fluid FORD KUGA 2011 1.G Manual Online

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1374 of 2057

Brake Pads(12 234 0)

Special Tool(s)206-005

Retractor, Brake Caliper

Piston

12014

Materials

Specification

Name

WSS-M6C57-A2

Brake Fluid - Super

DOT4

WSS-M12A4-A2 / 1C1J-

19584-BA

Lubricating Paste

Removal

NOTE:

Removal steps in this procedure may

contain installation details.

1. Refer to: Brake System Health and Safety

Precautions (100-00 General Information,

Description and Operation).

2. Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

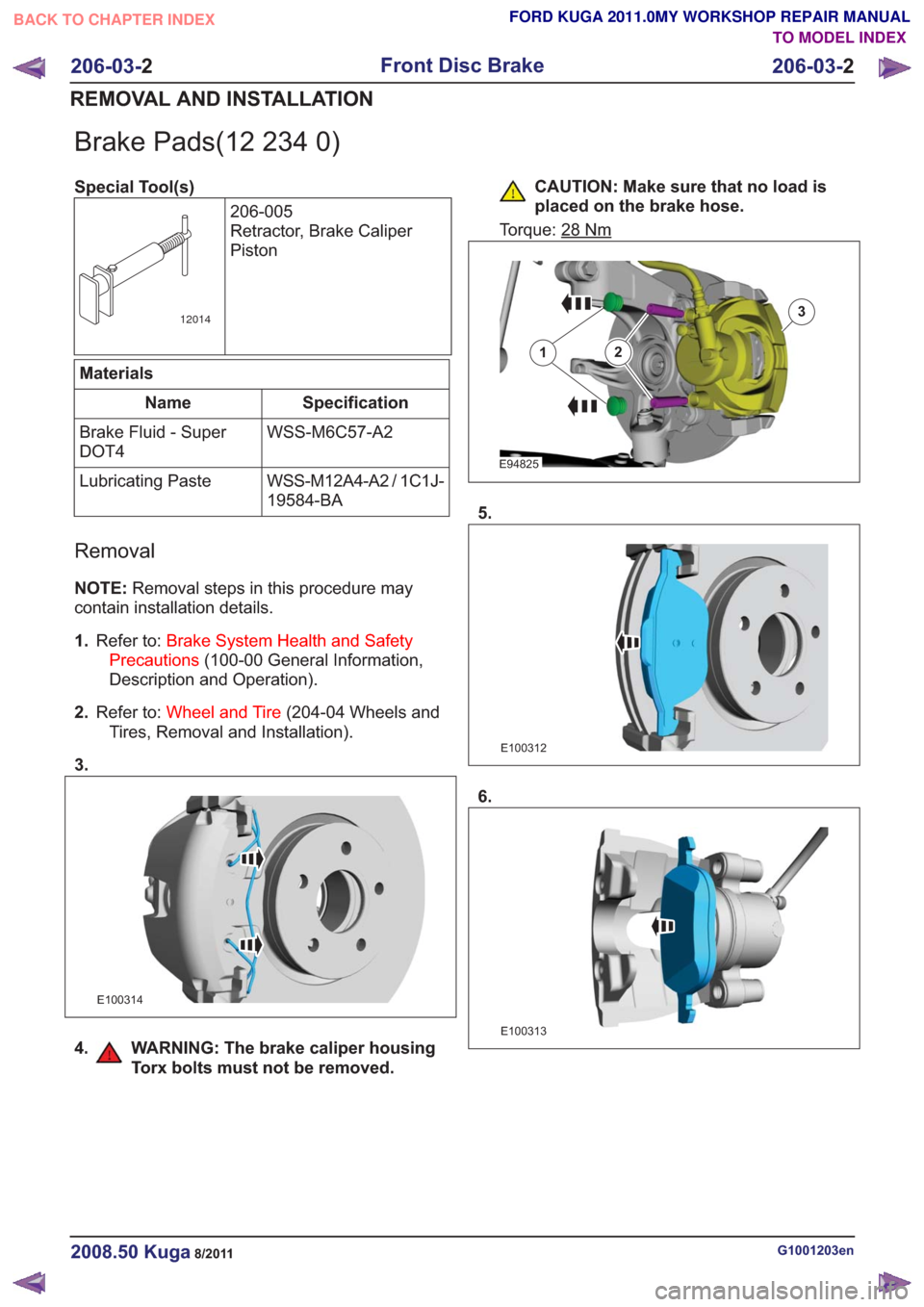

3.

E100314

4. WARNING: The brake caliper housing Torx bolts must not be removed.

CAUTION: Make sure that no load is

placed on the brake hose.

Torque: 28

Nm

E94825

12

3

5.

E100312

6.

E100313

G1001203en2008.50 Kuga8/2011

206-03- 2

Front Disc Brake

206-03- 2

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1375 of 2057

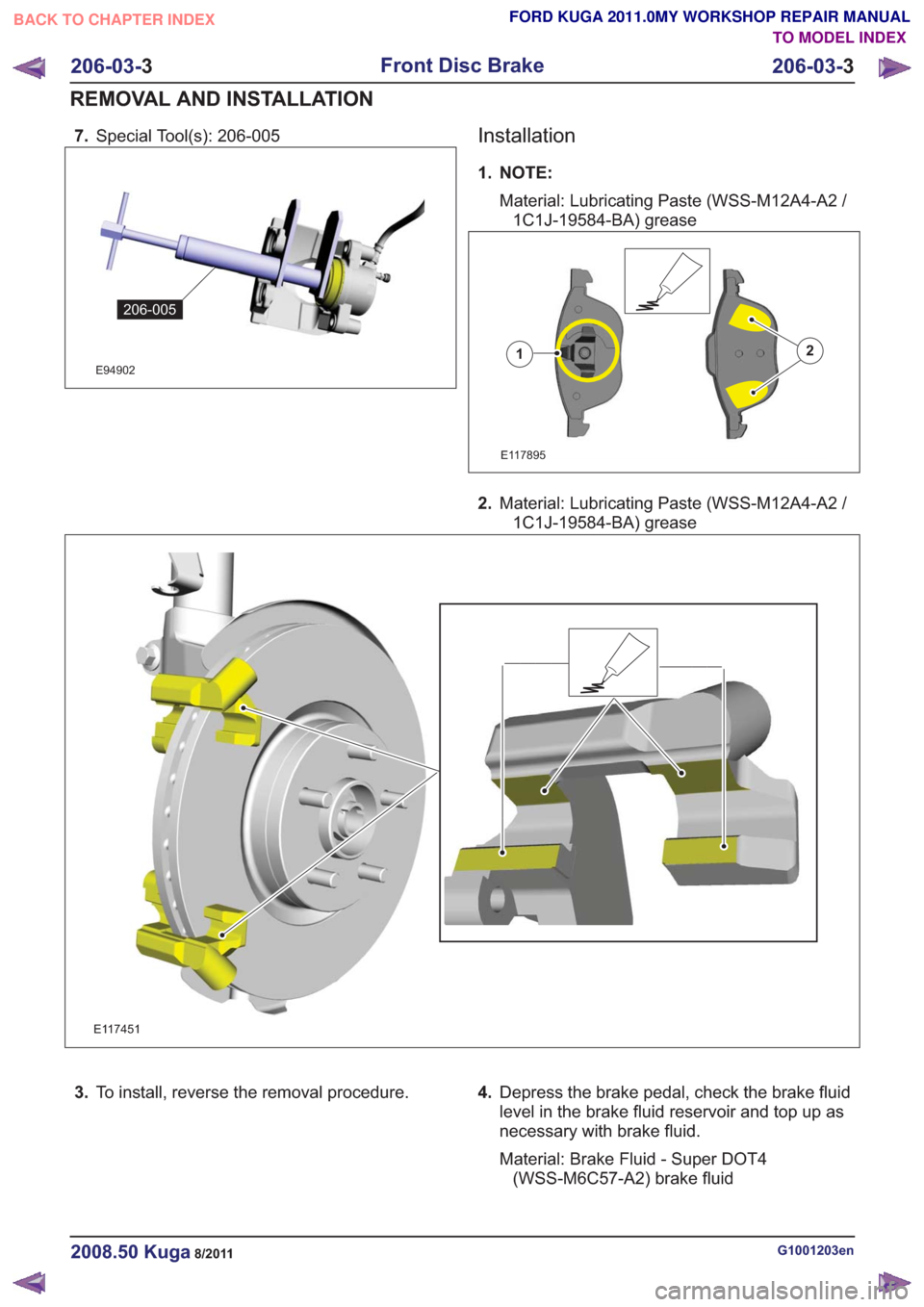

7.Special Tool(s): 206-005

E94902

206-005

Installation

1. NOTE:

Material: Lubricating Paste (WSS-M12A4-A2 /1C1J-19584-BA) grease

E117895

12

2. Material: Lubricating Paste (WSS-M12A4-A2 /

1C1J-19584-BA) grease

E117451

3. To install, reverse the removal procedure. 4.Depress the brake pedal, check the brake fluid

level in the brake fluid reservoir and top up as

necessary with brake fluid.

Material: Brake Fluid - Super DOT4

(WSS-M6C57-A2) brake fluid

G1001203en2008.50 Kuga8/2011

206-03- 3

Front Disc Brake

206-03- 3

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1377 of 2057

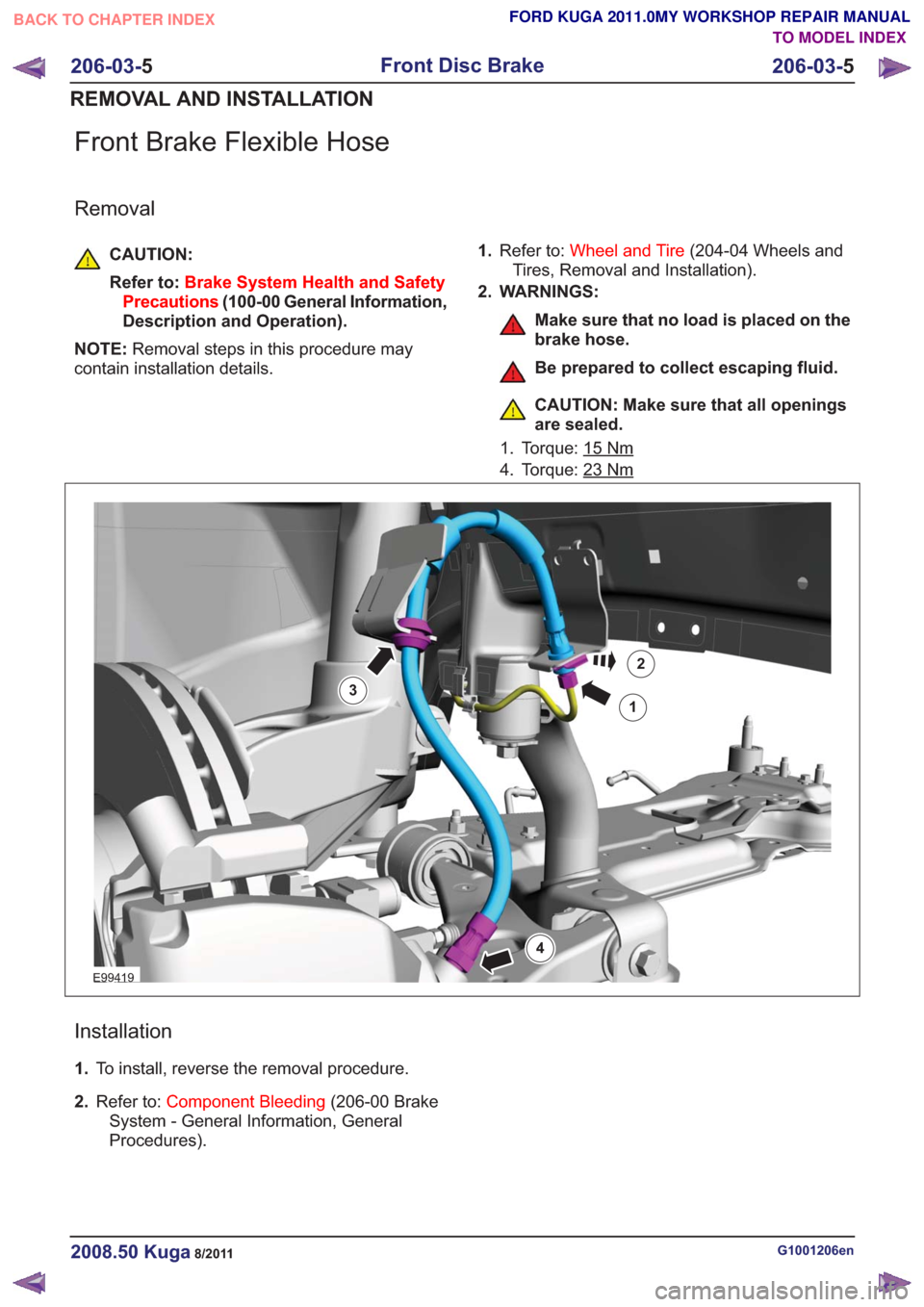

Front Brake Flexible Hose

Removal

CAUTION:

Refer to:Brake System Health and Safety

Precautions (100-00 General Information,

Description and Operation).

NOTE: Removal steps in this procedure may

contain installation details. 1.

Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

2. WARNINGS:

Make sure that no load is placed on the

brake hose.

Be prepared to collect escaping fluid.

CAUTION: Make sure that all openings

are sealed.

1. Torque: 15

Nm

4. Torque: 23Nm

E99419

1

2

3

4

Installation

1. To install, reverse the removal procedure.

2. Refer to: Component Bleeding (206-00 Brake

System - General Information, General

Procedures).

G1001206en2008.50 Kuga8/2011

206-03- 5

Front Disc Brake

206-03- 5

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1379 of 2057

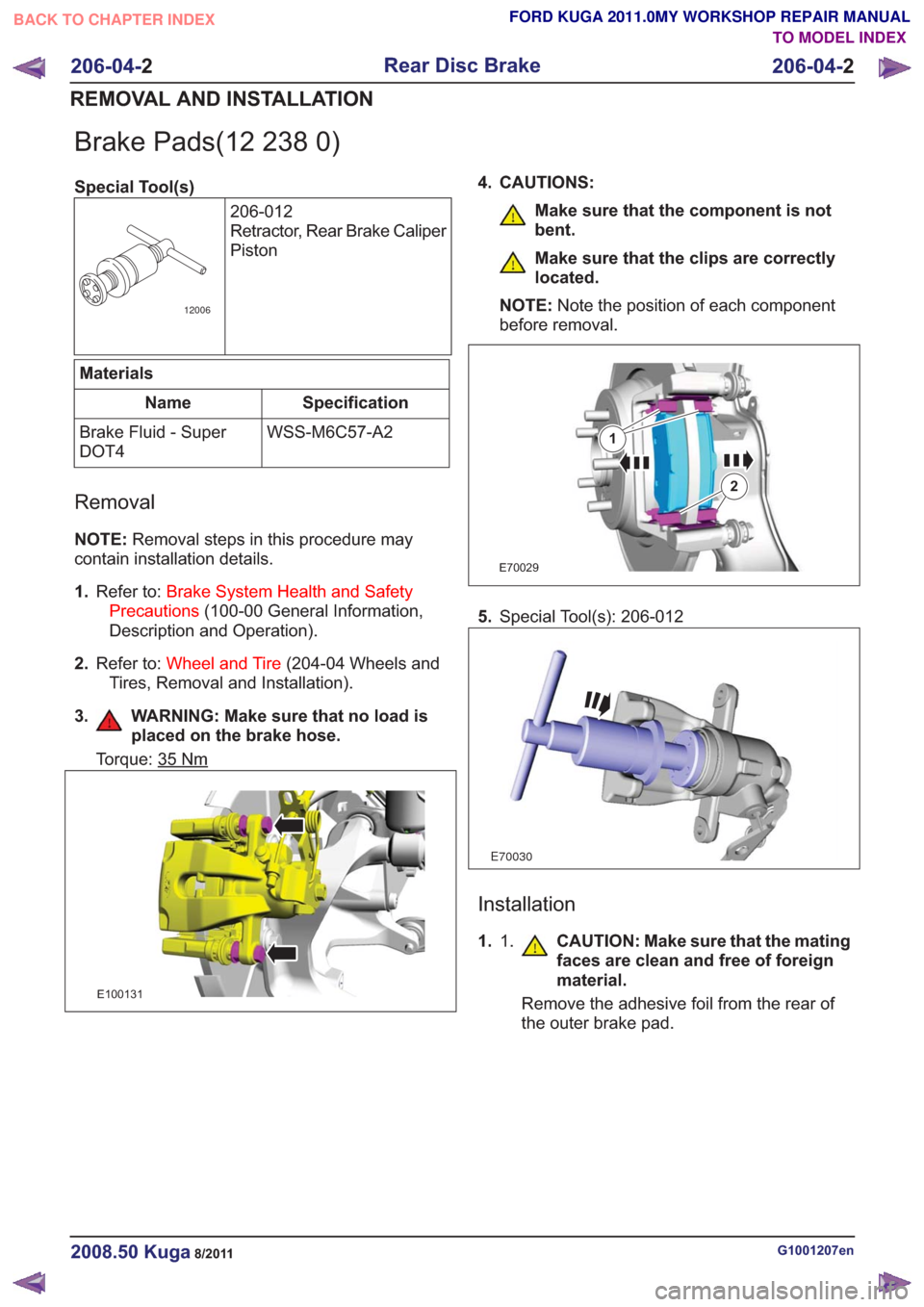

Brake Pads(12 238 0)

Special Tool(s)206-012

Retractor, Rear Brake Caliper

Piston

12006

Materials

Specification

Name

WSS-M6C57-A2

Brake Fluid - Super

DOT4

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. Refer to: Brake System Health and Safety

Precautions (100-00 General Information,

Description and Operation).

2. Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

3. WARNING: Make sure that no load is placed on the brake hose.

Torque: 35Nm

E100131

4. CAUTIONS:

Make sure that the component is not

bent.

Make sure that the clips are correctly

located.

NOTE: Note the position of each component

before removal.

E70029

1

2

5. Special Tool(s): 206-012

E70030

Installation

1. 1. CAUTION: Make sure that the mating

faces are clean and free of foreign

material.

Remove the adhesive foil from the rear of

the outer brake pad.

G1001207en2008.50 Kuga8/2011

206-04- 2

Rear Disc Brake

206-04- 2

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1380 of 2057

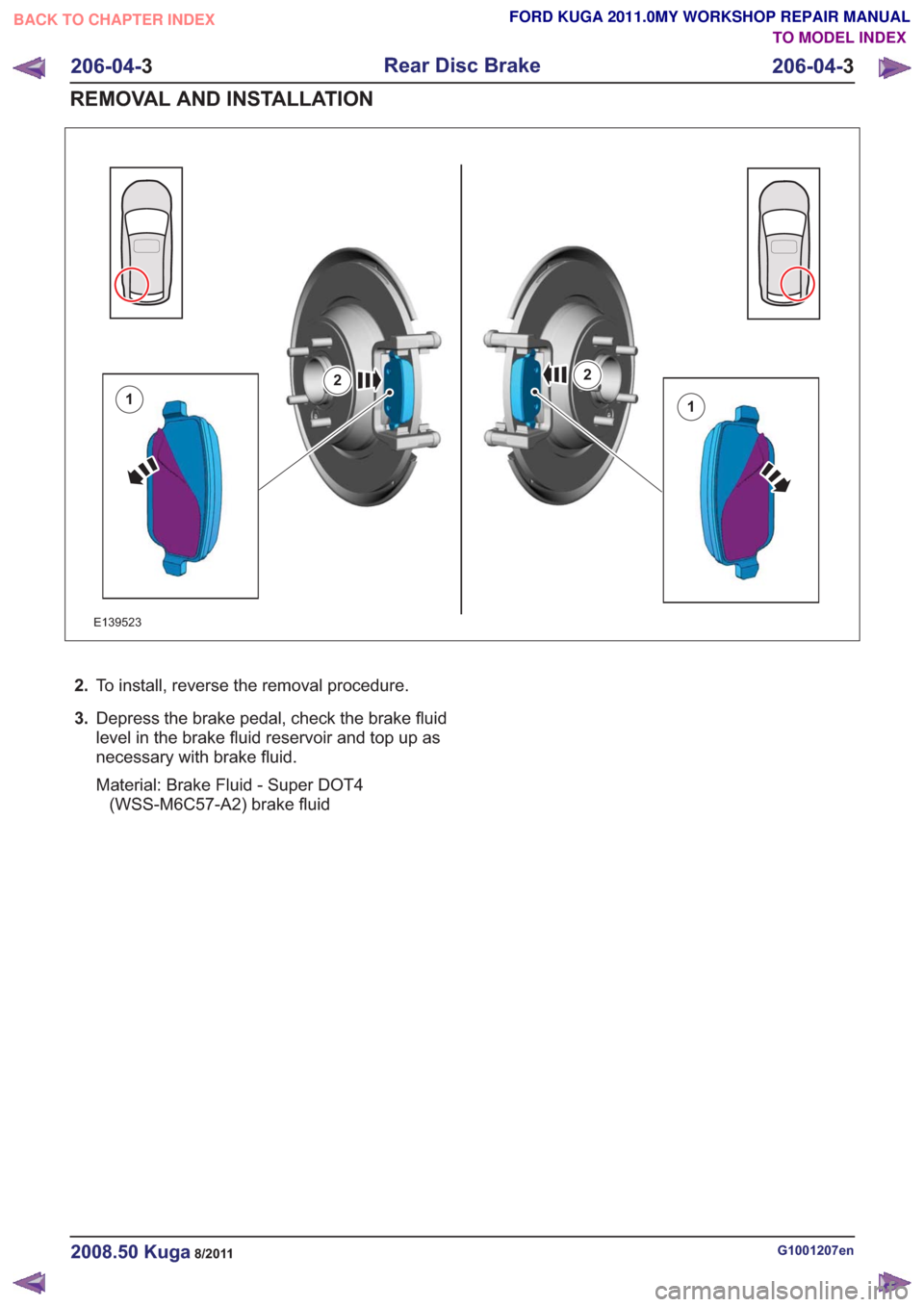

E139523

11

22

2.To install, reverse the removal procedure.

3. Depress the brake pedal, check the brake fluid

level in the brake fluid reservoir and top up as

necessary with brake fluid.

Material: Brake Fluid - Super DOT4

(WSS-M6C57-A2) brake fluid

G1001207en2008.50 Kuga8/2011

206-04- 3

Rear Disc Brake

206-04- 3

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1381 of 2057

Brake Caliper(12 253 0)

General EquipmentHose Clamp(s)

Materials

Specification

Name

WSS-M6C57-A2

Brake Fluid - Super

DOT4

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. Refer to: Brake System Health and Safety

Precautions (100-00 General Information,

Description and Operation).

2. Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

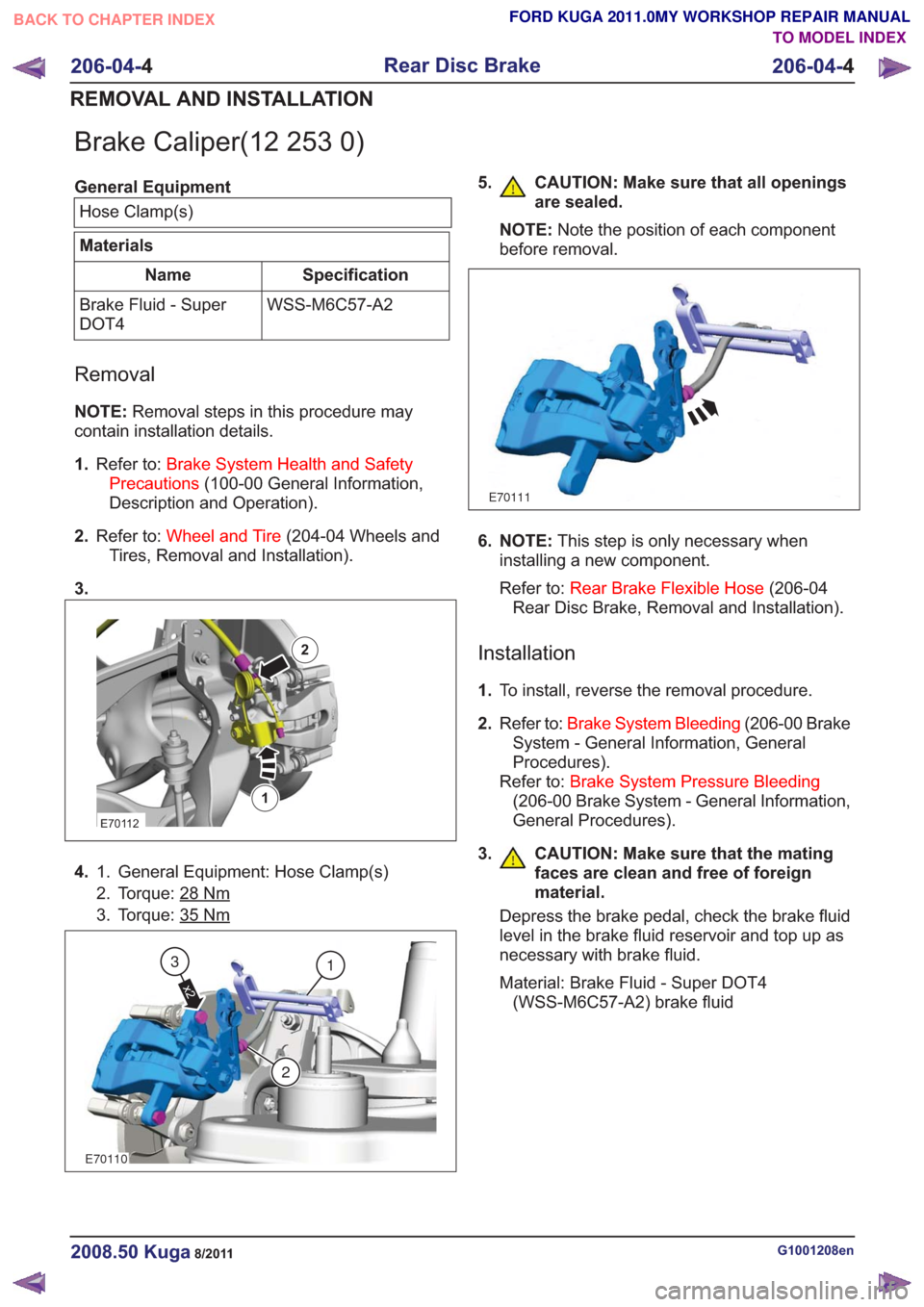

3.

E70112

1

2

4. General Equipment: Hose Clamp(s)

1.

2. Torque: 28

Nm

3. Torque: 35Nm

E70110

1

2

x2

3

5. CAUTION: Make sure that all openings

are sealed.

NOTE: Note the position of each component

before removal.

E70111

6. NOTE: This step is only necessary when

installing a new component.

Refer to: Rear Brake Flexible Hose (206-04

Rear Disc Brake, Removal and Installation).

Installation

1. To install, reverse the removal procedure.

2. Refer to: Brake System Bleeding (206-00 Brake

System - General Information, General

Procedures).

Refer to: Brake System Pressure Bleeding

(206-00 Brake System - General Information,

General Procedures).

3.

CAUTION: Make sure that the mating

faces are clean and free of foreign

material.

Depress the brake pedal, check the brake fluid

level in the brake fluid reservoir and top up as

necessary with brake fluid.

Material: Brake Fluid - Super DOT4 (WSS-M6C57-A2) brake fluid

G1001208en2008.50 Kuga8/2011

206-04- 4

Rear Disc Brake

206-04- 4

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1382 of 2057

Rear Brake Flexible Hose

Removal

CAUTION:

Refer to:Brake System Health and Safety

Precautions (100-00 General Information,

Description and Operation).

NOTE: Removal steps in this procedure may

contain installation details. 1.

Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

2. WARNINGS:

Make sure that no load is placed on the

brake hose.

Be prepared to collect escaping fluid.

CAUTION: Make sure that all openings

are sealed.

1. Torque: 15

Nm

E99425

1

2

3

G1001210en2008.50 Kuga8/2011

206-04- 5

Rear Disc Brake

206-04- 5

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1402 of 2057

Brake Master Cylinder — 2.5L Duratec (147kW/200PS) -VI5(12 343 0)

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. Refer to: Brake System Health and Safety

Precautions (100-00 General Information,

Description and Operation).

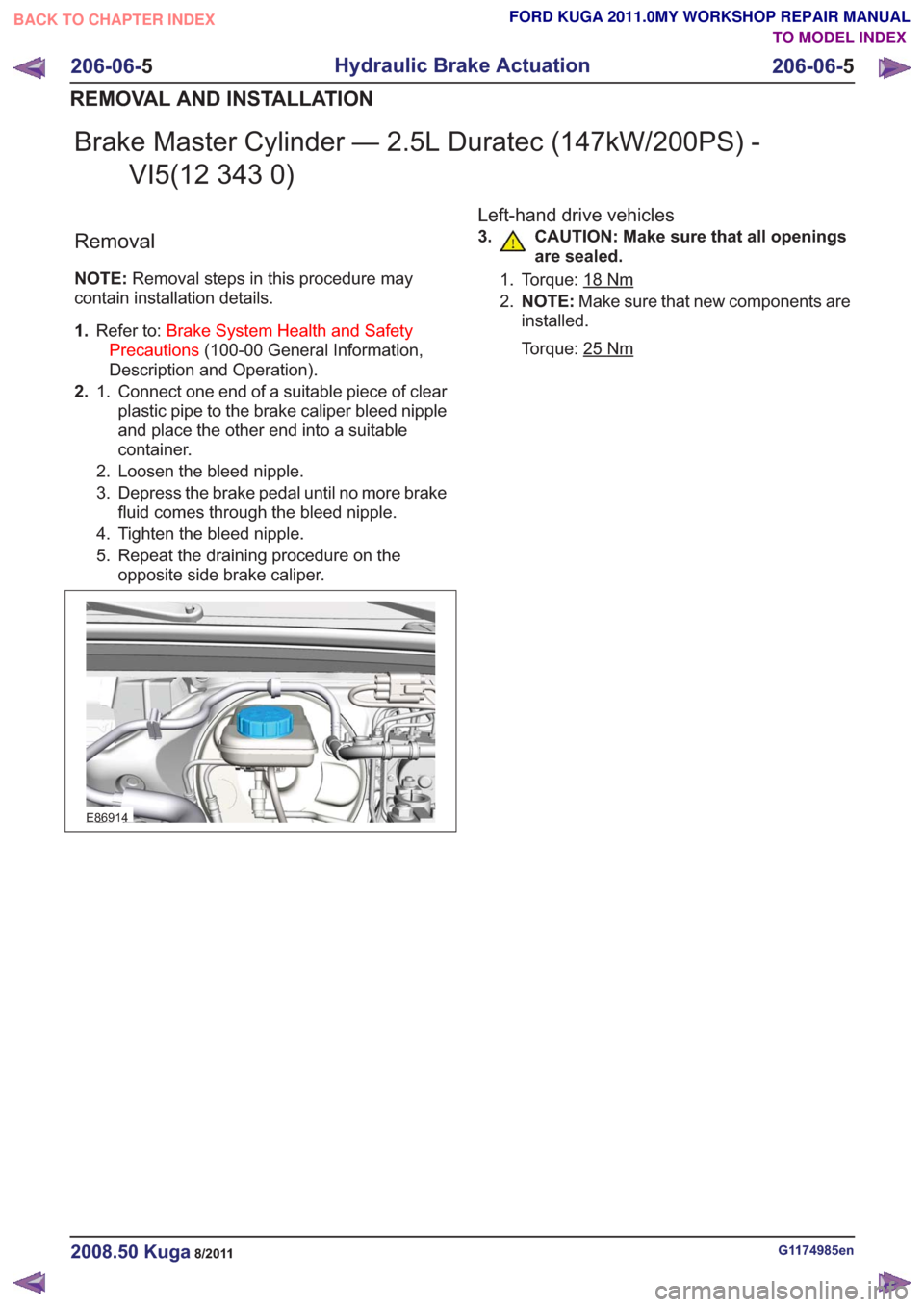

2. Connect one end of a suitable piece of clear

plastic pipe to the brake caliper bleed nipple

1.

and place the other end into a suitable

container.

2. Loosen the bleed nipple.

3. Depress the brake pedal until no more brake fluid comes through the bleed nipple.

4. Tighten the bleed nipple.

5. Repeat the draining procedure on the opposite side brake caliper.

E86914

Left-hand drive vehicles

3. CAUTION: Make sure that all openings are sealed.

1. Torque: 18Nm

2.NOTE: Make sure that new components are

installed.

Torque: 25

Nm

G1174985en2008.50 Kuga8/2011

206-06- 5

Hydraulic Brake Actuation

206-06- 5

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1422 of 2057

Description

Item

Front wheel sensor, right-hand side

8Description

Item

9 ESP switch

Testing the brakes on a roller dynamometer

- 4X4 vehicles only

On 4X4 vehicles a brake test on a roller

dynamometer must only be performed under the

following conditions.

• The brake test must not exceed a duration of 1 minute.

• Ignition key in position 0.

• The roller speed must not exceed 5 km/h.

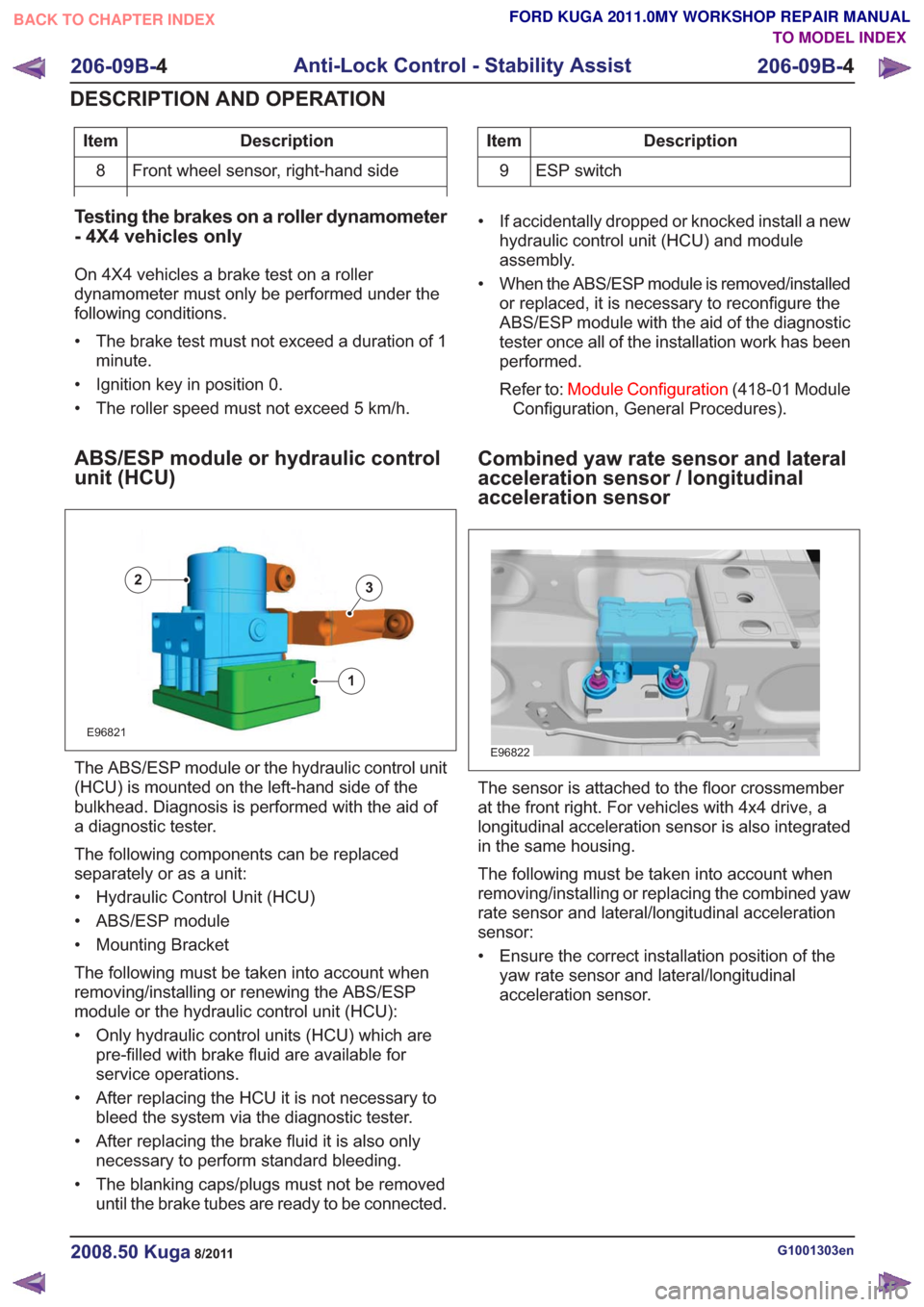

ABS/ESP module or hydraulic control

unit (HCU)

E96821

1

23

The ABS/ESP module or the hydraulic control unit

(HCU) is mounted on the left-hand side of the

bulkhead. Diagnosis is performed with the aid of

a diagnostic tester.

The following components can be replaced

separately or as a unit:

• Hydraulic Control Unit (HCU)

• ABS/ESP module

• Mounting Bracket

The following must be taken into account when

removing/installing or renewing the ABS/ESP

module or the hydraulic control unit (HCU):

• Only hydraulic control units (HCU) which are pre-filled with brake fluid are available for

service operations.

• After replacing the HCU it is not necessary to bleed the system via the diagnostic tester.

• After replacing the brake fluid it is also only necessary to perform standard bleeding.

• The blanking caps/plugs must not be removed until the brake tubes are ready to be connected. • If accidentally dropped or knocked install a new

hydraulic control unit (HCU) and module

assembly.

• When the ABS/ESP module is removed/installed or replaced, it is necessary to reconfigure the

ABS/ESP module with the aid of the diagnostic

tester once all of the installation work has been

performed.

Refer to: Module Configuration (418-01 Module

Configuration, General Procedures).

Combined yaw rate sensor and lateral

acceleration sensor / longitudinal

acceleration sensor

E96822

The sensor is attached to the floor crossmember

at the front right. For vehicles with 4x4 drive, a

longitudinal acceleration sensor is also integrated

in the same housing.

The following must be taken into account when

removing/installing or replacing the combined yaw

rate sensor and lateral/longitudinal acceleration

sensor:

• Ensure the correct installation position of the yaw rate sensor and lateral/longitudinal

acceleration sensor.

G1001303en2008.50 Kuga8/2011

206-09B- 4

Anti-Lock Control - Stability Assist

206-09B- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1426 of 2057

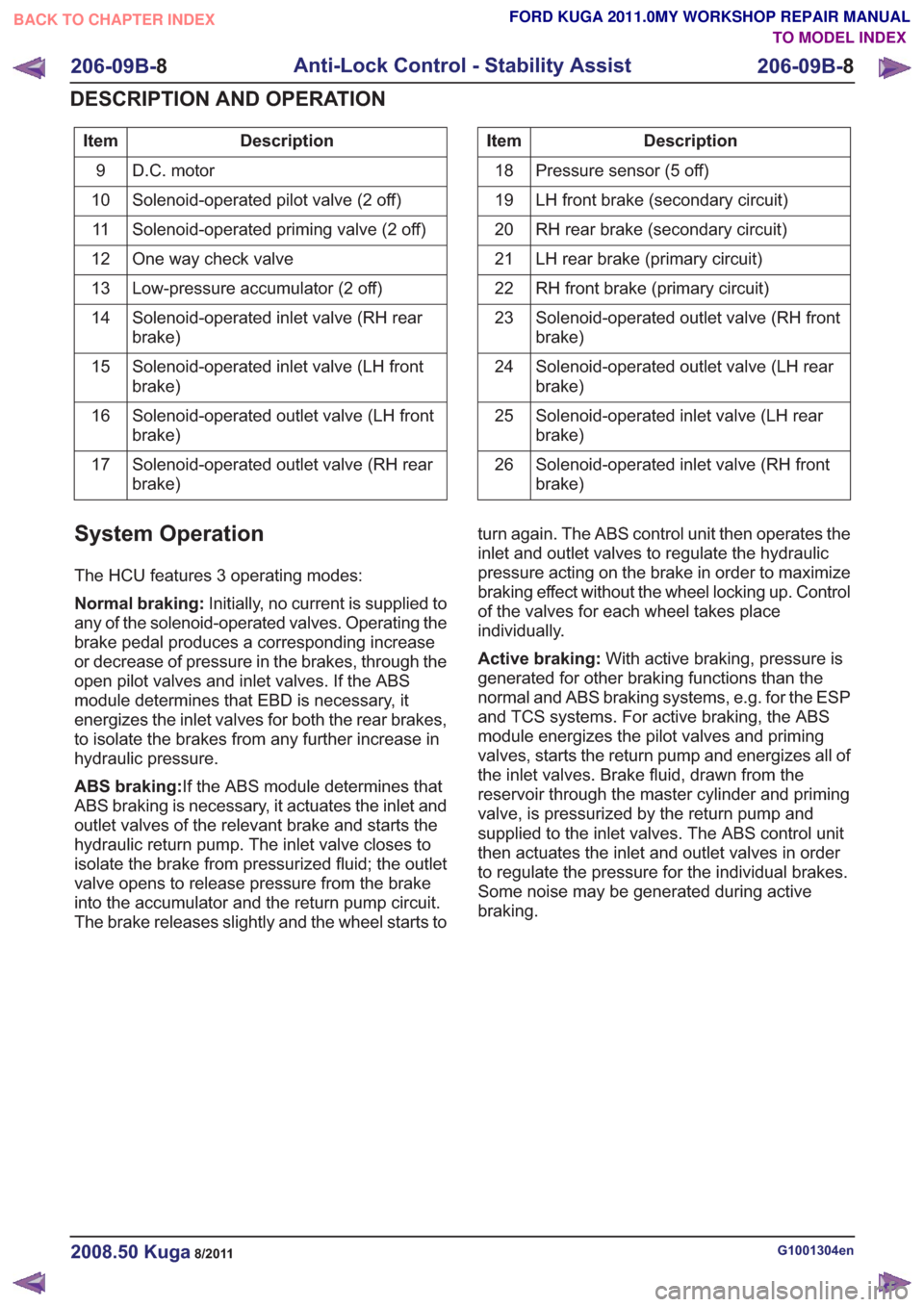

Description

Item

D.C. motor

9

Solenoid-operated pilot valve (2 off)

10

Solenoid-operated priming valve (2 off)

11

One way check valve

12

Low-pressure accumulator (2 off)

13

Solenoid-operated inlet valve (RH rear

brake)

14

Solenoid-operated inlet valve (LH front

brake)

15

Solenoid-operated outlet valve (LH front

brake)

16

Solenoid-operated outlet valve (RH rear

brake)

17Description

Item

Pressure sensor (5 off)

18

LH front brake (secondary circuit)

19

RH rear brake (secondary circuit)

20

LH rear brake (primary circuit)

21

RH front brake (primary circuit)

22

Solenoid-operated outlet valve (RH front

brake)

23

Solenoid-operated outlet valve (LH rear

brake)

24

Solenoid-operated inlet valve (LH rear

brake)

25

Solenoid-operated inlet valve (RH front

brake)

26

System Operation

The HCU features 3 operating modes:

Normal braking:

Initially, no current is supplied to

any of the solenoid-operated valves. Operating the

brake pedal produces a corresponding increase

or decrease of pressure in the brakes, through the

open pilot valves and inlet valves. If the ABS

module determines that EBD is necessary, it

energizes the inlet valves for both the rear brakes,

to isolate the brakes from any further increase in

hydraulic pressure.

ABS braking: If the ABS module determines that

ABS braking is necessary, it actuates the inlet and

outlet valves of the relevant brake and starts the

hydraulic return pump. The inlet valve closes to

isolate the brake from pressurized fluid; the outlet

valve opens to release pressure from the brake

into the accumulator and the return pump circuit.

The brake releases slightly and the wheel starts to turn again. The ABS control unit then operates the

inlet and outlet valves to regulate the hydraulic

pressure acting on the brake in order to maximize

braking effect without the wheel locking up. Control

of the valves for each wheel takes place

individually.

Active braking:

With active braking, pressure is

generated for other braking functions than the

normal and ABS braking systems, e.g. for the ESP

and TCS systems. For active braking, the ABS

module energizes the pilot valves and priming

valves, starts the return pump and energizes all of

the inlet valves. Brake fluid, drawn from the

reservoir through the master cylinder and priming

valve, is pressurized by the return pump and

supplied to the inlet valves. The ABS control unit

then actuates the inlet and outlet valves in order

to regulate the pressure for the individual brakes.

Some noise may be generated during active

braking.

G1001304en2008.50 Kuga8/2011

206-09B- 8

Anti-Lock Control - Stability Assist

206-09B- 8

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL