Lock FORD KUGA 2011 1.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1354 of 2057

4. Remove the vacuum hose from the brakebooster. Manifold vacuum should be available

at the brake booster end of the hose with the

engine at idle speed and the transaxle in the

NEUTRAL position. Make sure that all unused

vacuum outlets are correctly capped, hose

connectors are correctly secured and vacuum

hoses are in good condition. When it is

established that manifold vacuum is available

to the brake booster, connect the vacuum hose

to the brake booster and repeat Step 3. If no

downward movement of the brake pedal is felt,

install a new brake booster.

5. Operate the engine a minimum of 10 seconds at approximately 1200 rpm. Stop the engine and

let the vehicle stand for 10 minutes. Then, apply

the brake pedal with approximately 89 N (20 lb)

force. The pedal feel (brake application) should

be the same as that noted with the engine

operating. If the brake pedal feels hard (no

power assist), install a new vacuum check valve

and then repeat the test. If the brake pedal still

feels hard, install a new brake booster. If the

brake pedal movement feels spongy, bleed the

brake system. REFER to: (206-00 Brake System

- General Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General

Procedures),

Component Bleeding (General Procedures).

Brake Master Cylinder

Usually, the first and strongest indicator of anything

wrong with the braking system is a feeling through

the brake pedal. In diagnosing the condition of the

brake master cylinder, check pedal feel as

evidence of a brake concern. Check for the red

brake warning indicator illumination and the fluid

level in the master cylinder reservoir.

Normal Conditions

The following conditions are considered normal

and are not indications that the brake master

cylinder is in need of service.

– Modern brake systems are not designed to

produce as hard a pedal effort as in the past.

Complaints of light pedal efforts should be compared to pedal efforts of another vehicle, of

the same model and year.

– During normal operation of the brake pedal, the fluid level in the reservoir will rise during brake

pedal application and fall during release. The

net fluid level (i.e., after brake pedal application

and release) will remain unchanged.

– A trace of brake fluid will exists on the brake booster shell below the master cylinder

mounting flange. This results from the normal

lubricating action of the master cylinder bore

end seal.

– The fluid level will fall with brake shoe and lining wear.

Abnormal Conditions

NOTE: Prior to performing any diagnosis, make

sure the brake system warning indicator is

functional.

Changes in brake pedal feel or travel are indicators

that something could be wrong with the braking

system. The diagnostic procedure and techniques

use brake pedal feel, warning indicator illumination

and low brake fluid level as indicators in diagnosing

braking system concerns. The following conditions

are considered abnormal and indicate that the

brake master cylinder is in need of service.

– The brake pedal goes down fast. This could be caused by an external or internal leak.

– The brake pedal eases down slowly. This could be caused by an external or internal leak.

– The brake pedal is low and or feels spongy. This condition may be caused by no fluid in the brake

master cylinder reservoir, reservoir cap vent

holes clogged or air in the hydraulic system.

– The brake pedal effort is excessive. This may be caused by a bind or obstruction in the pedal

or linkage, clogged fluid control valve or

insufficient booster vacuum.

– The rear brakes lock up during light pedal force. This may be caused by incorrect tire pressures,

grease or fluid on the brake shoes and linings,

damaged brake shoes and linings, incorrectly

adjusted parking brake, or damaged or

contaminated brake pressure control valves.

– The brake pedal effort is erratic. This condition could be caused by a brake booster malfunction,

extreme caliper piston knock back or incorrectly

installed brake shoes and linings.

– The red brake warning indicator is ON. This may be caused by low fluid level, ignition wire routing

G1058975en2008.50 Kuga8/2011

206-00- 18

Brake System - General Information

206-00- 18

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1414 of 2057

SECTION 206-09A Anti-Lock Control

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

DESCRIPTION AND OPERATION

206-09A-2

Anti-Lock Control (Component Location) ........................................................................\

...

206-09A-3

Anti-Lock Control (Overview) ........................................................................\

......................

206-09A-3

Anti-lock Brake System ........................................................................\

..............................

206-09A-4

Anti-Lock Control (System Operation and Component Description) ..................................

206-09A-4

System Operation ........................................................................\

.......................................

DIAGNOSIS AND TESTING 206-09A-5

Anti-Lock Control ........................................................................\

........................................

206-09A-5

Inspection and Verification ........................................................................\

..........................

206-09A-1

Anti-Lock Control

206-09A- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1415 of 2057

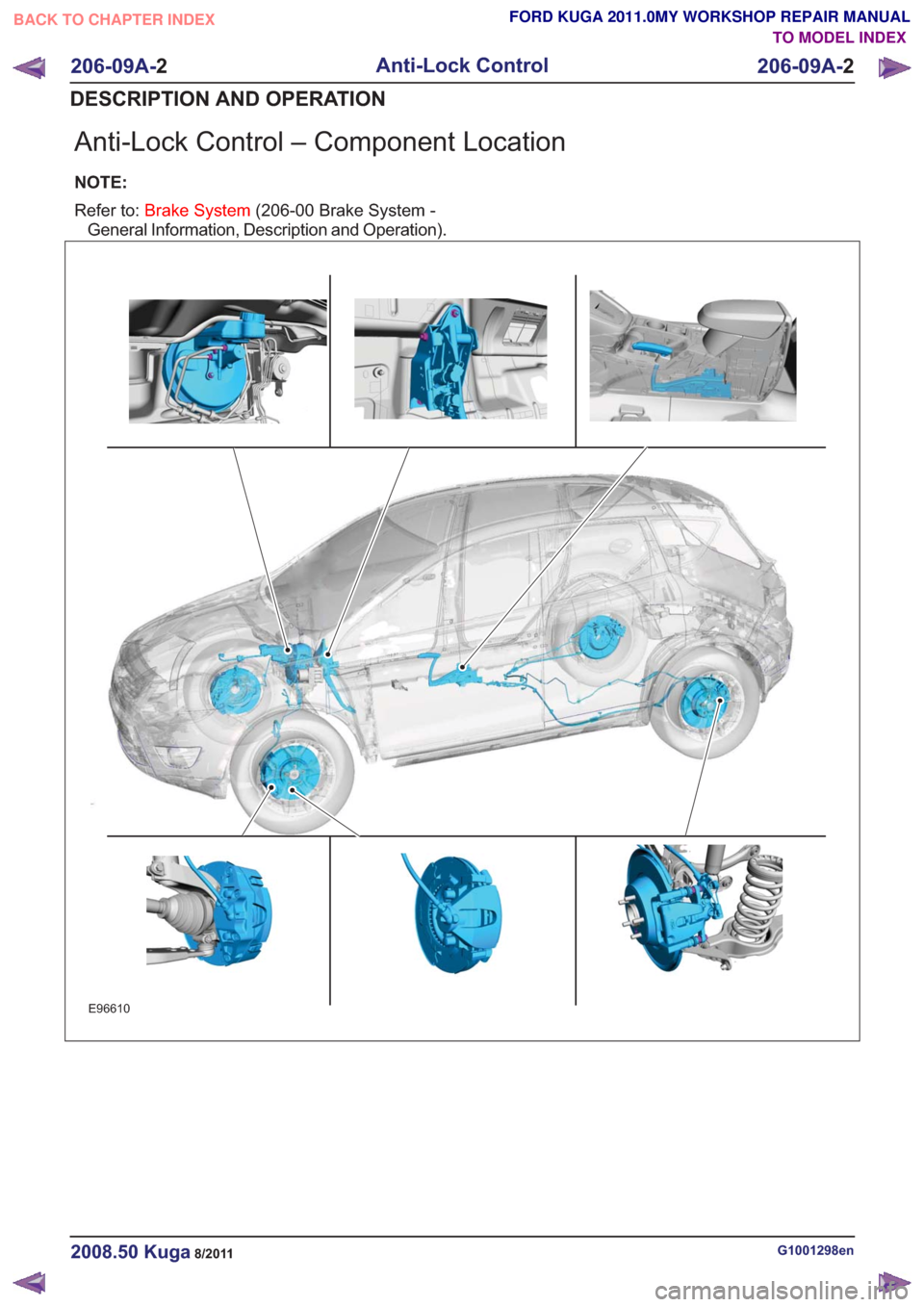

Anti-Lock Control – Component Location

NOTE:

Refer to:Brake System (206-00 Brake System -

General Information, Description and Operation).

E96610

G1001298en2008.50 Kuga8/2011

206-09A- 2

Anti-Lock Control

206-09A- 2

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1416 of 2057

Anti-Lock Control – Overview

Anti-lock Brake System

Refer to:Anti-Lock Control - Stability Assist (206-09

Anti-Lock Control - Stability Assist, Description

and Operation).

G1001218en2008.50 Kuga8/2011

206-09A- 3

Anti-Lock Control

206-09A- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1417 of 2057

Anti-Lock Control – System Operation and Component Description

System Operation

Refer to:Anti-Lock Control - Stability Assist (206-09

Anti-Lock Control - Stability Assist, Description

and Operation).

G1001220en2008.50 Kuga8/2011

206-09A- 4

Anti-Lock Control

206-09A- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1418 of 2057

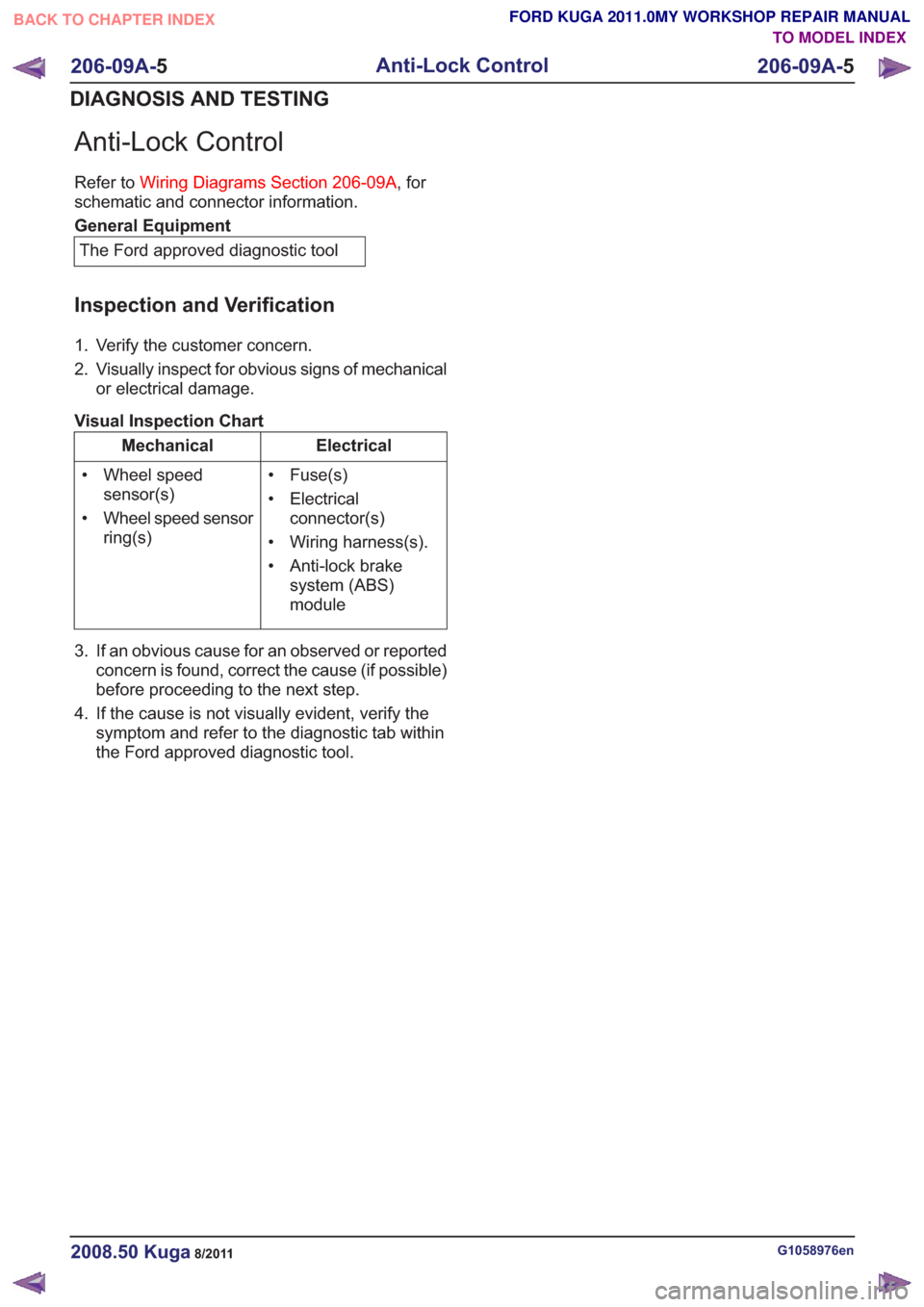

Anti-Lock Control

schematic

and connector information.

General Equipment

The Ford approved diagnostic tool

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection Chart

Electrical

Mechanical

• Fuse(s)

• Electricalconnector(s)

• Wiring harness(s).

• Anti-lock brake system (ABS)

module

• Wheel speed

sensor(s)

• Wheel speed sensor ring(s)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the diagnostic tab within

the Ford approved diagnostic tool.

G1058976en2008.50 Kuga8/2011

206-09A- 5

Anti-Lock Control

206-09A- 5

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Refer to

Wiring Diagrams Section 206-09A, for

Page 1419 of 2057

SECTION 206-09B Anti-Lock Control - Stability Assist

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

DESCRIPTION AND OPERATION

206-09B-2

Anti-Lock Control - Stability Assist (Component Location) .................................................

206-09B-3

Anti-Lock Control - Stability Assist (Overview) ...................................................................

206-09B-3

Overview ........................................................................\

.....................................................

206-09B-4

Testing the brakes on a roller dynamometer - 4X4 vehicles only ...................................

206-09B-4

ABS/ESP module or hydraulic control unit (HCU) ..............................................................

206-09B-4

Combined yaw rate sensor and lateral acceleration sensor / longitudinal acceleration

sensor ........................................................................\

.......................................................

206-09B-5

Front wheel sensor ........................................................................\

.....................................

206-09B-5

Rear wheel sensor ........................................................................\

......................................

206-09B-5

Opto-electronic steering wheel rotation sensor ..................................................................

206-09B-6

ESP switch ........................................................................\

.................................................

206-09B-7

Anti-Lock Control - Stability Assist (System Operation and Component Description) ........

206-09B-7

System Diagram ........................................................................\

.........................................

206-09B-8

System Operation ........................................................................\

.......................................

206-09B-9

PRINCIPLES OF OPERATION ........................................................................\

...............

206-09B-11

Component Description ........................................................................\

..............................

206-09B-?

Opto-electronic steering wheel rotation sensor ..............................................................

206-09B-?

ABS/ESP module or hydraulic control unit (HCU) ..........................................................

206-09B-?

ESP switch ........................................................................\

..............................................

206-09B-?

Combined yaw rate sensor and lateral acceleration sensor / longitudinal acceleration

sensor........................................................................\

................................................... 206-09B-?

Front wheel sensor ........................................................................\

.................................

206-09B-?

Rear wheel sensor ........................................................................\

..................................

REMOVAL AND INSTALLATION 206-09B-16

Hydraulic Control Unit (HCU) ........................................................................\

.....................

206-09B-19

Stability Assist Module ........................................................................\

................................

206-09B-21

Front Wheel Speed Sensor ........................................................................\

........................

206-09B-22

Rear Wheel Speed Sensor ........................................................................\

.........................

206-09B-23

Yaw Rate Sensor ........................................................................\

........................................

206-09B-1

Anti-Lock Control - Stability Assist

206-09B- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1420 of 2057

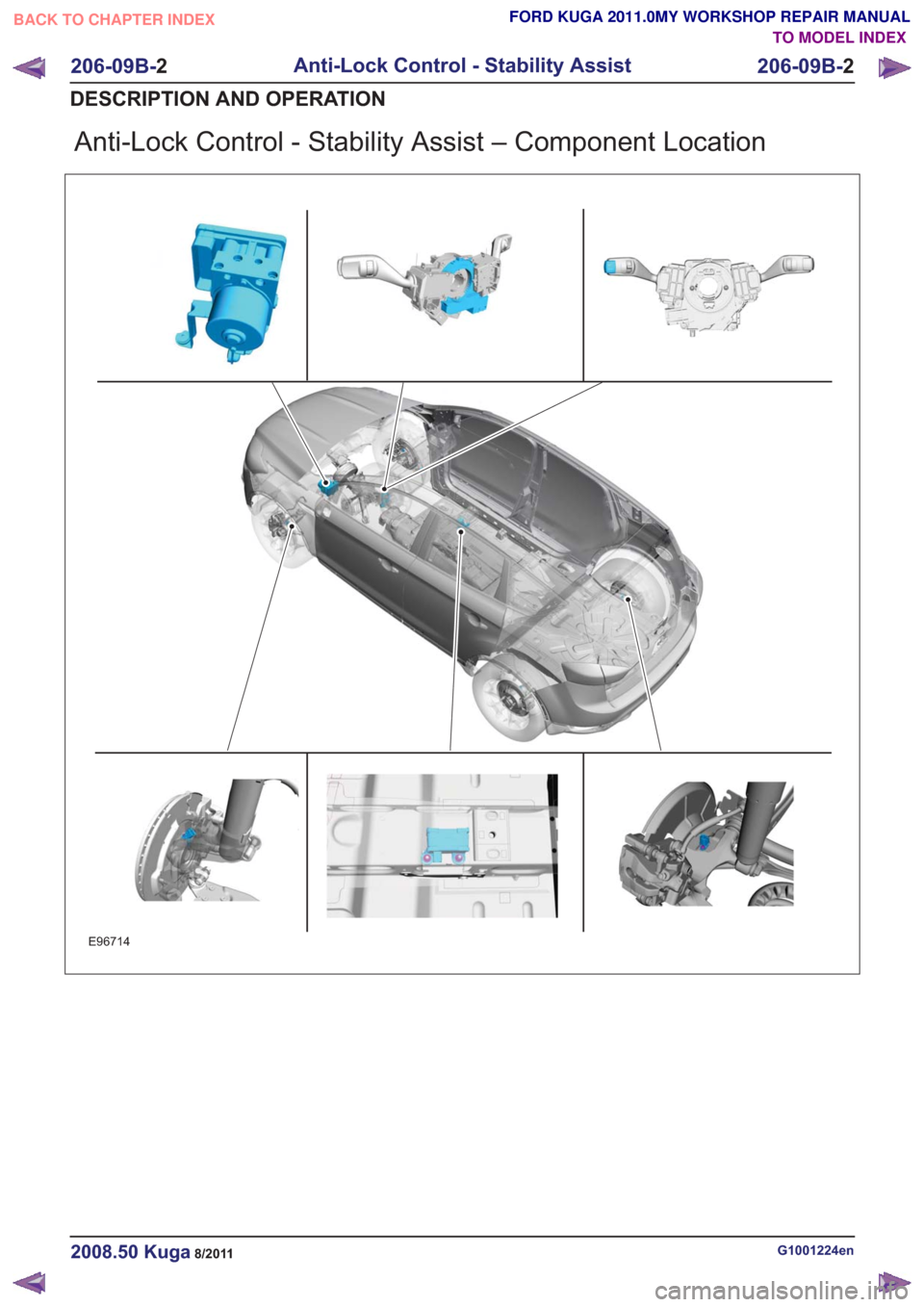

Anti-Lock Control - Stability Assist – Component Location

E96714

G1001224en2008.50 Kuga8/2011

206-09B-2

Anti-Lock Control - Stability Assist

206-09B- 2

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1421 of 2057

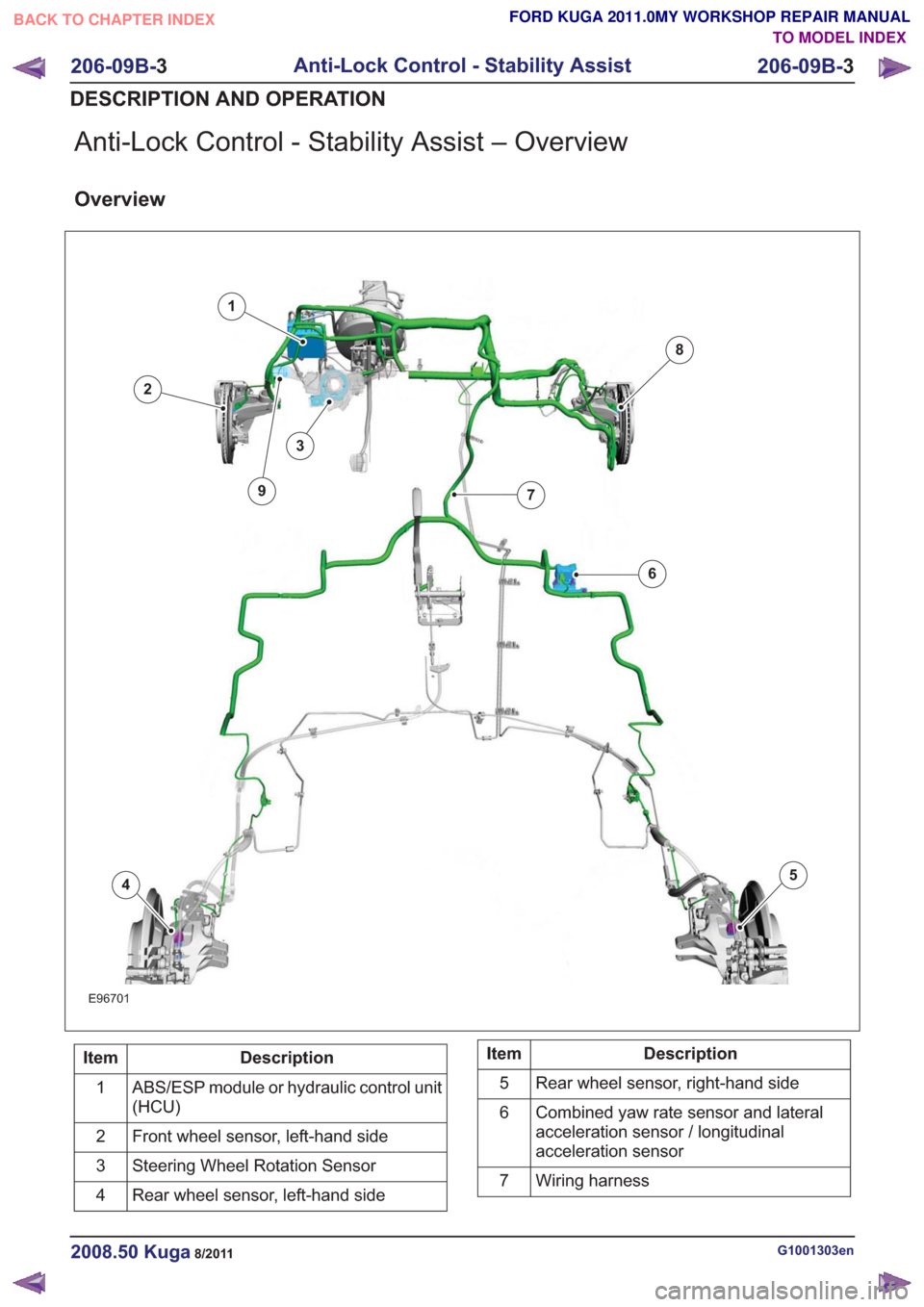

Anti-Lock Control - Stability Assist – Overview

Overview

E96701

1

2

3

45

6

7

8

9

Description

Item

ABS/ESP module or hydraulic control unit

(HCU)

1

Front wheel sensor, left-hand side

2

Steering Wheel Rotation Sensor

3

Rear wheel sensor, left-hand side

4Description

Item

Rear wheel sensor, right-hand side

5

Combined yaw rate sensor and lateral

acceleration sensor / longitudinal

acceleration sensor

6

Wiring harness

7

G1001303en2008.50 Kuga8/2011

206-09B- 3

Anti-Lock Control - Stability Assist

206-09B- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1422 of 2057

Description

Item

Front wheel sensor, right-hand side

8Description

Item

9 ESP switch

Testing the brakes on a roller dynamometer

- 4X4 vehicles only

On 4X4 vehicles a brake test on a roller

dynamometer must only be performed under the

following conditions.

• The brake test must not exceed a duration of 1 minute.

• Ignition key in position 0.

• The roller speed must not exceed 5 km/h.

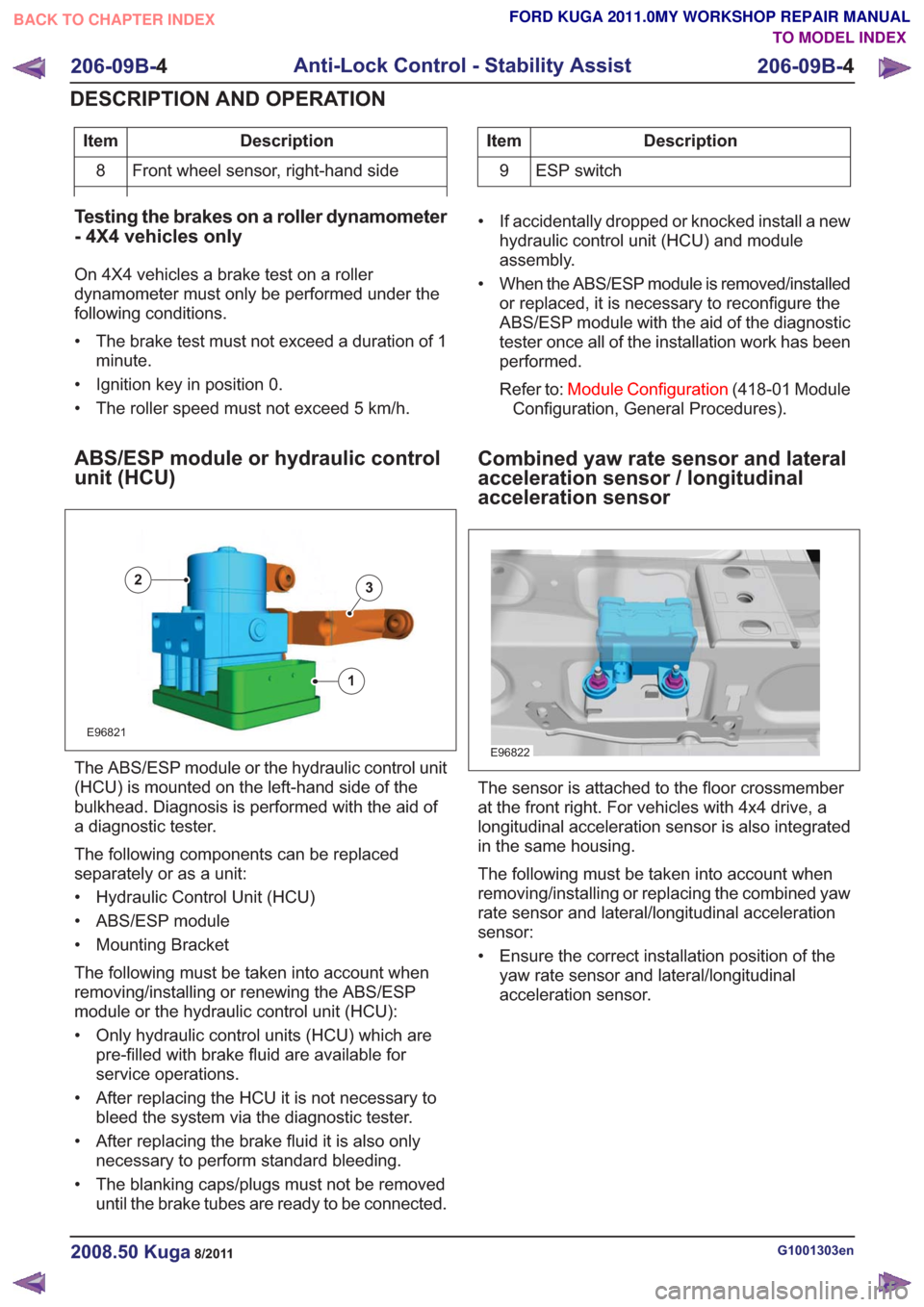

ABS/ESP module or hydraulic control

unit (HCU)

E96821

1

23

The ABS/ESP module or the hydraulic control unit

(HCU) is mounted on the left-hand side of the

bulkhead. Diagnosis is performed with the aid of

a diagnostic tester.

The following components can be replaced

separately or as a unit:

• Hydraulic Control Unit (HCU)

• ABS/ESP module

• Mounting Bracket

The following must be taken into account when

removing/installing or renewing the ABS/ESP

module or the hydraulic control unit (HCU):

• Only hydraulic control units (HCU) which are pre-filled with brake fluid are available for

service operations.

• After replacing the HCU it is not necessary to bleed the system via the diagnostic tester.

• After replacing the brake fluid it is also only necessary to perform standard bleeding.

• The blanking caps/plugs must not be removed until the brake tubes are ready to be connected. • If accidentally dropped or knocked install a new

hydraulic control unit (HCU) and module

assembly.

• When the ABS/ESP module is removed/installed or replaced, it is necessary to reconfigure the

ABS/ESP module with the aid of the diagnostic

tester once all of the installation work has been

performed.

Refer to: Module Configuration (418-01 Module

Configuration, General Procedures).

Combined yaw rate sensor and lateral

acceleration sensor / longitudinal

acceleration sensor

E96822

The sensor is attached to the floor crossmember

at the front right. For vehicles with 4x4 drive, a

longitudinal acceleration sensor is also integrated

in the same housing.

The following must be taken into account when

removing/installing or replacing the combined yaw

rate sensor and lateral/longitudinal acceleration

sensor:

• Ensure the correct installation position of the yaw rate sensor and lateral/longitudinal

acceleration sensor.

G1001303en2008.50 Kuga8/2011

206-09B- 4

Anti-Lock Control - Stability Assist

206-09B- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL