................................................................\

........................................

303-14-8

Powertrain Control Module (PCM) ........................................................................\

..............

303-14-8

Knock Sensor ........................................................................\

.............................................

303-14-8

Camshaft Position (CMP) Sensor ........................................................................\

...............

303-14-9

Crankshaft Position (CKP) sensor ........................................................................\

..............

303-14-9

Camshaft adjuster solenoid valve........................................................................\

...............

303-14-9

Manifold absolute pressure and temperature sensor .........................................................

303-14-9

Accelerator pedal position (APP) sensor ........................................................................\

....

303-14-10

Throttle control unit ........................................................................\

.....................................

303-14-10

Engine Coolant Temperature (ECT) sensor.......................................................................

303-14-10

Ignition coil-on-plug ........................................................................\

....................................

303-14-12

Electronic Engine Controls (System Operation and Component Description) ...................

303-14-12

System Diagram ........................................................................\

.........................................

303-14-16

System Operation ........................................................................\

.......................................

303-14-18

Speed and TDC recording ........................................................................\

......................

303-14-19

Calculation of the ignition angle ........................................................................\

..............

303-14-20

Engine fueling ........................................................................\

.........................................

303-14-22

Engine speed control ........................................................................\

..............................

303-14-22

Oil monitoring ........................................................................\

..........................................

303-14-23

Calculation of valve timing adjustment angle..................................................................

303-14-23

Boost pressure control ........................................................................\

............................

303-14-24

Starting process ........................................................................\

......................................

303-14-24

Alternator control (Smart Charge) ........................................................................\

...........

303-14-24

Component Description ........................................................................\

..............................

303-14-24

CKP sensor ........................................................................\

.............................................

303-14-25

Broadband HO2S ........................................................................\

...................................

303-14-26

VCT (variable camshaft timing) solenoids ......................................................................

303-14-27

MAF sensor ........................................................................\

.............................................

303-14-28

APP sensor ........................................................................\

.............................................

303-14-29

CPP sensor ........................................................................\

.............................................

303-14-29

BPP switches ........................................................................\

..........................................

303-14-30

Air conditioning (A/C) pressure sensor ........................................................................\

...

303-14-30

Throttle

control unit ........................................................................\

.................................

303-14-31

ECT sensor ........................................................................\

.............................................

303-14-31

Cooling fan module ........................................................................\

.................................

303-14-32

injectors........................................................................\

...................................................

303-14-32

Ignition coil-on-plug ........................................................................\

.................................

303-14-33

Fuel pressure/fuel temperature sensor ........................................................................\

...

303-14-33

Wastegate control valve ........................................................................\

..........................

303-14-34

Engine oil level, temperature and quality sensor ............................................................

303-14-1

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

PAGE 1 OF 2

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1776 of 2057

303-14-34

Exterior aor temperature sensor ........................................................................\

.............

DIAGNOSIS AND TESTING 303-14-35

Electronic Engine Controls ........................................................................\

.........................

303-14-35

Inspection and Verification ........................................................................\

..........................

REMOVAL AND INSTALLATION 303-14-36

(29 232 0)

Camshaft Position (CMP) Sensor ...................................................................

303-14-37

(29 219 0)

Catalyst Monitor Sensor ........................................................................\

.........

303-14-38

(29 230 0)

Crankshaft Position (CKP) Sensor .................................................................

303-14-40

(29 220 0)

Heated Oxygen Sensor (HO2S) .....................................................................

303-14-41

(29 222 0)

Knock Sensor (KS) ........................................................................\

.................

303-14-42

(29 226 0)

Mass Air Flow (MAF) Sensor ........................................................................\

..

303-14-43

(29 200 0)

Powertrain Control Module (PCM) .................................................................

303-14-45

(29 233 0)

Variable Valve Timing (VVT) Oil Control Solenoid ..........................................

303-14-46

(33 502 0)

Brake Pedal Position (BPP) Switch ................................................................

303-14-47

(33 503 0)

Clutch Pedal Position (CPP) Switch ...............................................................

303-14-2

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

2

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

PAGE 2 OF 2

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1777 of 2057

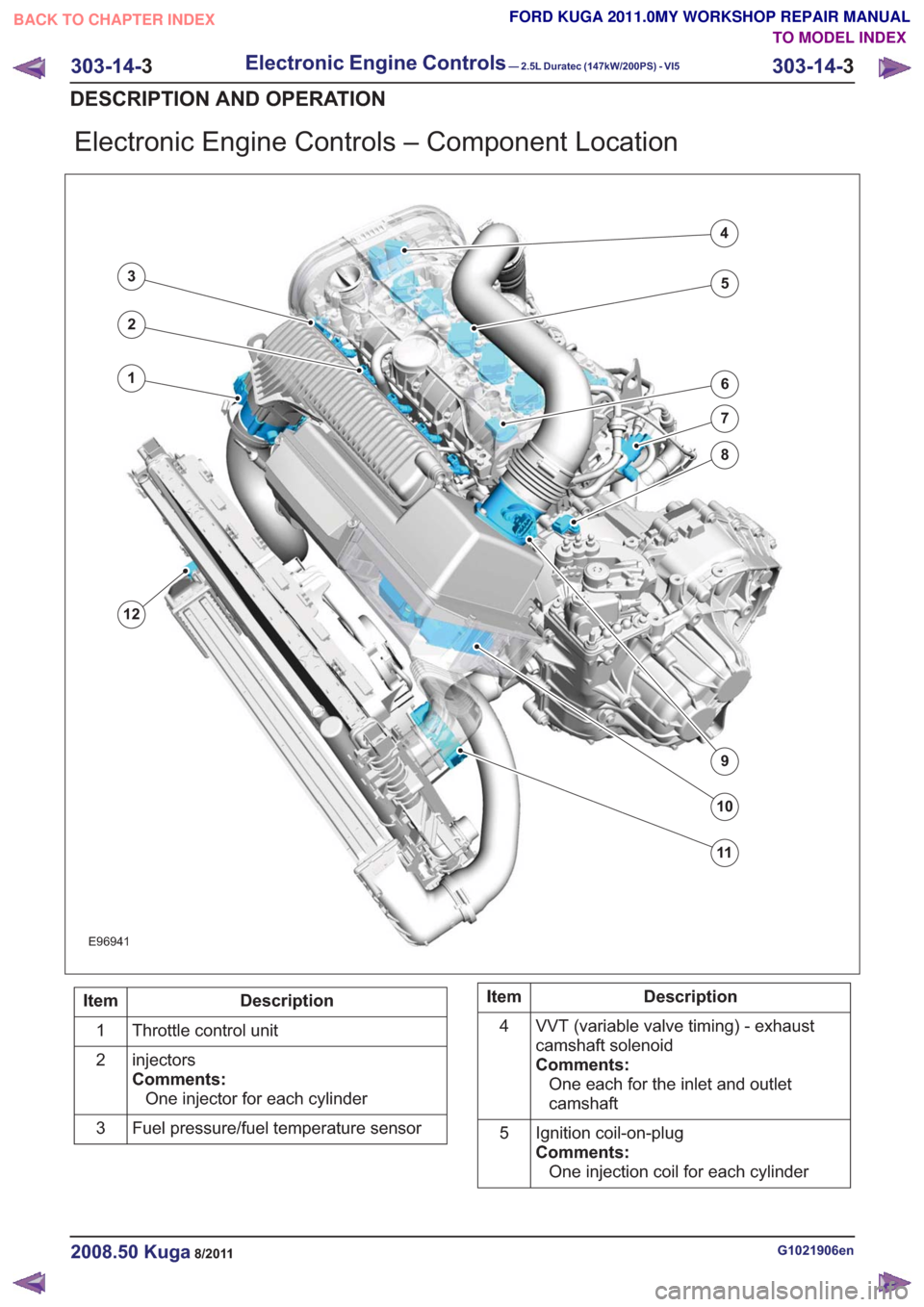

Electronic Engine Controls – Component Location

E96941

1

12

2

3

4

5

6

7

8

9

10

11

Description

Item

Throttle control unit

1

injectors

Comments:One injector for each cylinder

2

Fuel pressure/fuel temperature sensor

3Description

Item

VVT (variable valve timing) - exhaust

camshaft solenoid

Comments:One each for the inlet and outlet

camshaft

4

Ignition coil-on-plug

Comments:One injection coil for each cylinder

5

G1021906en2008.50 Kuga8/2011

303-14-

3

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1778 of 2057

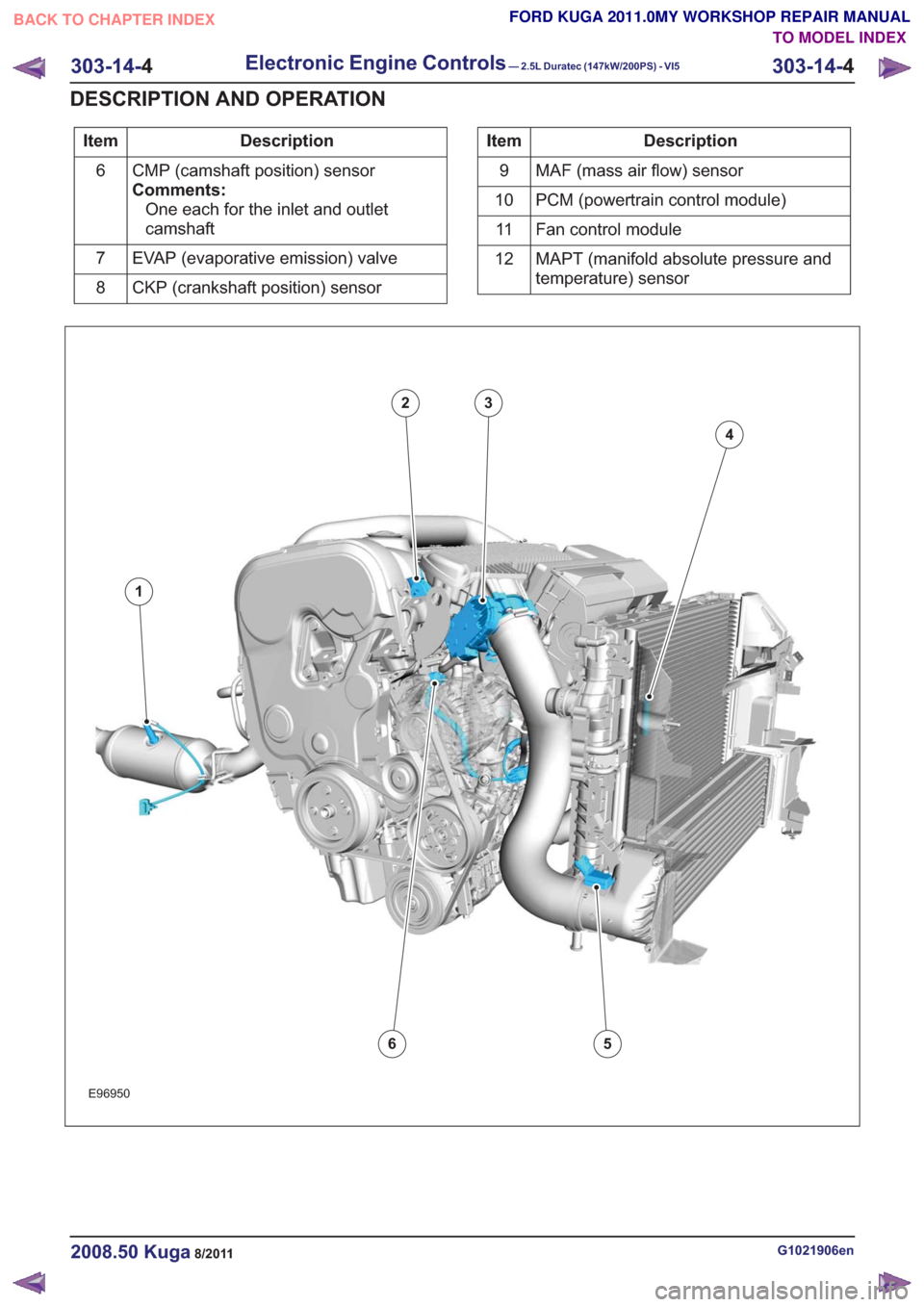

Description

Item

CMP (camshaft position) sensor

Comments:One each for the inlet and outlet

camshaft

6

EVAP (evaporative emission) valve

7

CKP (crankshaft position) sensor

8Description

Item

MAF (mass air flow) sensor

9

PCM (powertrain control module)

10

Fan control module

11

MAPT (manifold absolute pressure and

temperature) sensor

12

E96950

1

23

4

56

G1021906en2008.50 Kuga8/2011

303-14-

4

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1779 of 2057

Description

Item

Catalyst monitor sensor

1

Fuel pressure/fuel temperature sensor

2

Throttle control unit

3

Ambient air temperature sensor

4Description

Item

MAPT sensor

5

KS (knock sensor)

Comments:Two, on 2nd and 4th cylinder

6

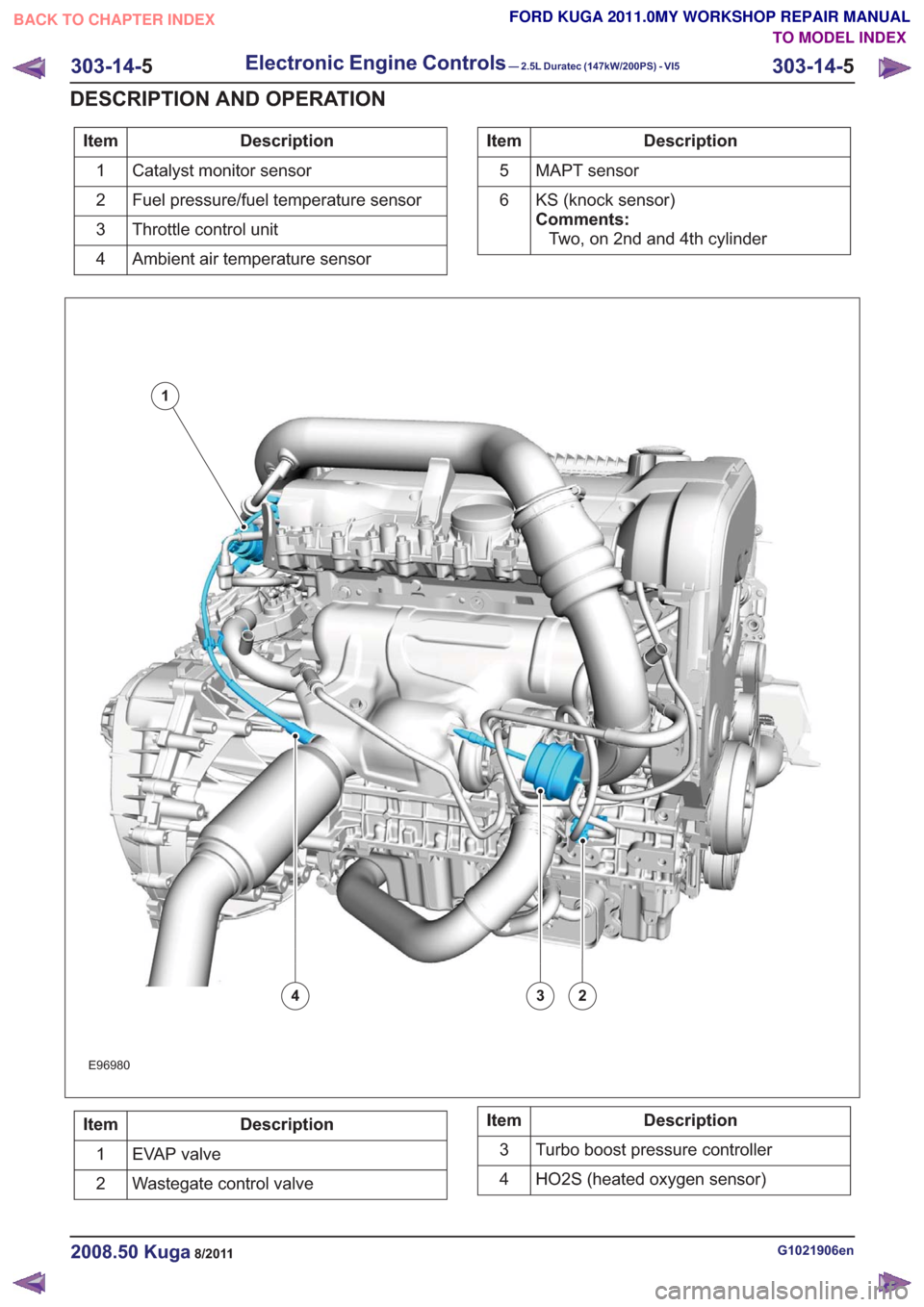

E96980

1

234

Description

Item

EVAP valve

1

Wastegate control valve

2Description

Item

Turbo boost pressure controller

3

HO2S (heated oxygen sensor)

4

G1021906en2008.50 Kuga8/2011

303-14- 5

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

5

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1781 of 2057

Electronic Engine Controls – Overview

General overview

Engine Management System

• Bosch ME 9.0 engine management system

• Knock control with two knock sensors

• Electronic Throttle Control Unit.

• Electronic accelerator pedal

• Variable camshaft timing for intake and exhaustcamshafts • Fuel injection supply manifold with combined

fuel pressure and temperature sensor

• Sequential multi-port fuel injection

• Camshaft position (CMP) sensors for intake and exhaust camshafts.

• satisfies the European exhaust emissions standard IV

• EOBD (European On-board Diagnostic) for the monitoring of emissions-related components.

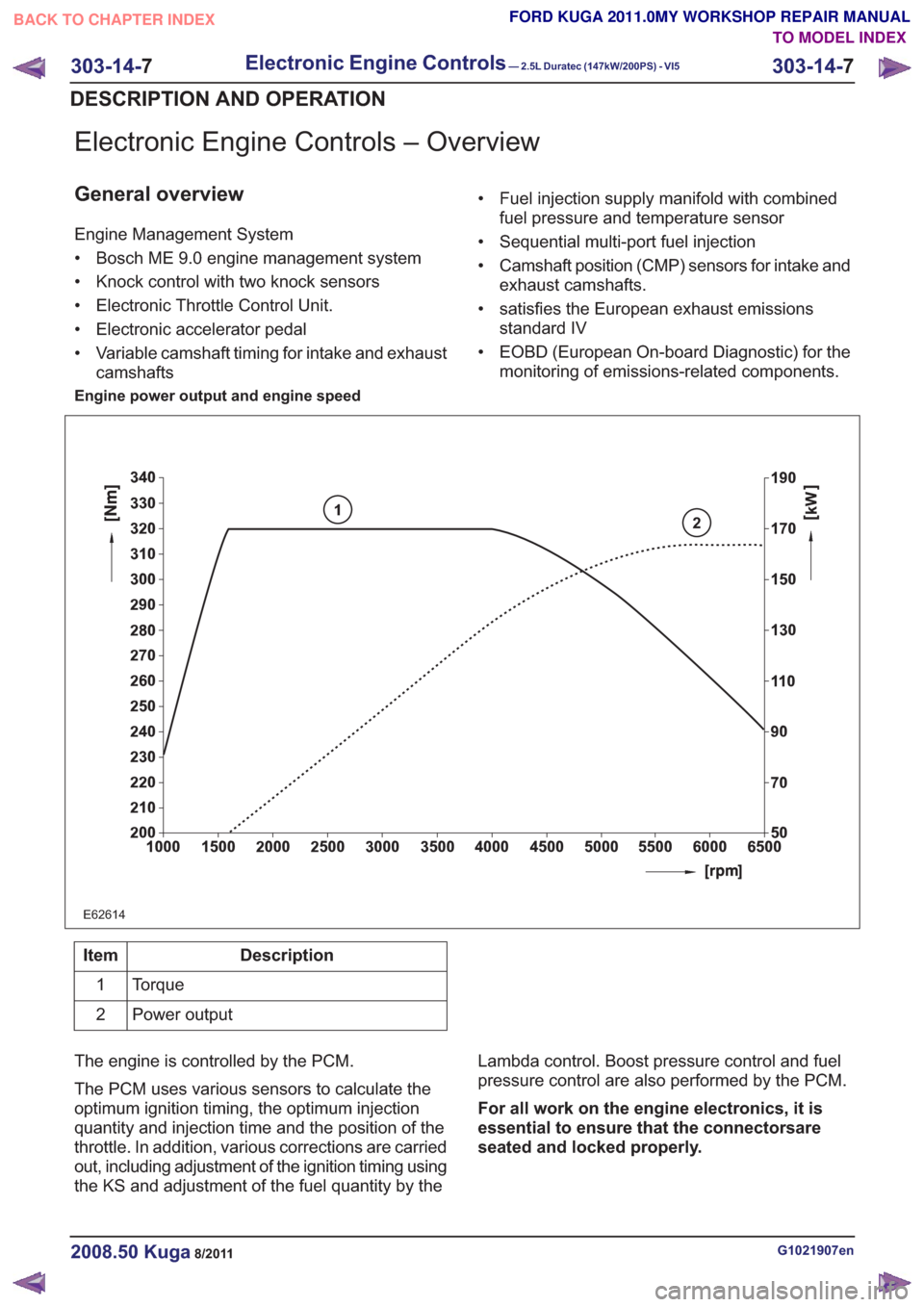

Engine power output and engine speed

2

E62614

1

Description

Item

Torque

1

Power output

2

The engine is controlled by the PCM.

The PCM uses various sensors to calculate the

optimum ignition timing, the optimum injection

quantity and injection time and the position of the

throttle. In addition, various corrections are carried

out, including adjustment of the ignition timing using

the KS and adjustment of the fuel quantity by the Lambda control. Boost pressure control and fuel

pressure control are also performed by the PCM.

For all work on the engine electronics, it is

essential to ensure that the connectorsare

seated and locked properly.

G1021907en2008.50 Kuga8/2011

303-14-

7

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

7

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1783 of 2057

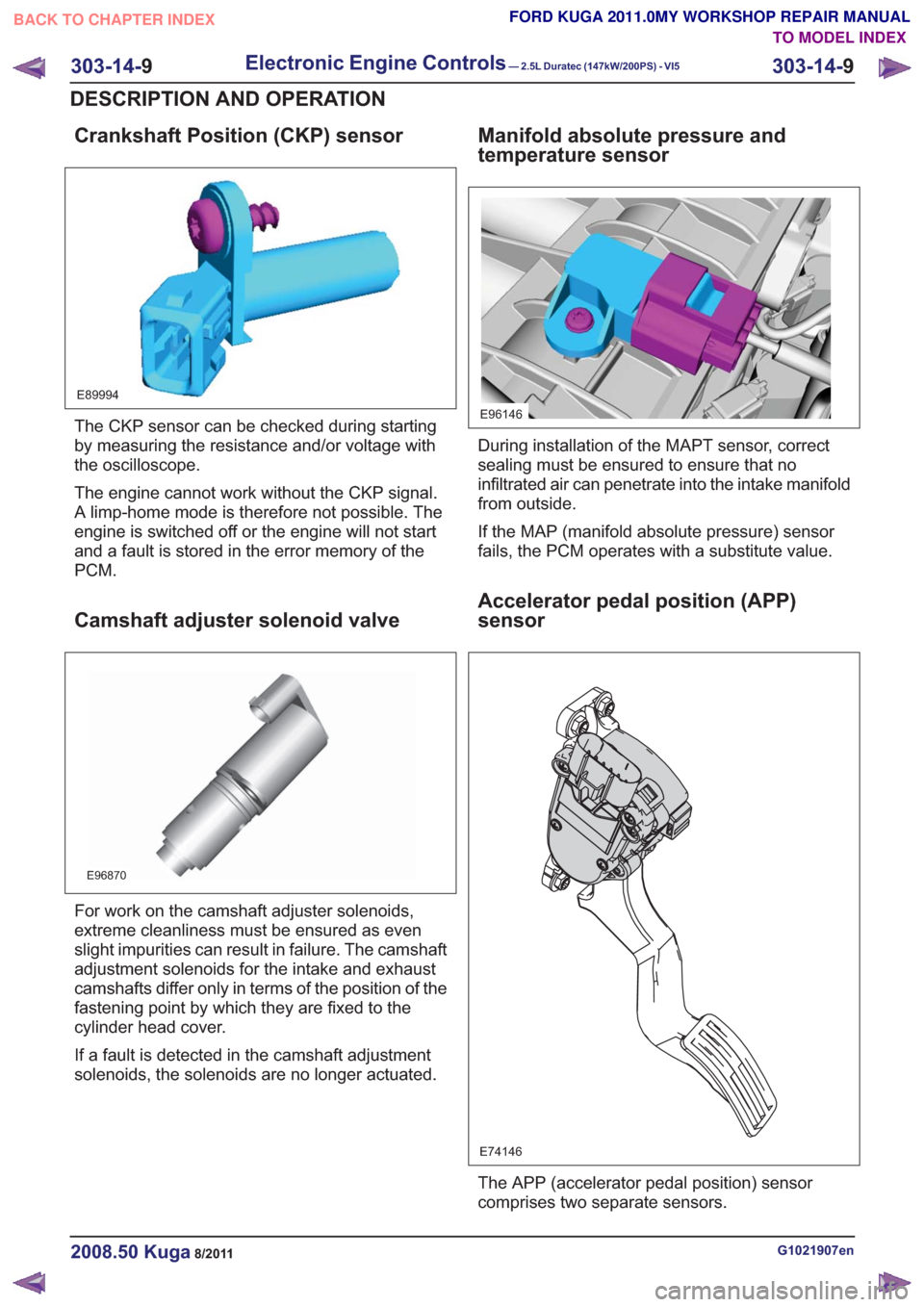

Crankshaft Position (CKP) sensor

E89994

The CKP sensor can be checked during starting

by measuring the resistance and/or voltage with

the oscilloscope.

The engine cannot work without the CKP signal.

A limp-home mode is therefore not possible. The

engine is switched off or the engine will not start

and a fault is stored in the error memory of the

PCM.

Camshaft adjuster solenoid valve

E96870

For work on the camshaft adjuster solenoids,

extreme cleanliness must be ensured as even

slight impurities can result in failure. The camshaft

adjustment solenoids for the intake and exhaust

camshafts differ only in terms of the position of the

fastening point by which they are fixed to the

cylinder head cover.

If a fault is detected in the camshaft adjustment

solenoids, the solenoids are no longer actuated.

Manifold absolute pressure and

temperature sensor

E96146

During installation of the MAPT sensor, correct

sealing must be ensured to ensure that no

infiltrated air can penetrate into the intake manifold

from outside.

If the MAP (manifold absolute pressure) sensor

fails, the PCM operates with a substitute value.

Accelerator pedal position (APP)

sensor

E74146

The APP (accelerator pedal position) sensor

comprises two separate sensors.

G1021907en2008.50 Kuga8/2011

303-14-9

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

9

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL