air condition FORD KUGA 2011 1.G Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1233 of 2057

Wheels and Tires

Inspection and Verification

Visual Inspection Chart

MechanicalWheel(s)Tire(s)

Tire pressure(s) * Wheel nuts

Wheel studs

* Vehicles equipped with a tire deflation detection system (DDS) must be inspected for correct operation using the Ford approved diagnostic tool.

To maximize tire performance, inspect the tires for

signs of incorrect inflation and uneven wear which

may indicate a need for balancing, rotation or

suspension alignment. Tires should also be

checked frequently for cuts, stone bruises,

abrasions, blisters and for objects that may have

become embedded in the tread. More frequent

inspections are recommended when rapid or

extreme temperature changes occur or when road

surfaces are rough or occasionally littered with

foreign material.

As a further visible check of tire condition, tread

wear indicators are molded into the bottom of the

tread grooves. When these indicator bands become

visible, new tires must be installed.

Tire Wear Diagnosis

Uneven wear is usually caused by either excessive

camber or excessive toe on tires.

Sometimes incorrect toe settings or worn struts will

cause severe `cupping' or `scalloped' tire wear on

non-driven wheels.

Severely incorrect toe settings will also cause other

unusual wear patterns.

Tire Vibration Diagnosis

A tire vibration diagnostic procedure always begins

with a road test. The road test and customer

interview (if available) will provide much of the

information needed to find the source of a vibration. During the road test, drive the vehicle on a road

that is smooth and free of undulations. If vibration

is apparent, note and record the following:

– the speed at which the vibration occurs.

– what type of vibration occurs in each speed

range.

– mechanical or audible

– how the vibration is affected by changes in the following:

– engine torque

– vehicle speed

– engine speed

– type of vibration - sensitivity: – torque sensitive

– vehicle speed sensitive

– engine speed sensitive

The following explanations help isolate the source

of the vibration.

Torque Sensitive

This means that the condition can be improved or

made worse by accelerating, decelerating,

coasting, maintaining a steady vehicle speed or

applying engine torque.

Vehicle Speed Sensitive

This means that the vibration always occurs at the

same vehicle speed and is not affected by engine

torque, engine speed or the transmission gear

selected.

G1061329en2008.50 Kuga8/2011

204-04- 6

Wheels and Tires

204-04- 6

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1234 of 2057

Engine Speed Sensitive

This means that the vibration occurs at varying

vehicle speeds when a different transmission gear

is selected. It can sometimes be isolated by

increasing or decreasing engine speed with the

transmission in NEUTRAL or by stall testing with

the transmission in gear. If the condition is engine

speed sensitive, the cause is probably not related

to the tires.

If the road test indicates that there is tire whine,

but no shake or vibration, the noise originates with

the contact between the tire and the road surface.A thumping noise usually means that the tire is flat

or has soft spots making a noise as they slap the

roadway. Tire whine can be distinguished from axle

noise. Tire whine remains the same over a range

of speeds.

A complete road test procedure is described in

Section 100-04.

REFER to:

Noise, Vibration and Harshness (NVH)

(100-04 Noise, Vibration and Harshness,

Diagnosis and Testing).

Symptom Chart

Action

Possible Sources

Symptom

• ADJUST the tire pressure andreset the DDS. For additional

information REFER to the

owners guide.

• Loss of tire pressure.

• DDS warning lamp illuminated

• REFER to the DDS resetprocedure. For additional

information REFER to the

owners guide.

• The DDS reset procedure was

not carried out after adjustment

of the tire pressure.

• DDS warning lamp illuminated

with the correct tire pressure

• ADJUST the tire pressure andreset the DDS. For additional

information REFER to the

owners guide.

• The DDS reset procedure was

carried out under incorrect tire

conditions.

• DDS warning lamp not illumin-

ated when one or more tire(s)

have the incorrect tire pressure

• REFER to the DDS resetprocedure. For additional

information REFER to the

owners guide.

• The DDS reset procedure was

not completed.

• DDS reset command was not

confirmed

• REFER to the Ford approveddiagnostic tool.

• Anti-lock brake system (ABS)

module.

• DDS failure warning display

• ADJUST the tire pressure(s).

• Tire(s) under-inflated.

• Tire(s) show excess wear on

edge of tread

• CORRECT as necessary.

• Vehicle overloaded.

• ADJUST the wheel alignment.REFER to: Suspension System

(204-00 Suspension System

- General Information,

Diagnosis and Testing).

• Incorrect wheel alignment.

• ADJUST the tire pressure(s).

• Tire(s) over-inflated.

• Tire(s) show excess wear in

center of tread

• ADJUST the tire pressure(s).

• Incorrect tire pressure(s).

• Other excessive tire wear

concerns

G1061329en2008.50 Kuga8/2011

204-04- 7

Wheels and Tires

204-04- 7

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1237 of 2057

Action

Possible Sources

Symptom

• CLEAN mounting surfaces.

• Foreign material between

wheel mounting face and hub

mounting surface.

• CHECK or INSTALL new wheelbearings as necessary.

REFER to: Front Wheel

Bearing (204-01 Front

Suspension, Removal and

Installation).

• Front wheel bearing.

• CAUTION: Do not permitlubricant to get on cone sets of

stud holes or on cone angle of

wheel nuts. If corrosion is

slight, wire brush away. If

corrosion is excessive,

INSTALL new wheel studs and

nuts.

REFER to: Wheel and Tire

(204-04 Wheels and Tires,

Removal and Installation).

If the condition persists,

LUBRICATE the first three

threads of each wheel stud with

a graphite-based lubricant.

• Corrosion.

• Seized wheel nuts

• CORRECT as necessary.

• Vehicle overloaded

G1061329en2008.50 Kuga8/2011

204-04- 10

Wheels and Tires

204-04- 10

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1251 of 2057

Rear Drive Axle and Differential – System Operation andComponent Description

System Operation

General Information

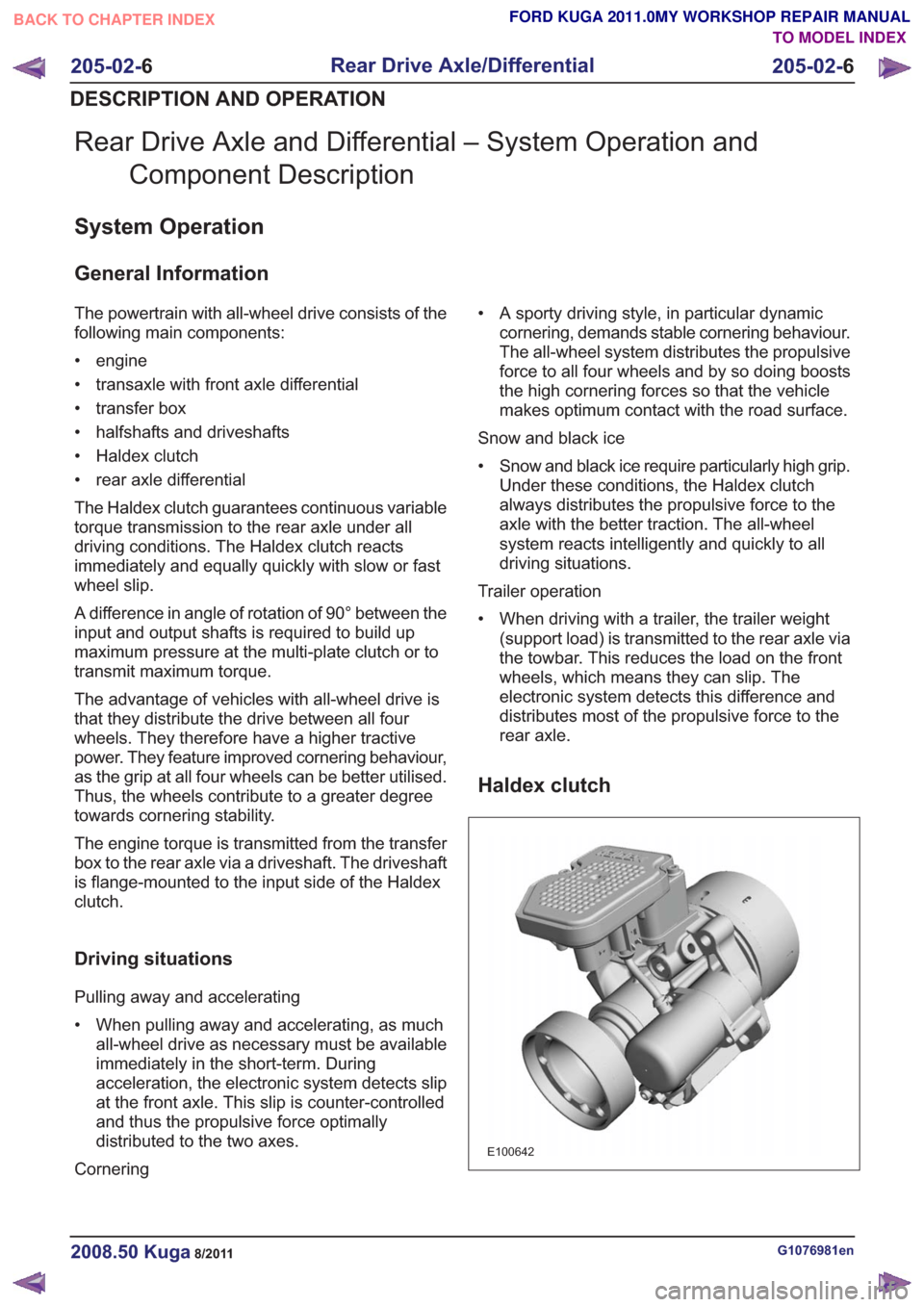

The powertrain with all-wheel drive consists of the

following main components:

• engine

• transaxle with front axle differential

• transfer box

• halfshafts and driveshafts

• Haldex clutch

• rear axle differential

The Haldex clutch guarantees continuous variable

torque transmission to the rear axle under all

driving conditions. The Haldex clutch reacts

immediately and equally quickly with slow or fast

wheel slip.

A difference in angle of rotation of 90° between the

input and output shafts is required to build up

maximum pressure at the multi-plate clutch or to

transmit maximum torque.

The advantage of vehicles with all-wheel drive is

that they distribute the drive between all four

wheels. They therefore have a higher tractive

power. They feature improved cornering behaviour,

as the grip at all four wheels can be better utilised.

Thus, the wheels contribute to a greater degree

towards cornering stability.

The engine torque is transmitted from the transfer

box to the rear axle via a driveshaft. The driveshaft

is flange-mounted to the input side of the Haldex

clutch.

Driving situations

Pulling away and accelerating

• When pulling away and accelerating, as muchall-wheel drive as necessary must be available

immediately in the short-term. During

acceleration, the electronic system detects slip

at the front axle. This slip is counter-controlled

and thus the propulsive force optimally

distributed to the two axes.

Cornering • A sporty driving style, in particular dynamic

cornering, demands stable cornering behaviour.

The all-wheel system distributes the propulsive

force to all four wheels and by so doing boosts

the high cornering forces so that the vehicle

makes optimum contact with the road surface.

Snow and black ice

• Snow and black ice require particularly high grip. Under these conditions, the Haldex clutch

always distributes the propulsive force to the

axle with the better traction. The all-wheel

system reacts intelligently and quickly to all

driving situations.

Trailer operation

• When driving with a trailer, the trailer weight (support load) is transmitted to the rear axle via

the towbar. This reduces the load on the front

wheels, which means they can slip. The

electronic system detects this difference and

distributes most of the propulsive force to the

rear axle.

Haldex clutch

E100642

G1076981en2008.50 Kuga8/2011

205-02- 6

Rear Drive Axle/Differential

205-02- 6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

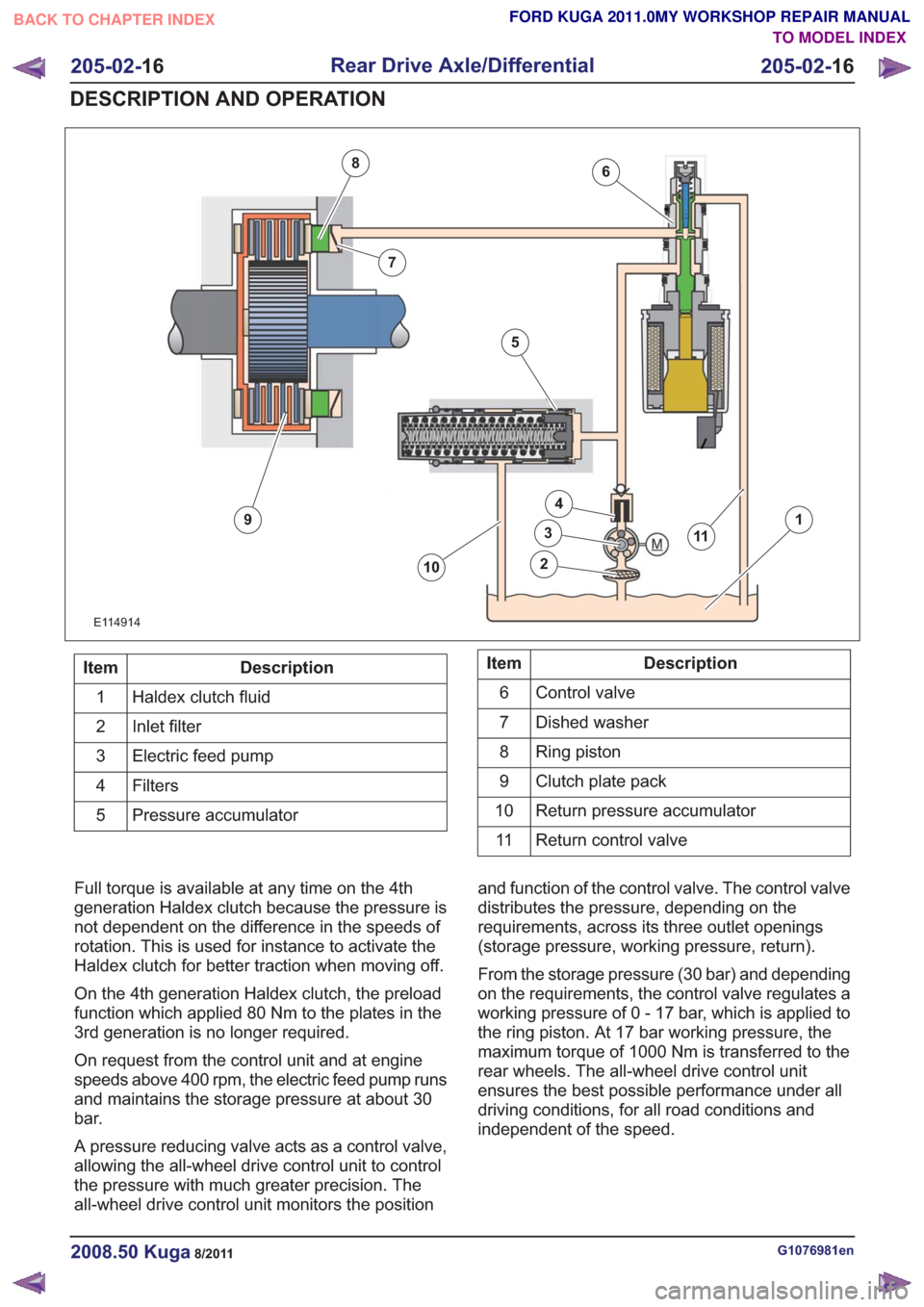

Page 1261 of 2057

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

11

E114914

Description

Item

Haldex clutch fluid

1

Inlet filter

2

Electric feed pump

3

Filters4

Pressure accumulator

5Description

Item

Control valve

6

Dished washer

7

Ring piston

8

Clutch plate pack

9

Return pressure accumulator

10

Return control valve

11

Full torque is available at any time on the 4th

generation Haldex clutch because the pressure is

not dependent on the difference in the speeds of

rotation. This is used for instance to activate the

Haldex clutch for better traction when moving off.

On the 4th generation Haldex clutch, the preload

function which applied 80 Nm to the plates in the

3rd generation is no longer required.

On request from the control unit and at engine

speeds above 400 rpm, the electric feed pump runs

and maintains the storage pressure at about 30

bar.

A pressure reducing valve acts as a control valve,

allowing the all-wheel drive control unit to control

the pressure with much greater precision. The

all-wheel drive control unit monitors the position and function of the control valve. The control valve

distributes the pressure, depending on the

requirements, across its three outlet openings

(storage pressure, working pressure, return).

From the storage pressure (30 bar) and depending

on the requirements, the control valve regulates a

working pressure of 0 - 17 bar, which is applied to

the ring piston. At 17 bar working pressure, the

maximum torque of 1000 Nm is transferred to the

rear wheels. The all-wheel drive control unit

ensures the best possible performance under all

driving conditions, for all road conditions and

independent of the speed.

G1076981en2008.50 Kuga8/2011

205-02-

16

Rear Drive Axle/Differential

205-02- 16

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1298 of 2057

Front Drive Halfshafts

Inspection and Verification

NOTE:New front wheel drive halfshafts should not

be installed unless disassembly and inspection

reveals unusual wear.

1. Inspect front wheel driveshaft joint boots for evidence of cracks, tears or splits.

NOTE: While inspecting the front wheel driveshaft

CV joint boots, watch for indentations (dimples) in

the boot convolutions. If an indentation is observed,

it must be removed.

2. Inspect the underbody for any indication of grease splatter in the vicinity of the front wheel

driveshaft CV joint boots outboard and inboard

locations, which is an indication of front wheel

driveshaft CV joint boot and/or front wheel

driveshaft CV joint boot clamp damage. 3. Inspect for inboard CV joint stub shaft pilot

bearing housing seal leakage at the front wheel

driveshaft CV joint.

4. Make sure front axle wheel hub retainer is the correct prevailing torque type.

5. The silicone front wheel driveshaft CV joint boot will sweat during operation, causing a light film

of grease to show on the outside of the front

wheel driveshaft CV joint boot. This condition

is normal.

NOTE: Halfshafts are not balanced and do not

contribute to rotational vibration.

6. If the concerns remain after the inspection, determine the symptoms and go to the Symptom

Chart. For additional Noise, Vibration and

Harshness (NVH). REFER to Section 100-04

[Noise, Vibration and Harshness] .

Symptom Chart

Action

Possible Sources

Symptom

• INSPECT, CLEAN andLUBRICATE as necessary.

• Inadequate or contaminated

lube in outboard/inboard front

wheel driveshaft CV joint.

• Clicking, Popping or Grinding

Noises While Turning

• INSPECT and REPAIR asnecessary.

• Another component contacting

driveshaft assembly.

• INSPECT and REPAIR asnecessary. REFER to

Section 204-00 [Suspension

System - General Information]

/ 206-00 [Brake System -

General Information] /211-00

[Steering System - General

Information] .

• Wheel bearings, brakes,

suspension or steering

components.

• REPAIR or INSTALL new asnecessary. REFER to

Section 204-04 [Wheels and

Tires] .

• Out of balance front wheels or

tires.

• Vibration at Highway Speeds

• REPAIR or INSTALL new asnecessary. REFER to

Section 204-04 [Wheels and

Tires] .

• Out-of-round tires.

• REPAIR or INSTALL new asnecessary.

REFER to Halfshaft Disas-

semblv and Assembly in this

section.

• Incorrectly seated outboard

front wheel driveshaft CV joint

in front wheel hub.

G17442en2008.50 Kuga8/2011

205-04- 3

Front Drive Halfshafts

205-04- 3

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1340 of 2057

Brake System

General EquipmentPressure/vacuum gauge set

The Ford approved diagnostic tool

The brake system operates by transferring effort

applied to the brake pedal by the driver to the

brakes at each wheel.

The braking effort is distributed to each wheel,

using a hydraulic system. The system is assisted

using a vacuum brake booster that reduces pedal

effort and increases hydraulic pressure.

The parking brake operates on the rear wheels

and is applied using a hand operated control.

Inspection and Verification

NOTE: Before carrying out any diagnosis, make

sure that the brake system warning indicator is

functional.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection Chart

Electrical

Mechanical

• Electricalconnector(s)

• Wiring harness(s)

• Switch(es)

• Tire pressure(s)

• Wheels and tires

• Fluid leak(s)

3. If an obvious cause for an observed or reported concern is found, correct the case (if possible)

before proceeding to the next step.

4. If the cause if not visually evident, verify the symptom and refer to the Symptom Chart.

Road Test

Carry out a road test to compare actual vehicle

braking performance with the performance

standards expected by the driver. The ability of the

test driver to make valid comparisons and detect

performance deficiencies will depend on

experience.

The driver should have a thorough knowledge of

the brake system operation and accepted general performance guidelines to make good comparisons

and detect performance concerns.

An experienced technician will always establish a

route that will be used for all brake diagnosis road

tests. The road selected will be reasonably smooth

and level. Gravel or bumpy roads are not suitable

because the surface does not allow the tires to grip

the road equally. Crowned roads should be avoided

because of the large amount of weight shifted to

the low set of wheels on this type of road. Once

the route is established and consistently used, the

road surface variable can be eliminated from the

test results.

Before a road test, get a complete description of

the customer concerns or suspected condition.

From the description, the technician will be able to

match possible causes with symptoms. Certain

components will be identified as possible sources

while others will be eliminated by the evidence.

More importantly, the customer description can

reveal unsafe conditions which should be checked

or corrected before a road test. The description will

also help form the basic approach to the road test

by narrowing the concern to specific components,

vehicle speed or conditions.

Begin the road test with a general brake

performance check. Using the description of the

concern, test the brakes at different vehicle speeds

using both light and heavy pedal pressure.

Determine if the concern is in the front or rear

braking system. First use the foot brake and then

the parking brake. If the condition (i.e. pull,

vibration, pulsation) occurs only on operation of

the parking brake, the concern is in the rear brake

system. If the condition occurs when the foot brake

is depressed, the concern is in the front brake

system.

Avoid locking the brakes and sliding the tires. This

condition will not indicate brake efficiency. A heavily

braked but turning wheel will stop the vehicle in a

shorter distance than locked wheels.

If the concern becomes evident during this check,

make sure it fits the description given before the

road test. If the concern is not evident, attempt to

duplicate the condition using the information from

the description.

If a concern exists, use the Brake System Symptom

Chart in order to isolate it to a specific sub-system

and condition description. From this description, a

list of possible sources can be used to further

G1058975en2008.50 Kuga8/2011

206-00-

4

Brake System - General Information

206-00- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1341 of 2057

narrow the cause to a specific component or condition.

Symptom Chart

Action

Possible Sources

Symptom

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Worn or damaged brake shoes

or brake pads and linings.

• Brakes pull or drift

• INSTALL a new front brakedisc.

REFER to: Brake Caliper (206-

03 Front Disc Brake,

Removal and Installation).

• Abnormal wear or distortion of

front brake disc.

• ADJUST the parking brakecable.

REFER to: Parking Brake

Cable Adjustment (206-05

Parking Brake and Actuation,

General Procedures).

• Incorrect rear brake adjust-

ment.

• ADJUST the wheel alignment.REFER to: (204-00 Suspension

System - General Information)

Front Toe Adjustment (General

Procedures),

Rear Toe Adjustment (General

Procedures).

• Incorrect wheel alignment

adjustment.

• ADJUST or INSTALL a newwheel bearing.

REFER to: Front Wheel

Bearing (204-01 Front

Suspension, Removal and

Installation).

• Incorrect wheel bearing preload

adjustment.

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Grease or fluid on the brake

shoes or brake pads; glazed

linings.

• INSTALL a new wheel cylinderor brake caliper.

REFER to: Brake Caliper (206-

04 Rear Disc Brake, Removal

and Installation).

• Stuck or seized wheel cylinders

or brake calipers.

• FILL the reservoir. CHECK thebrake and clutch system for

leaks including brake fluid in

the brake booster.

• Low brake fluid level.

• The red brake warning indicator

is always on

G1058975en2008.50 Kuga8/2011

206-00- 5

Brake System - General Information

206-00- 5

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1346 of 2057

Action

Possible Sources

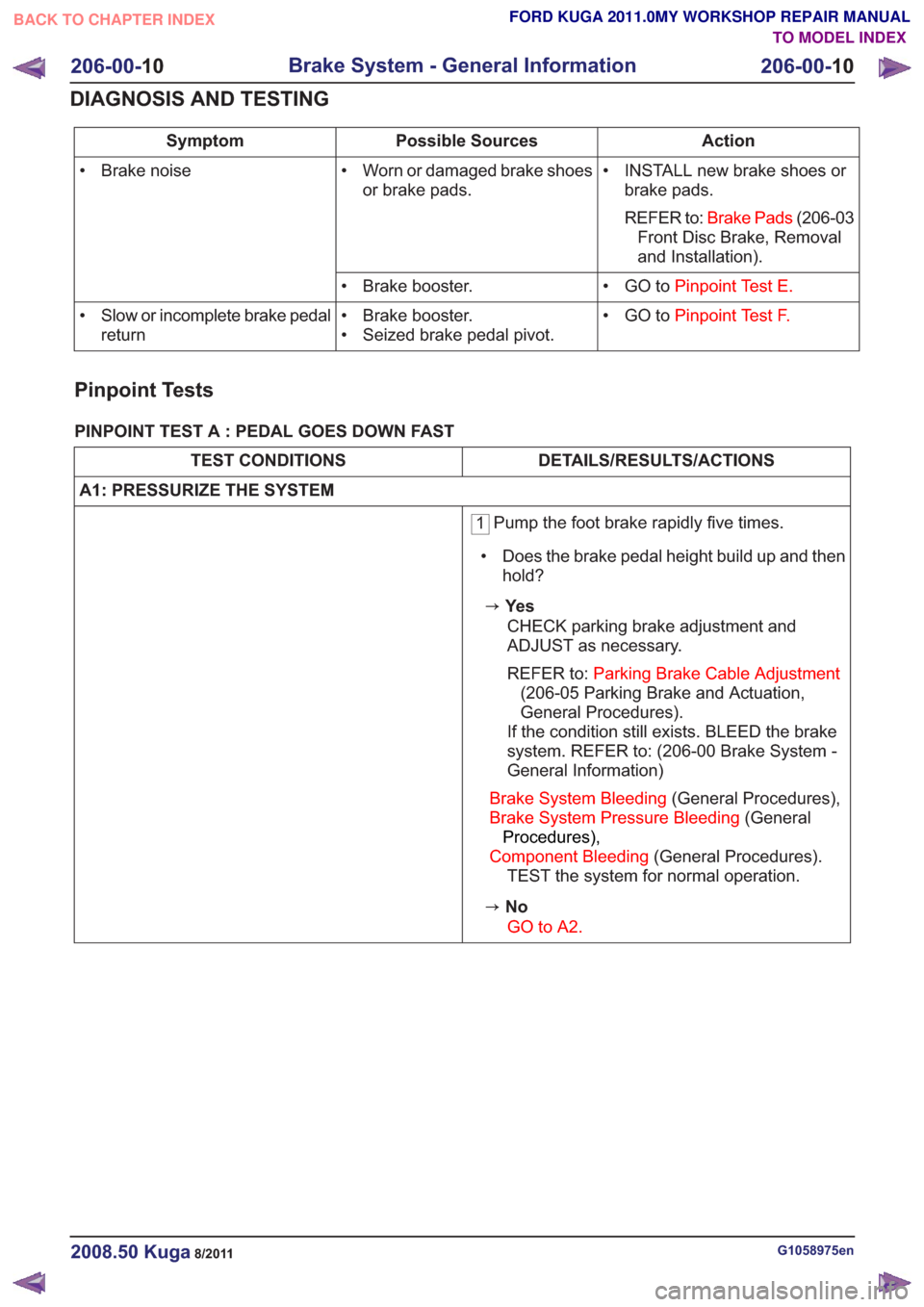

Symptom

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Worn or damaged brake shoes

or brake pads.

• Brake noise

• GO toPinpoint Test E.

• Brake booster.

• GO toPinpoint Test F.

• Brake booster.

• Seized brake pedal pivot.

• Slow or incomplete brake pedal

return

Pinpoint Tests

PINPOINT TEST A : PEDAL GOES DOWN FAST

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

A1: PRESSURIZE THE SYSTEM

1 Pump the foot brake rapidly five times.

• Does the brake pedal height build up and then hold?

zYe s

CHECK parking brake adjustment and

ADJUST as necessary.

REFER to: Parking Brake Cable Adjustment

(206-05 Parking Brake and Actuation,

General Procedures).

If the condition still exists. BLEED the brake

system. REFER to: (206-00 Brake System -

General Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General

Procedures),

Component Bleeding (General Procedures).

TEST the system for normal operation.

zNo

GO to A2.

G1058975en2008.50 Kuga8/2011

206-00- 10

Brake System - General Information

206-00- 10

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1347 of 2057

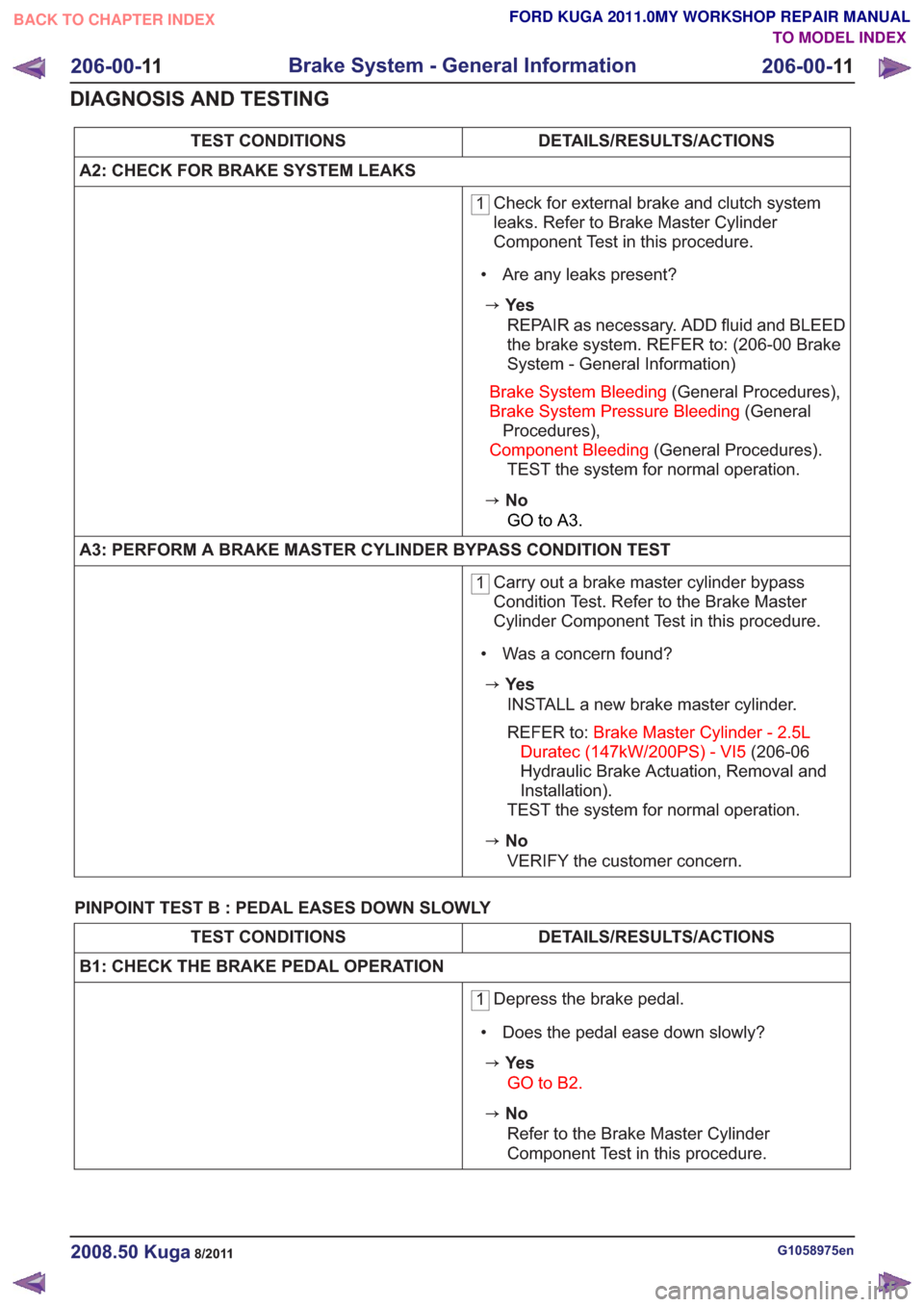

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

A2: CHECK FOR BRAKE SYSTEM LEAKS

1 Check for external brake and clutch system

leaks. Refer to Brake Master Cylinder

Component Test in this procedure.

• Are any leaks present?

zYe s REPAIR as necessary. ADD fluid and BLEED

the brake system. REFER to: (206-00 Brake

System - General Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General

Procedures),

Component Bleeding (General Procedures).

TEST the system for normal operation.

zNo

GO to A3.

A3: PERFORM A BRAKE MASTER CYLINDER BYPASS CONDITION TEST

1 Carry out a brake master cylinder bypass

Condition Test. Refer to the Brake Master

Cylinder Component Test in this procedure.

• Was a concern found?

zYe s INSTALL a new brake master cylinder.

REFER to: Brake Master Cylinder - 2.5L

Duratec (147kW/200PS) - VI5 (206-06

Hydraulic Brake Actuation, Removal and

Installation).

TEST the system for normal operation.

zNo

VERIFY the customer concern.

PINPOINT TEST B : PEDAL EASES DOWN SLOWLY

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

B1: CHECK THE BRAKE PEDAL OPERATION

1 Depress the brake pedal.

• Does the pedal ease down slowly?

zYe s GO to B2.

zNoRefer to the Brake Master Cylinder

Component Test in this procedure.

G1058975en2008.50 Kuga8/2011

206-00- 11

Brake System - General Information

206-00- 11

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL