Servicing FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 65 of 2057

Air Conditioning (A/C) System Health and Safety Precautions

WARNINGS:

Only qualified technicians are allowed to

work on air conditioning (A/C) systems.

Air conditioning (A/C) system components

can become particularly hot or cold.

Make sure that the air conditioning (A/C)

system is at ambient temperature before

carrying out any repair.

When handling refrigerants, always wear

protective goggles and gloves made of

fluoroelastomer. Leather or fabric gloves

are not suitable.

SKIN CONTACT: If liquid refrigerant comes

into contact with the skin, it produces

severe frostbite. Immediately flush affected

areas with plenty of cold running water for

15 minutes. Seek medical attention.

EYE CONTACT: If refrigerant comes into

contact with the eyes, immediately flush

the eyes with plenty of running water for

15 minutes. Seek medical attention.

INHALED: Toxic gases generated when

refrigerant is heated are hazardous to

health. The gases have an irritating smell

and can cause lung damage. The

symptoms can continue for a long time

after having been in contact with the gases.

The gases can cause lung damage even if

the amount of gas in the air is too small to

smell.

Refrigerant is flammable and explosive.

Make sure that refrigerant bottles are not

exposed to temperatures greater than 45°C.

Make sure that the local regulations

regarding work on air conditioning (A/C)

systems are adhered to.

Make sure that refrigerant bottles are

closed properly.

Gaseous refrigerant has a higher density

than air. There is a danger of suffocation

when working close to the ground or in

workshop pits.

Provide adequate ventilation when

handling refrigerant.

Never release refrigerant into the

atmosphere.

Only use special tools, equipment and

lubricants that are approved for the type

of refrigerant being used.

Always follow the manufacturer’s

instructions for the correct servicing unit

operating procedure.

CAUTIONS:

Do not mix refrigerant oils for different

types of refrigerant.

Never mix different types of refrigerant or

equipment intended for them.

Only use refrigerant in gas form when

filling the system through the low-pressure

connection.

Only use refrigerant in liquid form when

filling the system through the

high-pressure connection.

Refrigerant attacks certain plastics. Only

use seals suitable for refrigerant.

If the air conditioning (A/C) compressor is

damaged, the fixed orifice tube can

become blocked with metal particles.

Any sort of blockage in the refrigerant

circuit will damage the air conditioning

(A/C) compressor irreparably.

If the air conditioning (A/C) system has

been opened for a period greater than 2

hours, a new receiver drier must be

installed and the evacuating time to be

increased by a minimum of 2 hours.

NOTE: New air conditioning (A/C) compressors

are delivered prefilled.

NOTE: Refrigerant oil in new air conditioning (A/C)

compressors can contain Teflon, visible as white

particles, which will not harm the system.

G548993en2008.50 Kuga8/2011

100-00- 60

General Information

100-00- 60

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2024 of 2057

Contaminated Refrigerant Handling

1. CAUTION: Any R134a or R12 refrigerantwhich is contaminated with unsuitable

refrigerant should be extracted only by

means of a suitable servicing unit

designed for the purpose of collecting

and storing contaminated refrigerant,

so that the spread to other vehicles can

be prevented.

Use refrigerant identification equipment to check

that there is contaminated refrigerant in the air

conditioning system.

2. Inform the customer about the additional costs

involved to repair the system because of the

contamination.

3. Extract the contaminated refrigerant.

G549840en2008.50 Kuga8/2011

412-00- 13

Climate Control System - General Information

412-00- 13

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2037 of 2057

Climate Control – Overview

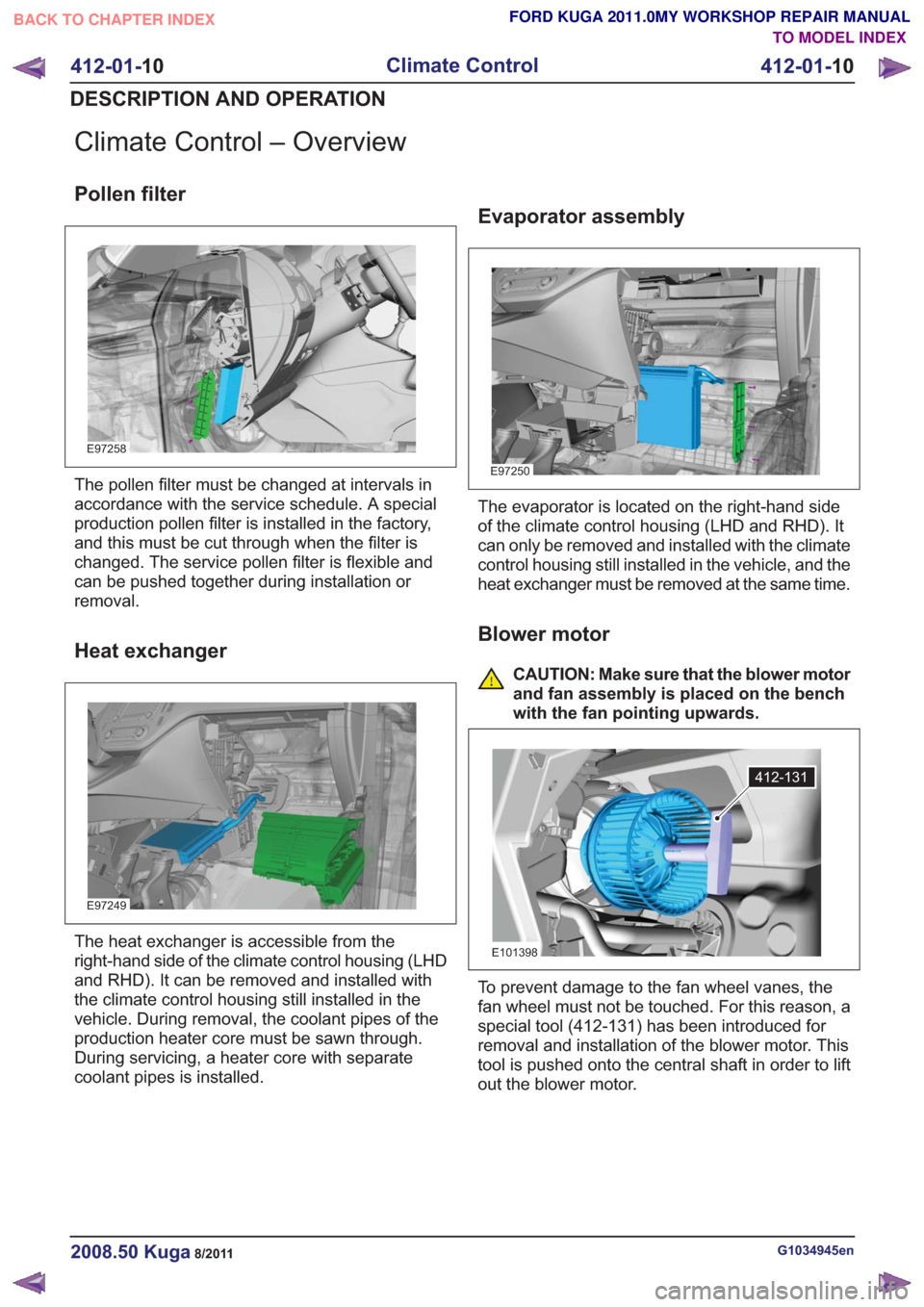

Pollen filter

E97258

The pollen filter must be changed at intervals in

accordance with the service schedule. A special

production pollen filter is installed in the factory,

and this must be cut through when the filter is

changed. The service pollen filter is flexible and

can be pushed together during installation or

removal.

Heat exchanger

E97249

The heat exchanger is accessible from the

right-hand side of the climate control housing (LHD

and RHD). It can be removed and installed with

the climate control housing still installed in the

vehicle. During removal, the coolant pipes of the

production heater core must be sawn through.

During servicing, a heater core with separate

coolant pipes is installed.

Evaporator assembly

E97250

The evaporator is located on the right-hand side

of the climate control housing (LHD and RHD). It

can only be removed and installed with the climate

control housing still installed in the vehicle, and the

heat exchanger must be removed at the same time.

Blower motor

CAUTION: Make sure that the blower motor

and fan assembly is placed on the bench

with the fan pointing upwards.

412-131

E101398

To prevent damage to the fan wheel vanes, the

fan wheel must not be touched. For this reason, a

special tool (412-131) has been introduced for

removal and installation of the blower motor. This

tool is pushed onto the central shaft in order to lift

out the blower motor.

G1034945en2008.50 Kuga8/2011

412-01-10

Climate Control

412-01- 10

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL