Lock FORD KUGA 2011 1.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1208 of 2057

Wheel Bearing and Wheel Hub

Removal

NOTE:Removal steps in this procedure may

contain installation details.

1. Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

2. Refer to: Rear Wheel Speed Sensor (206-09

Anti-Lock Control - Stability Assist, Removal

and Installation).

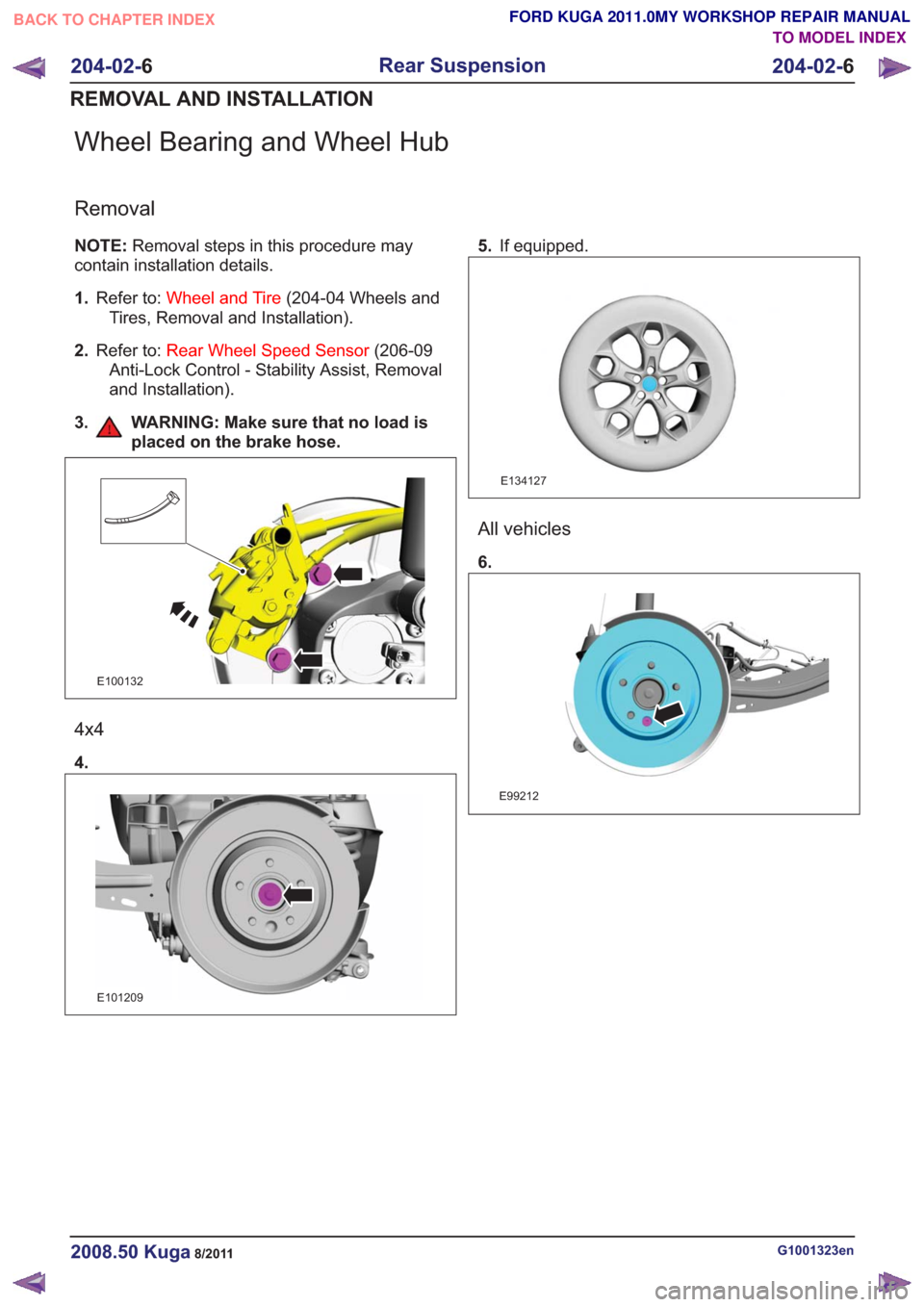

3. WARNING: Make sure that no load is placed on the brake hose.

E100132

4x4

4.

E101209

5.If equipped.

E134127

All vehicles

6.

E99212

G1001323en2008.50 Kuga8/2011

204-02- 6

Rear Suspension

204-02- 6

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1210 of 2057

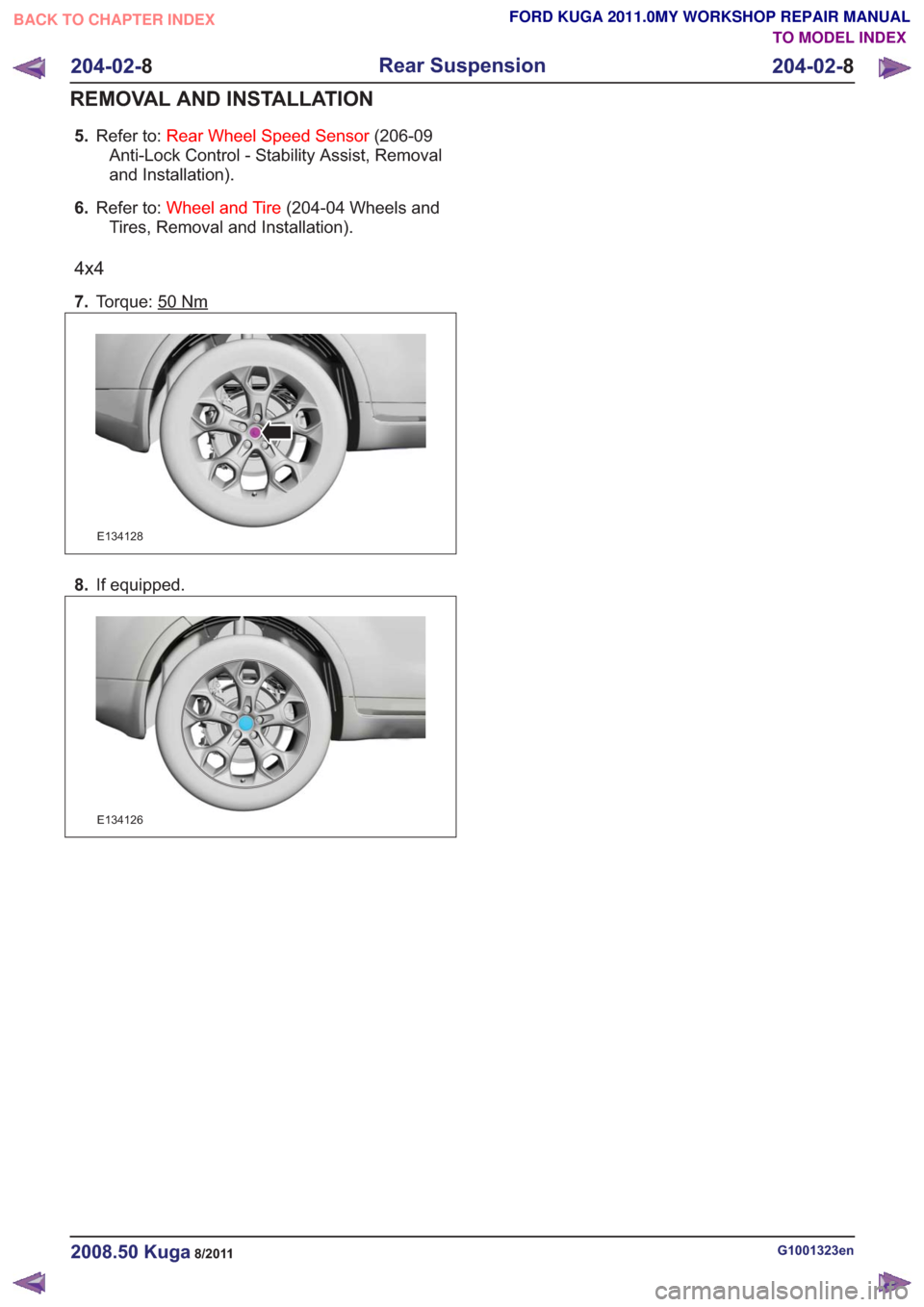

5.Refer to: Rear Wheel Speed Sensor (206-09

Anti-Lock Control - Stability Assist, Removal

and Installation).

6. Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

4x4

7. Torque: 50Nm

E134128

8.If equipped.

E134126

G1001323en2008.50 Kuga8/2011

204-02- 8

Rear Suspension

204-02- 8

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1232 of 2057

Tire Pressure Monitoring System (TPMS) – Overview

Description of operation

The tire pressure monitoring system is able to

detect loss of air in a tire at an early stage and warn

the driver. Because it can only compare the

behavior of the tires with each other, it is not

possible to draw conclusions about the absolute

tire pressure. It is also not possible to monitor the

spare tire pressure. In order for the system to

operate correctly, the tire pressures must be

regularly checked and corrected and the system

subsequently initialized (see below).

The tire pressure monitoring system used here,

depending on the equipment level, is built into the

anti-lock braking system (ABS) as an extra function

and therefore does not have its own sensors.

The ABS module determines the loss of pressure

in the tires by calculation using the wheel speed

sensors of the ABS system. If a tire loses pressure,

its diameter decreases and the speed of the wheel

therefore increases. If the ABS module detects

such a loss in pressure, it sends a signal to the

instrument cluster via the CAN bus and a warning

message is displayed in the driver information

system. The warning threshold depends among

other things on the dimension of the tires being

used, the vehicle operating conditions and the

status at the last initialization. Since neither the

absolute tire pressure nor the position of the tire is

known, after a tire pressure warning the pressure

of all the tires must be checked and the system

re-initialized. If necessary, the cause of the loss of

pressure must be investigated.

Furthermore, regular pressure checks are

necessary. The system must be initialized after a

tire is changed, winter or summer tires fitted, the

pressures corrected or adjusted to suit the vehicle

load. This can be done by the driver using the

driver information system. For further information,

see: Owner’s Manual.

G1001290en2008.50 Kuga8/2011

204-04-5

Wheels and Tires

204-04- 5

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1234 of 2057

Engine Speed Sensitive

This means that the vibration occurs at varying

vehicle speeds when a different transmission gear

is selected. It can sometimes be isolated by

increasing or decreasing engine speed with the

transmission in NEUTRAL or by stall testing with

the transmission in gear. If the condition is engine

speed sensitive, the cause is probably not related

to the tires.

If the road test indicates that there is tire whine,

but no shake or vibration, the noise originates with

the contact between the tire and the road surface.A thumping noise usually means that the tire is flat

or has soft spots making a noise as they slap the

roadway. Tire whine can be distinguished from axle

noise. Tire whine remains the same over a range

of speeds.

A complete road test procedure is described in

Section 100-04.

REFER to:

Noise, Vibration and Harshness (NVH)

(100-04 Noise, Vibration and Harshness,

Diagnosis and Testing).

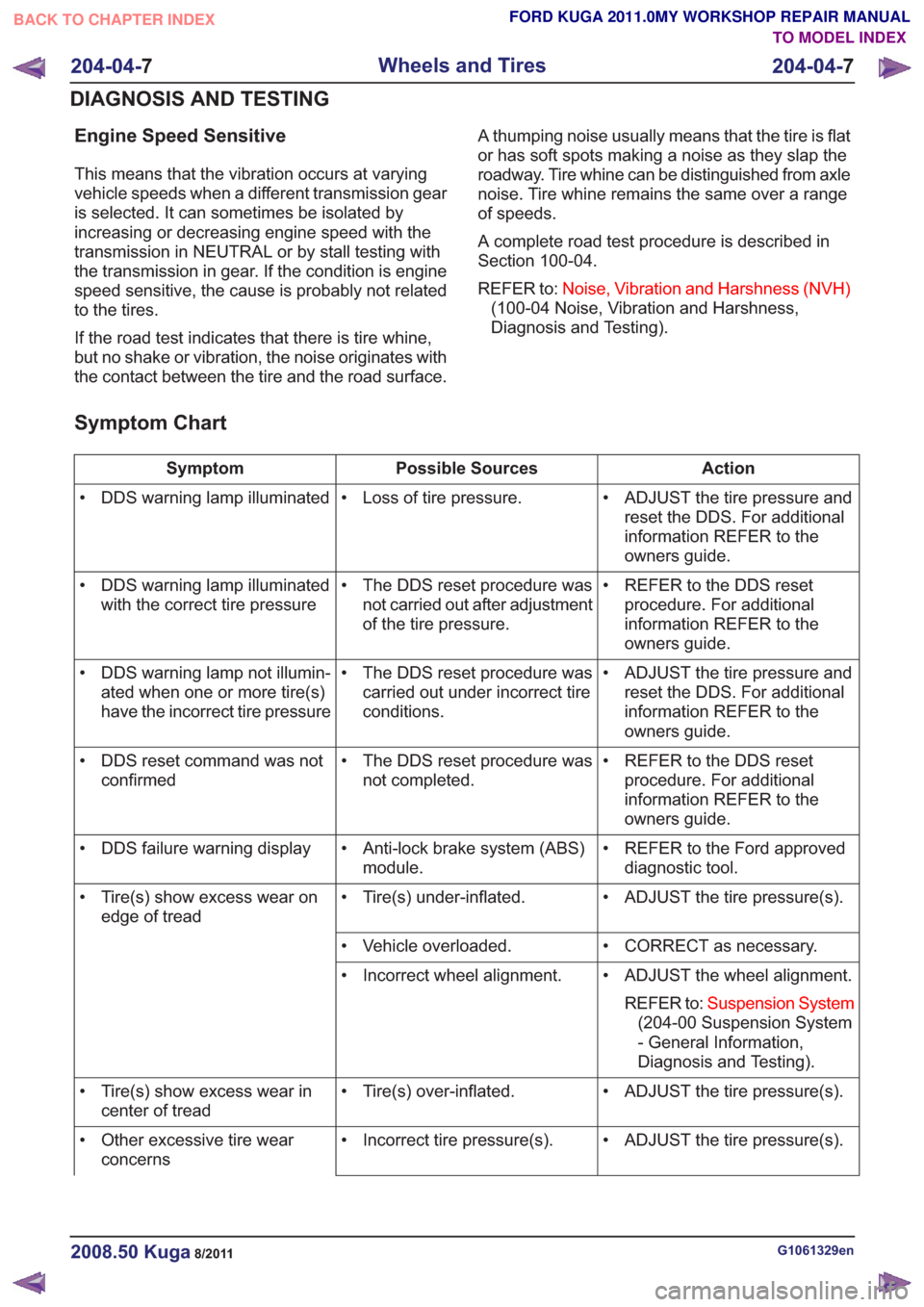

Symptom Chart

Action

Possible Sources

Symptom

• ADJUST the tire pressure andreset the DDS. For additional

information REFER to the

owners guide.

• Loss of tire pressure.

• DDS warning lamp illuminated

• REFER to the DDS resetprocedure. For additional

information REFER to the

owners guide.

• The DDS reset procedure was

not carried out after adjustment

of the tire pressure.

• DDS warning lamp illuminated

with the correct tire pressure

• ADJUST the tire pressure andreset the DDS. For additional

information REFER to the

owners guide.

• The DDS reset procedure was

carried out under incorrect tire

conditions.

• DDS warning lamp not illumin-

ated when one or more tire(s)

have the incorrect tire pressure

• REFER to the DDS resetprocedure. For additional

information REFER to the

owners guide.

• The DDS reset procedure was

not completed.

• DDS reset command was not

confirmed

• REFER to the Ford approveddiagnostic tool.

• Anti-lock brake system (ABS)

module.

• DDS failure warning display

• ADJUST the tire pressure(s).

• Tire(s) under-inflated.

• Tire(s) show excess wear on

edge of tread

• CORRECT as necessary.

• Vehicle overloaded.

• ADJUST the wheel alignment.REFER to: Suspension System

(204-00 Suspension System

- General Information,

Diagnosis and Testing).

• Incorrect wheel alignment.

• ADJUST the tire pressure(s).

• Tire(s) over-inflated.

• Tire(s) show excess wear in

center of tread

• ADJUST the tire pressure(s).

• Incorrect tire pressure(s).

• Other excessive tire wear

concerns

G1061329en2008.50 Kuga8/2011

204-04- 7

Wheels and Tires

204-04- 7

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1257 of 2057

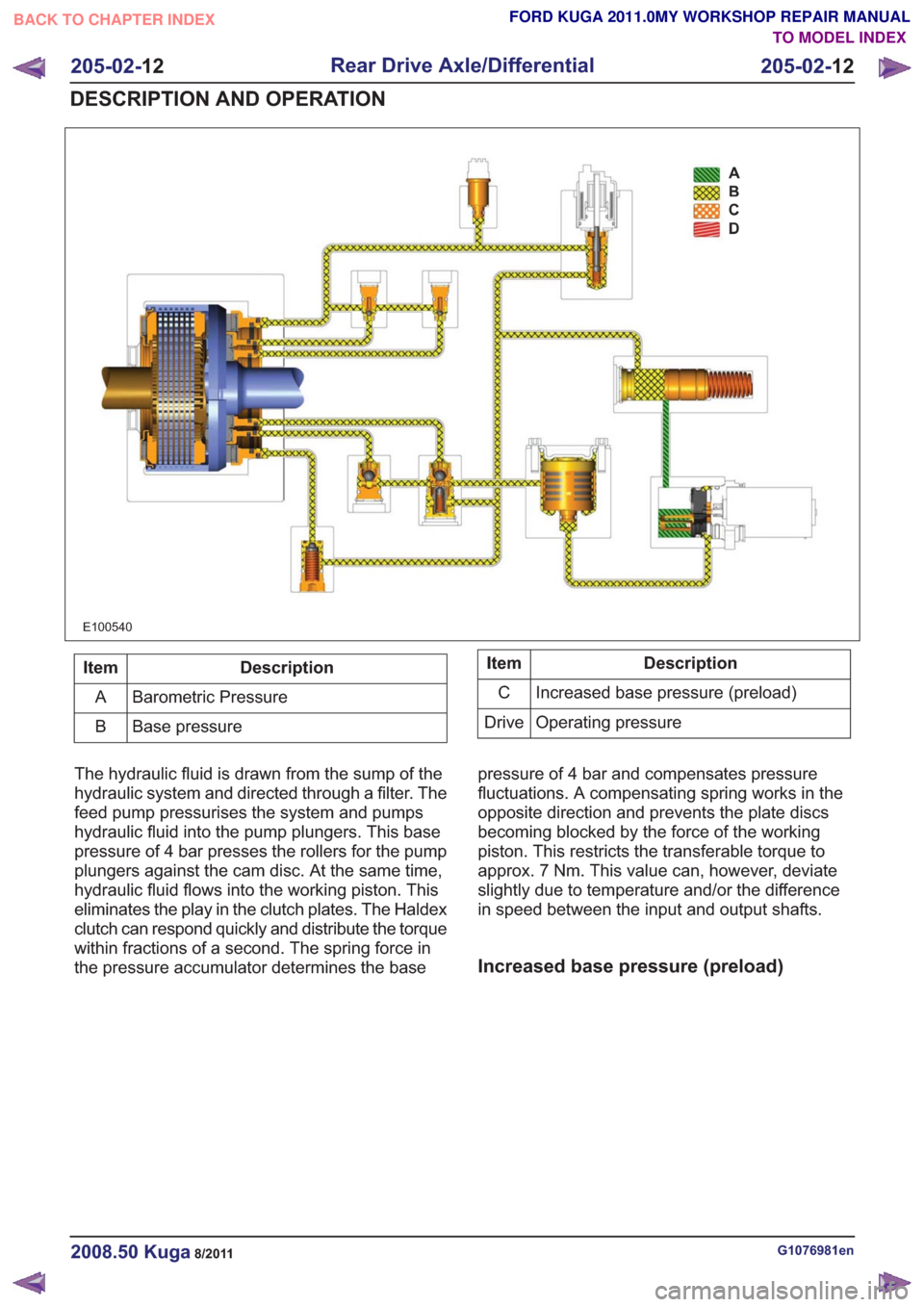

E100540

Description

Item

Barometric Pressure

A

Base pressure

BDescription

Item

Increased base pressure (preload)

C

Operating pressure

Drive

The hydraulic fluid is drawn from the sump of the

hydraulic system and directed through a filter. The

feed pump pressurises the system and pumps

hydraulic fluid into the pump plungers. This base

pressure of 4 bar presses the rollers for the pump

plungers against the cam disc. At the same time,

hydraulic fluid flows into the working piston. This

eliminates the play in the clutch plates. The Haldex

clutch can respond quickly and distribute the torque

within fractions of a second. The spring force in

the pressure accumulator determines the base pressure of 4 bar and compensates pressure

fluctuations. A compensating spring works in the

opposite direction and prevents the plate discs

becoming blocked by the force of the working

piston. This restricts the transferable torque to

approx. 7 Nm. This value can, however, deviate

slightly due to temperature and/or the difference

in speed between the input and output shafts.

Increased base pressure (preload)

G1076981en2008.50 Kuga8/2011

205-02-

12

Rear Drive Axle/Differential

205-02- 12

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1297 of 2057

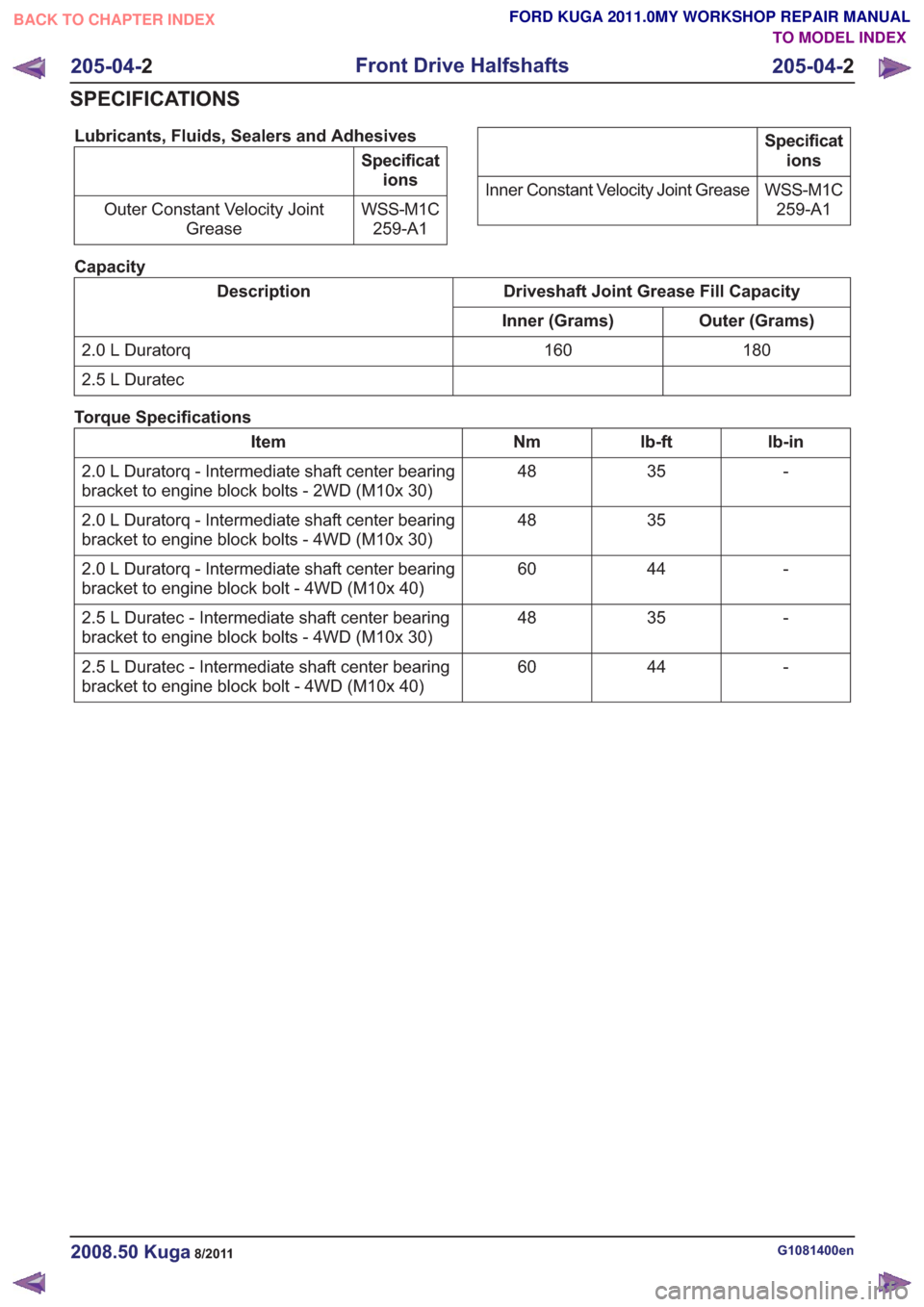

Lubricants, Fluids, Sealers and Adhesives

Specifications

WSS-M1C 259-A1

Outer Constant Velocity Joint

Grease

Specifications

WSS-M1C 259-A1

Inner Constant Velocity Joint Grease

Capacity

Driveshaft Joint Grease Fill Capacity

Description

Outer (Grams)

Inner (Grams)

180

160

2.0 L Duratorq

2.5 L Duratec

Torque Specifications

lb-in

lb-ft

Nm

Item

-

35

48

2.0 L Duratorq - Intermediate shaft center bearing

bracket to engine block bolts - 2WD (M10x 30)

35

48

2.0 L Duratorq - Intermediate shaft center bearing

bracket to engine block bolts - 4WD (M10x 30)

-

44

60

2.0 L Duratorq - Intermediate shaft center bearing

bracket to engine block bolt - 4WD (M10x 40)

-

35

48

2.5 L Duratec - Intermediate shaft center bearing

bracket to engine block bolts - 4WD (M10x 30)

-

44

60

2.5 L Duratec - Intermediate shaft center bearing

bracket to engine block bolt - 4WD (M10x 40)

G1081400en2008.50 Kuga8/2011

205-04- 2

Front Drive Halfshafts

205-04- 2

SPECIFICATIONS

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1340 of 2057

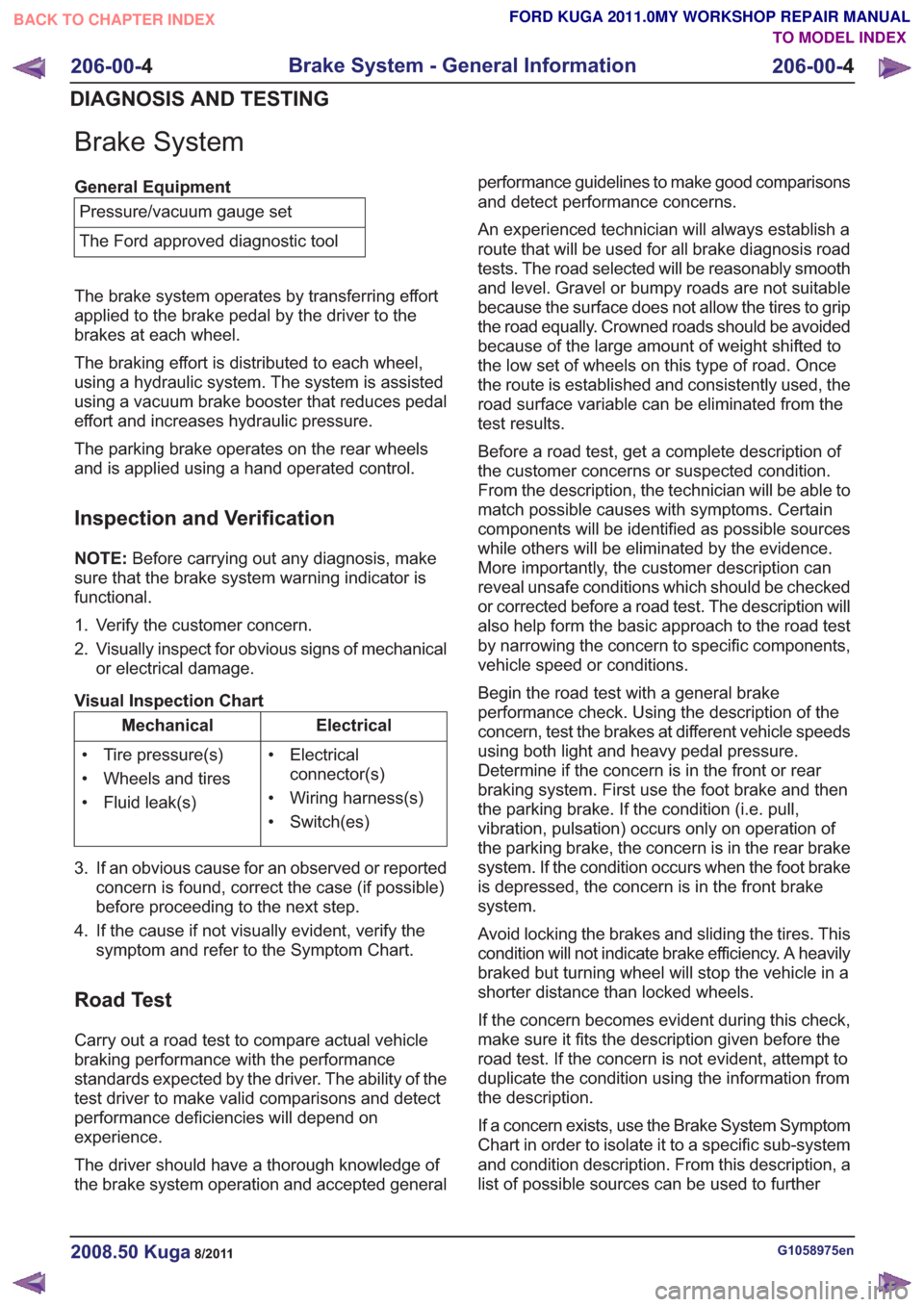

Brake System

General EquipmentPressure/vacuum gauge set

The Ford approved diagnostic tool

The brake system operates by transferring effort

applied to the brake pedal by the driver to the

brakes at each wheel.

The braking effort is distributed to each wheel,

using a hydraulic system. The system is assisted

using a vacuum brake booster that reduces pedal

effort and increases hydraulic pressure.

The parking brake operates on the rear wheels

and is applied using a hand operated control.

Inspection and Verification

NOTE: Before carrying out any diagnosis, make

sure that the brake system warning indicator is

functional.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection Chart

Electrical

Mechanical

• Electricalconnector(s)

• Wiring harness(s)

• Switch(es)

• Tire pressure(s)

• Wheels and tires

• Fluid leak(s)

3. If an obvious cause for an observed or reported concern is found, correct the case (if possible)

before proceeding to the next step.

4. If the cause if not visually evident, verify the symptom and refer to the Symptom Chart.

Road Test

Carry out a road test to compare actual vehicle

braking performance with the performance

standards expected by the driver. The ability of the

test driver to make valid comparisons and detect

performance deficiencies will depend on

experience.

The driver should have a thorough knowledge of

the brake system operation and accepted general performance guidelines to make good comparisons

and detect performance concerns.

An experienced technician will always establish a

route that will be used for all brake diagnosis road

tests. The road selected will be reasonably smooth

and level. Gravel or bumpy roads are not suitable

because the surface does not allow the tires to grip

the road equally. Crowned roads should be avoided

because of the large amount of weight shifted to

the low set of wheels on this type of road. Once

the route is established and consistently used, the

road surface variable can be eliminated from the

test results.

Before a road test, get a complete description of

the customer concerns or suspected condition.

From the description, the technician will be able to

match possible causes with symptoms. Certain

components will be identified as possible sources

while others will be eliminated by the evidence.

More importantly, the customer description can

reveal unsafe conditions which should be checked

or corrected before a road test. The description will

also help form the basic approach to the road test

by narrowing the concern to specific components,

vehicle speed or conditions.

Begin the road test with a general brake

performance check. Using the description of the

concern, test the brakes at different vehicle speeds

using both light and heavy pedal pressure.

Determine if the concern is in the front or rear

braking system. First use the foot brake and then

the parking brake. If the condition (i.e. pull,

vibration, pulsation) occurs only on operation of

the parking brake, the concern is in the rear brake

system. If the condition occurs when the foot brake

is depressed, the concern is in the front brake

system.

Avoid locking the brakes and sliding the tires. This

condition will not indicate brake efficiency. A heavily

braked but turning wheel will stop the vehicle in a

shorter distance than locked wheels.

If the concern becomes evident during this check,

make sure it fits the description given before the

road test. If the concern is not evident, attempt to

duplicate the condition using the information from

the description.

If a concern exists, use the Brake System Symptom

Chart in order to isolate it to a specific sub-system

and condition description. From this description, a

list of possible sources can be used to further

G1058975en2008.50 Kuga8/2011

206-00-

4

Brake System - General Information

206-00- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1342 of 2057

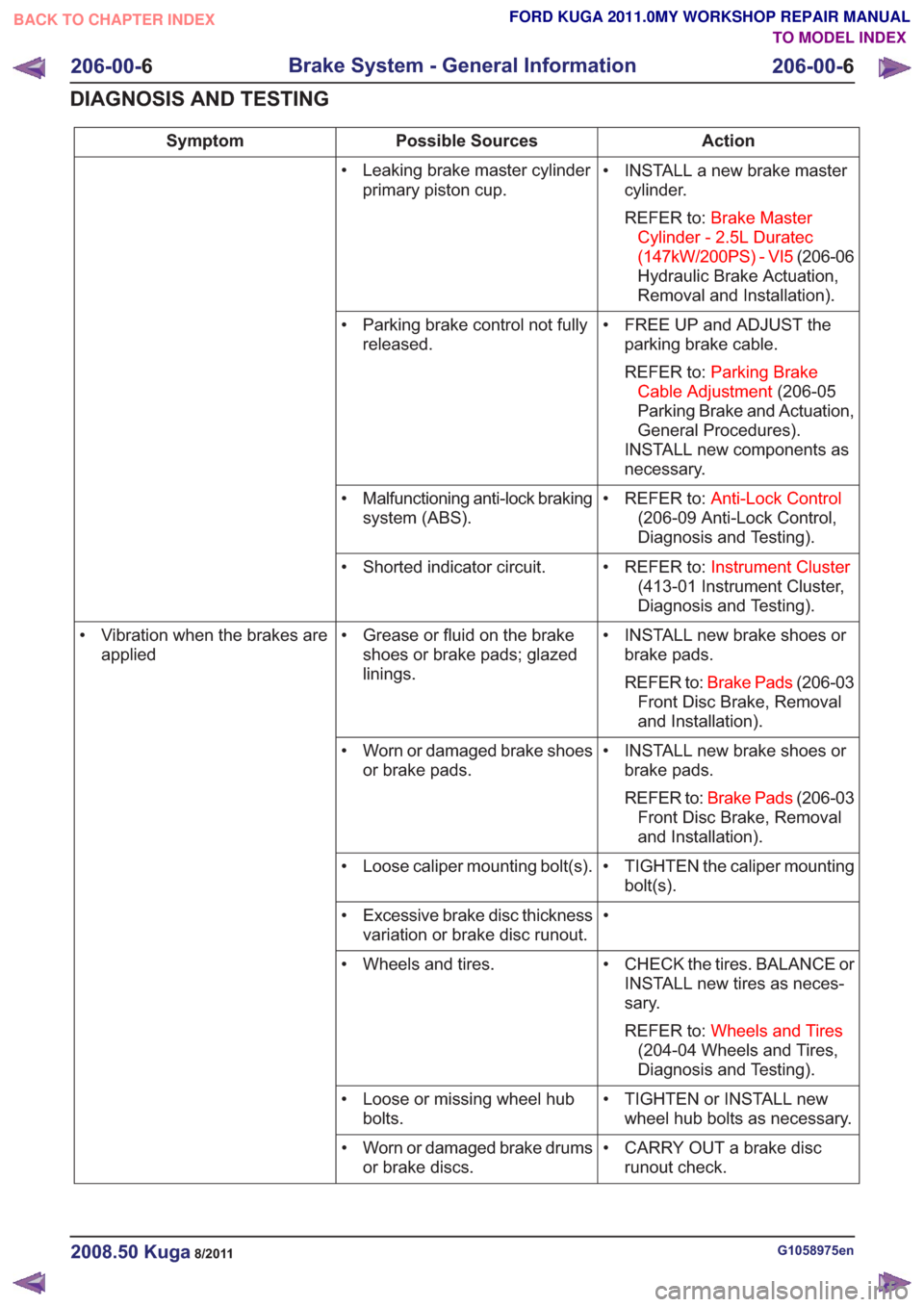

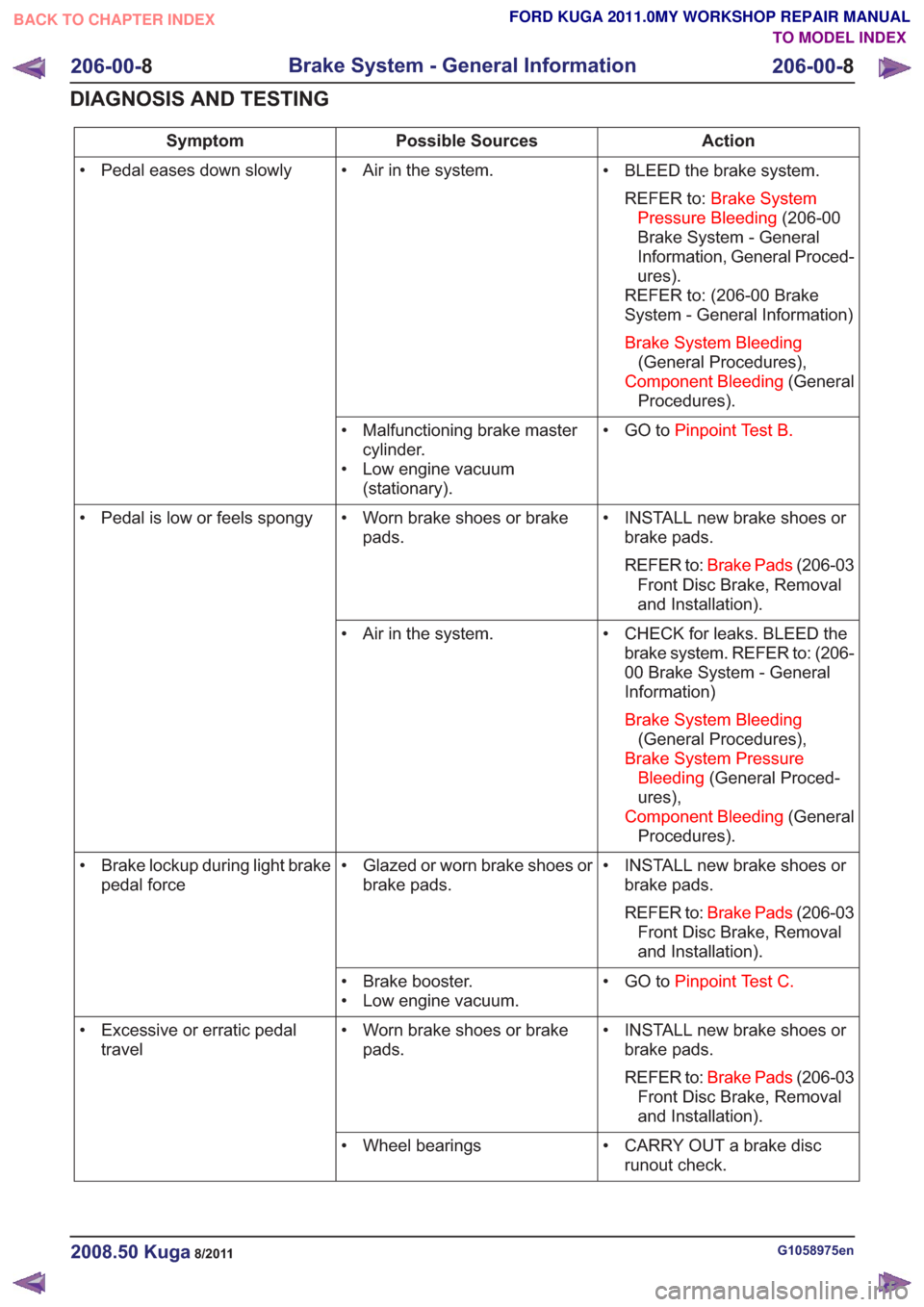

Action

Possible Sources

Symptom

• INSTALL a new brake mastercylinder.

REFER to: Brake Master

Cylinder - 2.5L Duratec

(147kW/200PS) - VI5 (206-06

Hydraulic Brake Actuation,

Removal and Installation).

• Leaking brake master cylinder

primary piston cup.

• FREE UP and ADJUST theparking brake cable.

REFER to: Parking Brake

Cable Adjustment (206-05

Parking Brake and Actuation,

General Procedures).

INSTALL new components as

necessary.

• Parking brake control not fully

released.

• REFER to:Anti-Lock Control

(206-09 Anti-Lock Control,

Diagnosis and Testing).

• Malfunctioning anti-lock braking

system (ABS).

• REFER to:Instrument Cluster

(413-01 Instrument Cluster,

Diagnosis and Testing).

• Shorted indicator circuit.

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Grease or fluid on the brake

shoes or brake pads; glazed

linings.

• Vibration when the brakes are

applied

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Worn or damaged brake shoes

or brake pads.

• TIGHTEN the caliper mountingbolt(s).

• Loose caliper mounting bolt(s).

•

• Excessive brake disc thickness

variation or brake disc runout.

• CHECK the tires. BALANCE orINSTALL new tires as neces-

sary.

REFER to: Wheels and Tires

(204-04 Wheels and Tires,

Diagnosis and Testing).

• Wheels and tires.

• TIGHTEN or INSTALL newwheel hub bolts as necessary.

• Loose or missing wheel hub

bolts.

• CARRY OUT a brake discrunout check.

• Worn or damaged brake drums

or brake discs.

G1058975en2008.50 Kuga8/2011

206-00- 6

Brake System - General Information

206-00- 6

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1344 of 2057

Action

Possible Sources

Symptom

• BLEED the brake system.REFER to: Brake System

Pressure Bleeding (206-00

Brake System - General

Information, General Proced-

ures).

REFER to: (206-00 Brake

System - General Information)

Brake System Bleeding (General Procedures),

Component Bleeding (General

Procedures).

• Air in the system.

• Pedal eases down slowly

• GO toPinpoint Test B.

• Malfunctioning brake master

cylinder.

• Low engine vacuum (stationary).

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Worn brake shoes or brake

pads.

• Pedal is low or feels spongy

• CHECK for leaks. BLEED thebrake system. REFER to: (206-

00 Brake System - General

Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General Proced-

ures),

Component Bleeding (General

Procedures).

• Air in the system.

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Glazed or worn brake shoes or

brake pads.

• Brake lockup during light brake

pedal force

• GO toPinpoint Test C.

• Brake booster.

• Low engine vacuum.

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Worn brake shoes or brake

pads.

• Excessive or erratic pedal

travel

• CARRY OUT a brake discrunout check.

• Wheel bearings

G1058975en2008.50 Kuga8/2011

206-00-

8

Brake System - General Information

206-00- 8

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1349 of 2057

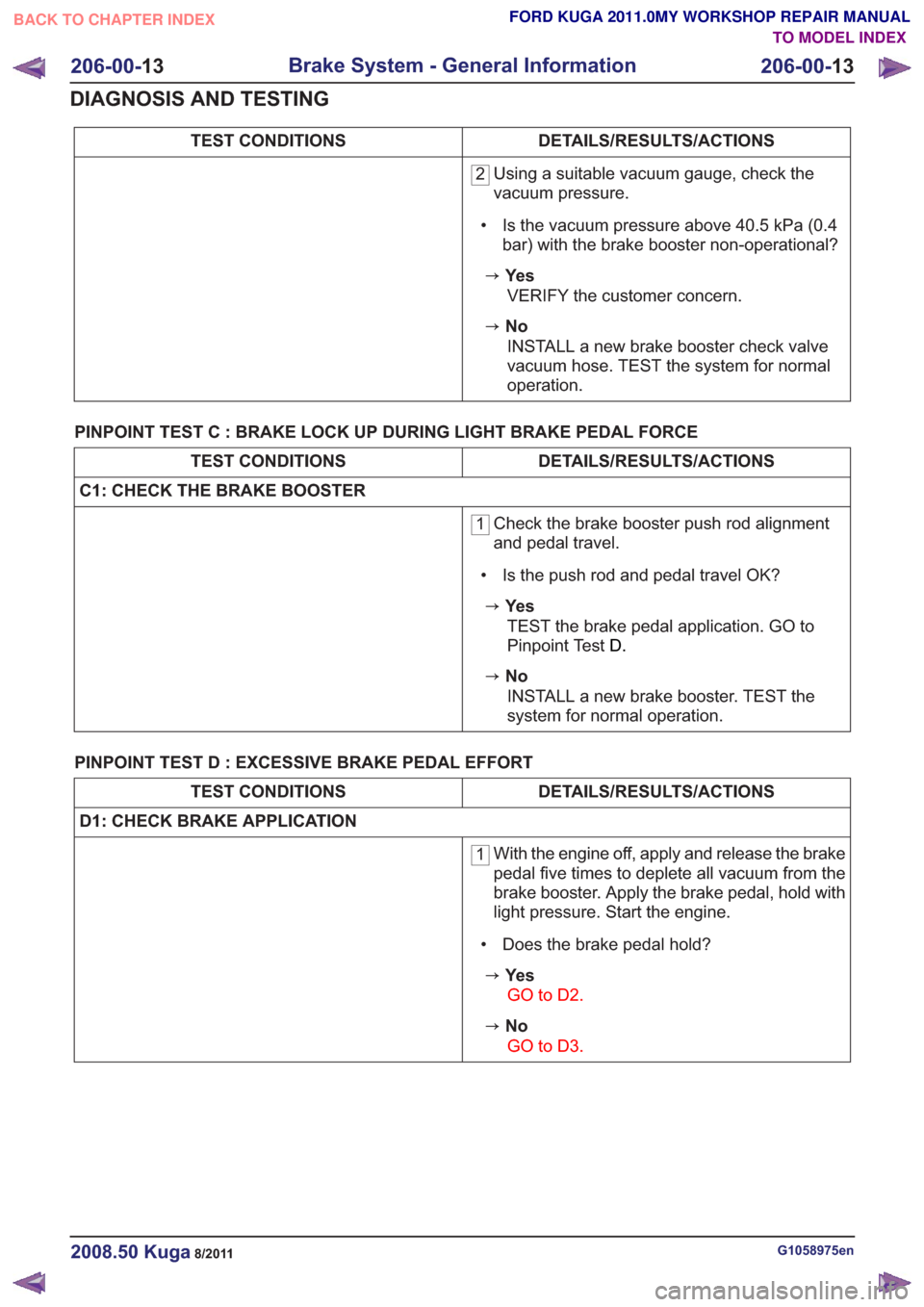

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

2 Using a suitable vacuum gauge, check the

vacuum pressure.

• Is the vacuum pressure above 40.5 kPa (0.4 bar) with the brake booster non-operational?

zYe s

VERIFY the customer concern.

zNoINSTALL a new brake booster check valve

vacuum hose. TEST the system for normal

operation.

PINPOINT TEST C : BRAKE LOCK UP DURING LIGHT BRAKE PEDAL FORCE

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

C1: CHECK THE BRAKE BOOSTER

1 Check the brake booster push rod alignment

and pedal travel.

• Is the push rod and pedal travel OK?

zYe s TEST the brake pedal application. GO to

Pinpoint Test D.

zNo

INSTALL a new brake booster. TEST the

system for normal operation.

PINPOINT TEST D : EXCESSIVE BRAKE PEDAL EFFORT

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

D1: CHECK BRAKE APPLICATION

1 With the engine off, apply and release the brake

pedal five times to deplete all vacuum from the

brake booster. Apply the brake pedal, hold with

light pressure. Start the engine.

• Does the brake pedal hold?

zYe s GO to D2 .

zNo

GO to D3 .

G1058975en2008.50 Kuga8/2011

206-00-13

Brake System - General Information

206-00- 13

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL