Index FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1253 of 2057

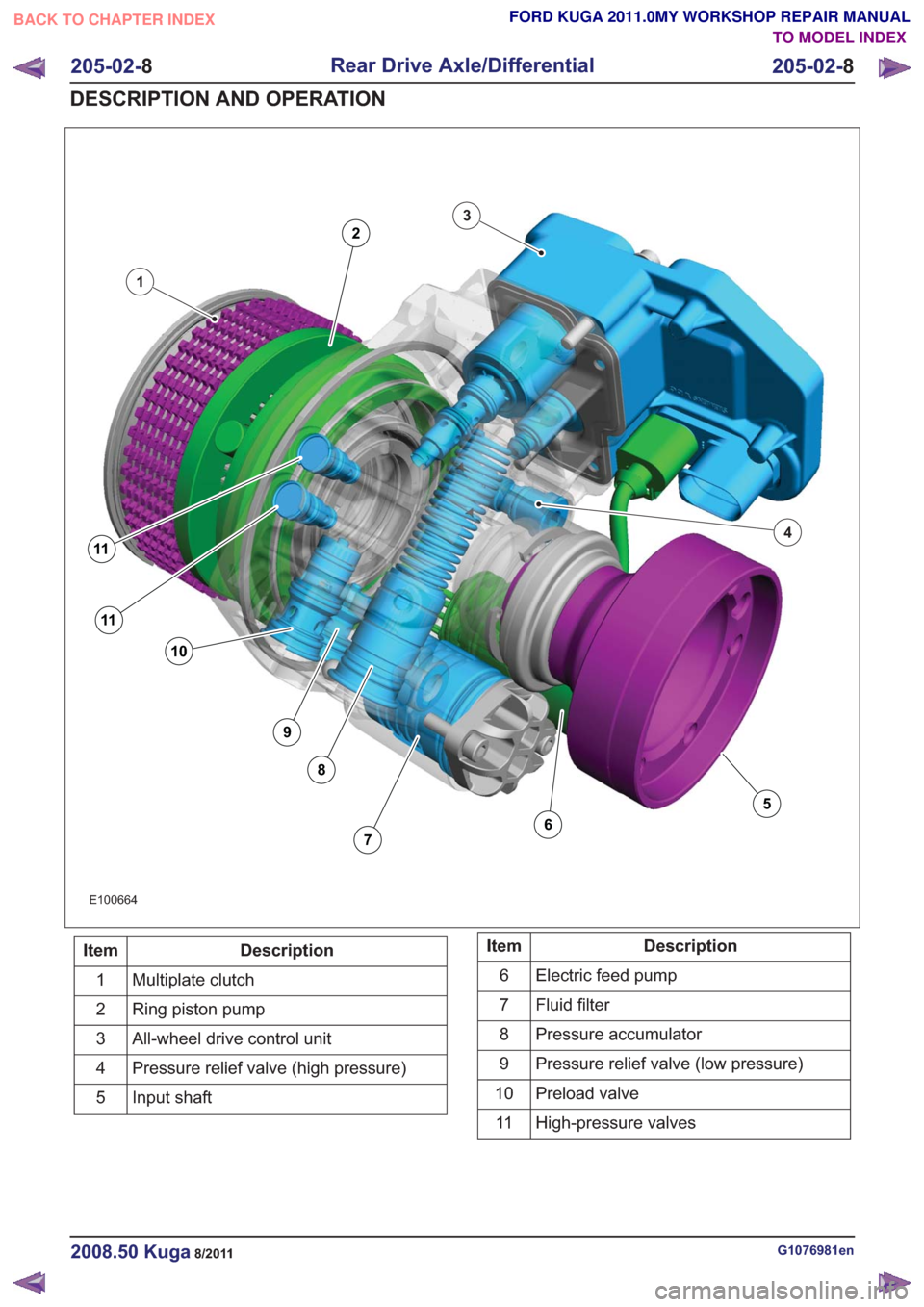

E100664

1

3

4

11

11

10

9

8

76

5

2

Description

Item

Multiplate clutch

1

Ring piston pump

2

All-wheel drive control unit

3

Pressure relief valve (high pressure)

4

Input shaft

5Description

Item

Electric feed pump

6

Fluid filter

7

Pressure accumulator

8

Pressure relief valve (low pressure)

9

Preload valve

10

High-pressure valves

11

G1076981en2008.50 Kuga8/2011

205-02- 8

Rear Drive Axle/Differential

205-02- 8

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1254 of 2057

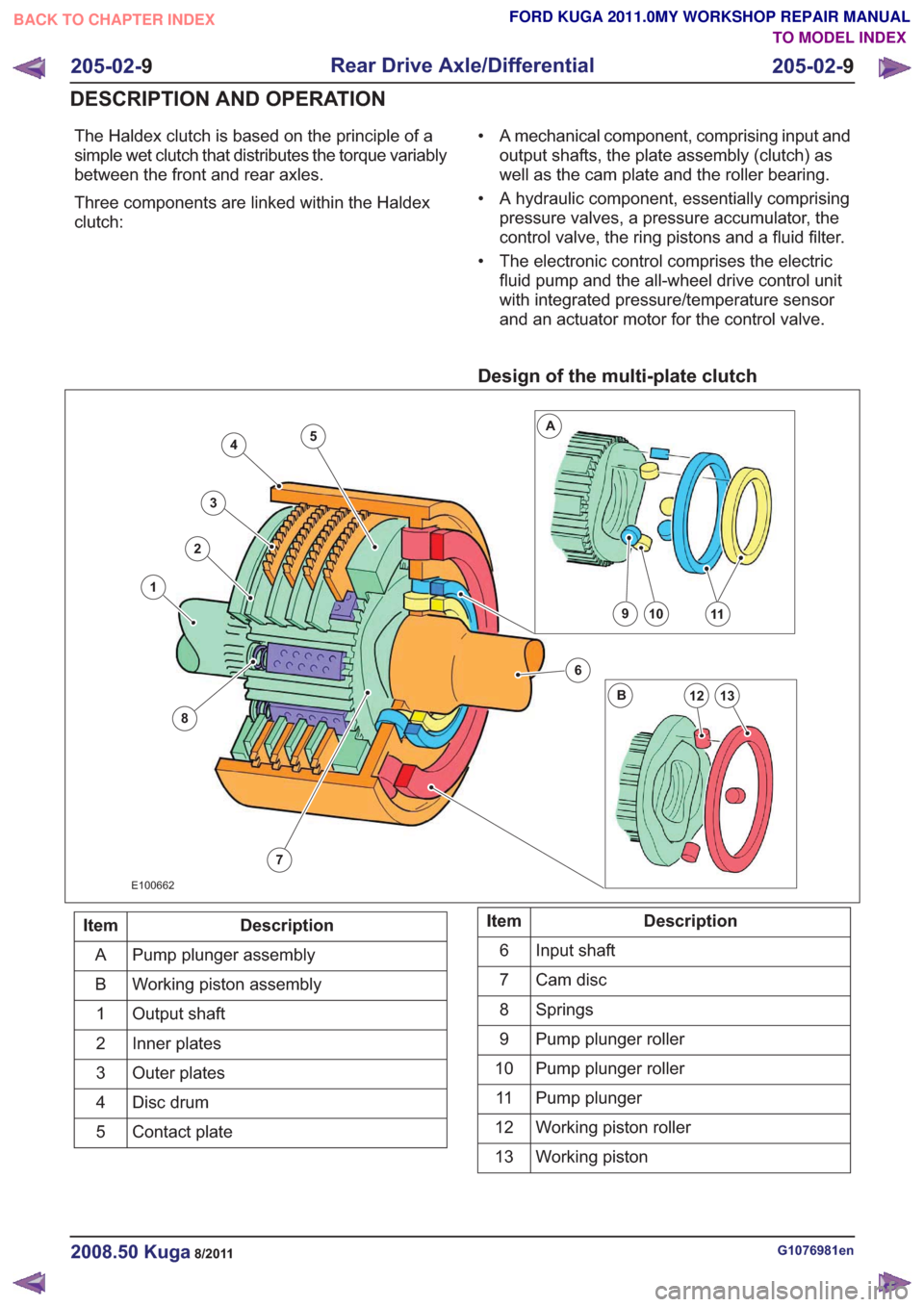

The Haldex clutch is based on the principle of a

simple wet clutch that distributes the torque variably

between the front and rear axles.

Three components are linked within the Haldex

clutch:• A mechanical component, comprising input and

output shafts, the plate assembly (clutch) as

well as the cam plate and the roller bearing.

• A hydraulic component, essentially comprising pressure valves, a pressure accumulator, the

control valve, the ring pistons and a fluid filter.

• The electronic control comprises the electric fluid pump and the all-wheel drive control unit

with integrated pressure/temperature sensor

and an actuator motor for the control valve.

Design of the multi-plate clutch

7

4

3

2

8

1

6

10911

13

A

B12

5

E100662

Description

Item

Pump plunger assembly

A

Working piston assembly

B

Output shaft

1

Inner plates

2

Outer plates

3

Disc drum

4

Contact plate

5Description

Item

Input shaft

6

Cam disc

7

Springs

8

Pump plunger roller

9

Pump plunger roller

10

Pump plunger

11

Working piston roller

12

Working piston

13

G1076981en2008.50 Kuga8/2011

205-02- 9

Rear Drive Axle/Differential

205-02- 9

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1255 of 2057

All-wheel drive control unit

E100663

14

3

2

5

Description

Item

Electronic Control Unit

1

Control valve

2

Pressure/temperature sensor

3

Electrical connection CAN (controller area

network) databus

4

Electric feed pump connection

5

The all-wheel drive control unit is bolted directly to

the housing of the Haldex clutch.

It forms one unit made up of the control valve, a

pressure/temperature sensor, and a control

module. It receives signals from the PCM and from

the ABS control module via the CAN data bus. The

control module in the control unit uses these

signals to determine the fluid pressure that is

needed to actuate the clutch plates depending on

the requirement. This determines how much torque

should be transmitted to the rear wheels. All-wheel

drive is deactivated if a fault occurs in the all-wheel

drive control unit.

A preload of approx. 80 Nm is always present at

the Haldex clutch. The temperature sensor of the Haldex clutch is

installed near the control valve in the control unit

and is surrounded by the hydraulic fluid. The

temperature is transmitted to the control module

and is used for adaptation to the changing viscosity

of the hydraulic fluid. If the hydraulic fluid is cold,

the control valve has to be opened slightly more

than requested. This allowance has to be reduced

as the temperature increases. The normal working

temperature of the hydraulic fluid is between +40

°C and +60 °C. If the temperature rises above 100

°C, the clutch is depressurised; if the temperature

falls below 95 °C, the clutch is pressurised again.

All-wheel drive is deactivated and a diagnostic

trouble code set if a fault occurs in the temperature

sensor.

With Haldex Generations I and II, the control valve

was actuated via a stepper motor. With Haldex

Generation III, the stepper motor has been omitted.

The control valve is now actuated via a solenoid

valve. The solenoid valve is actuated by the control

module in the all-wheel drive control unit by means

of pulse width modulation. The pulse width

modulation determines the position of the

adjustment spindle and thus the opening cross

section of the return hole. This is how the pressure

at the working piston of the plates is determined.

If the return hole is fully closed, maximum pressure

is applied to the plates. If the return hole is fully

open, the plates are unpressurized.

Electric feed pump

The electric feed pump is installed in the clutch

unit. It works according to the gerotor principle.

The main purpose of the feed pump is to fill the

pressure accumulator and the space behind the

pump plunger with hydraulic fluid, thereby ensuring

a fast response time of the Haldex clutch. The feed

pump used in the third generation is designed to

achieve an even higher pressure than the base

pressure of 4 bar. It is supplied with current by the

control module in the all-wheel drive control unit

when the engine is running above approx. 400 rpm.

Pressure control - 3rd generation

Haldex clutch

G1076981en2008.50 Kuga8/2011

205-02-

10

Rear Drive Axle/Differential

205-02- 10

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1256 of 2057

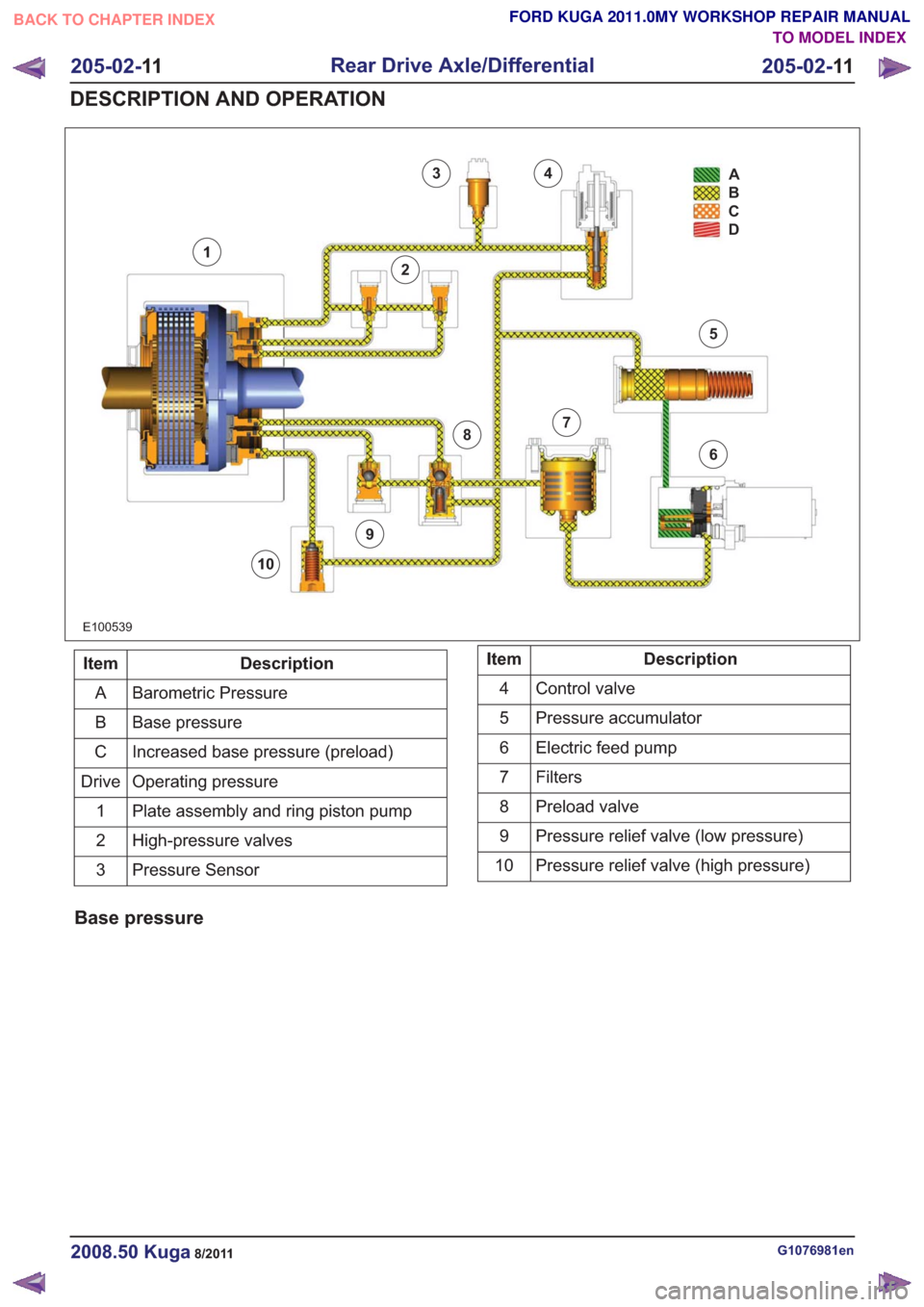

E100539

34

2

1

9

8

10

7

6

5A

B

C

D

Description

Item

Barometric Pressure

A

Base pressure

B

Increased base pressure (preload)

C

Operating pressure

Drive

Plate assembly and ring piston pump

1

High-pressure valves

2

Pressure Sensor

3Description

Item

Control valve

4

Pressure accumulator

5

Electric feed pump

6

Filters7

Preload valve

8

Pressure relief valve (low pressure)

9

Pressure relief valve (high pressure)

10

Base pressure

G1076981en2008.50 Kuga8/2011

205-02- 11

Rear Drive Axle/Differential

205-02- 11

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1257 of 2057

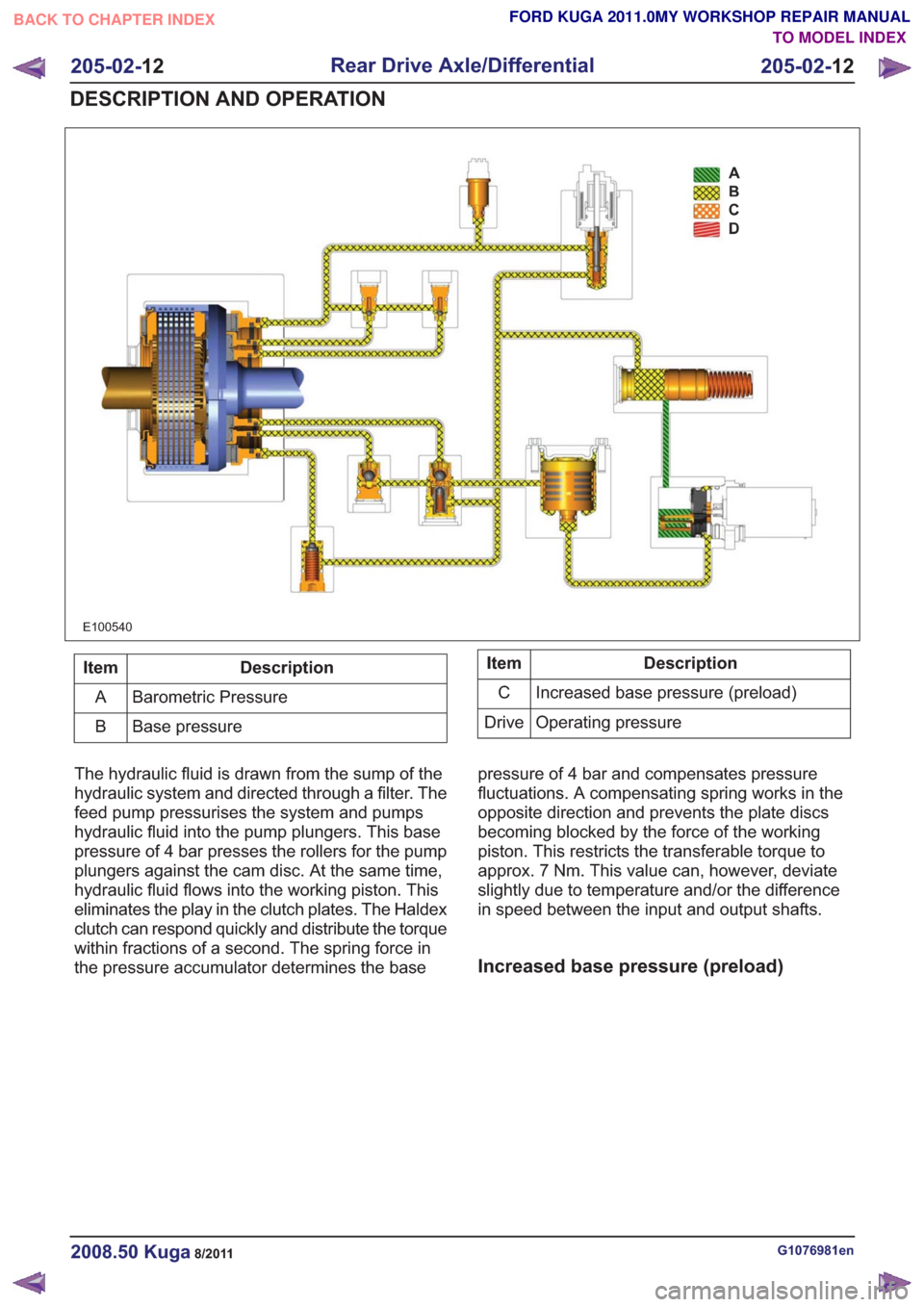

E100540

Description

Item

Barometric Pressure

A

Base pressure

BDescription

Item

Increased base pressure (preload)

C

Operating pressure

Drive

The hydraulic fluid is drawn from the sump of the

hydraulic system and directed through a filter. The

feed pump pressurises the system and pumps

hydraulic fluid into the pump plungers. This base

pressure of 4 bar presses the rollers for the pump

plungers against the cam disc. At the same time,

hydraulic fluid flows into the working piston. This

eliminates the play in the clutch plates. The Haldex

clutch can respond quickly and distribute the torque

within fractions of a second. The spring force in

the pressure accumulator determines the base pressure of 4 bar and compensates pressure

fluctuations. A compensating spring works in the

opposite direction and prevents the plate discs

becoming blocked by the force of the working

piston. This restricts the transferable torque to

approx. 7 Nm. This value can, however, deviate

slightly due to temperature and/or the difference

in speed between the input and output shafts.

Increased base pressure (preload)

G1076981en2008.50 Kuga8/2011

205-02-

12

Rear Drive Axle/Differential

205-02- 12

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1258 of 2057

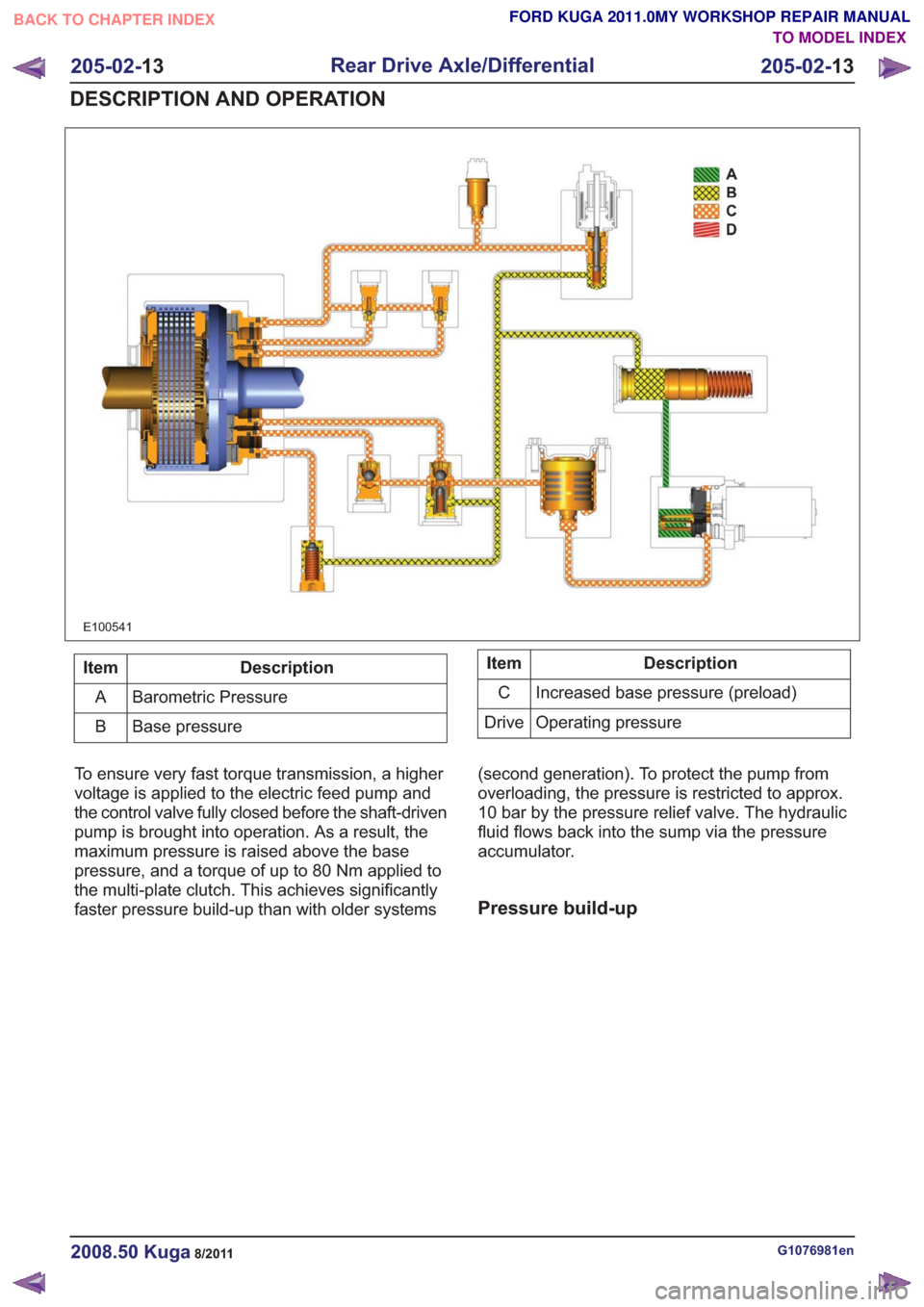

E100541

Description

Item

Barometric Pressure

A

Base pressure

BDescription

Item

Increased base pressure (preload)

C

Operating pressure

Drive

To ensure very fast torque transmission, a higher

voltage is applied to the electric feed pump and

the control valve fully closed before the shaft-driven

pump is brought into operation. As a result, the

maximum pressure is raised above the base

pressure, and a torque of up to 80 Nm applied to

the multi-plate clutch. This achieves significantly

faster pressure build-up than with older systems (second generation). To protect the pump from

overloading, the pressure is restricted to approx.

10 bar by the pressure relief valve. The hydraulic

fluid flows back into the sump via the pressure

accumulator.

Pressure build-up

G1076981en2008.50 Kuga8/2011

205-02-

13

Rear Drive Axle/Differential

205-02- 13

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1259 of 2057

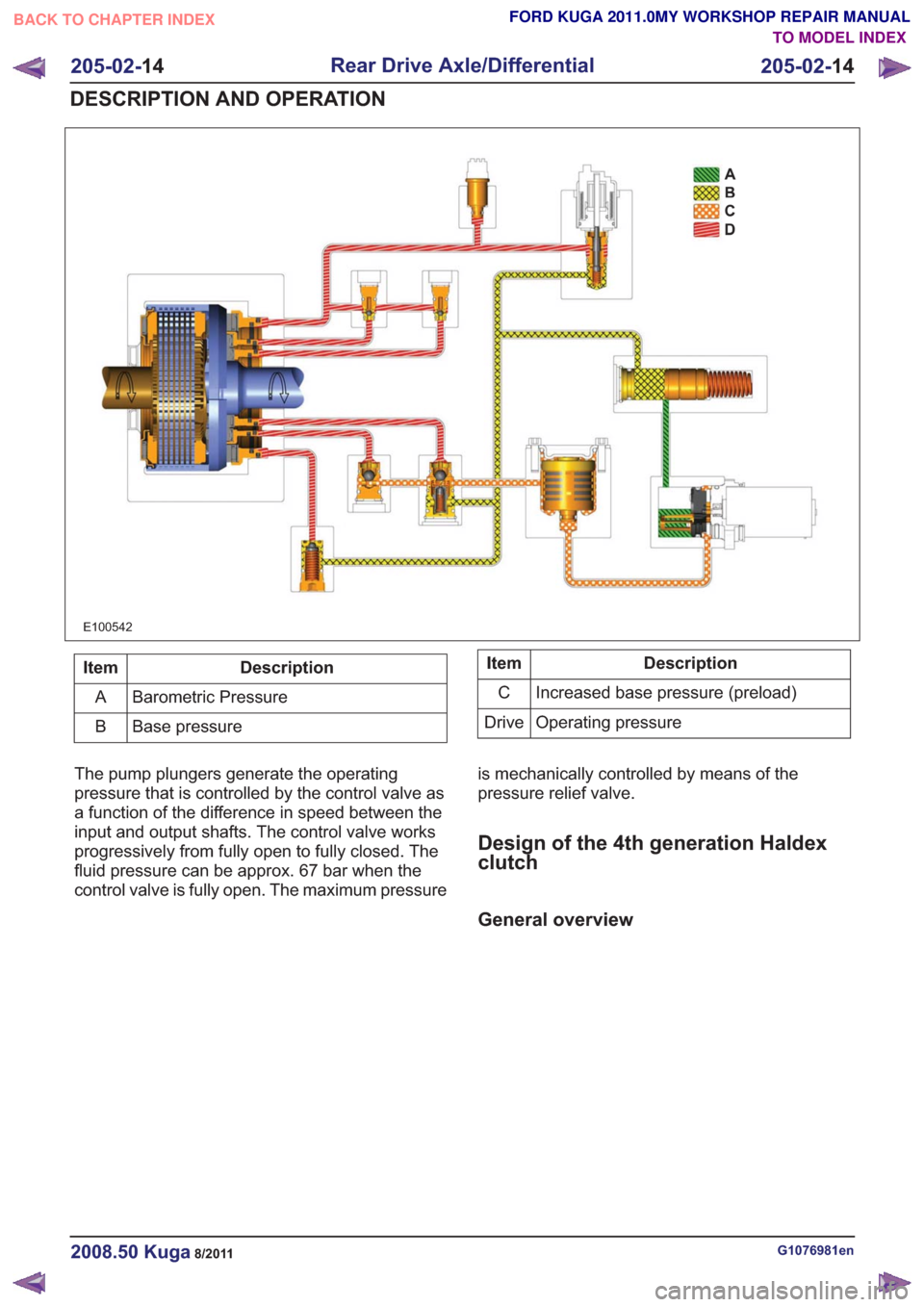

E100542

Description

Item

Barometric Pressure

A

Base pressure

BDescription

Item

Increased base pressure (preload)

C

Operating pressure

Drive

The pump plungers generate the operating

pressure that is controlled by the control valve as

a function of the difference in speed between the

input and output shafts. The control valve works

progressively from fully open to fully closed. The

fluid pressure can be approx. 67 bar when the

control valve is fully open. The maximum pressure is mechanically controlled by means of the

pressure relief valve.

Design of the 4th generation Haldex

clutch

General overview

G1076981en2008.50 Kuga8/2011

205-02-

14

Rear Drive Axle/Differential

205-02- 14

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1260 of 2057

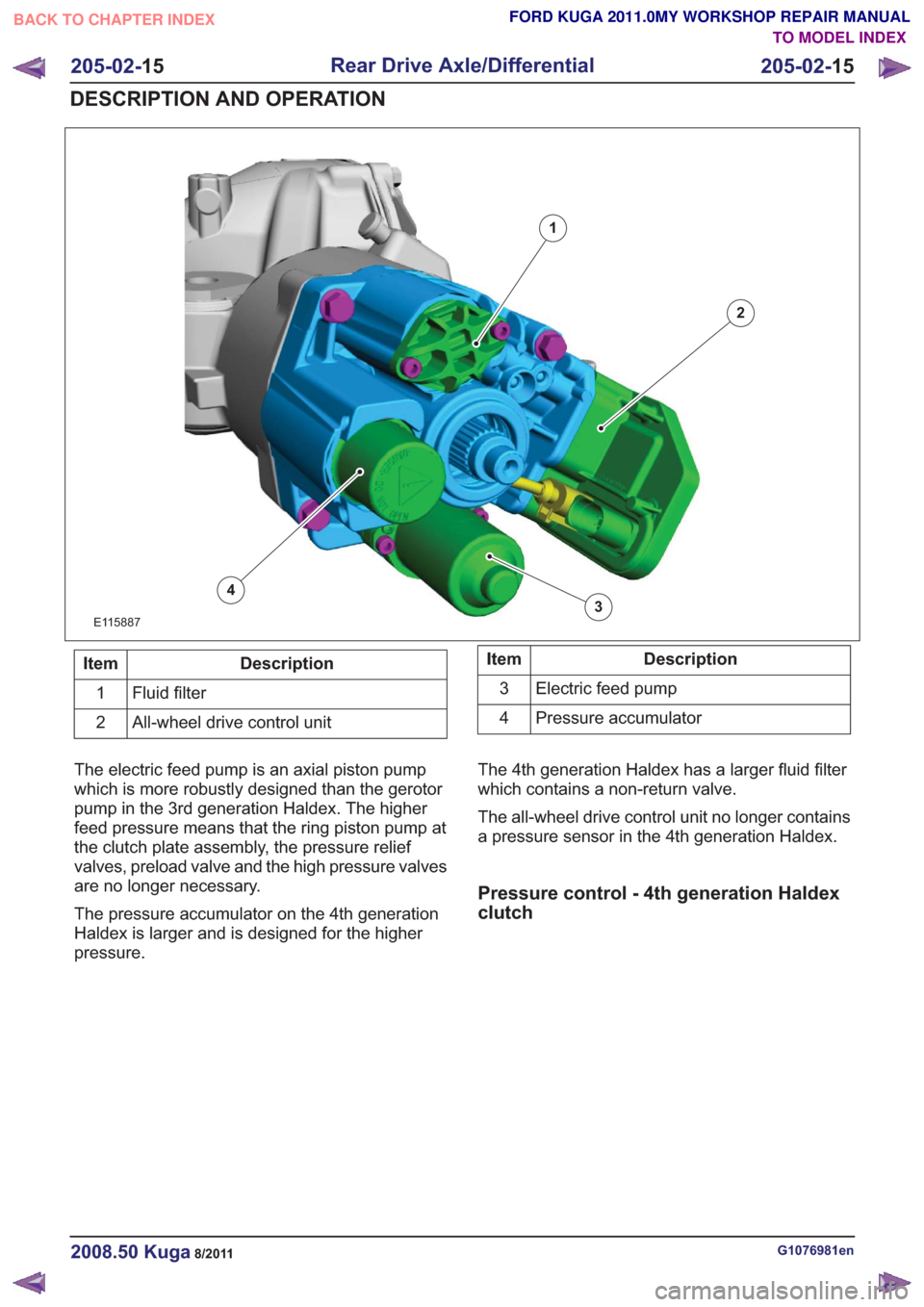

1

2

3

4

E115887

Description

Item

Fluid filter

1

All-wheel drive control unit

2Description

Item

Electric feed pump

3

Pressure accumulator

4

The electric feed pump is an axial piston pump

which is more robustly designed than the gerotor

pump in the 3rd generation Haldex. The higher

feed pressure means that the ring piston pump at

the clutch plate assembly, the pressure relief

valves, preload valve and the high pressure valves

are no longer necessary.

The pressure accumulator on the 4th generation

Haldex is larger and is designed for the higher

pressure. The 4th generation Haldex has a larger fluid filter

which contains a non-return valve.

The all-wheel drive control unit no longer contains

a pressure sensor in the 4th generation Haldex.

Pressure control - 4th generation Haldex

clutch

G1076981en2008.50 Kuga8/2011

205-02-

15

Rear Drive Axle/Differential

205-02- 15

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1261 of 2057

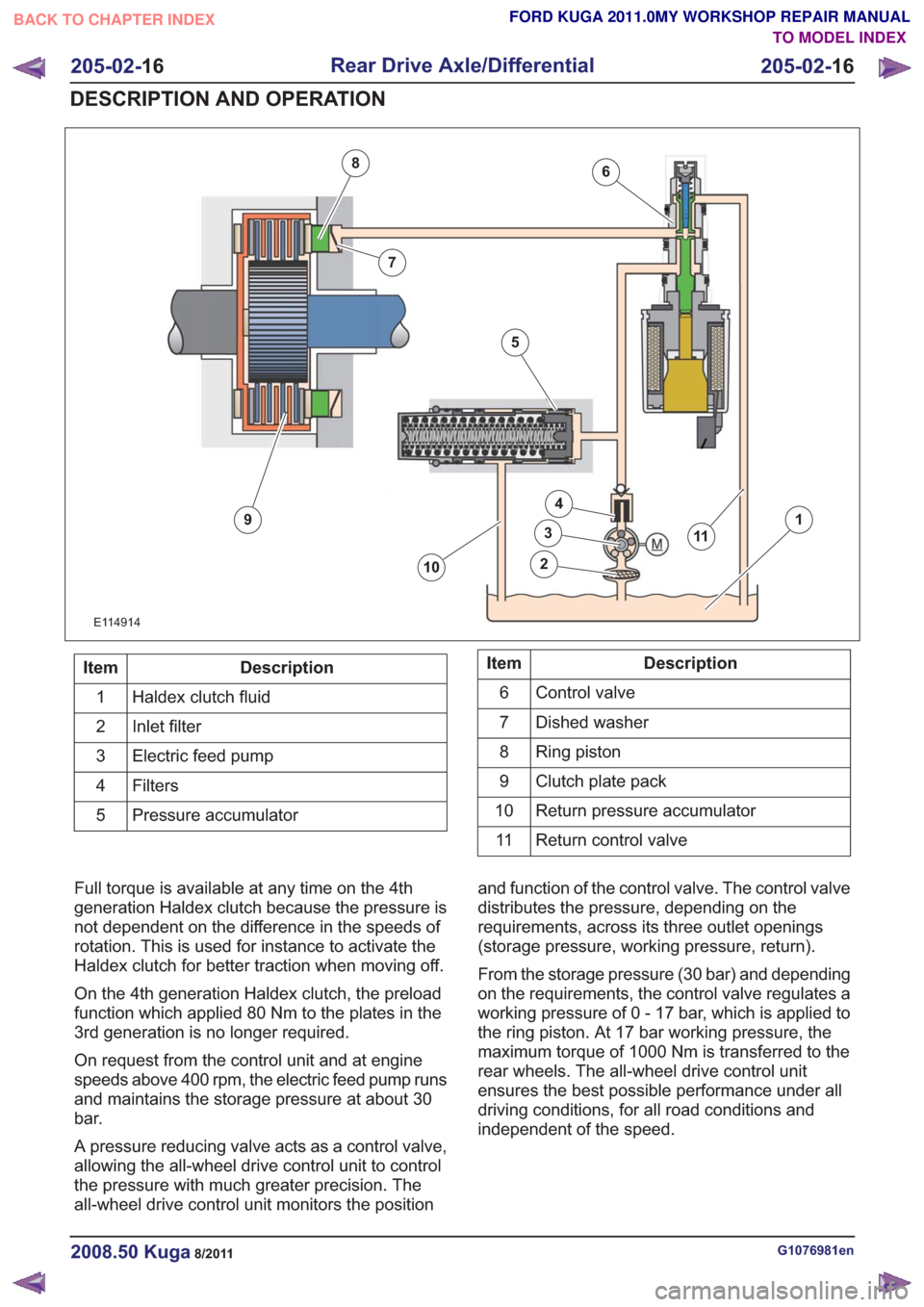

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

11

E114914

Description

Item

Haldex clutch fluid

1

Inlet filter

2

Electric feed pump

3

Filters4

Pressure accumulator

5Description

Item

Control valve

6

Dished washer

7

Ring piston

8

Clutch plate pack

9

Return pressure accumulator

10

Return control valve

11

Full torque is available at any time on the 4th

generation Haldex clutch because the pressure is

not dependent on the difference in the speeds of

rotation. This is used for instance to activate the

Haldex clutch for better traction when moving off.

On the 4th generation Haldex clutch, the preload

function which applied 80 Nm to the plates in the

3rd generation is no longer required.

On request from the control unit and at engine

speeds above 400 rpm, the electric feed pump runs

and maintains the storage pressure at about 30

bar.

A pressure reducing valve acts as a control valve,

allowing the all-wheel drive control unit to control

the pressure with much greater precision. The

all-wheel drive control unit monitors the position and function of the control valve. The control valve

distributes the pressure, depending on the

requirements, across its three outlet openings

(storage pressure, working pressure, return).

From the storage pressure (30 bar) and depending

on the requirements, the control valve regulates a

working pressure of 0 - 17 bar, which is applied to

the ring piston. At 17 bar working pressure, the

maximum torque of 1000 Nm is transferred to the

rear wheels. The all-wheel drive control unit

ensures the best possible performance under all

driving conditions, for all road conditions and

independent of the speed.

G1076981en2008.50 Kuga8/2011

205-02-

16

Rear Drive Axle/Differential

205-02- 16

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1262 of 2057

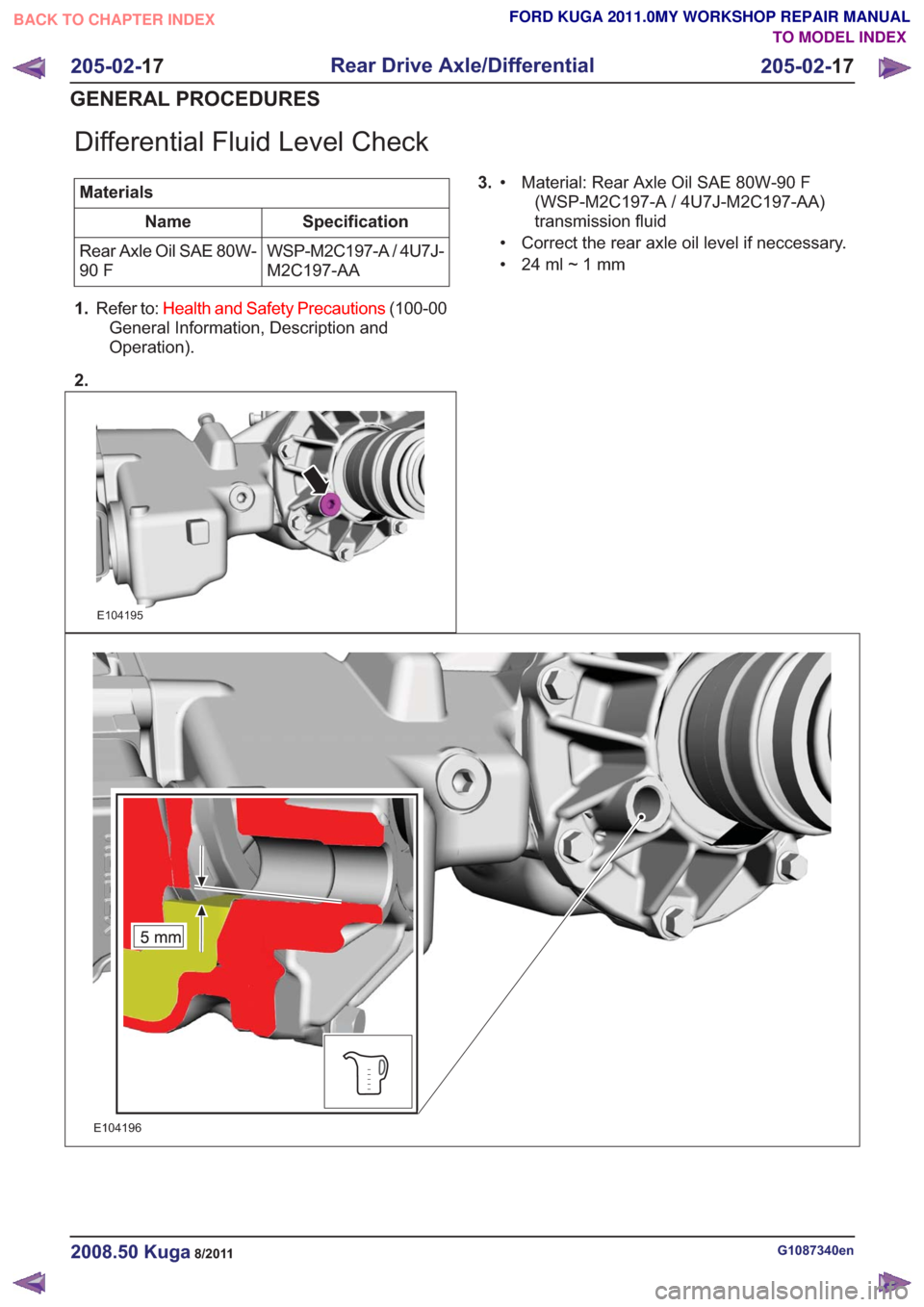

Differential Fluid Level Check

MaterialsSpecification

Name

WSP-M2C197-A / 4U7J-

M2C197-AA

Rear Axle Oil SAE 80W-

90 F

1. Refer to: Health and Safety Precautions (100-00

General Information, Description and

Operation).

2.

E104195

3. Material: Rear Axle Oil SAE 80W-90 F

(WSP-M2C197-A / 4U7J-M2C197-AA)

transmission fluid

•

• Correct the rear axle oil level if neccessary.

• 24ml~1mm

E104196

G1087340en2008.50 Kuga8/2011

205-02-

17

Rear Drive Axle/Differential

205-02- 17

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL