check engine light FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 63 of 2057

Road/Roller Testing

Road or roller testing may be carried out for various

reasons and a procedure detailing pre-test checks,

engine starting and stopping, pre-driving checks,

on-test checks and final checks to be completed

on completion of the test is given below.

Unless complete vehicle performance is being

checked, the full road test procedure need not be

carried out. Instead, those items particularly

relevant to the system(s) being checked can be

extracted.

Pre-Test Checks

WARNING: If the brake system hydraulic

fluid level is low, pedal travel is excessive

or a hydraulic leak is found, do not attempt

to road test the vehicle until the reason for

the low fluid level, excessive pedal travel

or hydraulic leak is found and rectified.

It is suggested that pre-test checks and functional

tests of those systems and circuits which affect the

safe and legal operations of the vehicle, such as

brakes, lights and steering, should always be

carried out before the road or roller test.

With the ignition switched off, check:

– the engine oil level.

– the engine coolant level.

– the tires, for correct pressure, compatible types and tread patterns, and wear within limits.

– that there is sufficient fuel in the tank to complete the test.

– all around the engine, transmission and under the vehicle for oil, coolant, hydraulic and fuel

leaks. Make a note of any apparent leaks and

wipe off the surrounding areas to make it easier

to identify the extent of the leak on completion

of the test.

Starting the Engine

NOTE: On initial drive away from cold and within

the first 1.5 km (1 mile), do not depress the

accelerator pedal beyond half travel until the

vehicle has attained a minimum speed of 25 km/h

(15 miles/h). Never operate at high engine speed

or with the accelerator pedal at full travel whilst the

engine is cold.

With the ignition switched off, check: – that the parking brake is applied.

– that the gear lever is in the neutral position.

– that all instrument gauges (except fuel gauge)

read zero.

With the ignition switched on, check:

– that the ignition controlled warning lamps are illuminated.

– that the engine temperature gauge registers a reading compatible with the engine temperature.

– that the fuel gauge registers a reading appropriate to the fuel level in the tank.

– the operation of the parking brake warning lamp and fluid level warning indicator.

Road or Roller Testing

CAUTION: If road testing, check the brake

operation while still traveling at low speed

before continuing with the test. If the

brakes pull to one side, or appear to be

otherwise faulty, do not continue with the

road test until the fault has been found and

rectified.

During the road or roller test, check:

– that the clutch pedal operation is not stiff or heavy.

– that the initial gear engagement is smooth and there is no evidence of clutch drag.

– that the parking brake control operates smoothly and releases quickly and completely.

– that the clutch takes up the drive smoothly, without slip or judder.

– that gear changing is smooth with no abnormal noises or vibrations from the transmission.

– the engine power output is satisfactory, full power is achieved, acceleration is smooth and

pedal operation is not stiff or heavy, and engine

speed returns to idle correctly.

– there is no excessive or abnormally colored smoke from the engine under normal driving,

heavy load or overrun conditions.

– that steering operation, including power steering (if equipped), is smooth, accurate, not

excessively heavy or with excessive free play

or vibration.

– that the steering does not pull to one side and self centers smoothly after cornering.

G17375en2008.50 Kuga8/2011

100-00- 58

General Information

100-00- 58

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 80 of 2057

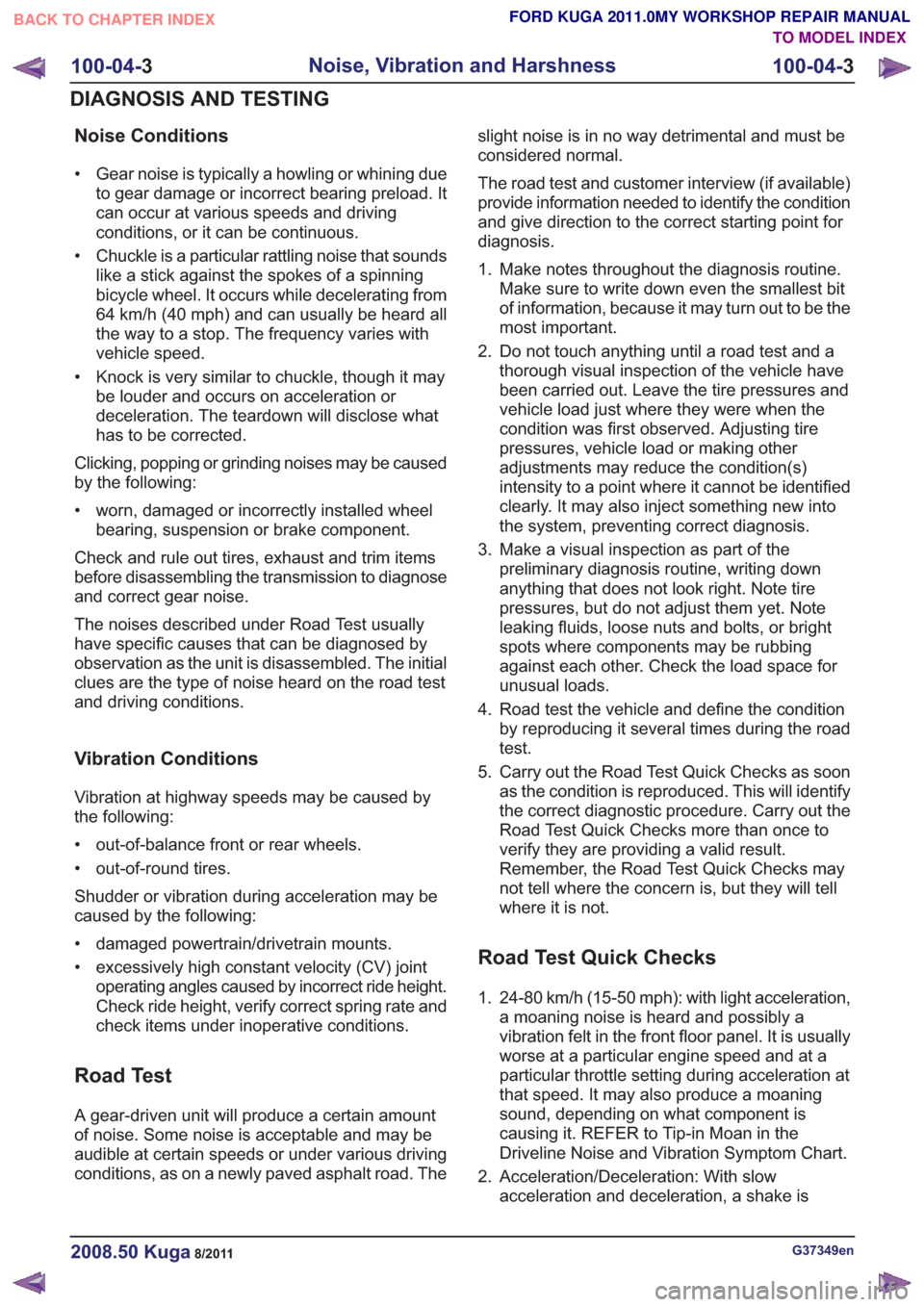

Noise Conditions

• Gear noise is typically a howling or whining dueto gear damage or incorrect bearing preload. It

can occur at various speeds and driving

conditions, or it can be continuous.

• Chuckle is a particular rattling noise that sounds like a stick against the spokes of a spinning

bicycle wheel. It occurs while decelerating from

64 km/h (40 mph) and can usually be heard all

the way to a stop. The frequency varies with

vehicle speed.

• Knock is very similar to chuckle, though it may be louder and occurs on acceleration or

deceleration. The teardown will disclose what

has to be corrected.

Clicking, popping or grinding noises may be caused

by the following:

• worn, damaged or incorrectly installed wheel bearing, suspension or brake component.

Check and rule out tires, exhaust and trim items

before disassembling the transmission to diagnose

and correct gear noise.

The noises described under Road Test usually

have specific causes that can be diagnosed by

observation as the unit is disassembled. The initial

clues are the type of noise heard on the road test

and driving conditions.

Vibration Conditions

Vibration at highway speeds may be caused by

the following:

• out-of-balance front or rear wheels.

• out-of-round tires.

Shudder or vibration during acceleration may be

caused by the following:

• damaged powertrain/drivetrain mounts.

• excessively high constant velocity (CV) joint operating angles caused by incorrect ride height.

Check ride height, verify correct spring rate and

check items under inoperative conditions.

Road Test

A gear-driven unit will produce a certain amount

of noise. Some noise is acceptable and may be

audible at certain speeds or under various driving

conditions, as on a newly paved asphalt road. The slight noise is in no way detrimental and must be

considered normal.

The road test and customer interview (if available)

provide information needed to identify the condition

and give direction to the correct starting point for

diagnosis.

1. Make notes throughout the diagnosis routine.

Make sure to write down even the smallest bit

of information, because it may turn out to be the

most important.

2. Do not touch anything until a road test and a thorough visual inspection of the vehicle have

been carried out. Leave the tire pressures and

vehicle load just where they were when the

condition was first observed. Adjusting tire

pressures, vehicle load or making other

adjustments may reduce the condition(s)

intensity to a point where it cannot be identified

clearly. It may also inject something new into

the system, preventing correct diagnosis.

3. Make a visual inspection as part of the preliminary diagnosis routine, writing down

anything that does not look right. Note tire

pressures, but do not adjust them yet. Note

leaking fluids, loose nuts and bolts, or bright

spots where components may be rubbing

against each other. Check the load space for

unusual loads.

4. Road test the vehicle and define the condition by reproducing it several times during the road

test.

5. Carry out the Road Test Quick Checks as soon as the condition is reproduced. This will identify

the correct diagnostic procedure. Carry out the

Road Test Quick Checks more than once to

verify they are providing a valid result.

Remember, the Road Test Quick Checks may

not tell where the concern is, but they will tell

where it is not.

Road Test Quick Checks

1. 24-80 km/h (15-50 mph): with light acceleration,a moaning noise is heard and possibly a

vibration felt in the front floor panel. It is usually

worse at a particular engine speed and at a

particular throttle setting during acceleration at

that speed. It may also produce a moaning

sound, depending on what component is

causing it. REFER to Tip-in Moan in the

Driveline Noise and Vibration Symptom Chart.

2. Acceleration/Deceleration: With slow acceleration and deceleration, a shake is

G37349en2008.50 Kuga8/2011

100-04- 3

Noise, Vibration and Harshness

100-04- 3

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 82 of 2057

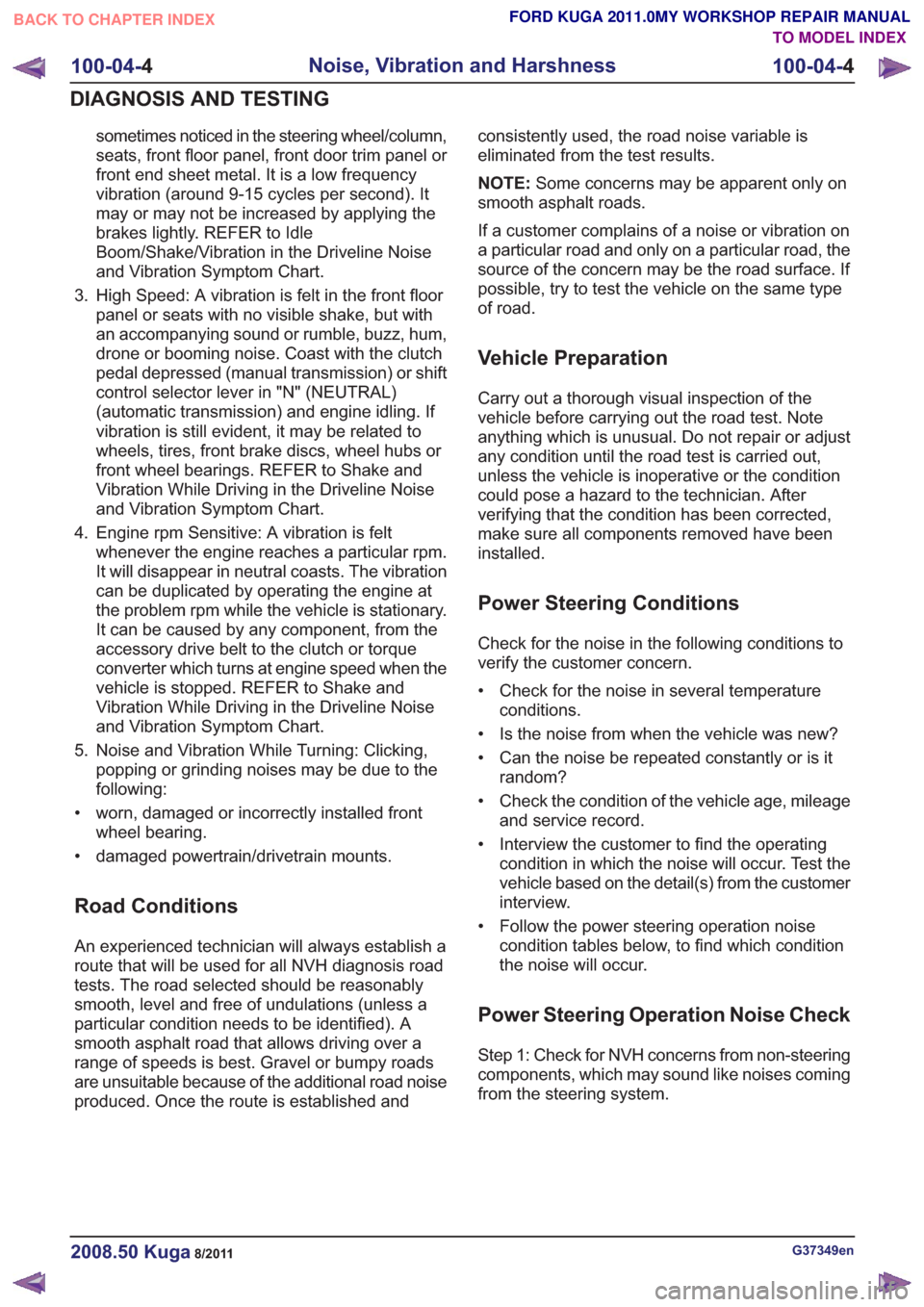

sometimes noticed in the steering wheel/column,

seats, front floor panel, front door trim panel or

front end sheet metal. It is a low frequency

vibration (around 9-15 cycles per second). It

may or may not be increased by applying the

brakes lightly. REFER to Idle

Boom/Shake/Vibration in the Driveline Noise

and Vibration Symptom Chart.

3. High Speed: A vibration is felt in the front floor panel or seats with no visible shake, but with

an accompanying sound or rumble, buzz, hum,

drone or booming noise. Coast with the clutch

pedal depressed (manual transmission) or shift

control selector lever in "N" (NEUTRAL)

(automatic transmission) and engine idling. If

vibration is still evident, it may be related to

wheels, tires, front brake discs, wheel hubs or

front wheel bearings. REFER to Shake and

Vibration While Driving in the Driveline Noise

and Vibration Symptom Chart.

4. Engine rpm Sensitive: A vibration is felt whenever the engine reaches a particular rpm.

It will disappear in neutral coasts. The vibration

can be duplicated by operating the engine at

the problem rpm while the vehicle is stationary.

It can be caused by any component, from the

accessory drive belt to the clutch or torque

converter which turns at engine speed when the

vehicle is stopped. REFER to Shake and

Vibration While Driving in the Driveline Noise

and Vibration Symptom Chart.

5. Noise and Vibration While Turning: Clicking, popping or grinding noises may be due to the

following:

• worn, damaged or incorrectly installed front wheel bearing.

• damaged powertrain/drivetrain mounts.

Road Conditions

An experienced technician will always establish a

route that will be used for all NVH diagnosis road

tests. The road selected should be reasonably

smooth, level and free of undulations (unless a

particular condition needs to be identified). A

smooth asphalt road that allows driving over a

range of speeds is best. Gravel or bumpy roads

are unsuitable because of the additional road noise

produced. Once the route is established and consistently used, the road noise variable is

eliminated from the test results.

NOTE:

Some concerns may be apparent only on

smooth asphalt roads.

If a customer complains of a noise or vibration on

a particular road and only on a particular road, the

source of the concern may be the road surface. If

possible, try to test the vehicle on the same type

of road.

Vehicle Preparation

Carry out a thorough visual inspection of the

vehicle before carrying out the road test. Note

anything which is unusual. Do not repair or adjust

any condition until the road test is carried out,

unless the vehicle is inoperative or the condition

could pose a hazard to the technician. After

verifying that the condition has been corrected,

make sure all components removed have been

installed.

Power Steering Conditions

Check for the noise in the following conditions to

verify the customer concern.

• Check for the noise in several temperature conditions.

• Is the noise from when the vehicle was new?

• Can the noise be repeated constantly or is it random?

• Check the condition of the vehicle age, mileage and service record.

• Interview the customer to find the operating condition in which the noise will occur. Test the

vehicle based on the detail(s) from the customer

interview.

• Follow the power steering operation noise condition tables below, to find which condition

the noise will occur.

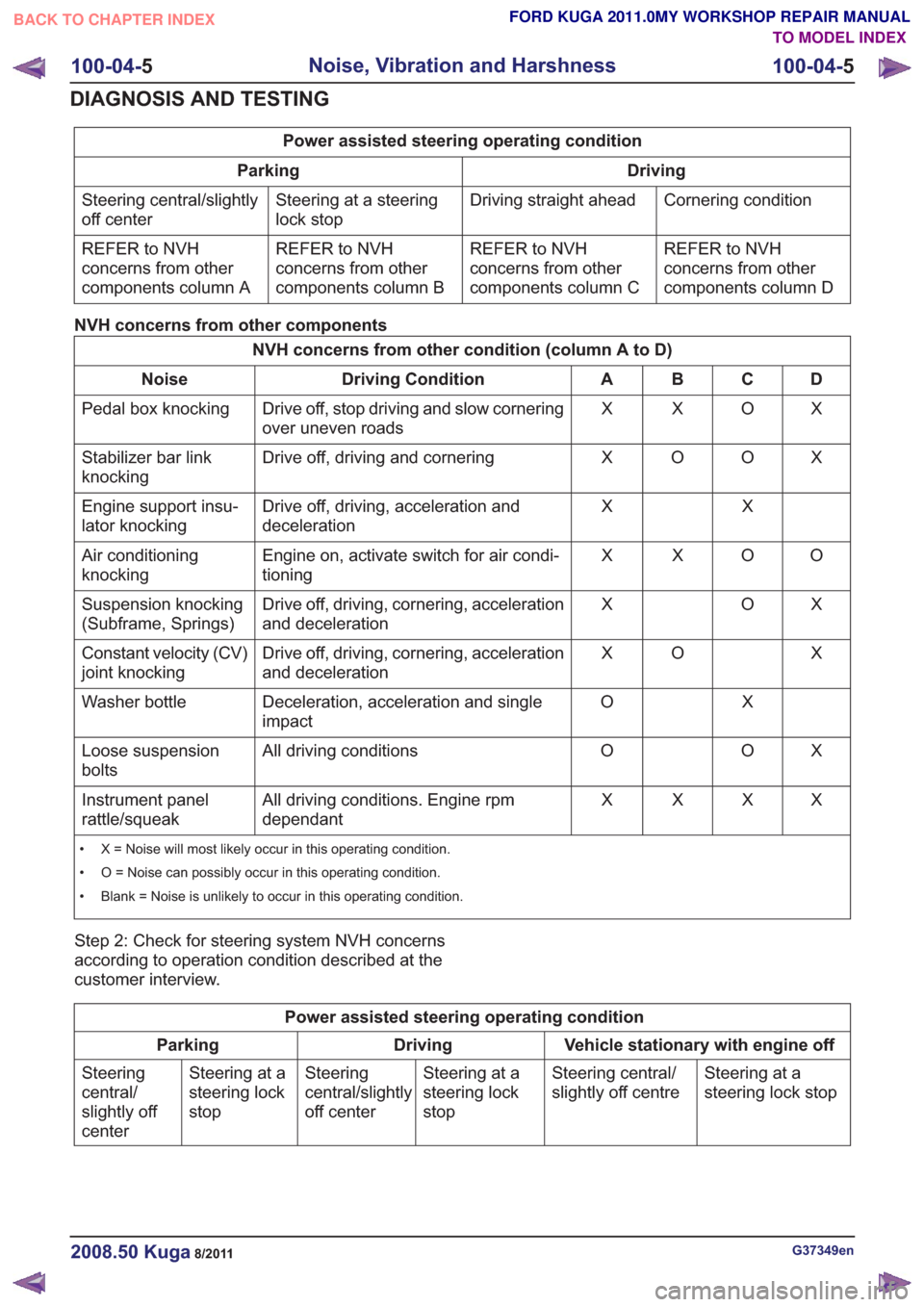

Power Steering Operation Noise Check

Step 1: Check for NVH concerns from non-steering

components, which may sound like noises coming

from the steering system.

G37349en2008.50 Kuga8/2011

100-04- 4

Noise, Vibration and Harshness

100-04- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 83 of 2057

Power assisted steering operating conditionDriving

Parking

Cornering condition

Driving straight ahead

Steering at a steering

lock stop

Steering central/slightly

off center

REFER to NVH

concerns from other

components column D

REFER to NVH

concerns from other

components column C

REFER to NVH

concerns from other

components column B

REFER to NVH

concerns from other

components column A

NVH concerns from other components

NVH concerns from other condition (column A to D) DCBA

Driving Condition

Noise

XOXX

Drive off, stop driving and slow cornering

over uneven roads

Pedal box knocking

XOOX

Drive off, driving and cornering

Stabilizer bar link

knocking

X

X

Drive off, driving, acceleration and

deceleration

Engine support insu-

lator knocking

OOXX

Engine on, activate switch for air condi-

tioning

Air conditioning

knocking

XO

X

Drive off, driving, cornering, acceleration

and deceleration

Suspension knocking

(Subframe, Springs)

X

OX

Drive off, driving, cornering, acceleration

and deceleration

Constant velocity (CV)

joint knocking

X

O

Deceleration, acceleration and single

impact

Washer bottle

XO

O

All driving conditions

Loose suspension

bolts

XXXX

All driving conditions. Engine rpm

dependant

Instrument panel

rattle/squeak

• X = Noise will most likely occur in this operating condition.

• O = Noise can possibly occur in this operating condition.

• Blank = Noise is unlikely to occur in this operating condition.

Step 2: Check for steering system NVH concerns

according to operation condition described at the

customer interview.

Power assisted steering operating condition

Vehicle stationary with engine off

Driving

Parking

Steering at a

steering lock stop

Steering central/

slightly off centre

Steering at a

steering lock

stop

Steering

central/slightly

off center

Steering at a

steering lock

stop

Steering

central/

slightly off

center

G37349en2008.50 Kuga8/2011

100-04-

5

Noise, Vibration and Harshness

100-04- 5

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 263 of 2057

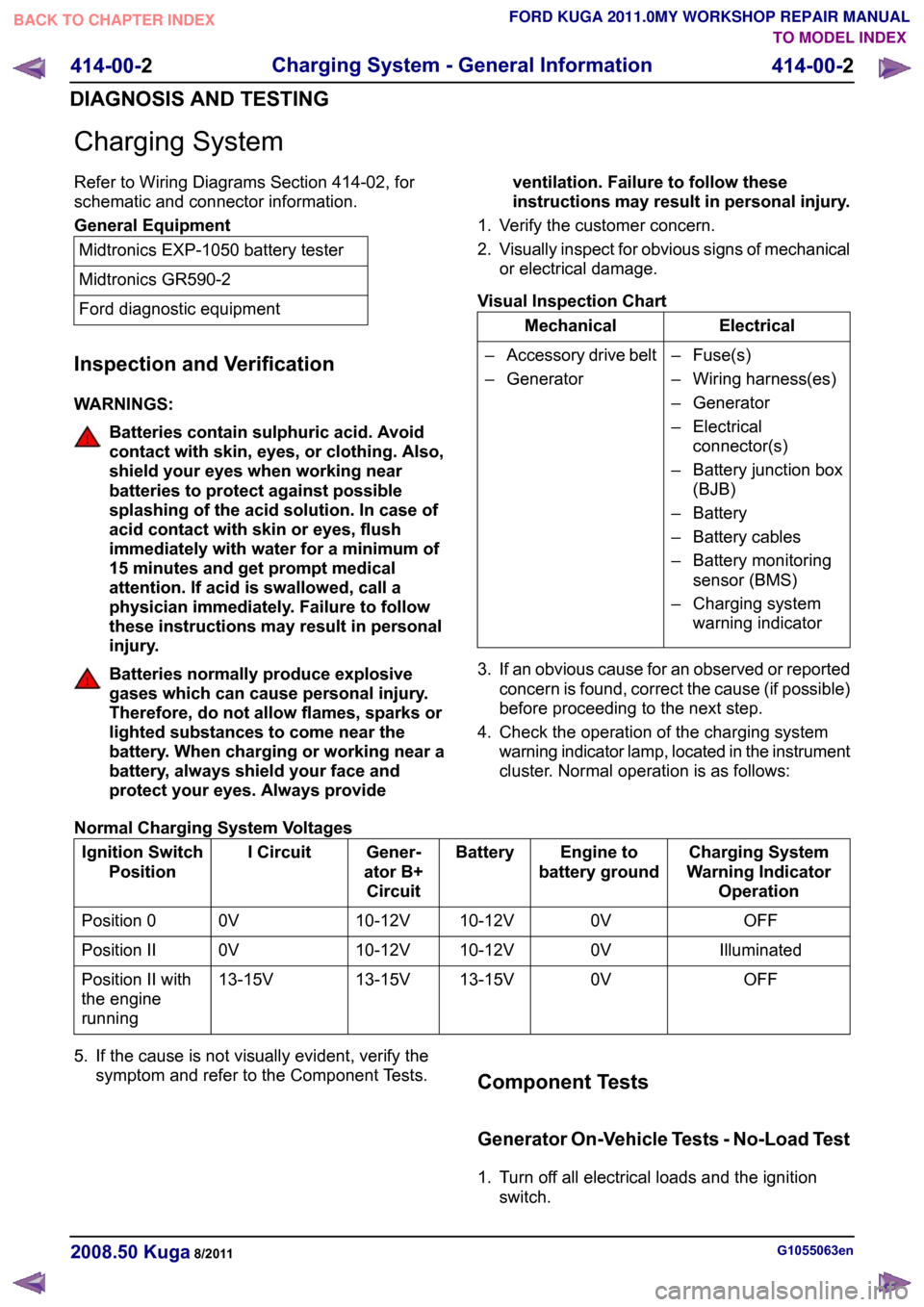

Charging System

Refer to Wiring Diagrams Section 414-02, for

schematic and connector information.

General Equipment

Midtronics EXP-1050 battery tester

Midtronics GR590-2

Ford diagnostic equipment

Inspection and Verification

WARNINGS: Batteries contain sulphuric acid. Avoid

contact with skin, eyes, or clothing. Also,

shield your eyes when working near

batteries to protect against possible

splashing of the acid solution. In case of

acid contact with skin or eyes, flush

immediately with water for a minimum of

15 minutes and get prompt medical

attention. If acid is swallowed, call a

physician immediately. Failure to follow

these instructions may result in personal

injury.

Batteries normally produce explosive

gases which can cause personal injury.

Therefore, do not allow flames, sparks or

lighted substances to come near the

battery. When charging or working near a

battery, always shield your face and

protect your eyes. Always provide

ventilation. Failure to follow these

instructions may result in personal injury.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

Visual Inspection Chart Electrical

Mechanical

– Fuse(s)

– Wiring harness(es)

– Generator

– Electricalconnector(s)

– Battery junction box (BJB)

– Battery

– Battery cables

– Battery monitoring sensor (BMS)

– Charging system warning indicator

–

Accessory drive belt

– Generator

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. Check the operation of the charging system warning indicator lamp, located in the instrument

cluster. Normal operation is as follows:

Normal Charging System Voltages Charging System

Warning Indicator Operation

Engine to

battery ground

Battery

Gener-

ator B+ Circuit

I Circuit

Ignition Switch

Position

OFF

0V

10-12V

10-12V

0V

Position 0

Illuminated

0V

10-12V

10-12V

0V

Position II

OFF

0V

13-15V

13-15V

13-15V

Position II with

the engine

running

5. If the cause is not visually evident, verify the symptom and refer to the Component Tests. Component Tests

Generator On-Vehicle Tests - No-Load Test

1. Turn off all electrical loads and the ignition

switch. G1055063en

2008.50 Kuga 8/2011 414-00-2

Charging System - General Information

414-00-2

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1344 of 2057

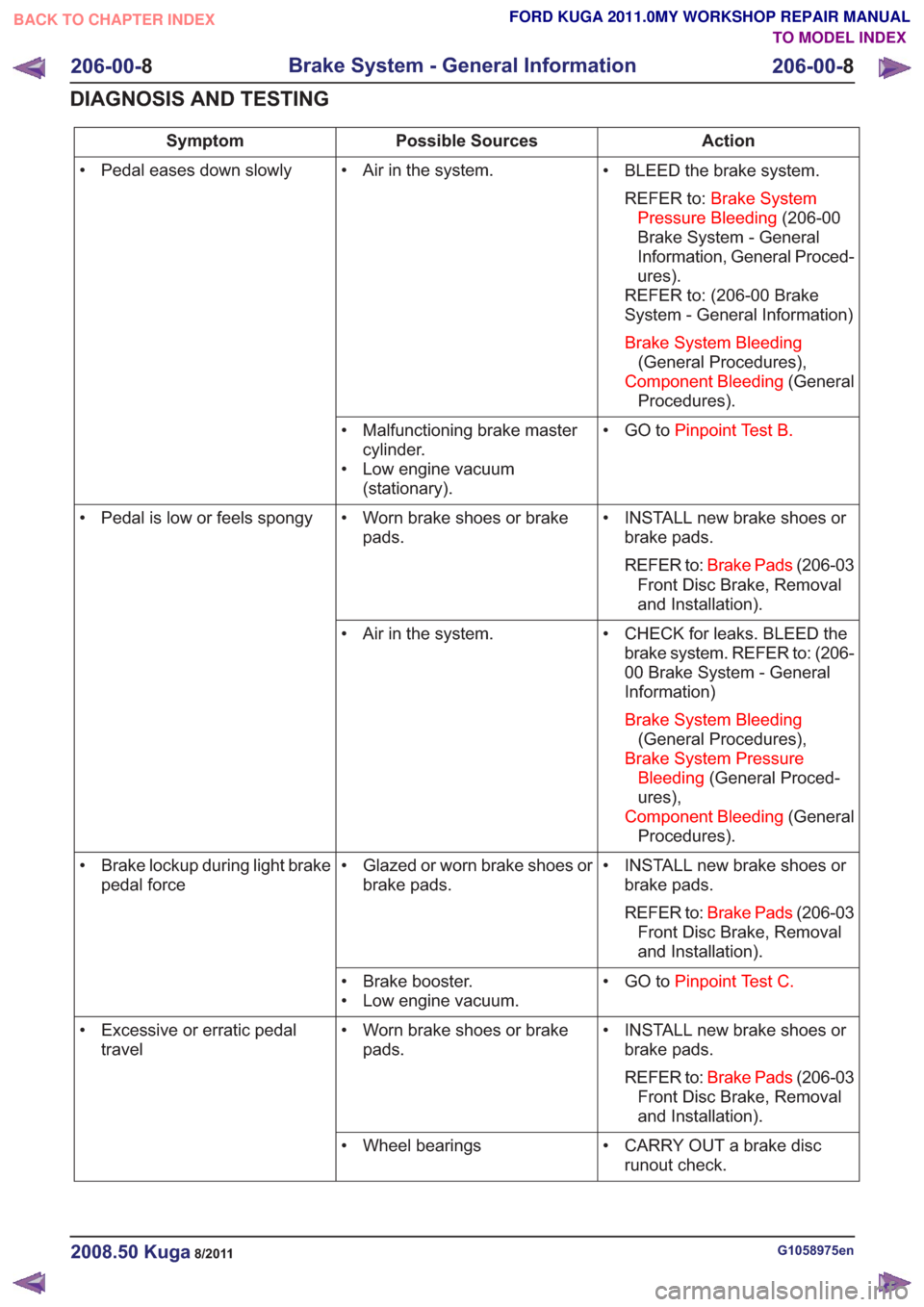

Action

Possible Sources

Symptom

• BLEED the brake system.REFER to: Brake System

Pressure Bleeding (206-00

Brake System - General

Information, General Proced-

ures).

REFER to: (206-00 Brake

System - General Information)

Brake System Bleeding (General Procedures),

Component Bleeding (General

Procedures).

• Air in the system.

• Pedal eases down slowly

• GO toPinpoint Test B.

• Malfunctioning brake master

cylinder.

• Low engine vacuum (stationary).

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Worn brake shoes or brake

pads.

• Pedal is low or feels spongy

• CHECK for leaks. BLEED thebrake system. REFER to: (206-

00 Brake System - General

Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General Proced-

ures),

Component Bleeding (General

Procedures).

• Air in the system.

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Glazed or worn brake shoes or

brake pads.

• Brake lockup during light brake

pedal force

• GO toPinpoint Test C.

• Brake booster.

• Low engine vacuum.

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Worn brake shoes or brake

pads.

• Excessive or erratic pedal

travel

• CARRY OUT a brake discrunout check.

• Wheel bearings

G1058975en2008.50 Kuga8/2011

206-00-

8

Brake System - General Information

206-00- 8

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1349 of 2057

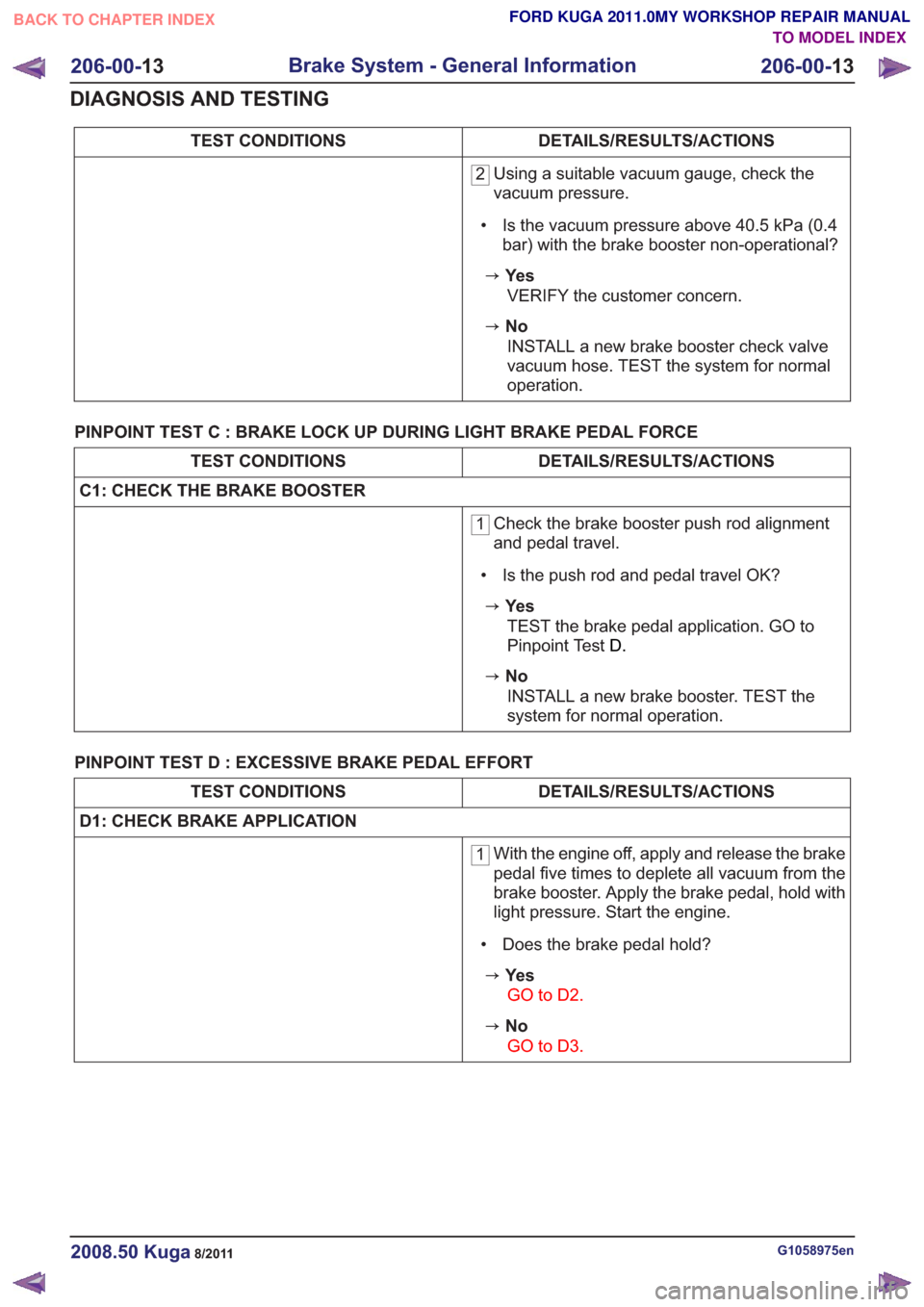

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

2 Using a suitable vacuum gauge, check the

vacuum pressure.

• Is the vacuum pressure above 40.5 kPa (0.4 bar) with the brake booster non-operational?

zYe s

VERIFY the customer concern.

zNoINSTALL a new brake booster check valve

vacuum hose. TEST the system for normal

operation.

PINPOINT TEST C : BRAKE LOCK UP DURING LIGHT BRAKE PEDAL FORCE

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

C1: CHECK THE BRAKE BOOSTER

1 Check the brake booster push rod alignment

and pedal travel.

• Is the push rod and pedal travel OK?

zYe s TEST the brake pedal application. GO to

Pinpoint Test D.

zNo

INSTALL a new brake booster. TEST the

system for normal operation.

PINPOINT TEST D : EXCESSIVE BRAKE PEDAL EFFORT

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

D1: CHECK BRAKE APPLICATION

1 With the engine off, apply and release the brake

pedal five times to deplete all vacuum from the

brake booster. Apply the brake pedal, hold with

light pressure. Start the engine.

• Does the brake pedal hold?

zYe s GO to D2 .

zNo

GO to D3 .

G1058975en2008.50 Kuga8/2011

206-00-13

Brake System - General Information

206-00- 13

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

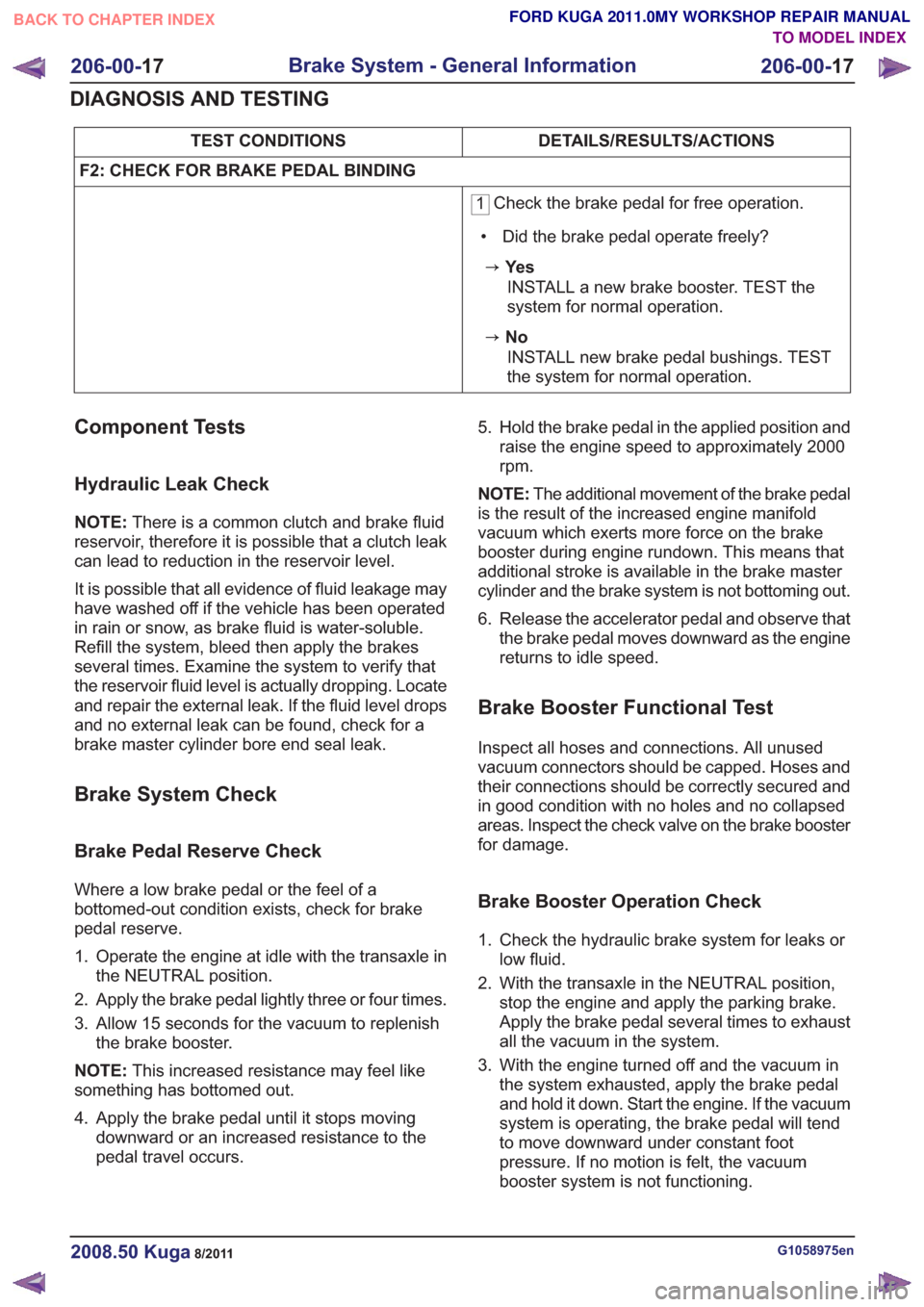

Page 1353 of 2057

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

F2: CHECK FOR BRAKE PEDAL BINDING

1 Check the brake pedal for free operation.

• Did the brake pedal operate freely?

zYe s INSTALL a new brake booster. TEST the

system for normal operation.

zNoINSTALL new brake pedal bushings. TEST

the system for normal operation.

Component Tests

Hydraulic Leak Check

NOTE: There is a common clutch and brake fluid

reservoir, therefore it is possible that a clutch leak

can lead to reduction in the reservoir level.

It is possible that all evidence of fluid leakage may

have washed off if the vehicle has been operated

in rain or snow, as brake fluid is water-soluble.

Refill the system, bleed then apply the brakes

several times. Examine the system to verify that

the reservoir fluid level is actually dropping. Locate

and repair the external leak. If the fluid level drops

and no external leak can be found, check for a

brake master cylinder bore end seal leak.

Brake System Check

Brake Pedal Reserve Check

Where a low brake pedal or the feel of a

bottomed-out condition exists, check for brake

pedal reserve.

1. Operate the engine at idle with the transaxle in the NEUTRAL position.

2. Apply the brake pedal lightly three or four times.

3. Allow 15 seconds for the vacuum to replenish the brake booster.

NOTE: This increased resistance may feel like

something has bottomed out.

4. Apply the brake pedal until it stops moving downward or an increased resistance to the

pedal travel occurs. 5. Hold the brake pedal in the applied position and

raise the engine speed to approximately 2000

rpm.

NOTE: The additional movement of the brake pedal

is the result of the increased engine manifold

vacuum which exerts more force on the brake

booster during engine rundown. This means that

additional stroke is available in the brake master

cylinder and the brake system is not bottoming out.

6. Release the accelerator pedal and observe that the brake pedal moves downward as the engine

returns to idle speed.

Brake Booster Functional Test

Inspect all hoses and connections. All unused

vacuum connectors should be capped. Hoses and

their connections should be correctly secured and

in good condition with no holes and no collapsed

areas. Inspect the check valve on the brake booster

for damage.

Brake Booster Operation Check

1. Check the hydraulic brake system for leaks orlow fluid.

2. With the transaxle in the NEUTRAL position, stop the engine and apply the parking brake.

Apply the brake pedal several times to exhaust

all the vacuum in the system.

3. With the engine turned off and the vacuum in the system exhausted, apply the brake pedal

and hold it down. Start the engine. If the vacuum

system is operating, the brake pedal will tend

to move downward under constant foot

pressure. If no motion is felt, the vacuum

booster system is not functioning.

G1058975en2008.50 Kuga8/2011

206-00- 17

Brake System - General Information

206-00- 17

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

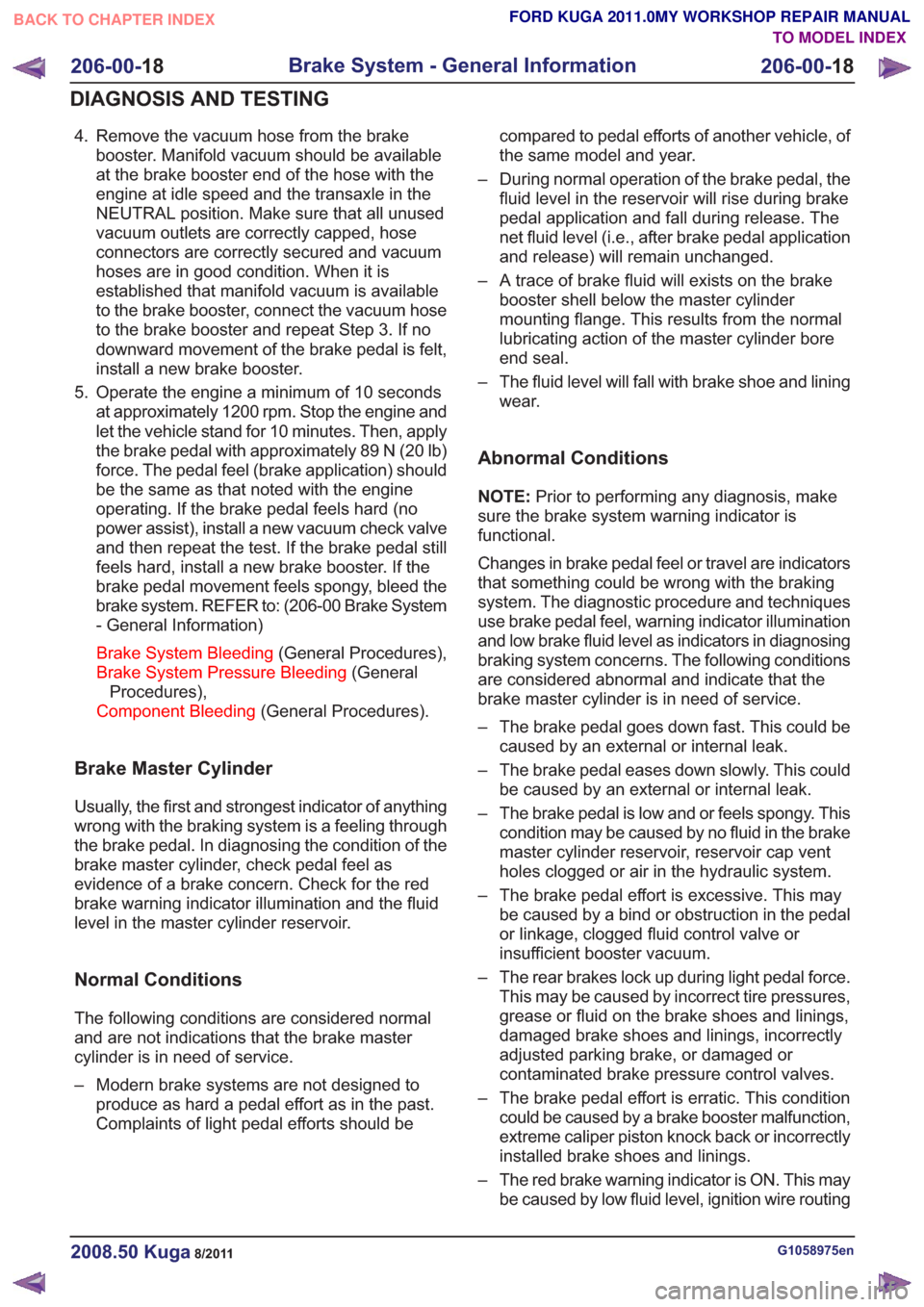

Page 1354 of 2057

4. Remove the vacuum hose from the brakebooster. Manifold vacuum should be available

at the brake booster end of the hose with the

engine at idle speed and the transaxle in the

NEUTRAL position. Make sure that all unused

vacuum outlets are correctly capped, hose

connectors are correctly secured and vacuum

hoses are in good condition. When it is

established that manifold vacuum is available

to the brake booster, connect the vacuum hose

to the brake booster and repeat Step 3. If no

downward movement of the brake pedal is felt,

install a new brake booster.

5. Operate the engine a minimum of 10 seconds at approximately 1200 rpm. Stop the engine and

let the vehicle stand for 10 minutes. Then, apply

the brake pedal with approximately 89 N (20 lb)

force. The pedal feel (brake application) should

be the same as that noted with the engine

operating. If the brake pedal feels hard (no

power assist), install a new vacuum check valve

and then repeat the test. If the brake pedal still

feels hard, install a new brake booster. If the

brake pedal movement feels spongy, bleed the

brake system. REFER to: (206-00 Brake System

- General Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General

Procedures),

Component Bleeding (General Procedures).

Brake Master Cylinder

Usually, the first and strongest indicator of anything

wrong with the braking system is a feeling through

the brake pedal. In diagnosing the condition of the

brake master cylinder, check pedal feel as

evidence of a brake concern. Check for the red

brake warning indicator illumination and the fluid

level in the master cylinder reservoir.

Normal Conditions

The following conditions are considered normal

and are not indications that the brake master

cylinder is in need of service.

– Modern brake systems are not designed to

produce as hard a pedal effort as in the past.

Complaints of light pedal efforts should be compared to pedal efforts of another vehicle, of

the same model and year.

– During normal operation of the brake pedal, the fluid level in the reservoir will rise during brake

pedal application and fall during release. The

net fluid level (i.e., after brake pedal application

and release) will remain unchanged.

– A trace of brake fluid will exists on the brake booster shell below the master cylinder

mounting flange. This results from the normal

lubricating action of the master cylinder bore

end seal.

– The fluid level will fall with brake shoe and lining wear.

Abnormal Conditions

NOTE: Prior to performing any diagnosis, make

sure the brake system warning indicator is

functional.

Changes in brake pedal feel or travel are indicators

that something could be wrong with the braking

system. The diagnostic procedure and techniques

use brake pedal feel, warning indicator illumination

and low brake fluid level as indicators in diagnosing

braking system concerns. The following conditions

are considered abnormal and indicate that the

brake master cylinder is in need of service.

– The brake pedal goes down fast. This could be caused by an external or internal leak.

– The brake pedal eases down slowly. This could be caused by an external or internal leak.

– The brake pedal is low and or feels spongy. This condition may be caused by no fluid in the brake

master cylinder reservoir, reservoir cap vent

holes clogged or air in the hydraulic system.

– The brake pedal effort is excessive. This may be caused by a bind or obstruction in the pedal

or linkage, clogged fluid control valve or

insufficient booster vacuum.

– The rear brakes lock up during light pedal force. This may be caused by incorrect tire pressures,

grease or fluid on the brake shoes and linings,

damaged brake shoes and linings, incorrectly

adjusted parking brake, or damaged or

contaminated brake pressure control valves.

– The brake pedal effort is erratic. This condition could be caused by a brake booster malfunction,

extreme caliper piston knock back or incorrectly

installed brake shoes and linings.

– The red brake warning indicator is ON. This may be caused by low fluid level, ignition wire routing

G1058975en2008.50 Kuga8/2011

206-00- 18

Brake System - General Information

206-00- 18

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1429 of 2057

HCU to check for sudden actuation of the brakes.

With the brake pedal pressed, the ABS module

triggers emergency braking if the rate of increase

of hydraulic pressure exceeds the predetermined

limit.

If the brake pedal is pressed so hard that the ABS

becomes active on the front wheels then the ABS

control unit increases the pressure to the rear

wheel brakes up to the ABS intervention threshold.

EBA operation continues until the driver releases

the brake pedal sufficiently for the hydraulic

pressure in the HCU to drop below a threshold

value stored in the ABS module.

Trailer stability control:If the vehicle is ordered

with a trailer coupling then the Trailer Stability

Control function is integrated in the ESP. The ESP

detects snaking when driving with a trailer and

reduces the speed of the vehicle and trailer through

adapted braking and, if necessary, by also reducing

the engine output until the snaking movement of

the trailer is corrected.

Roll-over protection: The ESP dynamically

determines the tipping tendency of the vehicle and

works in conjunction with the EBA system to

prevent the vehicle from tipping over during

dynamic maneuvers like lane changing or while

negotiating bends.

Emergency brake light: The emergency brake

light automatically switches on the hazard flasher

system to warn drivers of other vehicles that

emergency braking is being initiated. Based on a

defined delay value, the ABS/ESP module sends

a signal to the generic electronic module (GEM)

via the CAN data bus. The GEM activates the

hazard flasher system, that then flashes 7 times.

Prerequisites for activation of the emergency brake

light are:

• The speed is higher than 50 km/h.

• The brake pedal is being actuated.

• The deceleration is greater than 9 m/s².

To prevent activation on snow or ice, for example,

the following prerequisites must be met:

• The speed is higher than 50 km/h.

• The brake pedal is being actuated.

• ABS regulation takes place.

• The deceleration is greater than 6 m/s².

Tire pressure monitoring system: The tire

pressure monitoring system used in the Kuga is

able to detect loss of air in a tire at an early stage

and warn the driver. Because it can only compare

the behaviour of the tyres with each other, it is not possible to draw conclusions about the absolute

tyre pressure. It is also not possible to monitor the

spare tyre pressure. In order for the system to

operate correctly, the tyre pressures must be

regularly checked and corrected and the system

subsequently initialised (see below).

The tire pressure monitoring system used here,

depending on the equipment level, is built into the

anti-lock braking system (ABS) as an extra function

and therefore does not have its own sensors.

The ABS module measures the loss of pressure

in the tyres by calculation using the wheel speed

sensors of the ABS system. If a tyre loses

pressure, its diameter decreases and the speed of

the wheel therefore increases. If the ABS module

detects such a loss in pressure, it sends a signal

to the instrument cluster via the CAN bus and a

warning message is displayed in the message

centre. The warning threshold depends among

other things on the dimension of the tyres being

used, the vehicle operating conditions and the

status at the last initialisation. Since neither the

absolute tyre pressure nor the position of the tyre

is known, the pressure of all the tyres must be

checked and the system re-initialised after a tyre

pressure warning. If necessary, the cause of the

loss of pressure must be investigated.

Regular tyre pressure checks are still necessary.

The system must be initialised after a tyre is

changed, winter or summer tyres fitted, the

pressures corrected or adjusted to suit the vehicle

load. This can be done by the driver using the

driver information system. For further information,

see: Owner’s Manual.

Component Description

Opto-electronic steering wheel rotation

sensor

E80158

G1001304en2008.50 Kuga8/2011

206-09B-

11

Anti-Lock Control - Stability Assist

206-09B- 11

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL