Gas FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 6 of 2057

SECTION 100-00 General Information

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

DESCRIPTION AND OPERATION

100-00-3

About This Manual ........................................................................\

......................................

100-00-3

Introduction ........................................................................\

.................................................

100-00-4

How to use Repair Procedures ........................................................................\

...................

100-00-4

Global Authoring Standards (GAS) Repair Procedures ..................................................

100-00-18

How to use Diagnosis and Testing procedures ..................................................................

100-00-19

Symbols Glossary ........................................................................\

.......................................

100-00-41

Steering System Health and Safety Precautions ................................................................

100-00-42

Health and Safety Precautions ........................................................................\

...................

100-00-42

Introduction ........................................................................\

.................................................

100-00-42

Acids and Alkalis ........................................................................\

........................................

100-00-42

Air Bags ........................................................................\

......................................................

100-00-42

Air Conditioning Refrigerant ........................................................................\

.......................

100-00-42

Adhesives and Sealers ........................................................................\

...............................

100-00-43

Antifreeze ........................................................................\

...................................................

100-00-43

Asbestos ........................................................................\

.....................................................

100-00-44

Battery Acids ........................................................................\

..............................................

100-00-44

Brake and Clutch Linings and Pads ........................................................................\

...........

100-00-44

Brake Fluids (Polyalkylene Glycols) ........................................................................\

...........

100-00-44

Brazing ........................................................................\

.......................................................

100-00-44

Chemical Materials ........................................................................\

.....................................

100-00-45

Chlorofluorocarbons (CFC) ........................................................................\

........................

100-00-45

Clutch Fluids ........................................................................\

...............................................

100-00-45

Clutch Linings and Pads ........................................................................\

.............................

100-00-45

Corrosion Protection Materials ........................................................................\

...................

100-00-45

Cutting ........................................................................\

....................................................... .

100-00-45

Dewaxing ........................................................................\

....................................................

100-00-45

Dusts ........................................................................\

..........................................................

100-00-45

Electric Shock ........................................................................\

.............................................

100-00-45

Engine Oils ........................................................................\

.................................................

100-00-46

Exhaust Fumes ........................................................................\

...........................................

100-00-46

Fibre Insulation ........................................................................\

...........................................

100-00-46

Fire ........................................................................\

.............................................................

100-00-46

First Aid

........................................................................\

......................................................

100-00-46

Fluoroelastomer ........................................................................\

..........................................

100-00-46

Foams

- Polyurethane ........................................................................\

................................

100-00-47

Freon ........................................................................\

..........................................................

100-00-47

Fuels ........................................................................\

...........................................................

100-00-47

Gas Cylinders ........................................................................\

.............................................

100-00-47

Gases ........................................................................\

.........................................................

100-00-47

Gaskets (Fluoroelastomer) ........................................................................\

.........................

100-00-47

General Workshop Tools and Equipment ........................................................................\

...

100-00-48

High Pressure Air, Lubrication and Oil Test Equipment ......................................................

100-00-48

Halon ........................................................................\

..........................................................

100-00-48

Legal Aspects ........................................................................\

.............................................

100-00-1

General Information

100-00- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

PAGE 1 OF 2 FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 9 of 2057

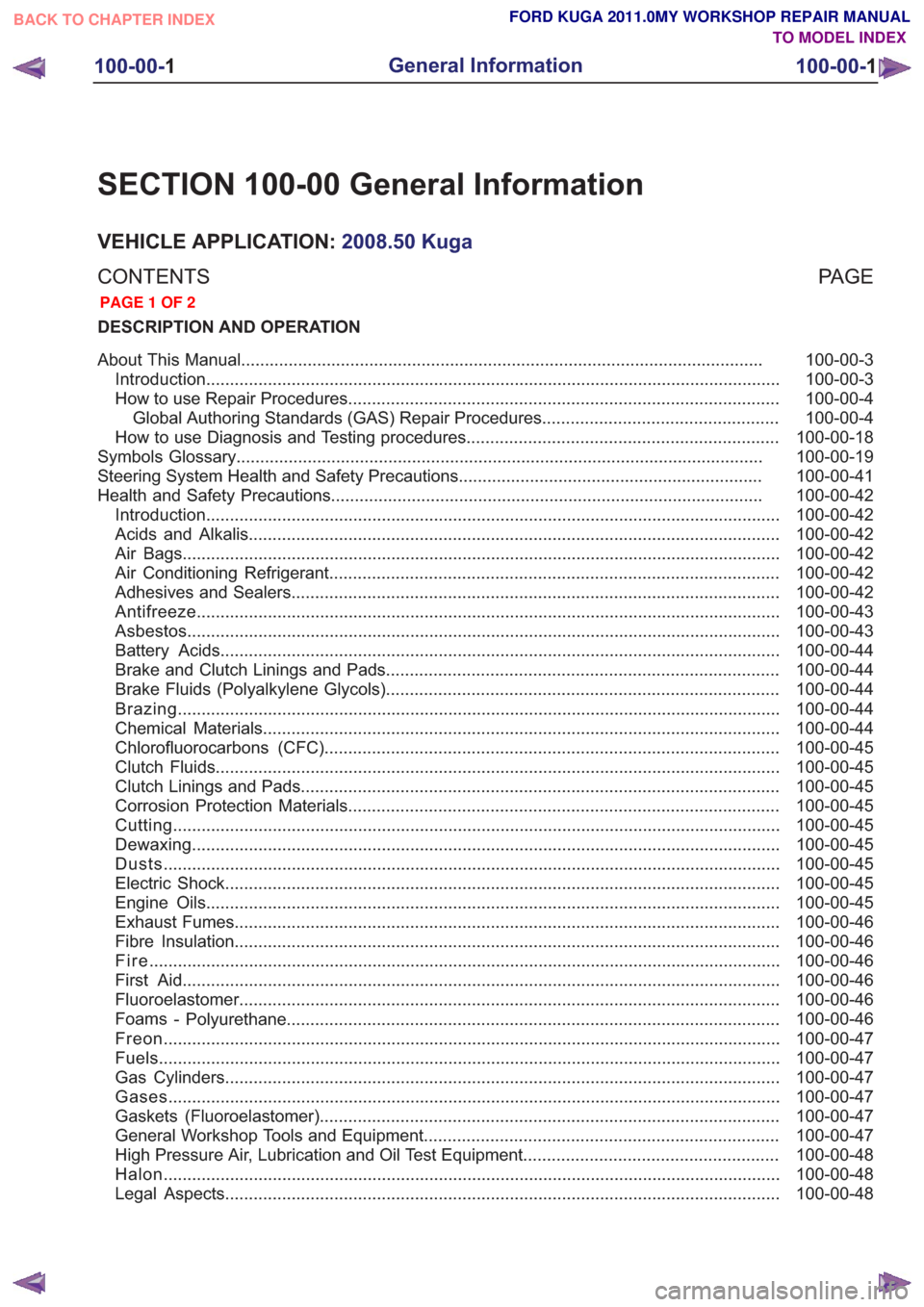

Powertrain LH and RH definition

E126781

1

2

3

4

Description

Item

front

1

right hand

2

rear

3

left hand

4

How to use Repair Procedures

This manual has been written in a format that is

designed to meet the needs of technicians

worldwide. It provides general descriptions for

accomplishing repair work with tested and effective

techniques.

Important Safety Instructions

Appropriate service methods and correct repair

procedures are essential for the safe and reliable

operation of all vehicles as well as the personal

safety of the individual carrying out the work.

Anyone who departs from the instructions provided

in this manual must first establish that personal safety or vehicle integrity is not compromised by

the choice of method, tools or components.

Warnings, Cautions and Notes in This

Manual

WARNING: Warnings are used to indicate

that failure to follow a procedure correctly

may result in personal injury.

CAUTION: Cautions are used to indicate

that failure to follow a procedure correctly

may result in damage to the vehicle or

equipment being used.

NOTE: Notes are used to provide additional

essential information required to carry out a

complete and satisfactory repair.

Generic warnings or cautions are in their relevant

description and operation procedure within section

100-00. If the generic warnings or cautions are

required for a procedure, there will be a referral to

the appropriate description and operation

procedure.

If a warning, caution or note only applies to one

step, it is placed at the beginning of the specific

step.

Global Authoring Standards (GAS) Repair

Procedures

NOTE: GAS style procedures can be identified by

steps that have no accompanying step text and

the magenta color of the electrical connectors and

fasteners such as nuts, bolts, clamps or clips.

A GAS removal and installation procedure uses a

sequence of color illustrations to indicate the order

to be followed when removing/disassembling or

installing/assembling a component.

Many of the GAS procedures will have the

installation information within the removal steps.

These procedures will have the following note at

the beginning of the procedure:

NOTE: Removal steps in this procedure may

contain installation details.

Reuse of fasteners and seals and gaskets

The following list details the general policy for the

reuse of fasteners and seals and gaskets.

G836098en2008.50 Kuga8/2011

100-00- 4

General Information

100-00- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 10 of 2057

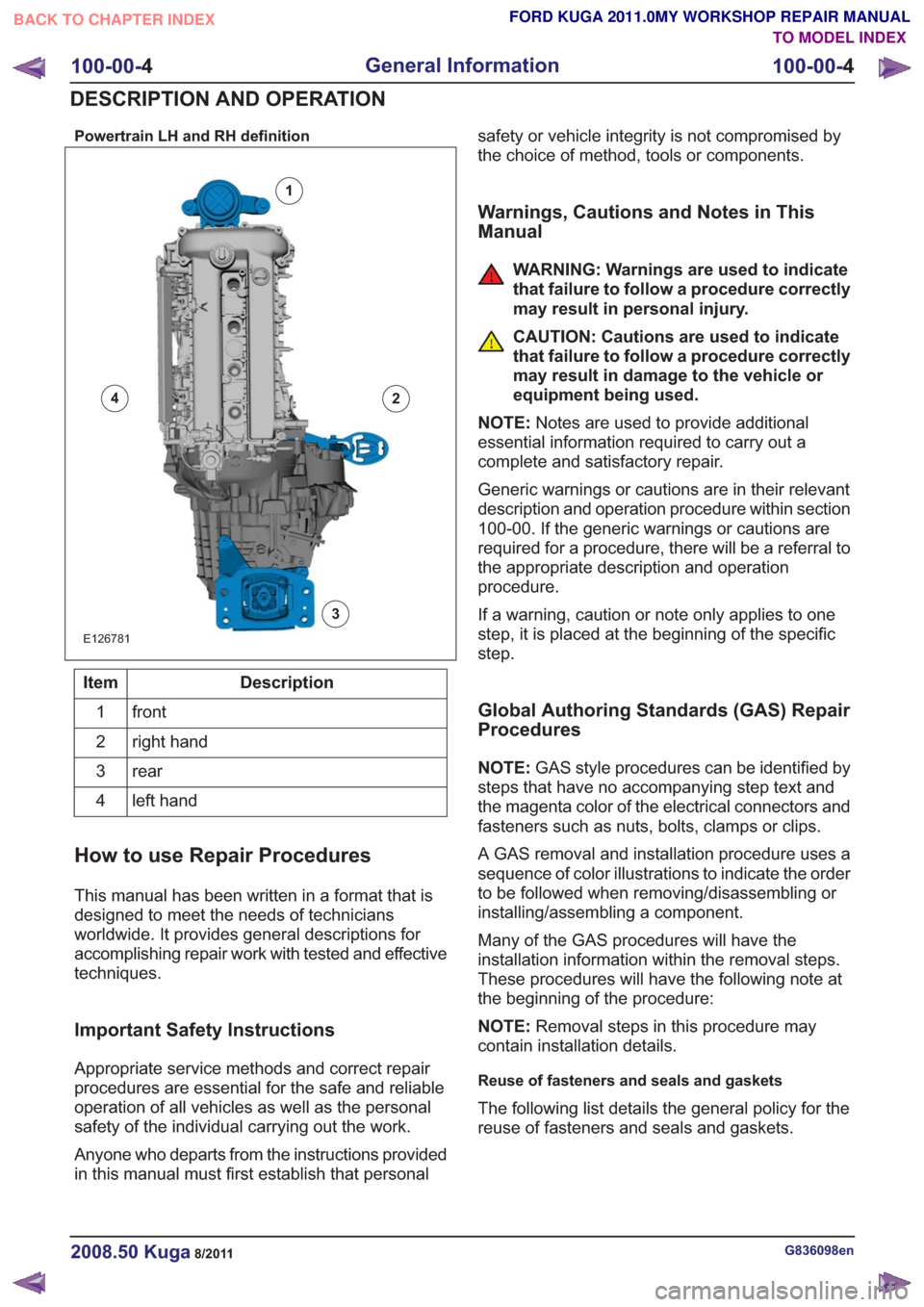

Types of self-locking nuts and bolts

NOTE:There are more types of self-locking fasteners available than shown in following illustration.

E126782

123

4567

Description

Item

Completely coated self-locking bolt

1

Partially coated self-locking bolt

2

Self-locking bolt with a locking washer

3

Self-locking nut with a plastic locking insert

4

Self-locking nut with thread deformation

(3 identations)

5

Self-locking nut with thread deformation

(to oval shape)

6

Self-locking nut with integrated locking ring

7

• All types of seals and gaskets must be discarded and new seals and gaskets installed

unless otherwise stated within the procedure.

• Nuts and bolts with a chemical coating for locking and/or sealing and/or antiseize must be

discarded unless the procedure advises to

reapply the coating with a specified material. • Nuts and bolts with a mechanical locking such

as thread inserts, thread deformation or locking

washers must be discarded and new nuts and

bolts installed unless otherwise stated within

the procedure.

• Torque to yield bolts must be discarded and new torque to yield bolts installed unless

otherwise stated within the procedure,

recognizable by a tightening torque with more

than one stage together with a torque angle.

Reuse of exterior trim parts

All type of glued exterior trim parts or parts

fastened with adhesive tape must be discarded

and new parts installed unless otherwise stated

within the procedure.

Specification data

Specification procedures will only contain technical

data that is not already part of a repair procedure.

Sequence of tasks

If components must be removed or installed in a

specific sequence, the sequence will be identified

G836098en2008.50 Kuga8/2011

100-00- 5

General Information

100-00- 5

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 11 of 2057

numerically in a graphic and the corresponding text

will be numbered accordingly.

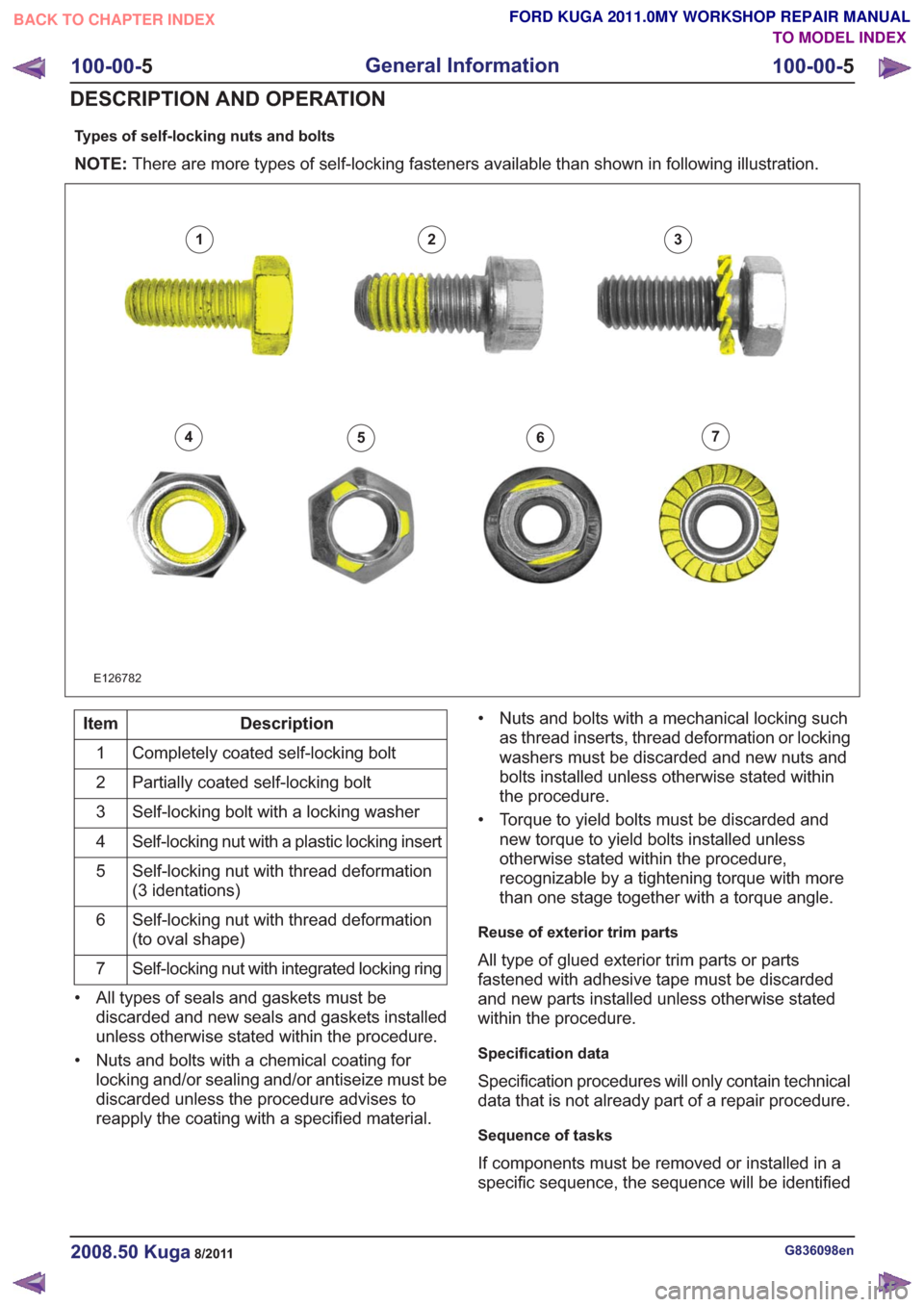

Special Tools, Equipment, Materials and Torque

Figures

Special tools will be shown with the tool numbers

in the illustration. The special tool numbers, general

equipment, materials and torque figures used for

the procedure step will be shown in the text

column.

GAS Graphics

NOTE:Colors used in the graphic are as follows:

4

6

5

14

2

36

5

E141161

Description

Item

Blue - Target or primary component to be

removed/installed (or

disassembled/assembled).

1

Green - Components that need to be

removed prior to or installed after the

target/primary.

2

Description

Item

Brown - Components that need to be

removed prior to or installed after the

target/primary.

3

Yellow - Components to be set aside only,

that remains in the vehicle. Also

highlighted areas to inspect or adjust.

4

Magenta - Electrical connectors and

fasteners such as nuts, bolts, clamps, or

5

clips to be: detached, attached, loosened,

moved, removed or installed.

Pale Blue - Special tool(s), general

equipment, or common tools (used in an

uncommon way).

6

One illustration may have multiple steps assigned

to it.

Numbered pointers are used to indicate the number

of electrical connectors and fasteners such as nuts,

bolts, clamps and clips.

Items in the illustration can be transparent or use

cutouts to show hidden details.

E132042

x2

1

2

3

G836098en2008.50 Kuga8/2011

100-00- 6

General Information

100-00- 6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 14 of 2057

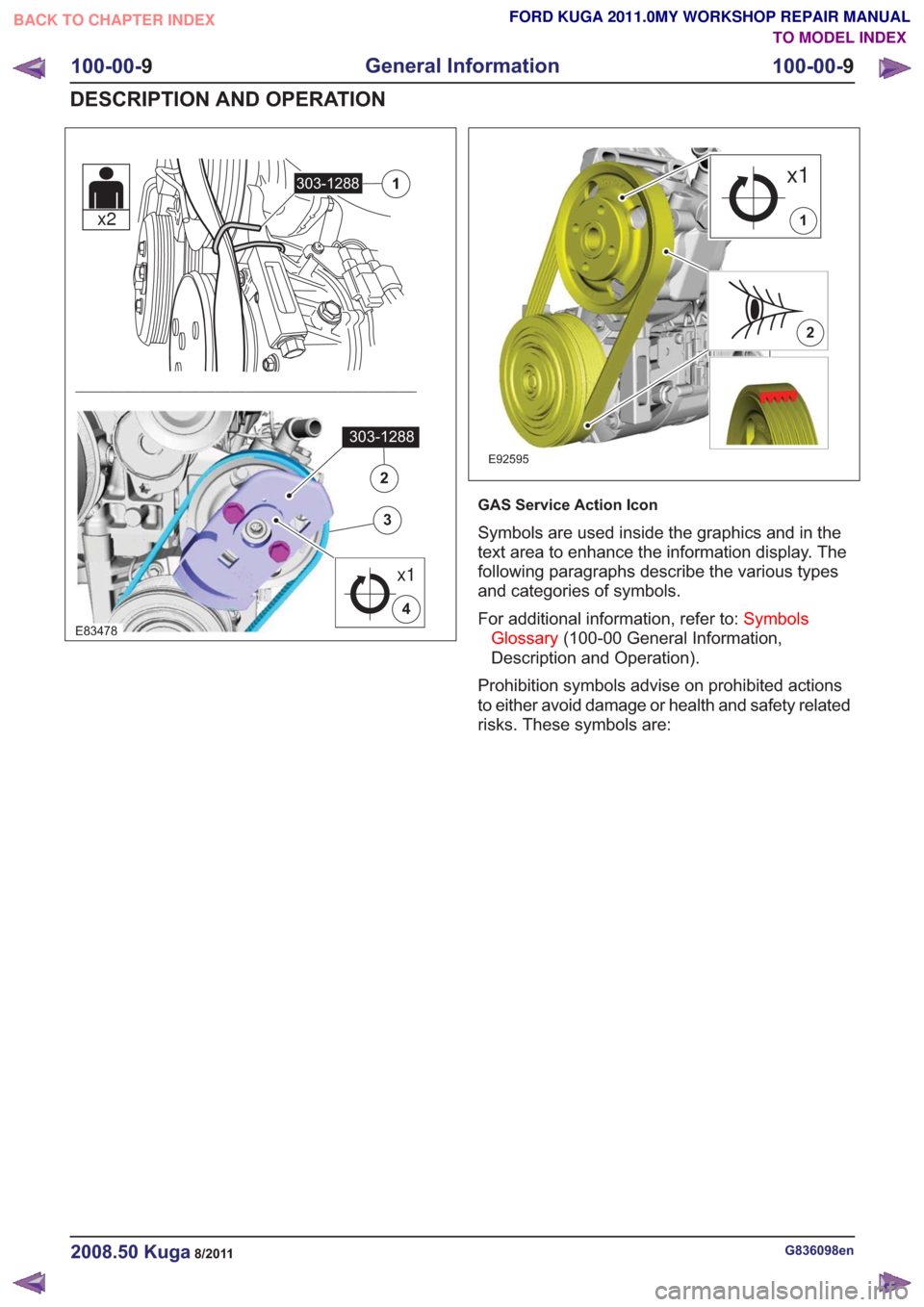

E83478

303-1288

x1

303-12881

2

3

4

x2

E92595

x1

1

2

2

GAS Service Action Icon

Symbols are used inside the graphics and in the

text area to enhance the information display. The

following paragraphs describe the various types

and categories of symbols.

For additional information, refer to:Symbols

Glossary (100-00 General Information,

Description and Operation).

Prohibition symbols advise on prohibited actions

to either avoid damage or health and safety related

risks. These symbols are:

G836098en2008.50 Kuga8/2011

100-00- 9

General Information

100-00- 9

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 41 of 2057

Description

Item

Securing strap

5

File with a specified size

6

Center punch

7

Marker

8

Metal inert gas (MIG) welding equipment

9

Hose clamp

10

Interior trim remover

11

Vacuum cleaner

12

Strap wrench

13Description

Item

Wedge

14

Pin Punch

15

Air blow gun

16

Mallet

17

Relocate and support the component

18

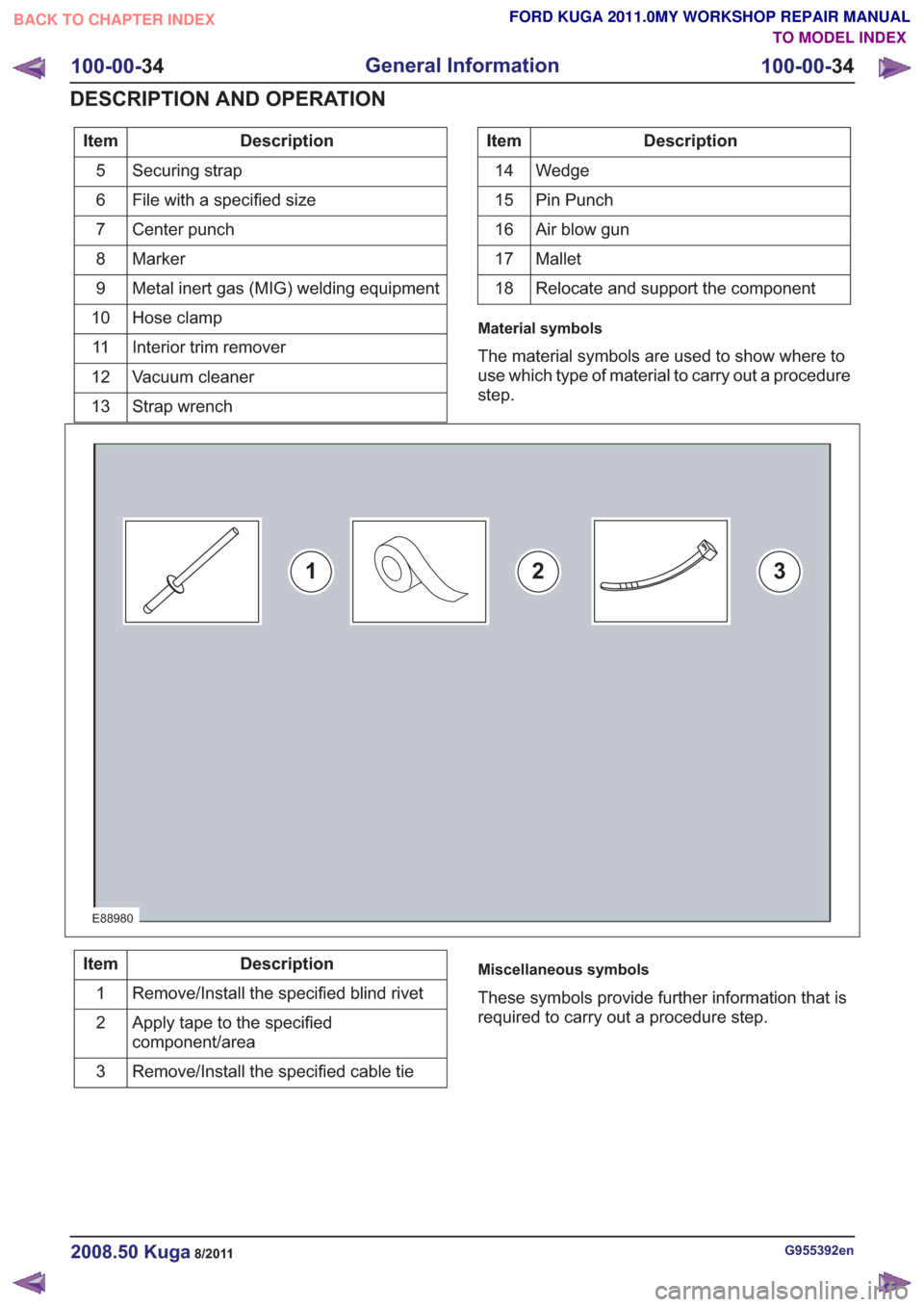

Material symbols

The material symbols are used to show where to

use which type of material to carry out a procedure

step.

123

E88980

Description

Item

Remove/Install the specified blind rivet

1

Apply tape to the specified

component/area

2

Remove/Install the specified cable tie

3Miscellaneous symbols

These symbols provide further information that is

required to carry out a procedure step.

G955392en2008.50 Kuga8/2011

100-00- 34

General Information

100-00- 34

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 47 of 2057

Exhaust Fumes

These contain asphyxiating, harmful and toxic

chemicals and particles such as carbon oxides,

nitrogen oxides, aldehydes, lead and aromatic

hydrocarbons. Engines should be run only under

conditions of adequate exhaust extraction or

general ventilation and not in confined spaces.

Gasoline (petrol) engine

There may not be adequate warning of odor or of

irritation before toxic or harmful effects arise. These

may be immediate or delayed.

Diesel engine

Soot, discomfort and irritation usually give

adequate warning of hazardous fume

concentrations.

Fibre Insulation

See alsoDusts.

Used in noise and sound insulation.

The fibrous nature of surfaces and cut edges can

cause skin irritation. This is usually a physical and

not a chemical effect.

Precautions should be taken to avoid excessive

skin contact through careful organization of work

practices and the use of gloves.

Fire

See also Welding,Foams,Legal Aspects.

Many of the materials found on or associated with

the repair of vehicles are highly flammable. Some

give off toxic or harmful fumes if burnt.

Observe strict fire safety when storing and handling

flammable materials or solvents, particularly near

electrical equipment or welding processes.

Make sure, before using electrical or welding

equipment, that there is no fire hazard present.

Have a suitable fire extinguisher available when

using welding or heating equipment.

First Aid

Apart from meeting any legal requirements it is

desirable for someone in the workshop to be

trained in First Aid procedures.

Splashes in the eye should be flushed carefully

with clean water for at least ten minutes.

Soiled skin should be washed with soap and water.

In case of cold burns, from alternative fuels, place

affected area in cool to cold water.

Individuals affected by inhalation of gases and

fumes should be removed to fresh air immediately.

If effects persist, consult a doctor.

If liquids are swallowed inadvertently, consult a

doctor giving him the information on the container

or label. Do not induce vomiting unless this action

is indicated on the label.

Fluoroelastomer

See Viton.

Foams - Polyurethane

See also Fire.

Used in sound and noise insulation. Cured foams

used in seat and trim cushioning.

Follow manufacturers instructions.

Unreacted components are irritating and may be

harmful to the skin and eyes. Wear gloves and

goggles.

Individuals with chronic respiratory diseases,

asthma, bronchial medical problems, or histories

of allergic diseases should not work in or near

uncured materials.

The components, vapors or spray mists can cause

direct irritation, sensitivity reactions and may be

toxic or harmful.

Vapors and spray mists must not be inhaled. These

materials must be applied with adequate ventilation

and respiratory protection. Do not remove the

respirator immediately after spraying; wait until the

vapors/mists have cleared.

Burning of the uncured components and the cured

foams can generate toxic and harmful fumes.

Smoking, naked flames or the use of electrical

equipment during foaming operations and until

vapors/mists have cleared should not be allowed.

Any heat cutting of cured foams or partially cured

G566527en2008.50 Kuga8/2011

100-00- 46

General Information

100-00- 46

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 48 of 2057

Health and Safety Precautions

Introduction

Many of the procedures associated with vehicle

maintenance and repair involve physical hazards

or other risks to health. This subsection lists,

alphabetically, some of these hazardous operations

and the materials and equipment associated with

them. Precautions necessary to avoid these

hazards are identified.

The list is not exhaustive and all operations and

procedures, and the handling of materials, should

be carried out with health and safety in mind.

Before using any product the Materials Safety Data

Sheet supplied by the manufacturer or supplier

should be consulted.

Acids and Alkalis

See alsoBattery Acids.

For example caustic soda, sulphuric acid.

Used in batteries and cleaning materials.

Irritant and corrosive to the skin, eyes, nose and

throat. Cause burns. Can destroy ordinary

protective clothing.

Avoid splashes to the skin, eyes and clothing. Wear

suitable protective impervious apron, gloves and

goggles. Do not breath mists.

Make sure access to eye wash bottles, shower and

soap are readily available for splashing accidents.

Display Eye Hazard sign.

Air Bags

See also Fire, Chemical Materials.

Highly flammable, explosive – observe No Smoking

policy.

Used as a safety restraint system mounted in the

steering wheel and passenger side of the

instrument panel.

The inflator contains a high-energetic propellant

which, when ignited, produces a VERY HOT GAS

(2500°C).

The gas generant used in air bags is Sodium Azide.

This material is hermetically sealed in the module

and is completely consumed during deployment.

No attempt should be made to open an air bag inflator as this will lead to the risk of exposure to

Sodium Azide. If a gas generator is ruptured, full

protective clothing should be worn when dealing

with the spillage.

After normal deployment, gloves and safety

goggles must be worn during the handling process.

Deployed air bags should be disposed of in a

plastic bag in accordance with local regulations at

an approved chemical waste site.

For additional information, refer to:

Supplemental

Restraint System (SRS) Health and Safety

Precautions (100-00 General Information,

Description and Operation).

Air Conditioning Refrigerant

See also Chlorofluorocarbon, Chemical Materials

Highly flammable, combustible – observe No

Smoking policy.

Skin contact may result in frostbite.

Instructions given by the manufacturer must be

followed. Avoid naked lights, wear suitable

protective gloves and goggles.

If refrigerant comes into contact with the skin or

eyes, immediately rinse the affected areas with

water. Eyes should also be rinsed with an

appropriate irrigation solution and should not be

rubbed. SEEK MEDICAL ASSISTANCE IF

NECESSARY.

For additional information, refer to: Air Conditioning

(A/C) System Health and Safety Precautions

(100-00 General Information, Description and

Operation).

Adhesives and Sealers

See also Fire, Chemical Materials.

Highly flammable, flammable, combustible –

observe No Smoking policy.

Generally should be stored in No Smoking areas.

Cleanliness and tidiness in use should be

observed, for example disposable paper covering

benches; should be dispensed from applicators

where possible; containers, including secondary

containers, should be labeled appropriately.

G566527en2008.50 Kuga8/2011

100-00- 42

General Information

100-00- 42

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 49 of 2057

Solvent-based Adhesives/Sealers - See

Solvents

Follow manufacturers instructions.

Water-based Adhesives/Sealers

Those based on polymer emulsions and rubber

latexes may contain small amounts of volatile toxic

and harmful chemicals. Skin and eye contact

should be avoided and adequate ventilation

provided during use.

Hot Melt Adhesives

In the solid state, they are safe. In the molten state

they may cause burns and health hazards may

arise from the inhalation of toxic fumes.

Use appropriate protective clothing and a

thermostatically controlled heater with a thermal

cut-out and adequate extraction.

Resin-based Adhesives/Sealers, for

example Epoxide and Formaldehyde

Resin-based

Mixing should be carried out in well ventilated

areas, as harmful or toxic volatile chemicals may

be released.

Skin contact with uncured resins and hardeners

can result in irritation, dermatitis, and absorption

of toxic or harmful chemicals through the skin.

Splashes can damage the eyes.

Provide adequate ventilation and avoid skin and

eye contact.

Anaerobic, Cyanoacrylate (super-glues)

and other Acrylic Adhesives

Many are irritant, sensitizing or harmful to the skin

and respiratory tract. Some are eye irritants.

Skin and eye contact should be avoided and the

manufacturers instructions followed.

Cyanoacrylate adhesives (super-glues) MUST NOT

contact the skin or eyes. If skin or eye tissue is

bonded, cover with a clean moist pad and SEEK

IMMEDIATE MEDICAL ATTENTION. Do not

attempt to pull tissue apart. Use in well ventilated

areas as vapors can cause irritation to the nose

and eyes.For two-pack systems see Resin-based and

Isocyanate Adhesives/Sealers.

Isocyanate (Polyurethane)

Adhesives/Sealers

See also

Resin-based Adhesives.

Individuals suffering from asthma or respiratory

allergies should not work with or near these

materials as sensitivity reactions can occur.

Over exposure is irritating to the eyes and

respiratory system. Excessive concentrations may

produce effects on the nervous system including

drowsiness. In extreme cases, loss of

consciousness may result. Long term exposure to

vapor concentrations may result in adverse health

effects.

Prolonged contact with the skin may have a

defatting effect which may lead to skin irritation

and in some cases, dermatitis.

Splashes entering the eye will cause discomfort

and possible damage.

Any spraying should preferably be carried out in

exhaust ventilated booths, removing vapors and

spray droplets from the breathing zone.

Wear appropriate gloves, eye and respiratory

protection.

Antifreeze

See also Fire, Solvents.

For example isopropanol, ethylene glycol,

methanol.

Highly flammable, flammable, combustible.

Used in vehicle coolant systems, brake air pressure

systems, screenwash solutions.

For additional information, refer to: Engine Cooling

System Health and Safety Precautions (100-00

General Information, Description and Operation).

Asbestos

See also Warning Symbols on Vehicles at the end

of this subsection.

Breathing asbestos dust may cause lung damage

or, in some cases, cancer.

Used in brake and clutch linings, transmission

brake bands and gaskets.

G566527en2008.50 Kuga8/2011

100-00- 43

General Information

100-00- 43

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 50 of 2057

foams should be conducted with extraction

ventilation. See also the vehicle Body Repair

Manual.

Freon

SeeAir Conditioning Refrigerant.

Fuels

See also, Fire, Legal Aspects, Chemicalsand

Solvents.

Avoid skin contact with fuel where possible. Should

contact occur, wash the affected skin with soap

and water.

Gasoline (Petrol)

Highly flammable - observe No Smoking policy.

For additional information, refer to: Petrol and

Petrol-Ethanol Fuel Systems Health and Safety

Precautions (100-00 General Information,

Description and Operation).

Gas-oil (Diesel Fuel)

Kerosene (Paraffin)

Used also as heating fuel, solvent and cleaning

agent.

Flammable - observe No Smoking policy.

Irritation of the mouth and throat may result from

swallowing. The main hazard from swallowing

arises if liquid aspiration into the lungs occurs.

Liquid contact dries the skin and can cause

irritation or dermatitis. Splashes in the eye may be

slightly irritating.

In normal circumstances the low volatility does not

give rise to harmful vapors. Exposure to mists and

vapors from kerosene at elevated temperature

should be avoided (mists may arise in dewaxing).

Avoid skin and eye contact and make sure there

is adequate ventilation.

Gas Cylinders

See also Fire. Gases such as oxygen, acetylene, argon and

propane are normally stored in cylinders at

pressures of up to 138 bar (2000 psi) and great

care should be taken in handling these cylinders

to avoid mechanical damage to them or to the valve

gear attached. The contents of each cylinder

should be clearly identified by appropriate

markings.

Cylinders should be stored in well-ventilated

enclosures, and protected from ice and snow, or

direct sunlight. Fuel gases, for example acetylene

and propane, should not be stored in close

proximity to oxygen cylinders.

Care should be exercised to prevent leaks from

gas cylinders and lines, and to avoid sources of

ignition.

Only trained personnel should undertake work

involving gas cylinders.

Gases

See

Gas Cylinders.

Gaskets (Fluoroelastomer)

SeeViton.

General Workshop Tools and

Equipment

It is essential that all tools and equipment are

maintained in good condition and that the correct

safety equipment is used where required.

Never use tools or equipment for any purpose other

than that for which they were designed. Never

overload equipment such as hoists, jacks, axle and

chassis stands or lifting slings. Damage caused by

overloading is not always immediately apparent

and may result in a fatal failure the next time that

the equipment is used.

Do not use damaged or defective tools or

equipment, particularly high-speed equipment such

as grinding wheels. A damaged grinding wheel can

disintegrate without warning and cause serious

injury.

Wear suitable eye protection when using grinding,

chiseling or sand blasting equipment.

Wear a suitable breathing mask when using

abrasive blasting equipment, working with

asbestos-based materials or using spraying

equipment.

G566527en2008.50 Kuga8/2011

100-00- 47

General Information

100-00- 47

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL