Suction FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 123 of 2057

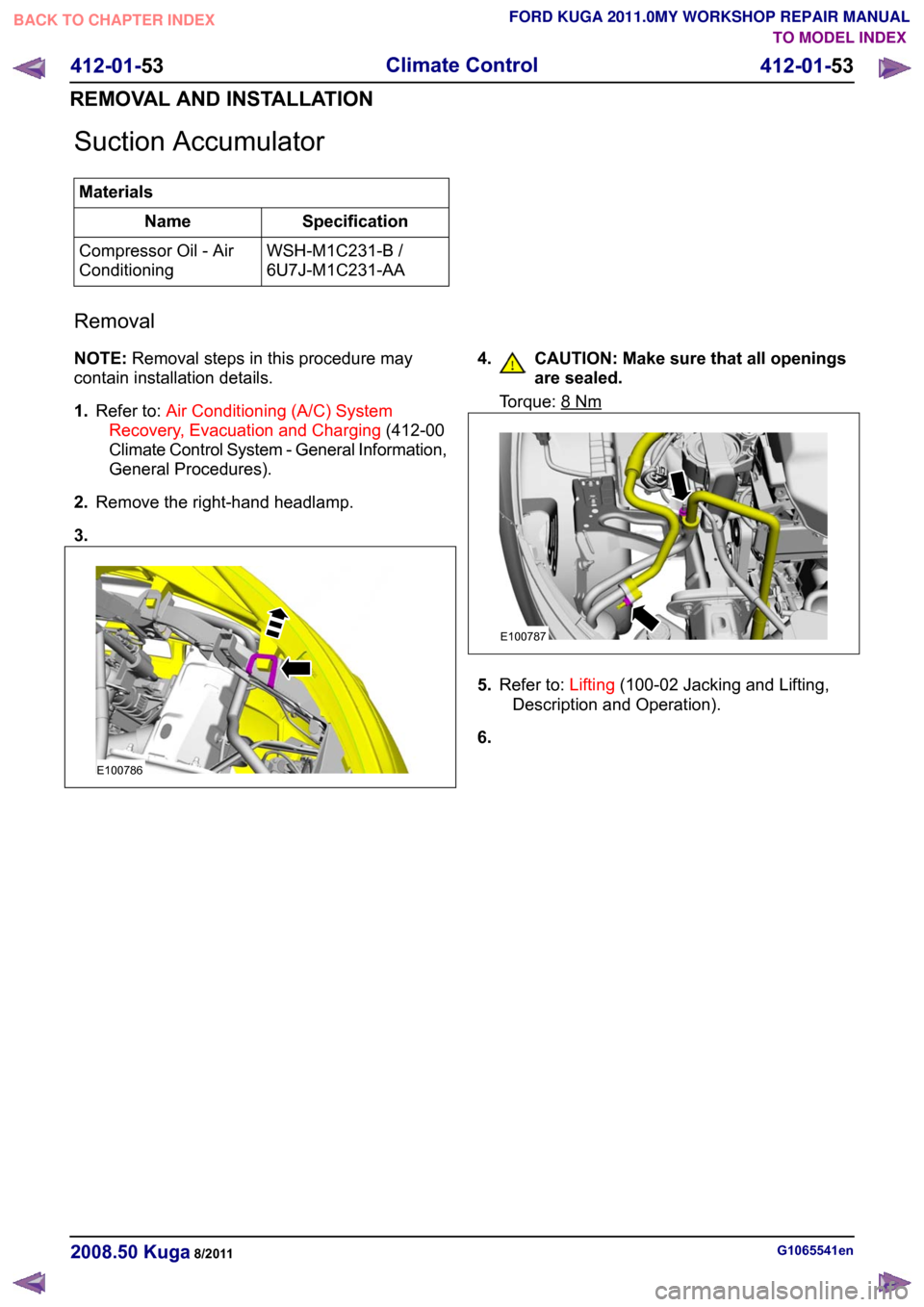

Suction Accumulator

Materials

Specification

Name

WSH-M1C231-B /

6U7J-M1C231-AA

Compressor Oil - Air

Conditioning

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. Refer to: Air Conditioning (A/C) System

Recovery, Evacuation and Charging (412-00

Climate Control System - General Information,

General Procedures).

2. Remove the right-hand headlamp.

3. 4. CAUTION: Make sure that all openings

are sealed. Torque: 8 Nm

5.

Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

6. G1065541en

2008.50 Kuga 8/2011 412-01-53

Climate Control

412-01-53

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE100786 E100787

Page 1466 of 2057

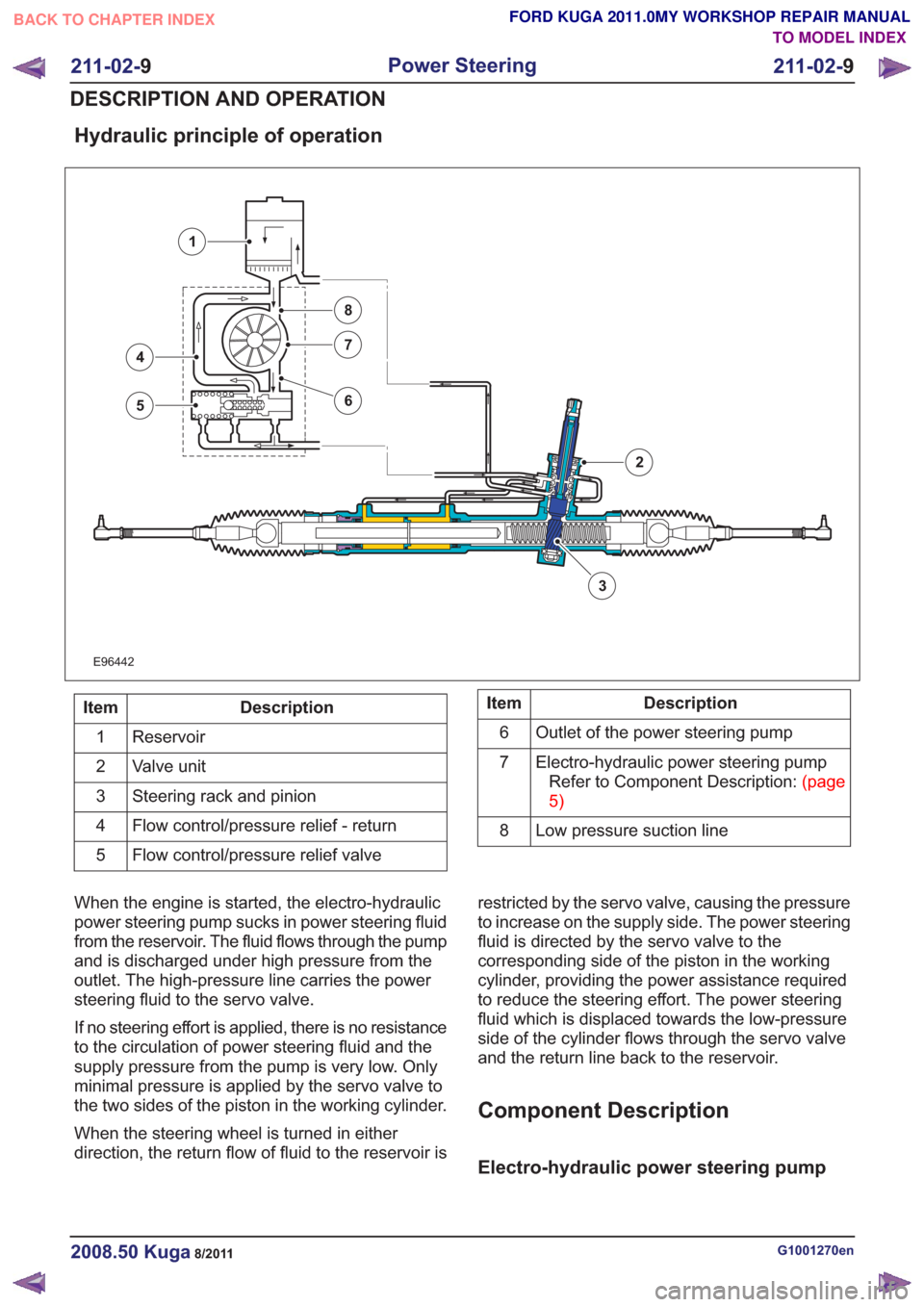

Hydraulic principle of operation

E96442

3

4

5

7

8

6

1

2

Description

Item

Reservoir

1

Valve unit

2

Steering rack and pinion

3

Flow control/pressure relief - return

4

Flow control/pressure relief valve

5Description

Item

Outlet of the power steering pump

6

Electro-hydraulic power steering pumpRefertoComponentDescription:(page

5)

7

Low pressure suction line

8

When the engine is started, the electro-hydraulic

power steering pump sucks in power steering fluid

from the reservoir. The fluid flows through the pump

and is discharged under high pressure from the

outlet. The high-pressure line carries the power

steering fluid to the servo valve.

If no steering effort is applied, there is no resistance

to the circulation of power steering fluid and the

supply pressure from the pump is very low. Only

minimal pressure is applied by the servo valve to

the two sides of the piston in the working cylinder.

When the steering wheel is turned in either

direction, the return flow of fluid to the reservoir is restricted by the servo valve, causing the pressure

to increase on the supply side. The power steering

fluid is directed by the servo valve to the

corresponding side of the piston in the working

cylinder, providing the power assistance required

to reduce the steering effort. The power steering

fluid which is displaced towards the low-pressure

side of the cylinder flows through the servo valve

and the return line back to the reservoir.

Component Description

Electro-hydraulic power steering pump

G1001270en2008.50 Kuga8/2011

211-02-

9

Power Steering

211-02- 9

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1984 of 2057

E105872

1

2

4

5

6

7

10

8

11

3

9

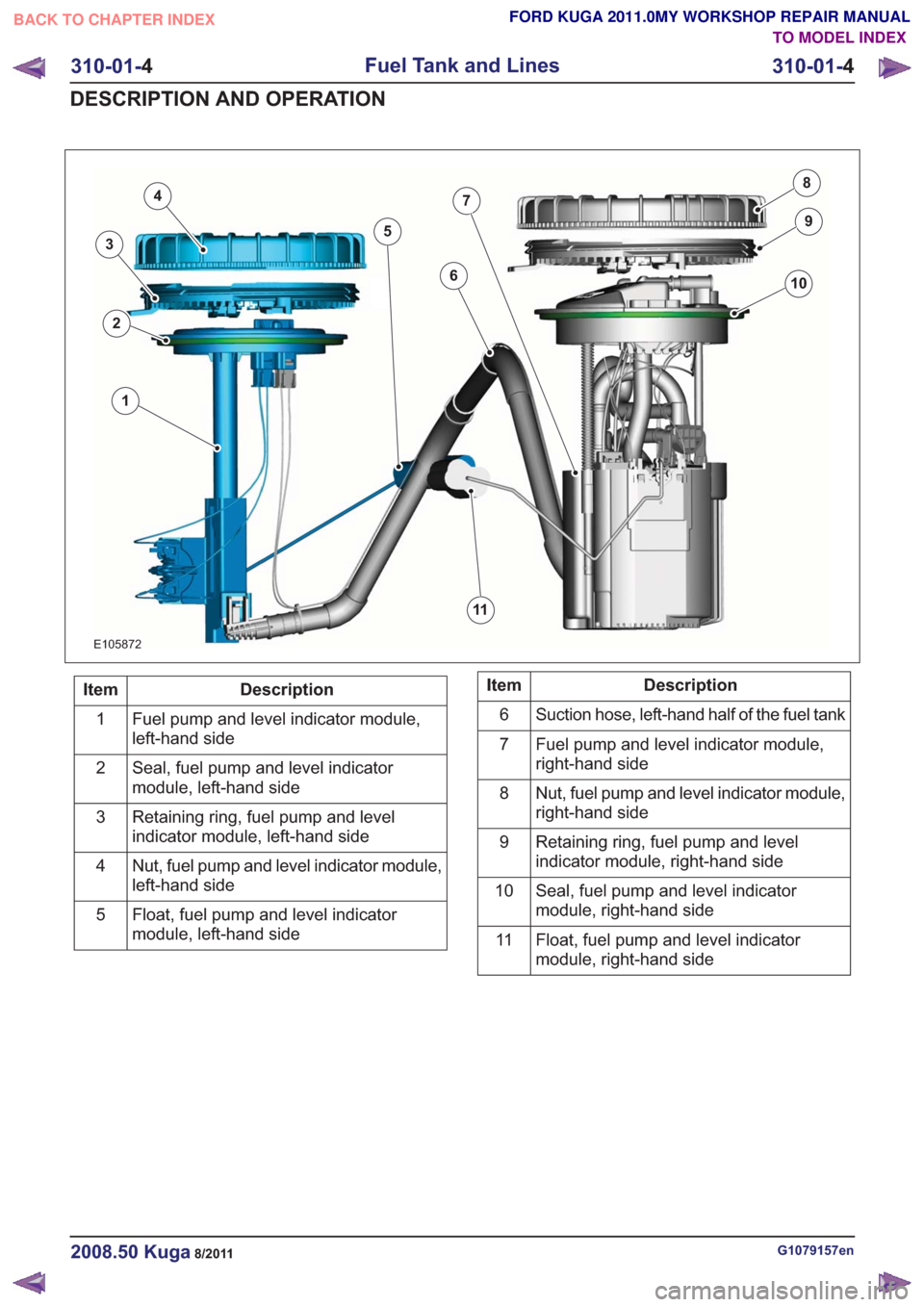

Description

Item

Fuel pump and level indicator module,

left-hand side

1

Seal, fuel pump and level indicator

module, left-hand side

2

Retaining ring, fuel pump and level

indicator module, left-hand side

3

Nut, fuel pump and level indicator module,

left-hand side

4

Float, fuel pump and level indicator

module, left-hand side

5Description

Item

Suction hose, left-hand half of the fuel tank

6

Fuel pump and level indicator module,

right-hand side

7

Nut, fuel pump and level indicator module,

right-hand side

8

Retaining ring, fuel pump and level

indicator module, right-hand side

9

Seal, fuel pump and level indicator

module, right-hand side

10

Float, fuel pump and level indicator

module, right-hand side

11

G1079157en2008.50 Kuga8/2011

310-01-

4

Fuel Tank and Lines

310-01- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1986 of 2057

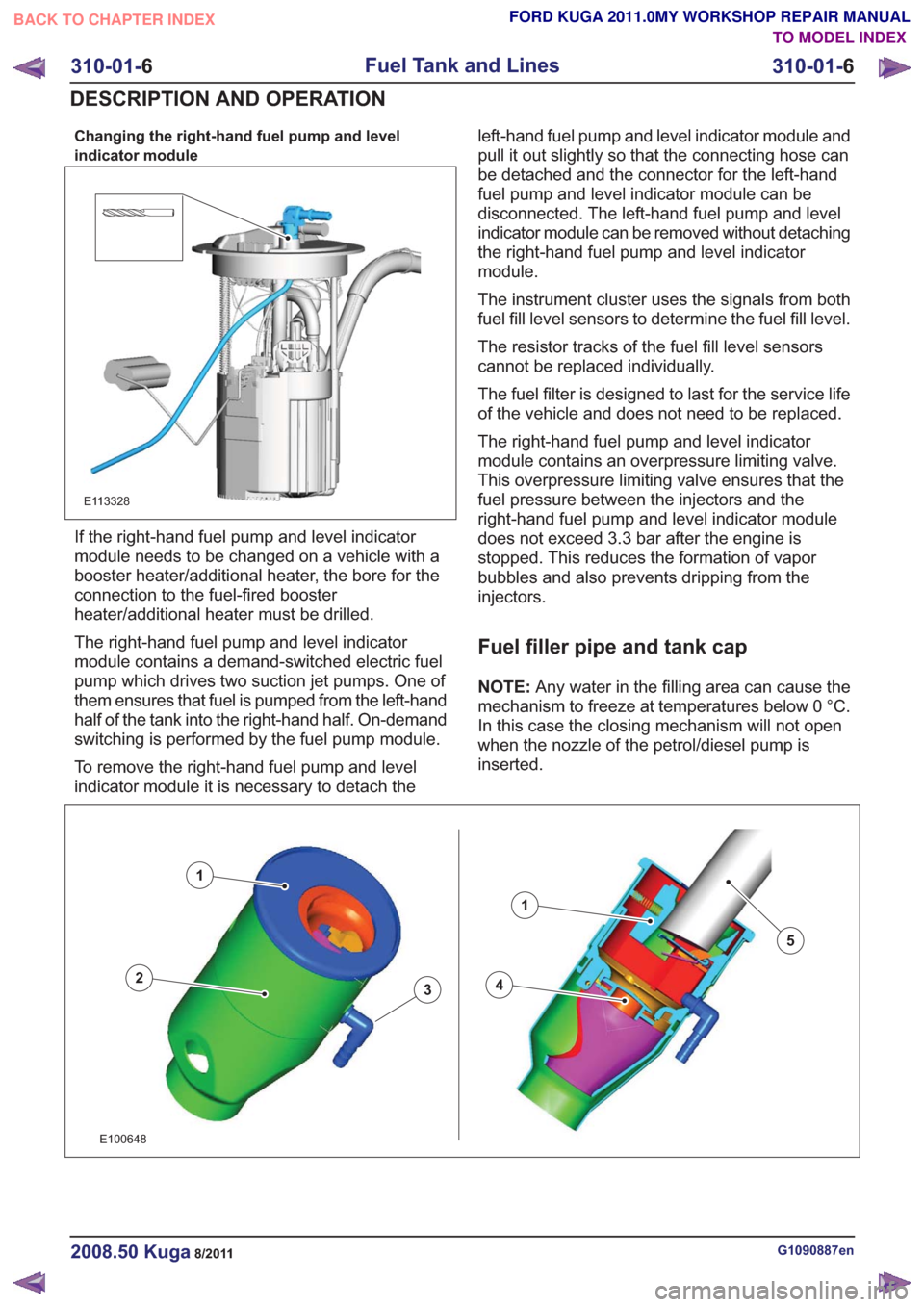

Changing the right-hand fuel pump and level

indicator module

E113328

If the right-hand fuel pump and level indicator

module needs to be changed on a vehicle with a

booster heater/additional heater, the bore for the

connection to the fuel-fired booster

heater/additional heater must be drilled.

The right-hand fuel pump and level indicator

module contains a demand-switched electric fuel

pump which drives two suction jet pumps. One of

them ensures that fuel is pumped from the left-hand

half of the tank into the right-hand half. On-demand

switching is performed by the fuel pump module.

To remove the right-hand fuel pump and level

indicator module it is necessary to detach theleft-hand fuel pump and level indicator module and

pull it out slightly so that the connecting hose can

be detached and the connector for the left-hand

fuel pump and level indicator module can be

disconnected. The left-hand fuel pump and level

indicator module can be removed without detaching

the right-hand fuel pump and level indicator

module.

The instrument cluster uses the signals from both

fuel fill level sensors to determine the fuel fill level.

The resistor tracks of the fuel fill level sensors

cannot be replaced individually.

The fuel filter is designed to last for the service life

of the vehicle and does not need to be replaced.

The right-hand fuel pump and level indicator

module contains an overpressure limiting valve.

This overpressure limiting valve ensures that the

fuel pressure between the injectors and the

right-hand fuel pump and level indicator module

does not exceed 3.3 bar after the engine is

stopped. This reduces the formation of vapor

bubbles and also prevents dripping from the

injectors.

Fuel filler pipe and tank cap

NOTE:

Any water in the filling area can cause the

mechanism to freeze at temperatures below 0 °C.

In this case the closing mechanism will not open

when the nozzle of the petrol/diesel pump is

inserted.

43

1

2

1

5

43

1

2

1

5

E100648

G1090887en2008.50 Kuga8/2011

310-01- 6

Fuel Tank and Lines

310-01- 6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2025 of 2057

Electronic Leak Detection

1.Refer to: Air Conditioning (A/C) System Health

and Safety Precautions (100-00 General

Information, Description and Operation).

2. WARNINGS:

Before starting leak detection, make

sure that the area where it is to be done

is well ventilated. If the surrounding air

is contaminated with refrigerant gas, the

leak detector will indicate this gas all

the time. Odors from other chemicals

such as antifreeze, diesel fuel, disc

brake cleaner, or other cleaning

solvents can cause the same problem.

Prevent air movement while performing

leak detection.

The refrigerant identification equipment

must be used before attaching the

manifold gauge set. Otherwise the

manifold gauge set may become

contaminated. Contaminated refrigerant

must be disposed of as special waste.

Follow the manufacturer's instructions

when working with the service unit.

NOTE: At 24°C with the engine switched off,

both manifold gauges should show 4.1 to 5.5

bar.

Attach the manifold gauge set to the service

gauge port valves.

3. For the leak test, close the manual valves on

the gauge set.

4. If little or no pressure is indicated, charge the

system with approx. 300g of refrigerant. Refer

to: Air Conditioning System - Evacuate and

Refill.

5. Use the R-134a Automatic Calibration Halogen

Leak Detector to leak test the refrigerant system.

Follow the instructions included with leak

detector for handling and operation techniques.

6. If any leak is found, extract the refrigerant under

suction. Refer to: Air Conditioning System -

Evacuate and Refill.

G549836en2008.50 Kuga8/2011

412-00- 14

Climate Control System - General Information

412-00- 14

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2029 of 2057

412-01-42

Heater Core and Evaporator Core Housing .......................................................................

412-01-45

(34 364 0)

Heater Core — RHD ........................................................................\

...............

412-01-53

Suction Accumulator ........................................................................\

...................................

412-01-56

Suction Accumulator to Air Conditioning (A/C) Compressor Line ......................................

412-01-57

Suction Accumulator to Air Conditioning (A/C) Compressor Line — 2.5L Duratec

(147kW/200PS) - VI5 ........................................................................\

................................

412-01-58

Low-Pressure Cutoff Switch ........................................................................\

.......................

412-01-59

High-Pressure Cutoff Switch ........................................................................\

.......................

412-01-60

Evaporator ........................................................................\

..................................................

412-01-62

Evaporator Outlet Line ........................................................................\

................................

412-01-65

Evaporator Core Orifice ........................................................................\

..............................

412-01-68

Condenser to Evaporator Line........................................................................\

....................

412-01-71

(34 300 0)

Climate Control Assembly — Vehicles With: Manual Temperature Control ....

412-01-72

(34 300 0)

Climate Control Assembly — Vehicles With: Automatic Temperature Control .

412-01-73

(34 485 4)

Footwell Air Discharge Temperature Sensor ..................................................

412-01-74

Center Register Air Discharge Temperature Sensor ..........................................................

412-01-75

In-Vehicle Temperature Sensor ........................................................................\

..................

412-01-76

(34 676 0)

Ambient Air Temperature Sensor ...................................................................

412-01-77

(34 665 0)

Sunload Sensor ........................................................................\

......................

412-01-78

(34 591 0)

Footwell Vent/Duct Blend Door Actuator — RHD ...........................................

412-01-79

(34 606 0)

Air Inlet Blend Door Actuator ........................................................................\

..

412-01-80

(34 608 0)

Driver Side Temperature Blend Door Actuator ...............................................

412-01-81

(34 608 0)

Passenger Side Temperature Blend Door Actuator .......................................

412-01-82

(34 591 0)

Defrost Vent/Register Blend Door Actuator — RHD ......................................

412-01-2

Climate Control

412-01- 2

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

PAGE 2 OF 2 FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2050 of 2057

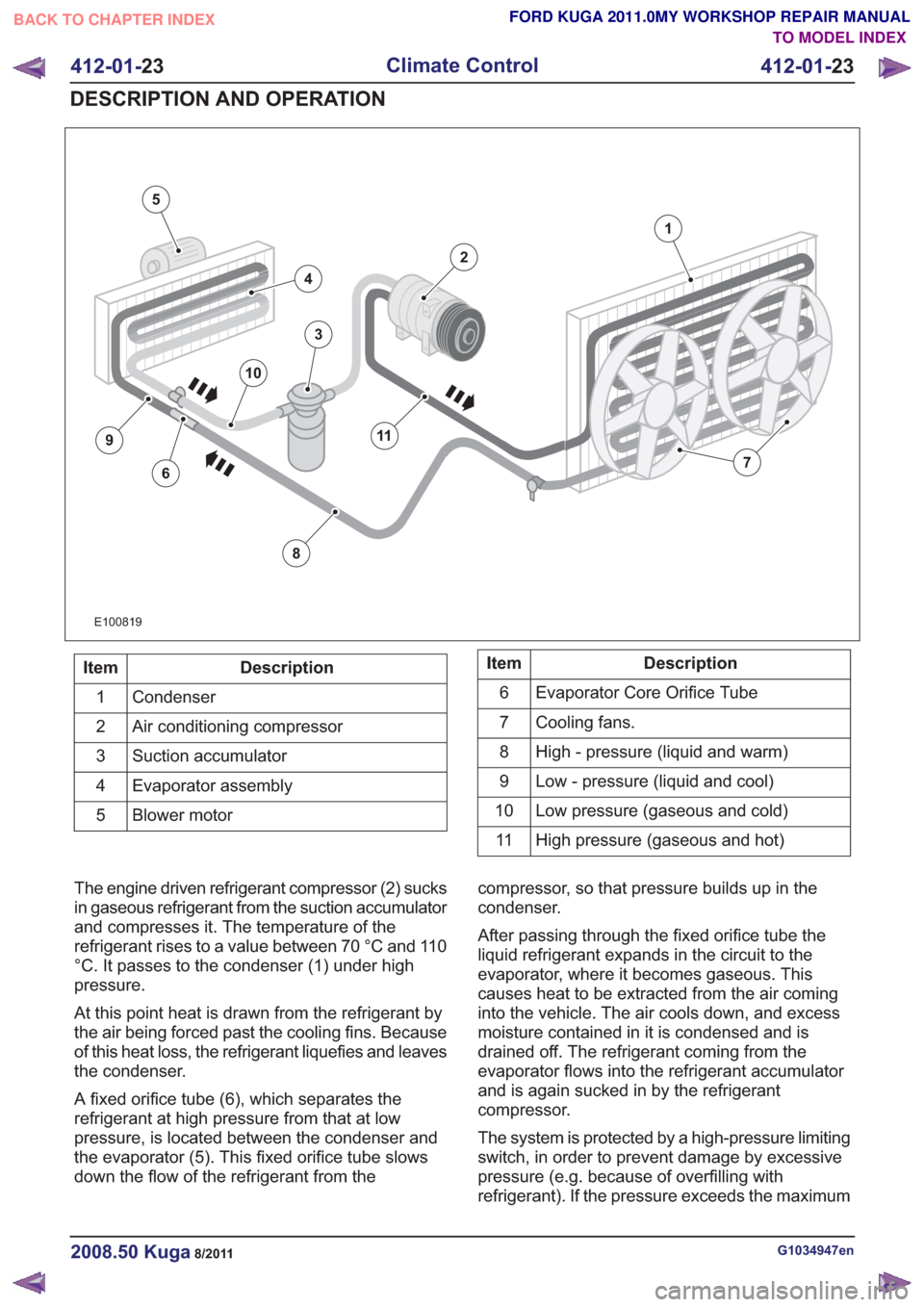

1

2

3

5

4

67

8

9

10

11

E100819

Description

Item

Condenser

1

Air conditioning compressor

2

Suction accumulator

3

Evaporator assembly

4

Blower motor

5Description

Item

Evaporator Core Orifice Tube

6

Cooling fans.

7

High - pressure (liquid and warm)

8

Low - pressure (liquid and cool)

9

Low pressure (gaseous and cold)

10

High pressure (gaseous and hot)

11

The engine driven refrigerant compressor (2) sucks

in gaseous refrigerant from the suction accumulator

and compresses it. The temperature of the

refrigerant rises to a value between 70 °C and 110

°C. It passes to the condenser (1) under high

pressure.

At this point heat is drawn from the refrigerant by

the air being forced past the cooling fins. Because

of this heat loss, the refrigerant liquefies and leaves

the condenser.

A fixed orifice tube (6), which separates the

refrigerant at high pressure from that at low

pressure, is located between the condenser and

the evaporator (5). This fixed orifice tube slows

down the flow of the refrigerant from the compressor, so that pressure builds up in the

condenser.

After passing through the fixed orifice tube the

liquid refrigerant expands in the circuit to the

evaporator, where it becomes gaseous. This

causes heat to be extracted from the air coming

into the vehicle. The air cools down, and excess

moisture contained in it is condensed and is

drained off. The refrigerant coming from the

evaporator flows into the refrigerant accumulator

and is again sucked in by the refrigerant

compressor.

The system is protected by a high-pressure limiting

switch, in order to prevent damage by excessive

pressure (e.g. because of overfilling with

refrigerant). If the pressure exceeds the maximum

G1034947en2008.50 Kuga8/2011

412-01-

23

Climate Control

412-01- 23

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL