air condition FORD KUGA 2011 1.G Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 125 of 2057

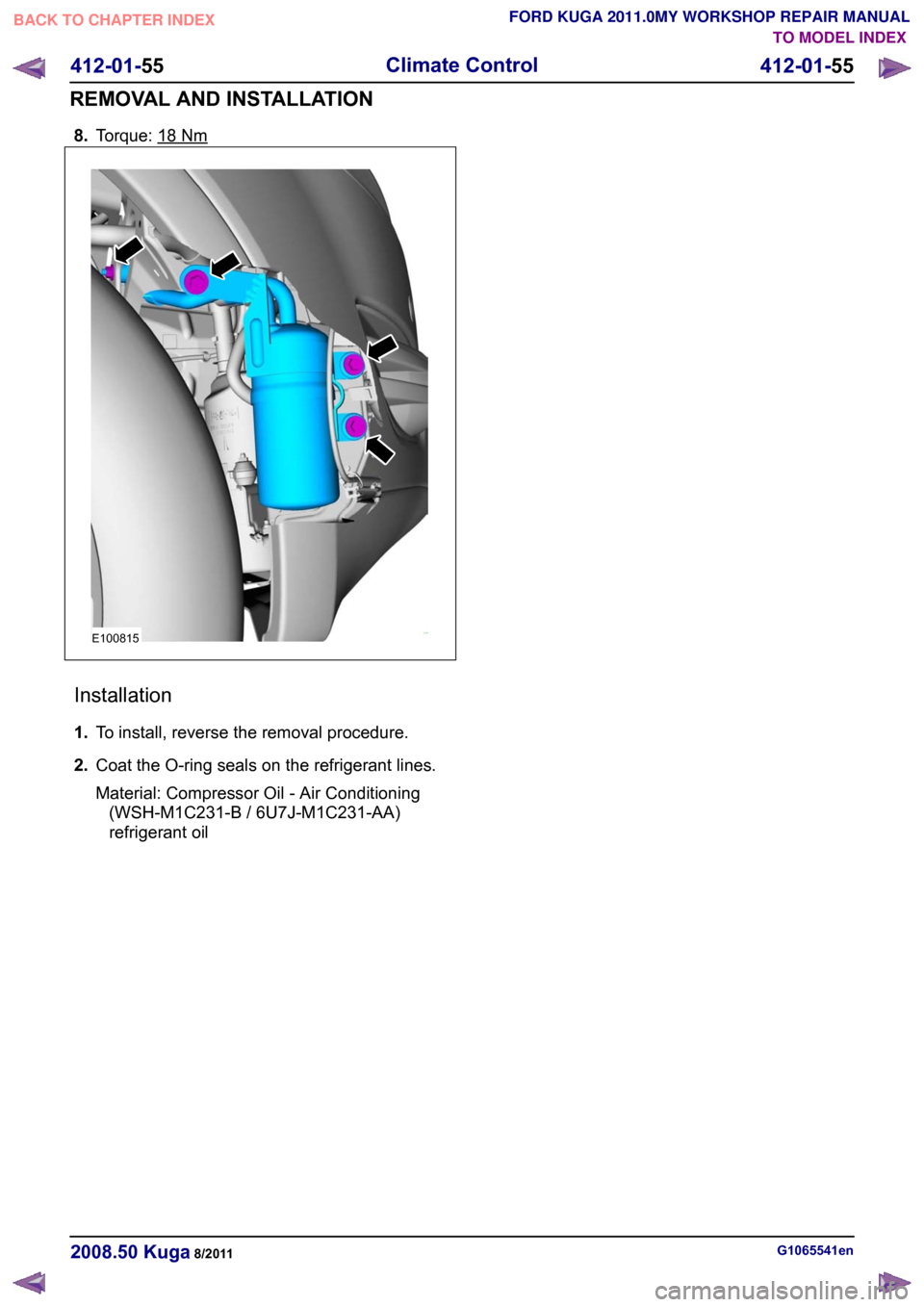

8.

Torque: 18 Nm

Installation

1.

To install, reverse the removal procedure.

2. Coat the O-ring seals on the refrigerant lines.

Material: Compressor Oil - Air Conditioning

(WSH-M1C231-B / 6U7J-M1C231-AA)

refrigerant oil G1065541en

2008.50 Kuga 8/2011 412-01-55

Climate Control

412-01-55

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE100815

Page 128 of 2057

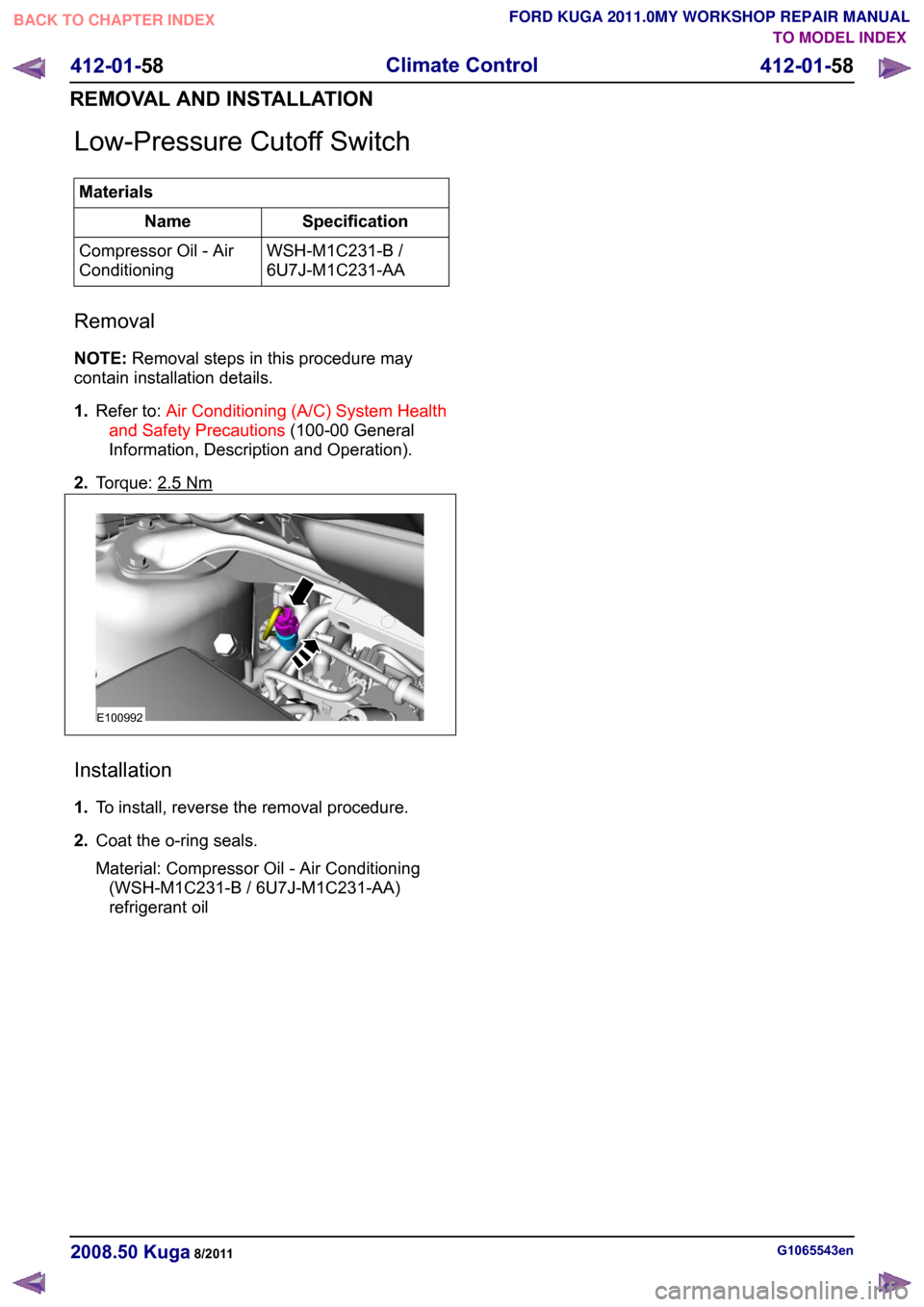

Low-Pressure Cutoff Switch

Materials

Specification

Name

WSH-M1C231-B /

6U7J-M1C231-AA

Compressor Oil - Air

Conditioning

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. Refer to: Air Conditioning (A/C) System Health

and Safety Precautions (100-00 General

Information, Description and Operation).

2. Torque: 2.5 Nm

Installation

1.

To install, reverse the removal procedure.

2. Coat the o-ring seals.

Material: Compressor Oil - Air Conditioning

(WSH-M1C231-B / 6U7J-M1C231-AA)

refrigerant oil G1065543en

2008.50 Kuga 8/2011 412-01-58

Climate Control

412-01-58

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE100992

Page 129 of 2057

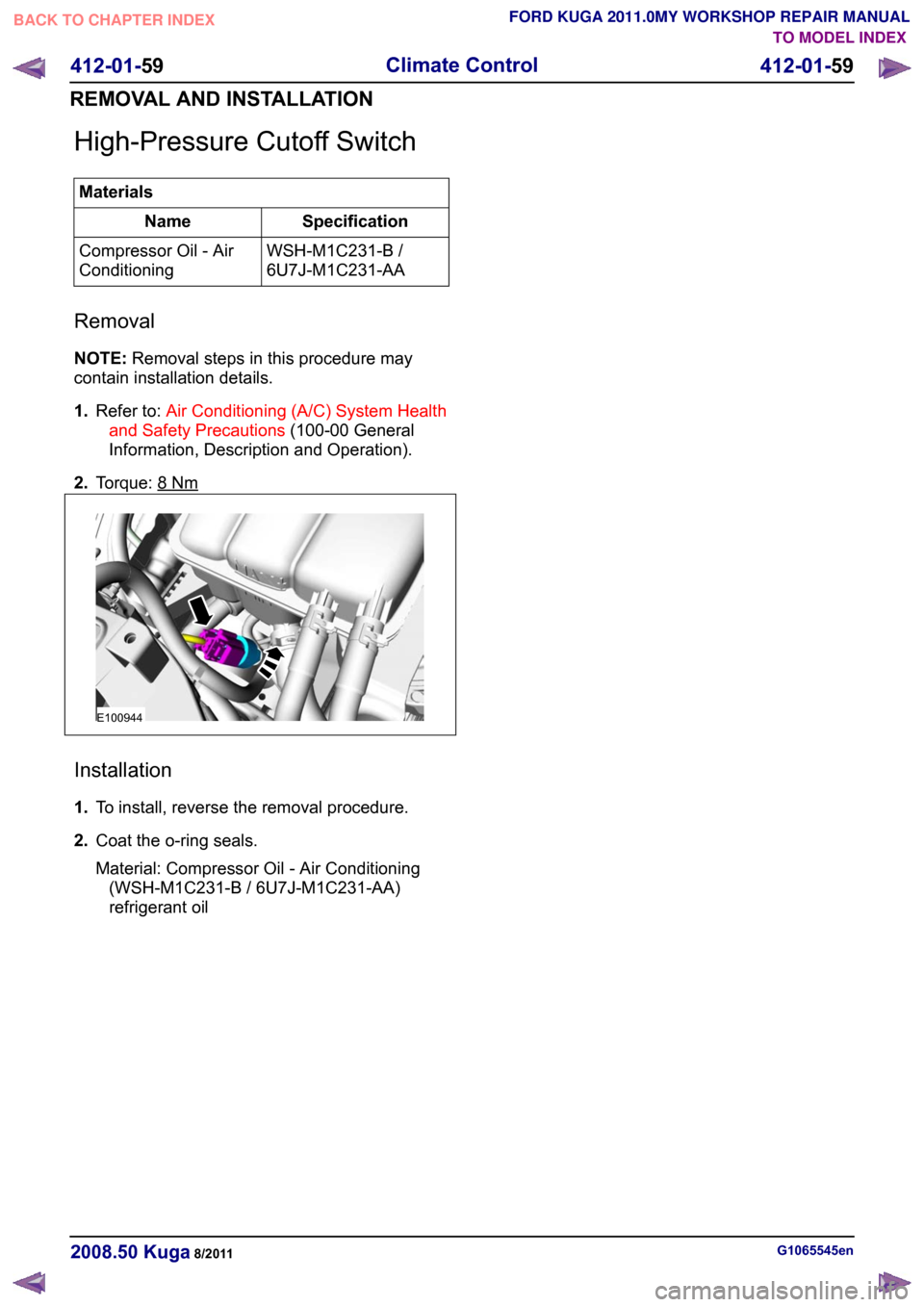

High-Pressure Cutoff Switch

Materials

Specification

Name

WSH-M1C231-B /

6U7J-M1C231-AA

Compressor Oil - Air

Conditioning

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. Refer to: Air Conditioning (A/C) System Health

and Safety Precautions (100-00 General

Information, Description and Operation).

2. Torque: 8 Nm

Installation

1.

To install, reverse the removal procedure.

2. Coat the o-ring seals.

Material: Compressor Oil - Air Conditioning

(WSH-M1C231-B / 6U7J-M1C231-AA)

refrigerant oil G1065545en

2008.50 Kuga 8/2011 412-01-59

Climate Control

412-01-59

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE100944

Page 135 of 2057

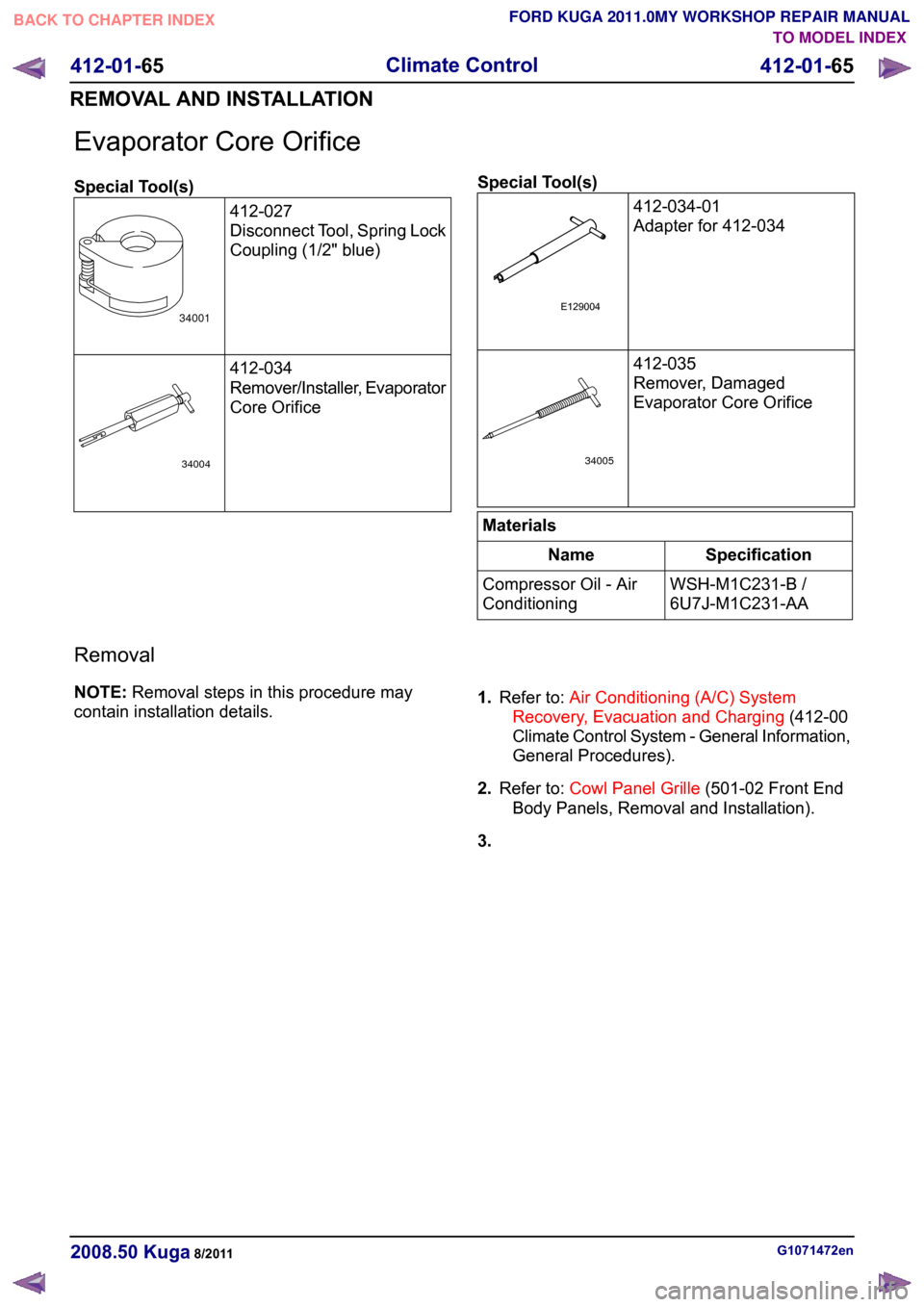

Evaporator Core Orifice

Special Tool(s)

412-027

Disconnect Tool, Spring Lock

Coupling (1/2" blue) 412-034

Remover/Installer, Evaporator

Core Orifice Special Tool(s)

412-034-01

Adapter for 412-034 412-035

Remover, Damaged

Evaporator Core Orifice

Materials

Specification

Name

WSH-M1C231-B /

6U7J-M1C231-AA

Compressor Oil - Air

Conditioning

Removal

NOTE: Removal steps in this procedure may

contain installation details. 1.

Refer to: Air Conditioning (A/C) System

Recovery, Evacuation and Charging (412-00

Climate Control System - General Information,

General Procedures).

2. Refer to: Cowl Panel Grille (501-02 Front End

Body Panels, Removal and Installation).

3. G1071472en

2008.50 Kuga 8/2011 412-01-65

Climate Control

412-01-65

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL34001 34004 E129004 34005

Page 137 of 2057

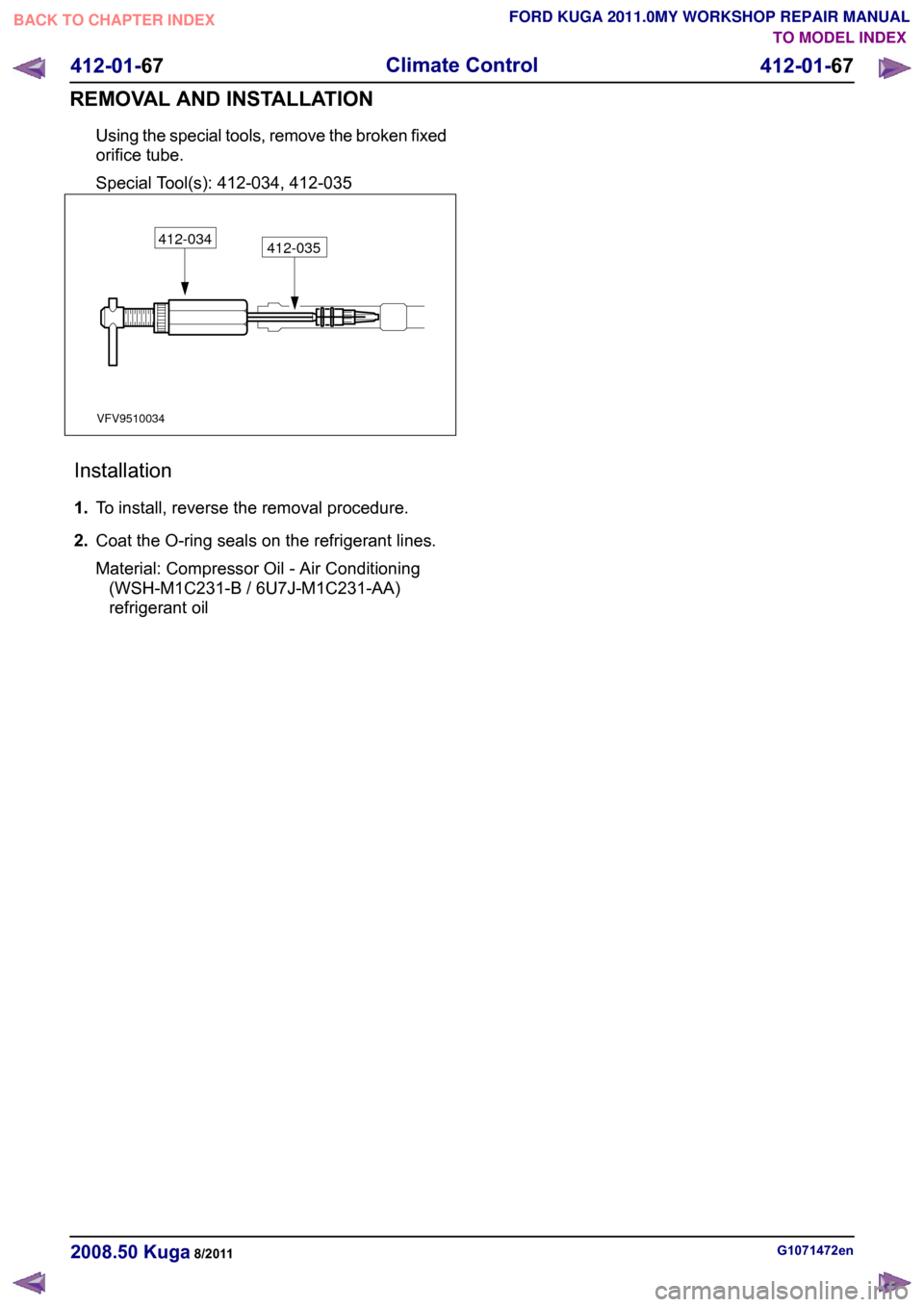

Using the special tools, remove the broken fixed

orifice tube.

Special Tool(s): 412-034, 412-035

Installation

1.

To install, reverse the removal procedure.

2. Coat the O-ring seals on the refrigerant lines.

Material: Compressor Oil - Air Conditioning

(WSH-M1C231-B / 6U7J-M1C231-AA)

refrigerant oil G1071472en

2008.50 Kuga 8/2011 412-01-67

Climate Control

412-01-67

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALVFV9510034412-034412-035

Page 165 of 2057

System Operation

Electric Booster Heater

In diesel vehicles which give off little residual heat,

a booster heater is used to heat the passenger

compartment rapidly in the case of low ambient

temperatures.

If the interior temperature has been set to HI, or if

the heater controls have been switched to the

highest setting, the two-zone air conditioning

system sends an "electric booster heater ON"

request signal to the CAN (controller area network)

via the medium speed GEM bus. If a manual air

conditioning system is installed, the signal is

transmitted via a conventional cable connection.

The GEM switches on the electric booster heater

depending on the following parameters:

• Engine coolant temperature is below 60 °C.

• Ambient air temperature is below 10 °C.

• Sufficient generator capacity is available.

The electric booster heater electronics activate

three output stages as a function of a pulse width

modulated signal PWM (pulse width modulation)

generated by the GEM. The output stages switch

the three heating elements of the electric booster

heater ON or OFF individually, whereby the heating

periods of the individual elements can overlap. Due

to the variable switch-on duration, continuously

variable temperature control is possible. The overall

heating power of the three heating elements is

linearly proportional to the PWM signal. If the PWM

signal is below 10% or above 95%, the electric

booster heater is not activated.

The electric booster heater is switched off when

an engine coolant temperature of 70°C or an

ambient air temperature of 20°C is exceeded.

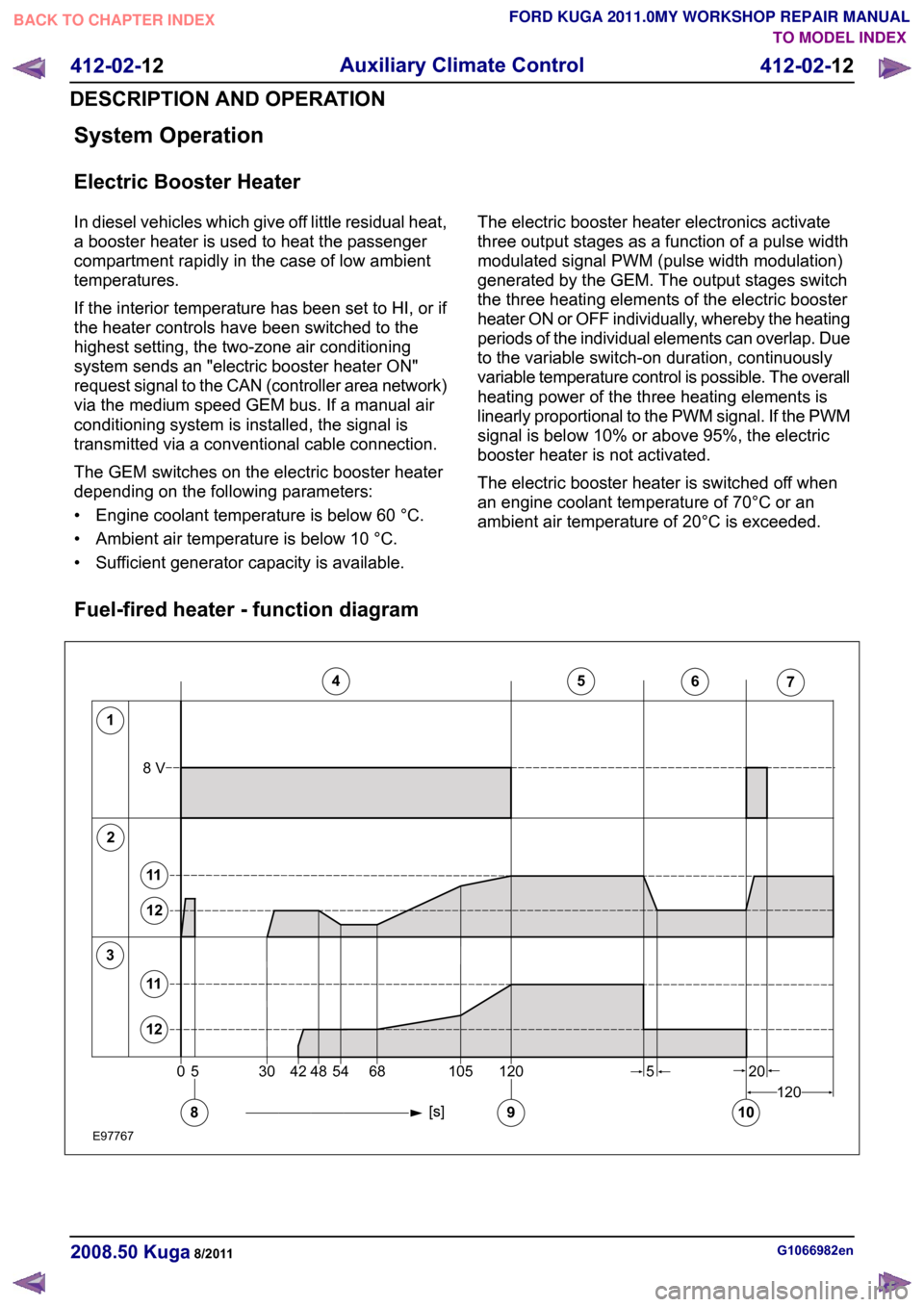

Fuel-fired heater - function diagram G1066982en

2008.50 Kuga 8/2011 412-02-12

Auxiliary Climate Control

412-02-12

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL12345671205304254481201056820108V58911121112E977670

Page 166 of 2057

Description

Item

Glow plug

1

Combustion Air Blower

2

Fuel pump

3

Fuel-fired heater on

4

Fuel-fired heater - large regulating step

5

Fuel-fired heater - small regulating step

6 Description

Item

Fuel-fired heater off

7

Blower motor on

8

Flame detection

9

Blower motor off

10

Large regulating step

11

Small regulating step

12

Boost heat mode

When the engine is running, the booster heater

helps the engine to heat the passenger

compartment at low ambient temperatures.

When the coolant temperature reaches 30 °C, the

control unit transmits a switch-on signal for the

passenger compartment blower via the CAN bus.

When the coolant temperature drops, the blower

remains on until the temperature reaches 20 °C

whereupon it is deactivated.

The fuel tank must be filled to at least 14% for the

system to be switched on. If the fuel level drops

below 8% then the system is switched off.

In boost mode, the fuel fired booster heater is only

switched on if all of the following criteria are met:

• Engine speed above 500 rpm. The fuel fired booster heater is not allowed to start up while

the engine is being cranked; this prevents a

shut-down due to low voltage if the battery

charge is low.

• Ambient temperature below 5 °C.

• Fuel level above 14% of total capacity.

• Function is active on the trip computer menu.

One of the following conditions is sufficient to

switch off the booster heater in boost heat mode:

• Engine speed below 500 rpm.

• Ambient temperature above 11 °C.

• Function is active on the trip computer menu.

• Fuel level below 8% of total capacity.

Programmable fuel fired booster heater

The programmable fuel fired booster heater has

two operating modes:

• Instant start

• Programmed start

The heater status is displayed on the instrument

cluster display. The parking heater mode is controlled via a menu in the message centre. The

fuel fired booster heater can be activated and

deactivated via the message centre. (If set to 'Auto'

the system is activated, if set to 'Off' the system is

completely deactivated)

Immediate start-up of the booster

heater

This function enables the fuel-fired booster heater

to be switched on manually when the engine is not

running. This function is activated via the menu on

the driver information system.

The ignition key must be in the II" position before

this menu can be accessed. The timer function of

the booster heater remains active when the ignition

key is in position "0".

After an immediate start-up of the booster heater

it is switched off again after 30 minutes (or if the

fuel level in the fuel tank drops below 8%). The

booster heater stops within 2 minutes of the engine

starting. This leaves enough time to check whether

the switch-on conditions for boost heat mode have

been met, thus preventing the booster heater from

having to switch off and switch back on again. The

heater can be switched off manually at any time

from the menu.

Programmed start-up of the booster

heater

The driver can use a menu to adjust the time at

which the vehicle is to be pre-heated. The following

options are available:

• Time setting. One or two times can be

programmed for each day of the week. It is

possible to program days either individually or

together in groups (Mon-Sun/Mon-Sat/Mon-Fri).

• Time and data setting

With the first option, the fuel-fired booster heater

will start repeatedly without needing to be G1066982en

2008.50 Kuga 8/2011 412-02-13

Auxiliary Climate Control

412-02-13

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 167 of 2057

reprogrammed. However, if the engine hasn't been

run since the last programmed start, the fuel-fired

booster heater will not start up the second time so

as to prevent the battery from being discharged.

The length of time required to pre-heat the vehicle

is calculated in the control unit of the fuel-fired

booster heater and is based on two temperature

values:

• Ambient air temperature: this message is taken

from the GEM via the CAN bus.

• Coolant temperature: this is determined via an internal sensor in the fuel-fired booster heater.

The maximum heating time is 30 minutes at an

outside air temperature of -10 °C or lower. The

heating time decreases proportionally with

increasing ambient temperature until the ambient

temperature is between +15 °C and +20 °C. Then

the minimum heating time is 10 minutes. The

parking heater is deactivated at temperatures

above +20 °C.

The sequence for a programmed start of the

booster heater is as follows:

• Two minutes before the start of the maximum heating time the driver information

system/instrument cluster sends an activation

message to the fuel-fired booster heater via the

CAN bus.

• The fuel-fired booster heater calculates the required heating time and, if necessary, sends

a delay request on the CAN bus.

• At the calculated time, the fuel-fired booster heater starts up. The conditions for start-up are:

engine not running and amount of fuel in the

fuel tank is above 14% of maximum.

• When the coolant temperature reaches +30 °C, the control unit of the fuel-fired booster heater

sends a request to switch on the passenger

compartment blower.

• Eight minutes after the programmed switch-off time, the booster heater stops heating mode

and starts a run-on operation to clean the

system's spark plugs.

• Ten minutes after the switch-off time, the post-cleaning operation is complete. The

additional ten minutes run-on time provides

some leeway in case the driver is late arriving.

After a programmed start-up of the booster heater

it is switched off again after the heating time has

elapsed (or if the fuel level in the fuel tank drops

below 8%). The booster heater stops within 2 minutes of the engine starting. This leaves enough

time to check whether the switch-on conditions for

boost heat mode have been met, thus preventing

the booster heater from having to switch off and

switch back on again. The heater can be switched

off manually at any time from the menu.

Whilst the fuel-fired booster heater is in additional

heating mode and/or parking heating mode, the

instrument cluster receives a fuel consumption

signal; this is used to re-calculate the vehicle's

remaining range and fuel consumption data.

Emergency shutoff

In the event of an accident in which the airbags

are deployed, the control unit of the fuel-fired

booster heater receives a message on the CAN

bus from the restraints control module (RCM).

When this message is received, the booster heater

system switches off immediately.

The booster heater control module deactivates the

system and does not respond to further messages

on the CAN bus. The booster heater control module

needs to be activated with WDS.

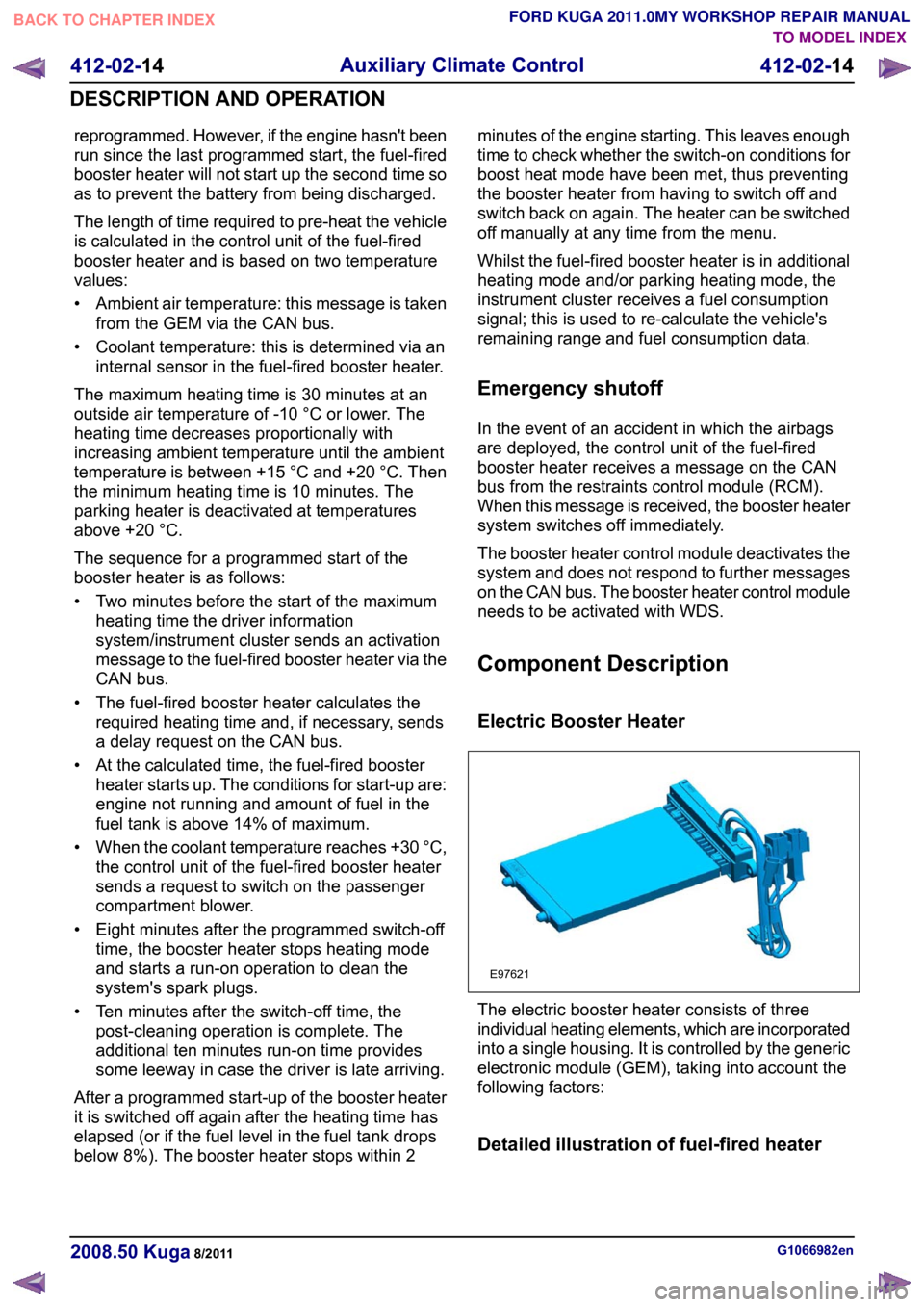

Component Description

Electric Booster Heater

The electric booster heater consists of three

individual heating elements, which are incorporated

into a single housing. It is controlled by the generic

electronic module (GEM), taking into account the

following factors:

Detailed illustration of fuel-fired heater

G1066982en

2008.50 Kuga 8/2011 412-02-14

Auxiliary Climate Control

412-02-14

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE97621

Page 264 of 2057

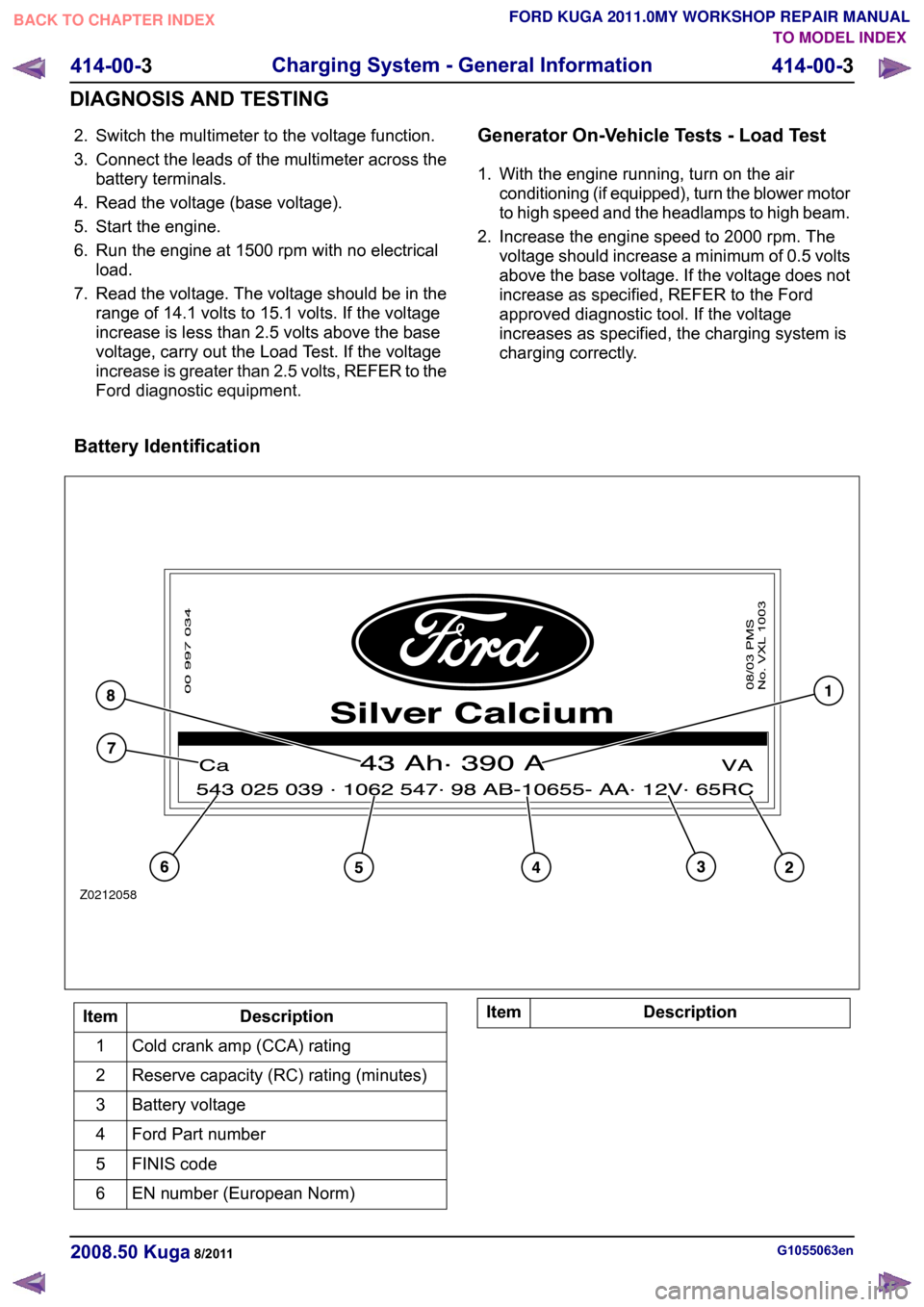

2. Switch the multimeter to the voltage function.

3. Connect the leads of the multimeter across the

battery terminals.

4. Read the voltage (base voltage).

5. Start the engine.

6. Run the engine at 1500 rpm with no electrical load.

7. Read the voltage. The voltage should be in the range of 14.1 volts to 15.1 volts. If the voltage

increase is less than 2.5 volts above the base

voltage, carry out the Load Test. If the voltage

increase is greater than 2.5 volts, REFER to the

Ford diagnostic equipment. Generator On-Vehicle Tests - Load Test

1. With the engine running, turn on the air

conditioning (if equipped), turn the blower motor

to high speed and the headlamps to high beam.

2. Increase the engine speed to 2000 rpm. The voltage should increase a minimum of 0.5 volts

above the base voltage. If the voltage does not

increase as specified, REFER to the Ford

approved diagnostic tool. If the voltage

increases as specified, the charging system is

charging correctly.

Battery Identification Description

Item

Cold crank amp (CCA) rating

1

Reserve capacity (RC) rating (minutes)

2

Battery voltage

3

Ford Part number

4

FINIS code

5

EN number (European Norm)

6 Description

Item G1055063en

2008.50 Kuga 8/2011 414-00-3

Charging System - General Information

414-00-3

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALZ0212058

Page 267 of 2057

Action

Battery Tester Reading WARNING: Do not recharge the battery.

Make sure that the surface charge was removed. A "REPLACE BATTERY" result could also mean

a poor connection between the battery cables and the battery. Check the connections are OK and

retest. If the result remains the same, INSTALL a NEW battery

REFER to: Battery(414-01 Battery, Mounting and

Cables, Removal and Installation).

REPLACE BATTERY or BAD CELL BATTERY

In addition it is advisable to check the vehicle electrical system. Check that the generator is functioning

correctly and the vehicle does not have an excessive key-off load (in general this should be under

20mA after 40 minutes of key off).

Midtronics EXP-1050 Battery Tester Test

Code

At the end of the test, use the arrow keys to scroll

down the screens to see additional information.

One of these is the TEST CODE.

The TEST CODE has 11 digits, for example:

0021U-B88WKX.

Using the Midtronics GR-590-2 The Midtronics GR-590-2 is both a battery charger

and battery tester and automatically removes the

surface charge as part of the normal operating

procedure.

The Midtronics GR-590-2 can be used on a battery

in-vehicle or out-of-vehicle.

• Disconnect the battery ground cable.

• Connect the positive red clamp from the

Midtronics GR-590-2 to the battery positive

terminal.

• Connect the negative black clamp from the Midtronics GR-590-2 to the battery negative

terminal.

• Connect the AC power cable to the mains outlet

and switch ON.

• Follow the instructions supplied with the Midtronics GR-590-2 to charge the battery.

• To disconnect the Midtronics GR-590-2, reverse

the connection procedure.

The Midtronics GR-590-2 will automatically carry

out a charge cycle before giving the resulting test

code. It will bring the battery into a serviceable

condition and if required can proceed to fully

charge the battery.

Functions on the front panel of the Midtronics

GR-590-2

• UP and DOWN button: The UP and DOWN buttons allow the operator to scroll through

selections on the display and increase or

decrease values.

• ENTER button: The ENTER button allows the operator to accept a selection and continue to

the next step. G1055063en

2008.50 Kuga 8/2011 414-00-6

Charging System - General Information

414-00-6

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE136266