tyre pressure FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1229 of 2057

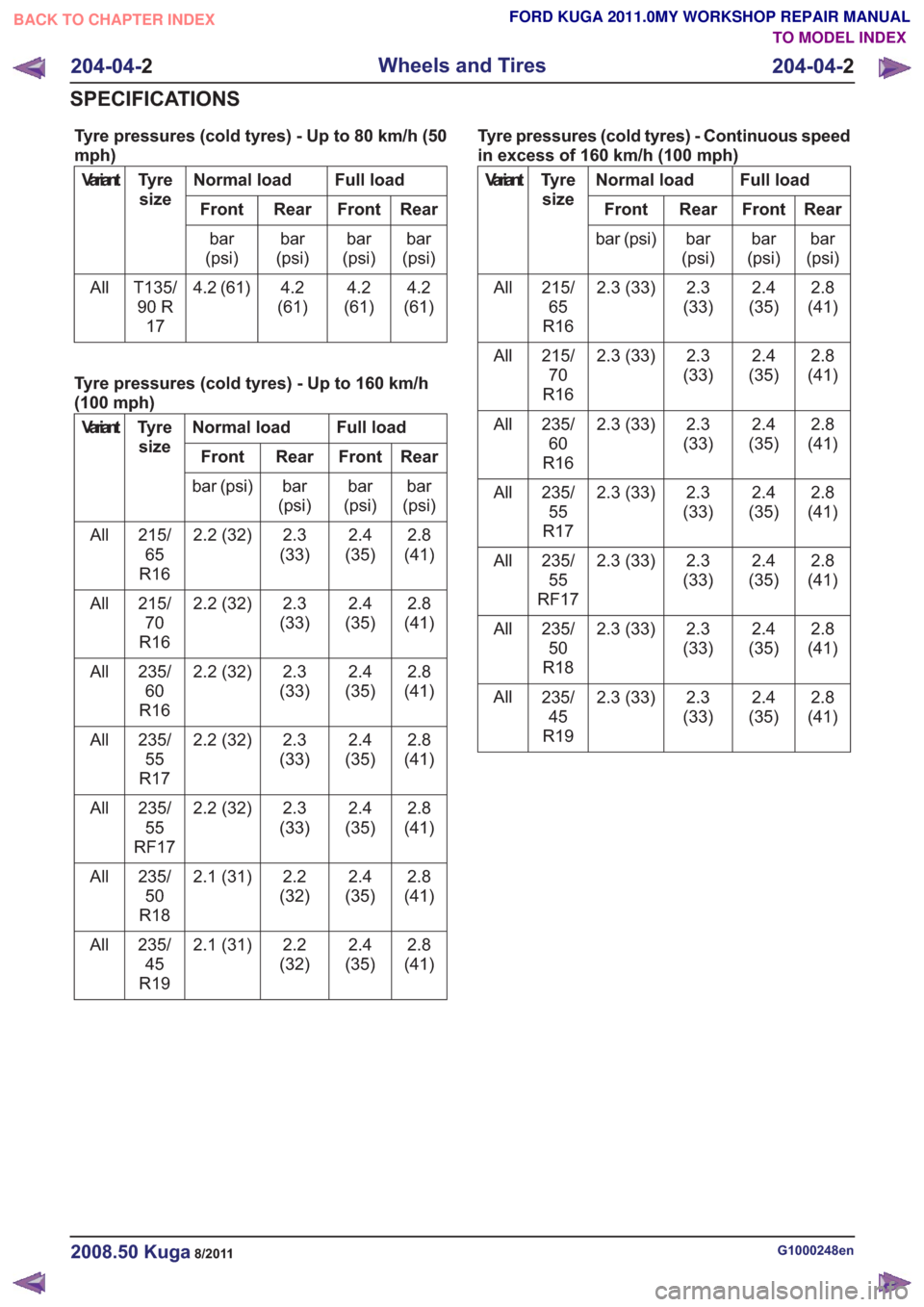

Tyre pressures (cold tyres) - Up to 80 km/h (50

mph)

Full load

Normal load

Tyre

size

Variant

Rear

Front

Rear

Front

bar

(psi)

bar

(psi)

bar

(psi)

bar

(psi)

4.2

(61)

4.2

(61)

4.2

(61)

4.2 (61)

T135/

90 R 17

All

Tyre pressures (cold tyres) - Up to 160 km/h

(100 mph)

Full load

Normal load

Tyre

size

Variant

Rear

Front

Rear

Front

bar

(psi)

bar

(psi)

bar

(psi)

bar (psi)

2.8

(41)

2.4

(35)

2.3

(33)

2.2 (32)

215/

65

R16

All

2.8

(41)

2.4

(35)

2.3

(33)

2.2 (32)

215/

70

R16

All

2.8

(41)

2.4

(35)

2.3

(33)

2.2 (32)

235/

60

R16

All

2.8

(41)

2.4

(35)

2.3

(33)

2.2 (32)

235/

55

R17

All

2.8

(41)

2.4

(35)

2.3

(33)

2.2 (32)

235/

55

RF17

All

2.8

(41)

2.4

(35)

2.2

(32)

2.1 (31)

235/

50

R18

All

2.8

(41)

2.4

(35)

2.2

(32)

2.1 (31)

235/

45

R19

All Tyre pressures (cold tyres) - Continuous speed

in excess of 160 km/h (100 mph)

Full load

Normal load

Tyre

size

Variant

Rear

Front

Rear

Front

bar

(psi)

bar

(psi)

bar

(psi)

bar (psi)

2.8

(41)

2.4

(35)

2.3

(33)

2.3 (33)

215/

65

R16

All

2.8

(41)

2.4

(35)

2.3

(33)

2.3 (33)

215/

70

R16

All

2.8

(41)

2.4

(35)

2.3

(33)

2.3 (33)

235/

60

R16

All

2.8

(41)

2.4

(35)

2.3

(33)

2.3 (33)

235/

55

R17

All

2.8

(41)

2.4

(35)

2.3

(33)

2.3 (33)

235/

55

RF17

All

2.8

(41)

2.4

(35)

2.3

(33)

2.3 (33)

235/

50

R18

All

2.8

(41)

2.4

(35)

2.3

(33)

2.3 (33)

235/

45

R19

All

G1000248en2008.50 Kuga8/2011

204-04-

2

Wheels and Tires

204-04- 2

SPECIFICATIONS

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1252 of 2057

General overview

Haldex clutches of the 3rd and 4th generations are

used in the Ford Kuga.

The development of the third generation Haldex

clutch represents a big step forward in modern

all-wheel technology. The Haldex clutch is

electro-hydraulically controlled. Additional

information is taken into consideration during

control tasks via the all-wheel drive control unit.

Slip alone is no longer decisive for the distribution

of the propulsive forces; the vehicle's driving

dynamics are also taken into consideration. The

control unit accesses the driving-related data via

the data bus. With this data, the control unit has

all the essential information about speed, cornering,

coasting or traction operation, and can optimally

react to every driving situation.

Compared with the previous generation, the 4th

generation Haldex clutches operate with higher

pressure and achieve shorter response times when

distributing the drive forces.

Advantages of the Haldex clutch:

• Permanent all-wheel drive withelectronically-controlled multi-plate clutch

• Fast response

• No straining when parking and manoeuvring

• Compatible with different tyres (e.g. emergency spare wheel)

• Fully combinable with driving dynamic control systems

The driveshaft is connected to the input shaft of

the Haldex clutch. Within the Haldex clutch, the

input shaft is separated from the output shaft to

the rear axle differential by means of a multi-plate

clutch. Torque is only transmitted to the rear axle

differential when the plate assembly of the Haldex

clutch is closed.

The multi-plate clutch is electro-hydraulically

controlled via the all-wheel drive control unit. For

ecological driving, the torque to the rear axle is reduced to a minimum up to a throttle position of

approx. 50%. A prerequisite for this is that there is

no difference in speed in the Haldex clutch between

the input and output shafts.

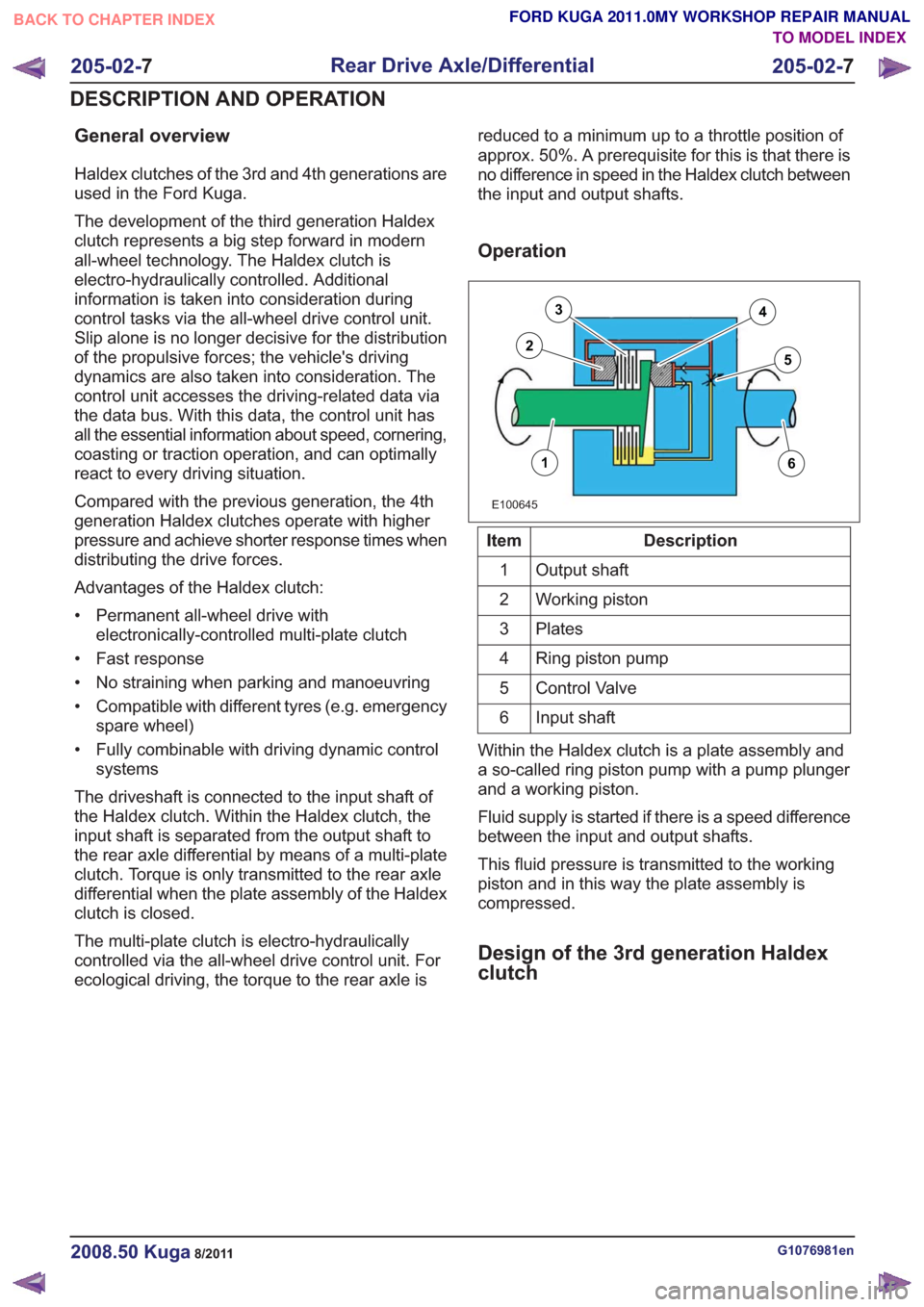

Operation

E100645

16

3

25

4

Description

Item

Output shaft

1

Working piston

2

Plates

3

Ring piston pump

4

Control Valve

5

Input shaft

6

Within the Haldex clutch is a plate assembly and

a so-called ring piston pump with a pump plunger

and a working piston.

Fluid supply is started if there is a speed difference

between the input and output shafts.

This fluid pressure is transmitted to the working

piston and in this way the plate assembly is

compressed.

Design of the 3rd generation Haldex

clutch

G1076981en2008.50 Kuga8/2011

205-02- 7

Rear Drive Axle/Differential

205-02- 7

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1429 of 2057

HCU to check for sudden actuation of the brakes.

With the brake pedal pressed, the ABS module

triggers emergency braking if the rate of increase

of hydraulic pressure exceeds the predetermined

limit.

If the brake pedal is pressed so hard that the ABS

becomes active on the front wheels then the ABS

control unit increases the pressure to the rear

wheel brakes up to the ABS intervention threshold.

EBA operation continues until the driver releases

the brake pedal sufficiently for the hydraulic

pressure in the HCU to drop below a threshold

value stored in the ABS module.

Trailer stability control:If the vehicle is ordered

with a trailer coupling then the Trailer Stability

Control function is integrated in the ESP. The ESP

detects snaking when driving with a trailer and

reduces the speed of the vehicle and trailer through

adapted braking and, if necessary, by also reducing

the engine output until the snaking movement of

the trailer is corrected.

Roll-over protection: The ESP dynamically

determines the tipping tendency of the vehicle and

works in conjunction with the EBA system to

prevent the vehicle from tipping over during

dynamic maneuvers like lane changing or while

negotiating bends.

Emergency brake light: The emergency brake

light automatically switches on the hazard flasher

system to warn drivers of other vehicles that

emergency braking is being initiated. Based on a

defined delay value, the ABS/ESP module sends

a signal to the generic electronic module (GEM)

via the CAN data bus. The GEM activates the

hazard flasher system, that then flashes 7 times.

Prerequisites for activation of the emergency brake

light are:

• The speed is higher than 50 km/h.

• The brake pedal is being actuated.

• The deceleration is greater than 9 m/s².

To prevent activation on snow or ice, for example,

the following prerequisites must be met:

• The speed is higher than 50 km/h.

• The brake pedal is being actuated.

• ABS regulation takes place.

• The deceleration is greater than 6 m/s².

Tire pressure monitoring system: The tire

pressure monitoring system used in the Kuga is

able to detect loss of air in a tire at an early stage

and warn the driver. Because it can only compare

the behaviour of the tyres with each other, it is not possible to draw conclusions about the absolute

tyre pressure. It is also not possible to monitor the

spare tyre pressure. In order for the system to

operate correctly, the tyre pressures must be

regularly checked and corrected and the system

subsequently initialised (see below).

The tire pressure monitoring system used here,

depending on the equipment level, is built into the

anti-lock braking system (ABS) as an extra function

and therefore does not have its own sensors.

The ABS module measures the loss of pressure

in the tyres by calculation using the wheel speed

sensors of the ABS system. If a tyre loses

pressure, its diameter decreases and the speed of

the wheel therefore increases. If the ABS module

detects such a loss in pressure, it sends a signal

to the instrument cluster via the CAN bus and a

warning message is displayed in the message

centre. The warning threshold depends among

other things on the dimension of the tyres being

used, the vehicle operating conditions and the

status at the last initialisation. Since neither the

absolute tyre pressure nor the position of the tyre

is known, the pressure of all the tyres must be

checked and the system re-initialised after a tyre

pressure warning. If necessary, the cause of the

loss of pressure must be investigated.

Regular tyre pressure checks are still necessary.

The system must be initialised after a tyre is

changed, winter or summer tyres fitted, the

pressures corrected or adjusted to suit the vehicle

load. This can be done by the driver using the

driver information system. For further information,

see: Owner’s Manual.

Component Description

Opto-electronic steering wheel rotation

sensor

E80158

G1001304en2008.50 Kuga8/2011

206-09B-

11

Anti-Lock Control - Stability Assist

206-09B- 11

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL