111 FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 33 of 2057

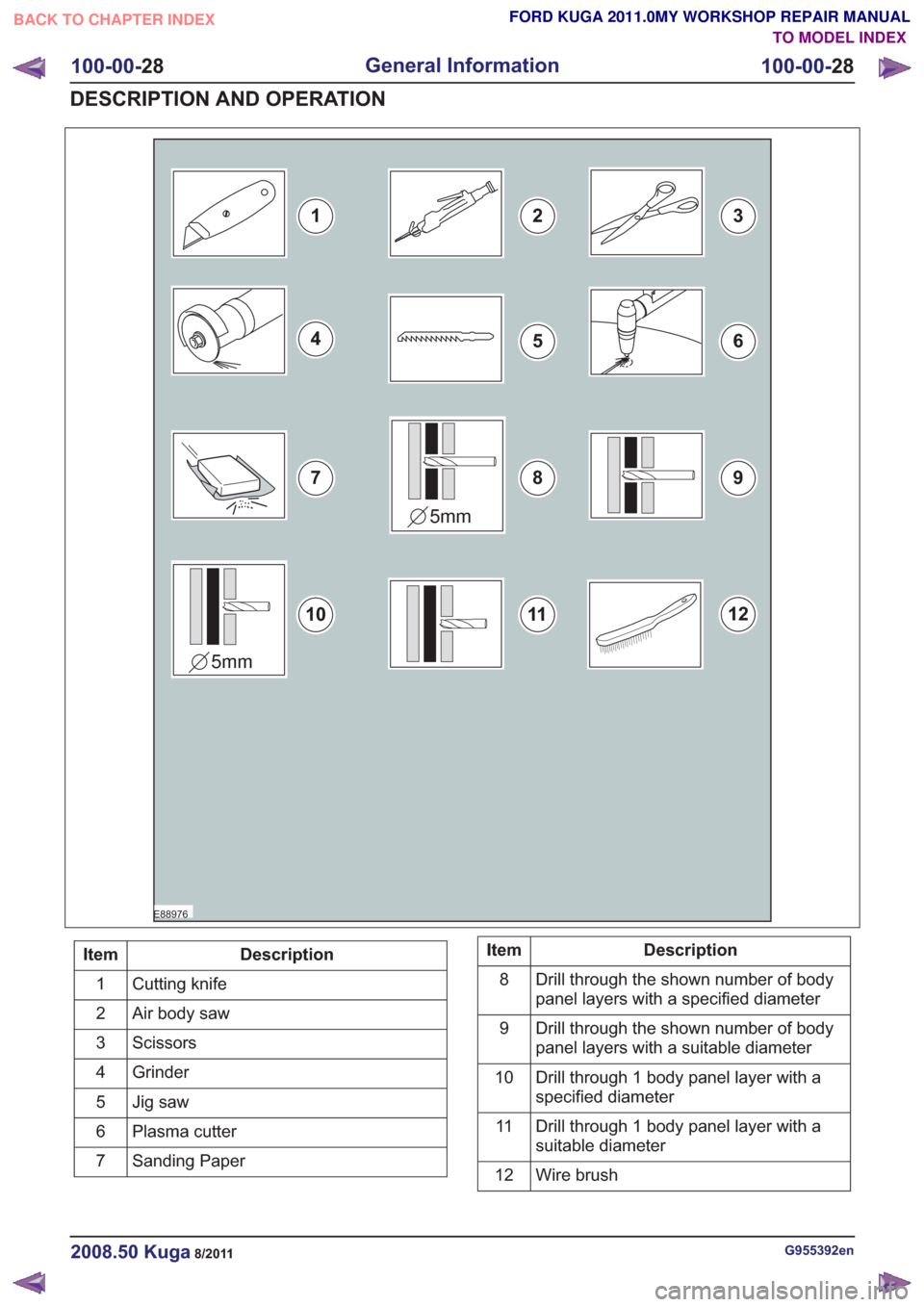

E88976

123

456

7

5mm

5mm

1110

98

12

Description

Item

Cutting knife

1

Air body saw

2

Scissors

3

Grinder

4

Jig saw

5

Plasma cutter

6

Sanding Paper

7Description

Item

Drill through the shown number of body

panel layers with a specified diameter

8

Drill through the shown number of body

panel layers with a suitable diameter

9

Drill through 1 body panel layer with a

specified diameter

10

Drill through 1 body panel layer with a

suitable diameter

11

Wire brush

12

G955392en2008.50 Kuga8/2011

100-00- 28

General Information

100-00- 28

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 37 of 2057

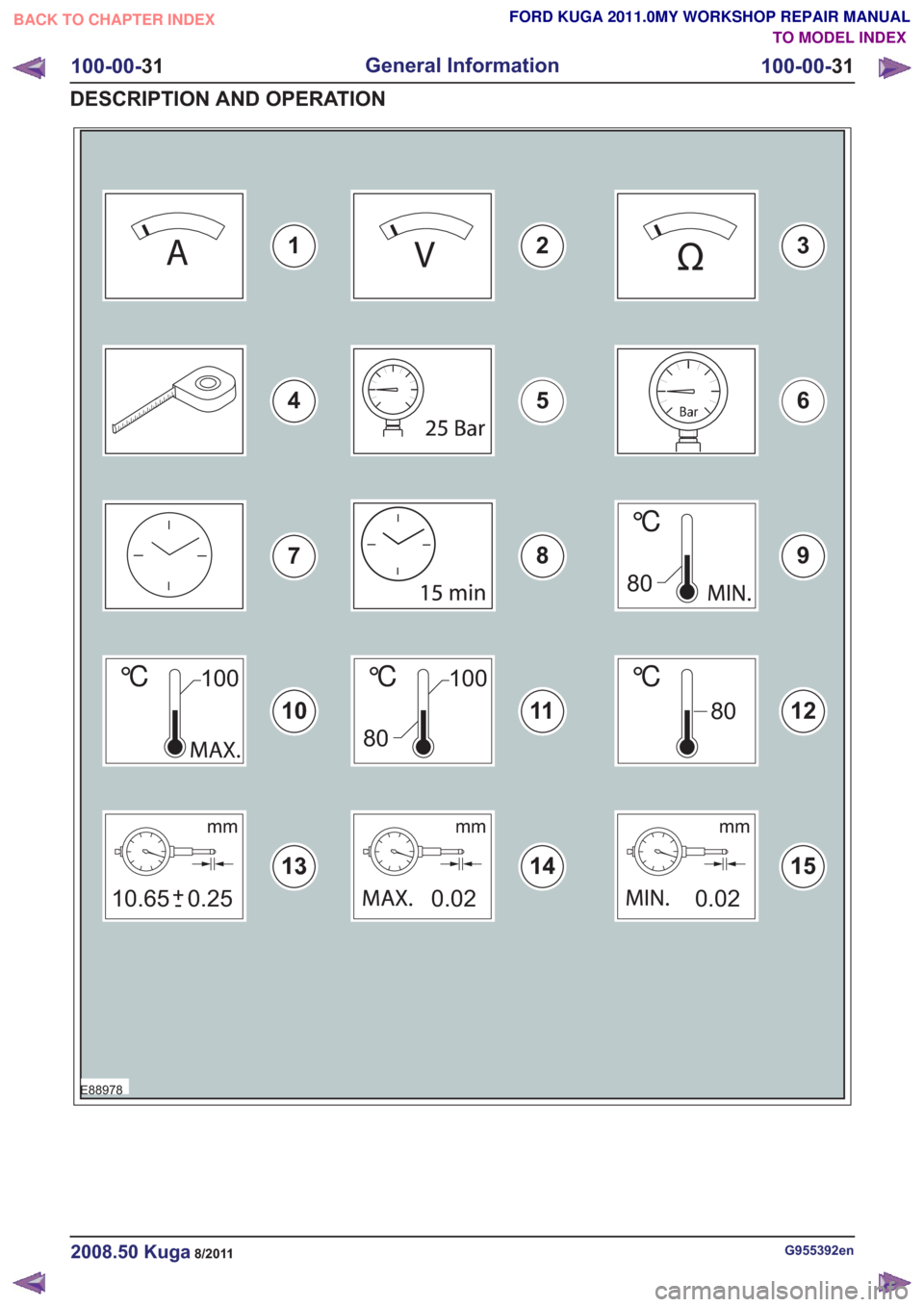

E88978

3

46

7

12

5

8

100

80°C100°C

80

°C

80

°C

121110

9

10.65 0.25+

-

mm

0.02

mm

0.02

mm

G955392en2008.50 Kuga8/2011

100-00- 31

General Information

100-00- 31

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 165 of 2057

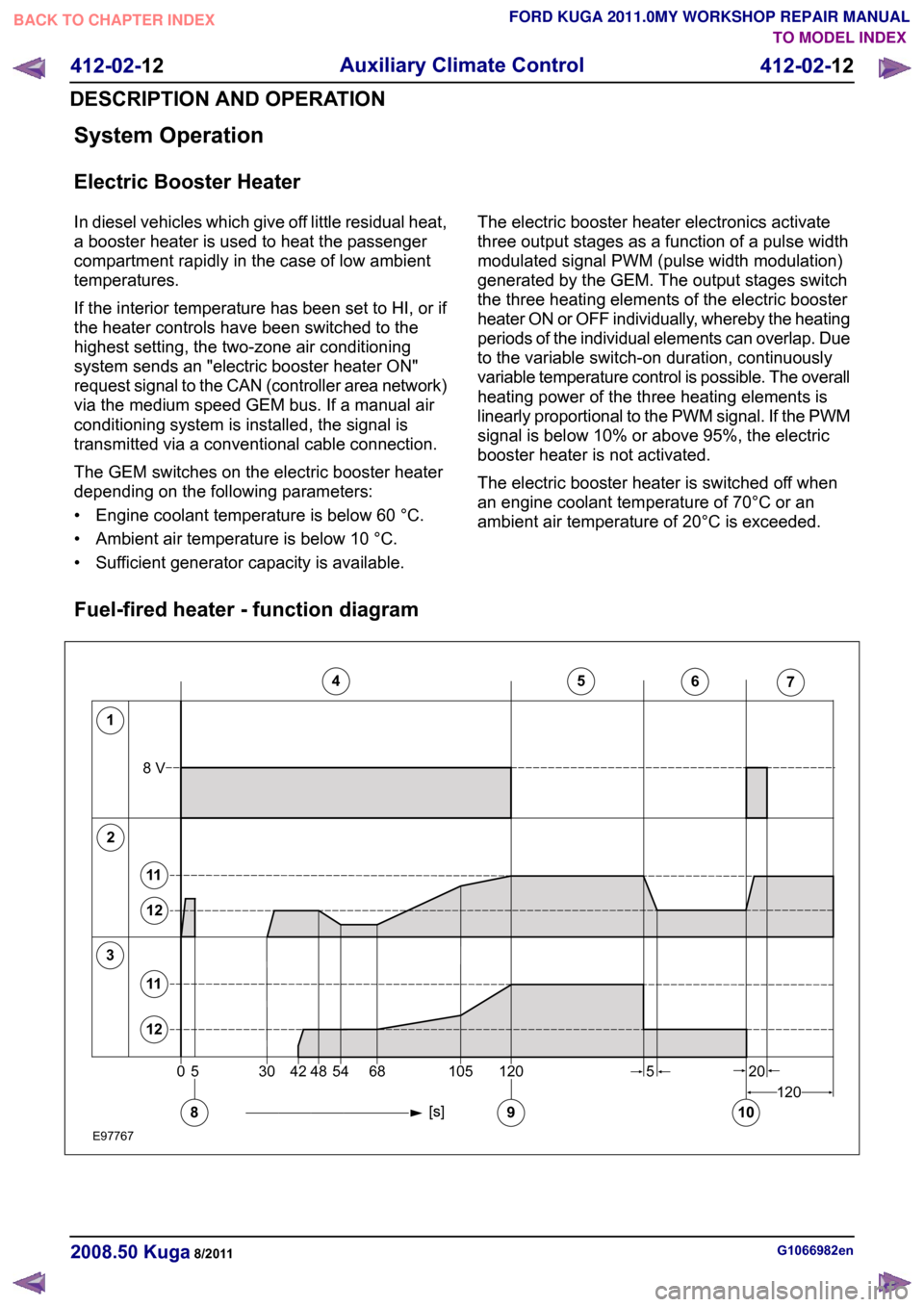

System Operation

Electric Booster Heater

In diesel vehicles which give off little residual heat,

a booster heater is used to heat the passenger

compartment rapidly in the case of low ambient

temperatures.

If the interior temperature has been set to HI, or if

the heater controls have been switched to the

highest setting, the two-zone air conditioning

system sends an "electric booster heater ON"

request signal to the CAN (controller area network)

via the medium speed GEM bus. If a manual air

conditioning system is installed, the signal is

transmitted via a conventional cable connection.

The GEM switches on the electric booster heater

depending on the following parameters:

• Engine coolant temperature is below 60 °C.

• Ambient air temperature is below 10 °C.

• Sufficient generator capacity is available.

The electric booster heater electronics activate

three output stages as a function of a pulse width

modulated signal PWM (pulse width modulation)

generated by the GEM. The output stages switch

the three heating elements of the electric booster

heater ON or OFF individually, whereby the heating

periods of the individual elements can overlap. Due

to the variable switch-on duration, continuously

variable temperature control is possible. The overall

heating power of the three heating elements is

linearly proportional to the PWM signal. If the PWM

signal is below 10% or above 95%, the electric

booster heater is not activated.

The electric booster heater is switched off when

an engine coolant temperature of 70°C or an

ambient air temperature of 20°C is exceeded.

Fuel-fired heater - function diagram G1066982en

2008.50 Kuga 8/2011 412-02-12

Auxiliary Climate Control

412-02-12

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL12345671205304254481201056820108V58911121112E977670

Page 168 of 2057

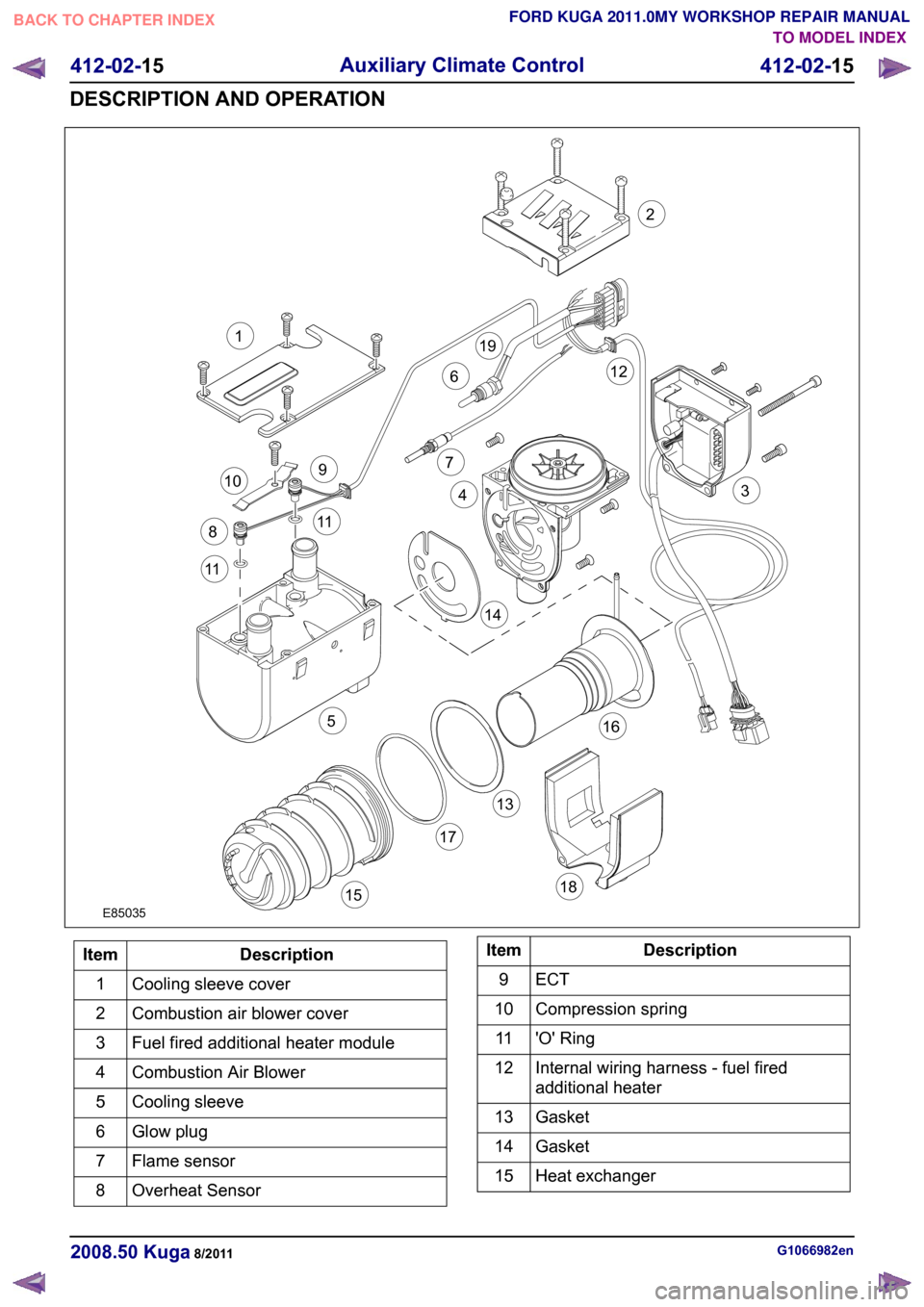

Description

Item

Cooling sleeve cover

1

Combustion air blower cover

2

Fuel fired additional heater module

3

Combustion Air Blower

4

Cooling sleeve

5

Glow plug

6

Flame sensor

7

Overheat Sensor

8 Description

Item

ECT9

Compression spring

10

'O' Ring

11

Internal wiring harness - fuel fired

additional heater

12

Gasket

13

Gasket

14

Heat exchanger

15 G1066982en

2008.50 Kuga 8/2011 412-02-15

Auxiliary Climate Control

412-02-15

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE850351132126791011115144316171518198

Page 338 of 2057

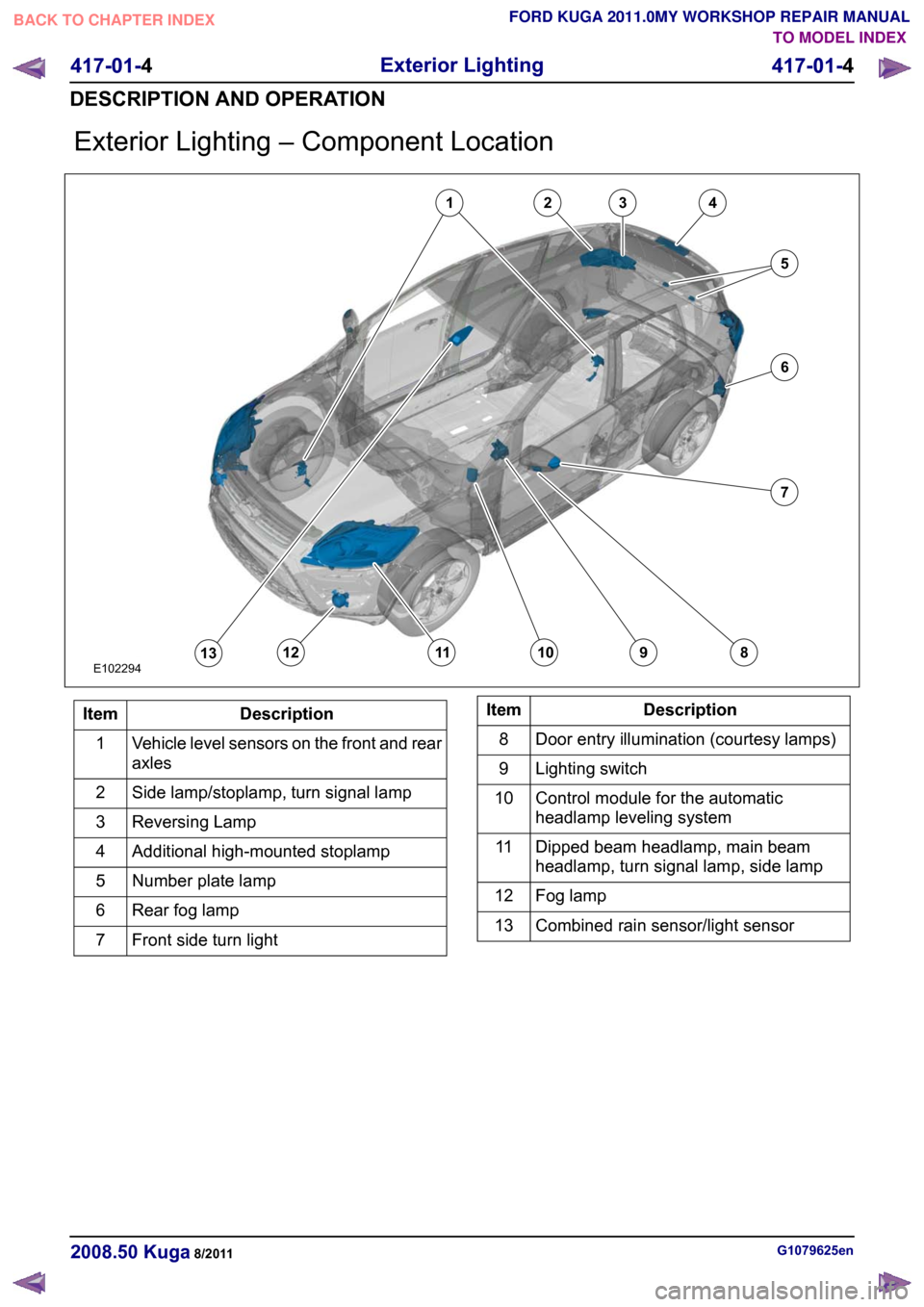

Exterior Lighting – Component Location

Description

Item

Vehicle level sensors on the front and rear

axles

1

Side lamp/stoplamp, turn signal lamp

2

Reversing Lamp

3

Additional high-mounted stoplamp

4

Number plate lamp

5

Rear fog lamp

6

Front side turn light

7 Description

Item

Door entry illumination (courtesy lamps)

8

Lighting switch

9

Control module for the automatic

headlamp leveling system

10

Dipped beam headlamp, main beam

headlamp, turn signal lamp, side lamp

11

Fog lamp

12

Combined rain sensor/light sensor

13 G1079625en

2008.50 Kuga 8/2011 417-01-4

Exterior Lighting

417-01-4

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE10229412345678910111213

Page 382 of 2057

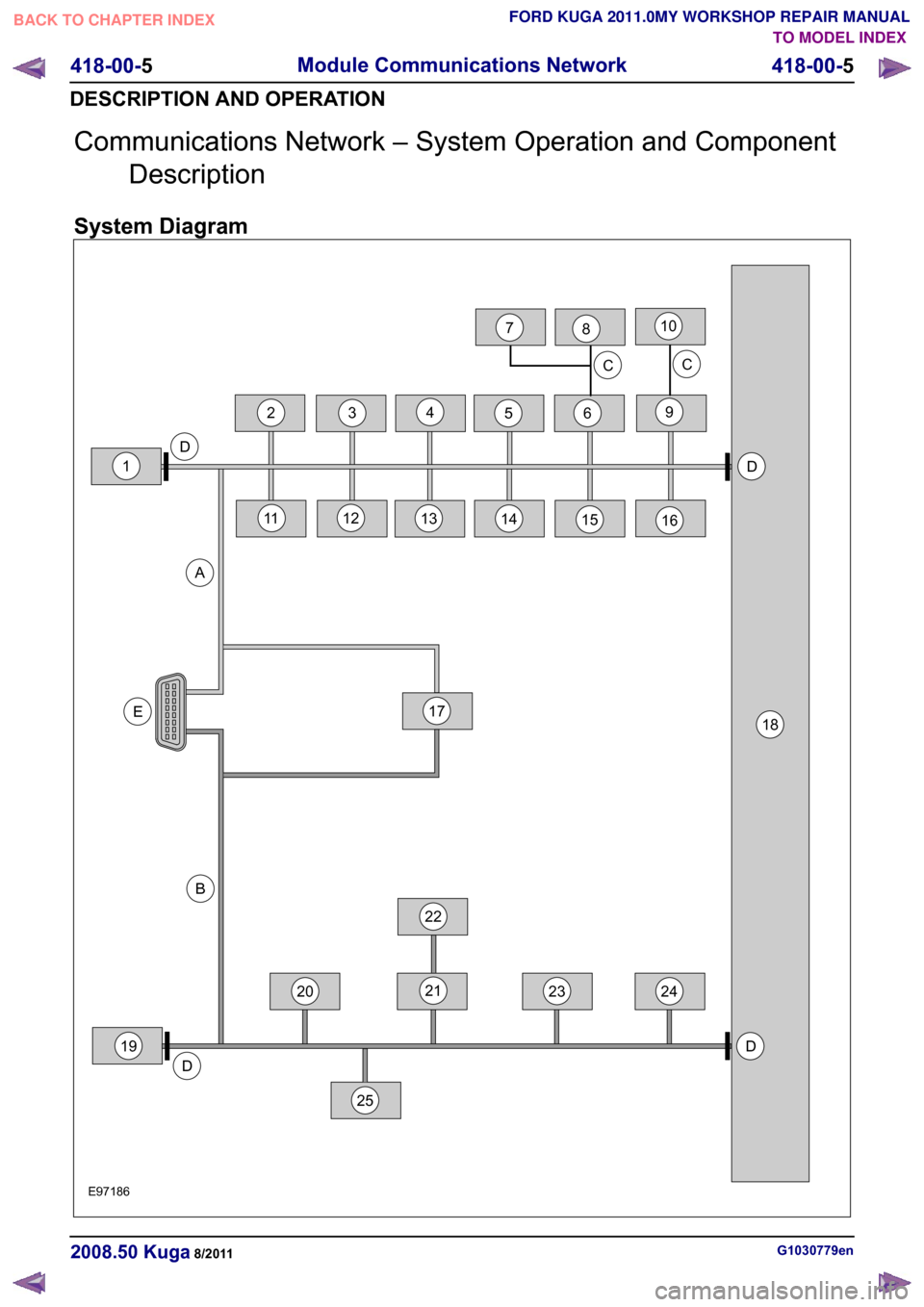

Communications Network – System Operation and Component

Description

System Diagram G1030779en

2008.50 Kuga 8/2011 418-00-5

Module Communications Network

418-00-5

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE971864522DD18E20212319DAB3242513141516D1917C1011126C782

Page 412 of 2057

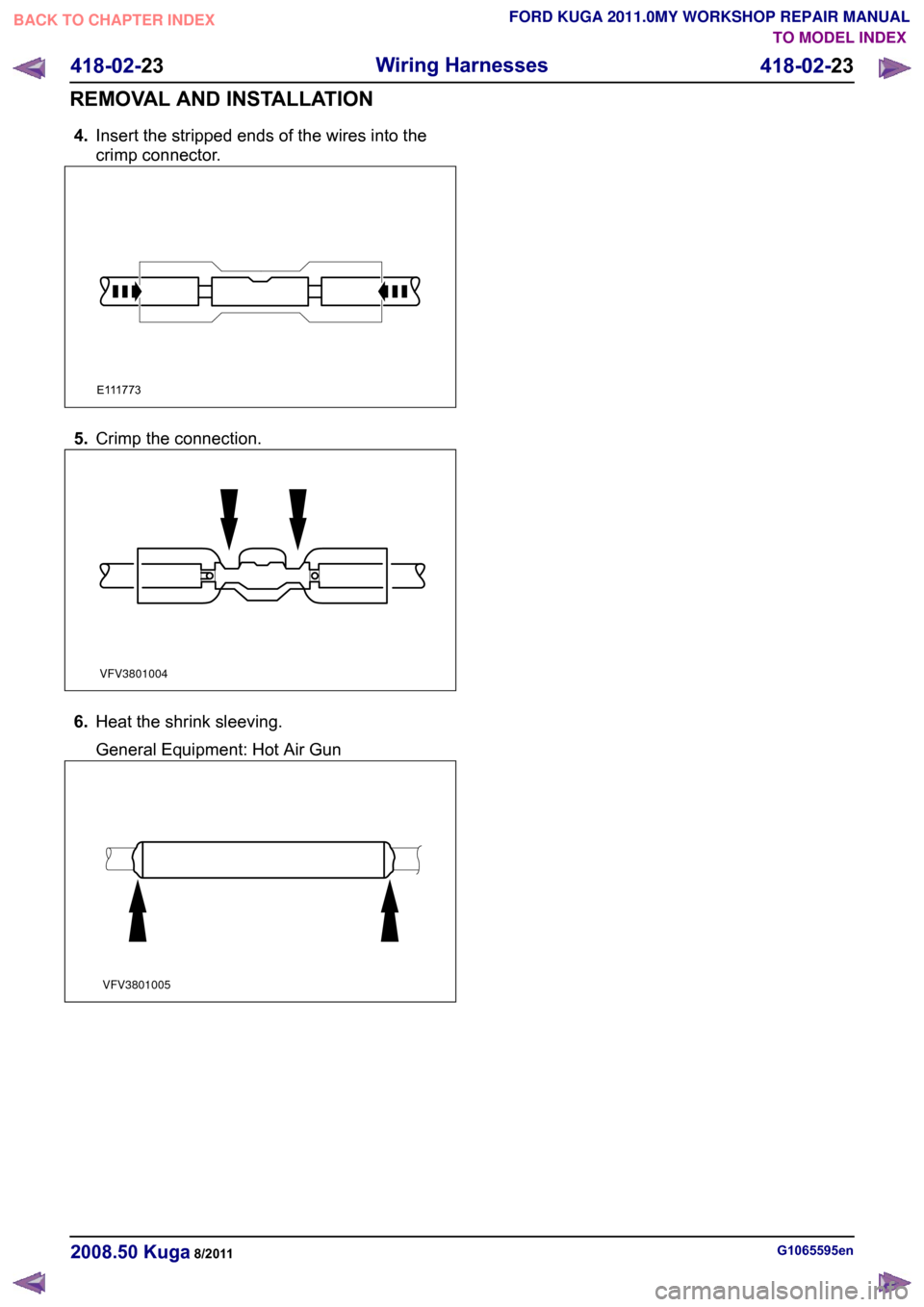

4.

Insert the stripped ends of the wires into the

crimp connector. 5.

Crimp the connection. 6.

Heat the shrink sleeving.

General Equipment: Hot Air Gun G1065595en

2008.50 Kuga 8/2011 418-02-23

Wiring Harnesses

418-02-23

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE111773 VFV3801004 VFV3801005

Page 464 of 2057

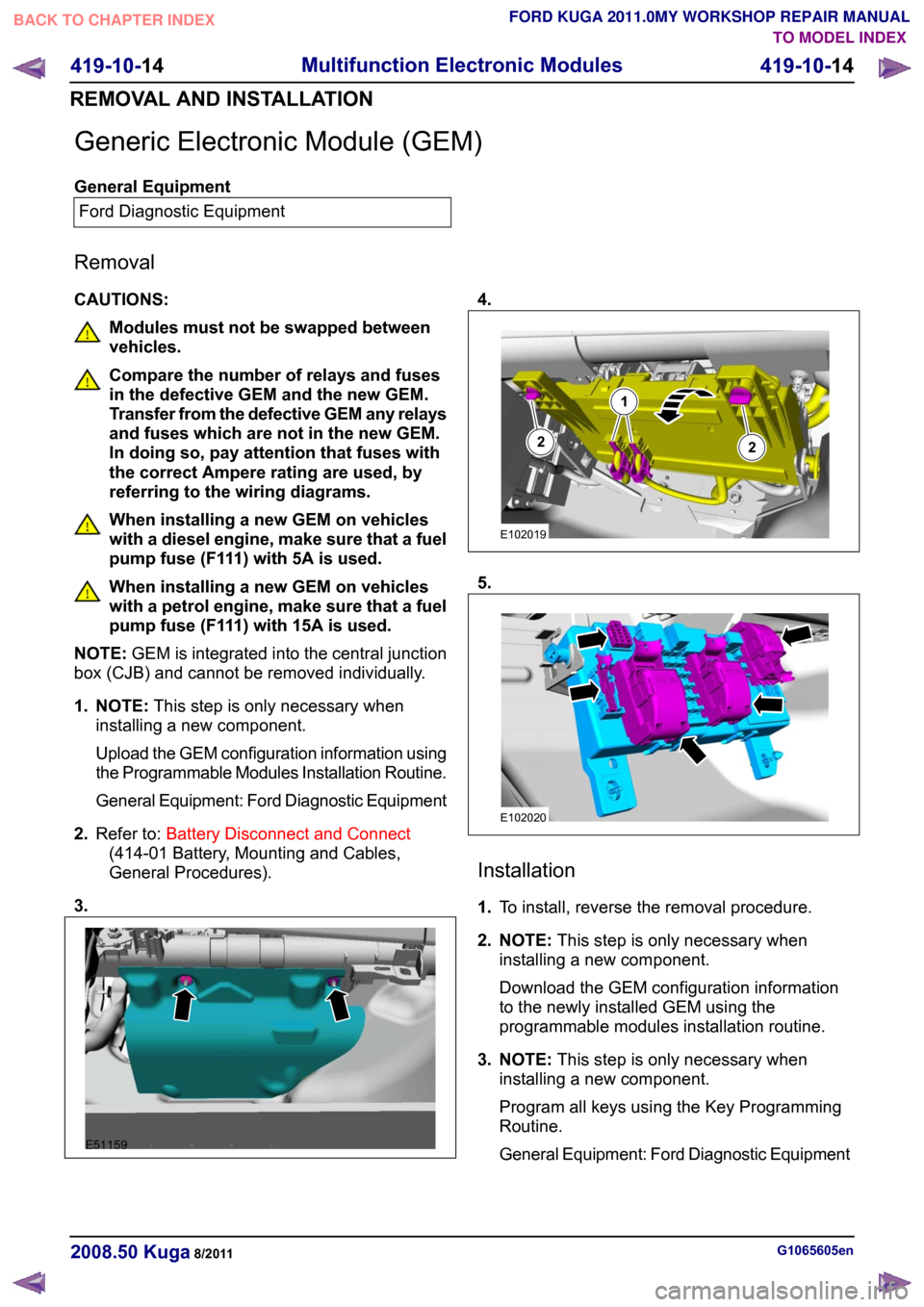

Generic Electronic Module (GEM)

General Equipment

Ford Diagnostic Equipment

Removal

CAUTIONS: Modules must not be swapped between

vehicles.

Compare the number of relays and fuses

in the defective GEM and the new GEM.

Transfer from the defective GEM any relays

and fuses which are not in the new GEM.

In doing so, pay attention that fuses with

the correct Ampere rating are used, by

referring to the wiring diagrams.

When installing a new GEM on vehicles

with a diesel engine, make sure that a fuel

pump fuse (F111) with 5A is used.

When installing a new GEM on vehicles

with a petrol engine, make sure that a fuel

pump fuse (F111) with 15A is used.

NOTE: GEM is integrated into the central junction

box (CJB) and cannot be removed individually.

1. NOTE: This step is only necessary when

installing a new component.

Upload the GEM configuration information using

the Programmable Modules Installation Routine.

General Equipment: Ford Diagnostic Equipment

2. Refer to: Battery Disconnect and Connect

(414-01 Battery, Mounting and Cables,

General Procedures).

3. 4.

5.

Installation

1.

To install, reverse the removal procedure.

2. NOTE: This step is only necessary when

installing a new component.

Download the GEM configuration information

to the newly installed GEM using the

programmable modules installation routine.

3. NOTE: This step is only necessary when

installing a new component.

Program all keys using the Key Programming

Routine.

General Equipment: Ford Diagnostic Equipment G1065605en

2008.50 Kuga 8/2011 419-10-14

Multifunction Electronic Modules

419-10-14

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE51159 122E102019 E102020

Page 1227 of 2057

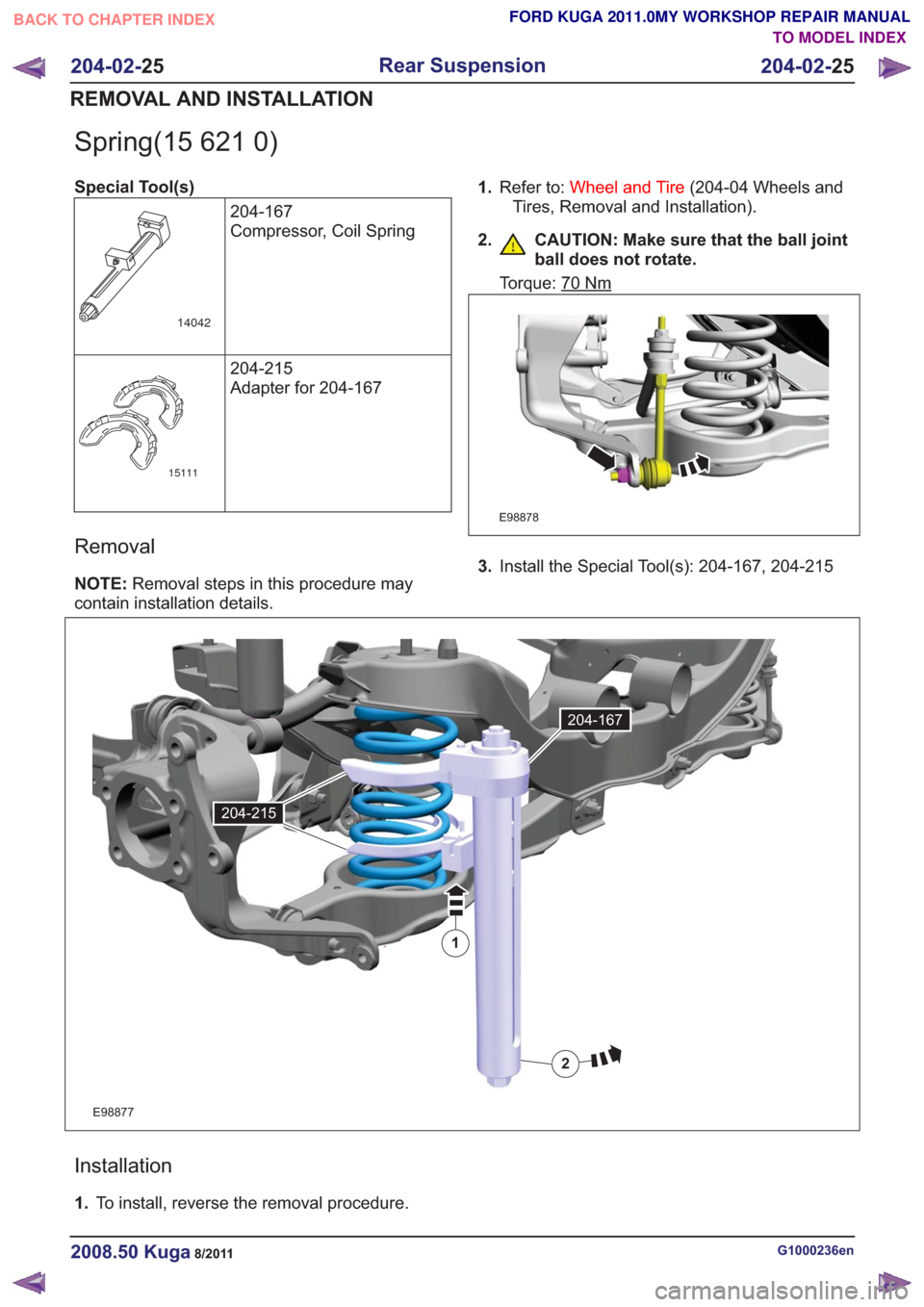

Spring(15 621 0)

Special Tool(s)204-167

Compressor, Coil Spring

14042

204-215

Adapter for 204-167

15111

Removal

NOTE:Removal steps in this procedure may

contain installation details. 1.

Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

2. CAUTION: Make sure that the ball joint ball does not rotate.

Torque: 70Nm

E98878

3.Install the Special Tool(s): 204-167, 204-215

E98877

1

2

204-167

204-215

Installation

1.To install, reverse the removal procedure.

G1000236en2008.50 Kuga8/2011

204-02- 25

Rear Suspension

204-02- 25

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1381 of 2057

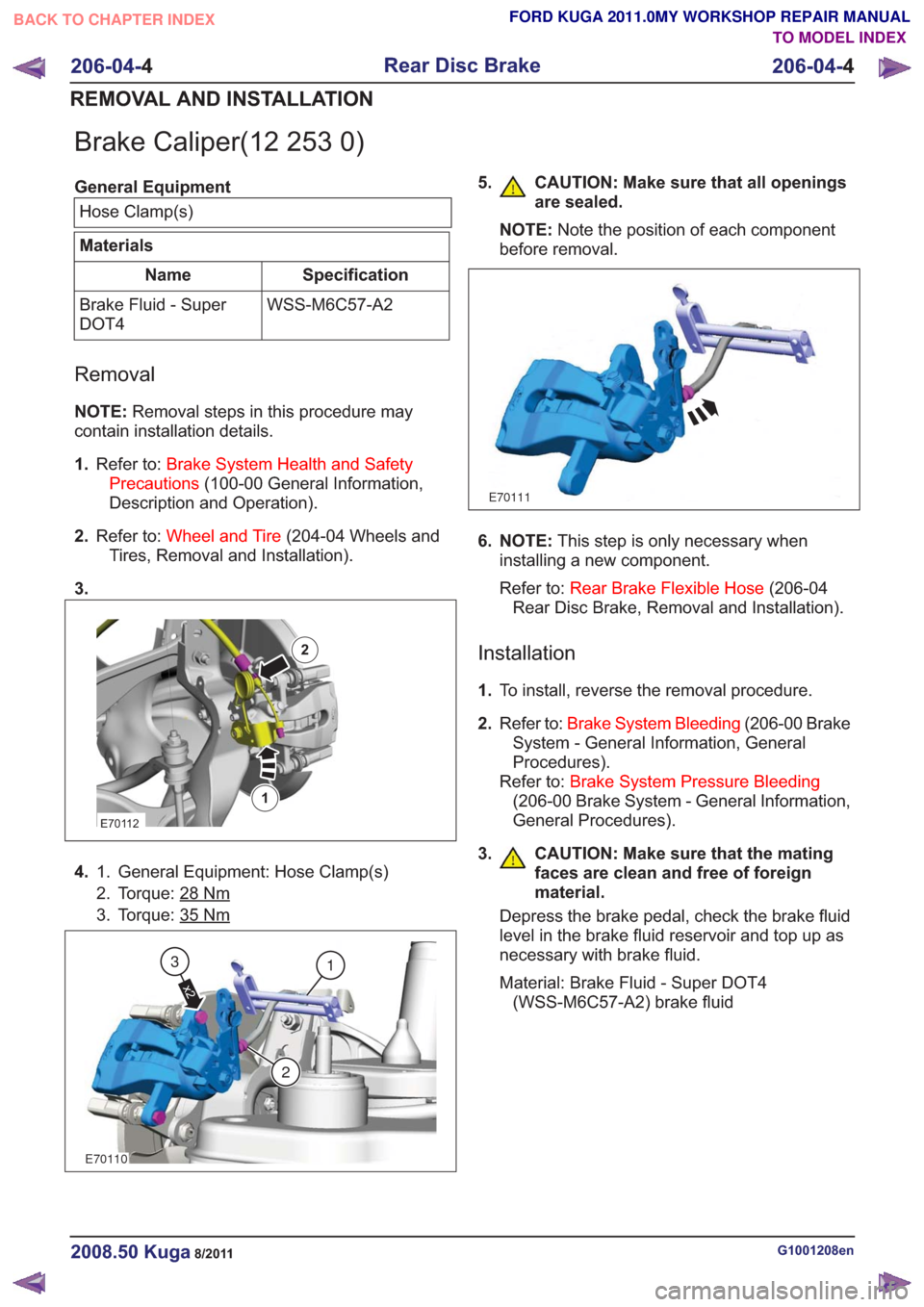

Brake Caliper(12 253 0)

General EquipmentHose Clamp(s)

Materials

Specification

Name

WSS-M6C57-A2

Brake Fluid - Super

DOT4

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. Refer to: Brake System Health and Safety

Precautions (100-00 General Information,

Description and Operation).

2. Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

3.

E70112

1

2

4. General Equipment: Hose Clamp(s)

1.

2. Torque: 28

Nm

3. Torque: 35Nm

E70110

1

2

x2

3

5. CAUTION: Make sure that all openings

are sealed.

NOTE: Note the position of each component

before removal.

E70111

6. NOTE: This step is only necessary when

installing a new component.

Refer to: Rear Brake Flexible Hose (206-04

Rear Disc Brake, Removal and Installation).

Installation

1. To install, reverse the removal procedure.

2. Refer to: Brake System Bleeding (206-00 Brake

System - General Information, General

Procedures).

Refer to: Brake System Pressure Bleeding

(206-00 Brake System - General Information,

General Procedures).

3.

CAUTION: Make sure that the mating

faces are clean and free of foreign

material.

Depress the brake pedal, check the brake fluid

level in the brake fluid reservoir and top up as

necessary with brake fluid.

Material: Brake Fluid - Super DOT4 (WSS-M6C57-A2) brake fluid

G1001208en2008.50 Kuga8/2011

206-04- 4

Rear Disc Brake

206-04- 4

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL