check engine light FORD MONDEO 1993 Service User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 32 of 279

of these components will cause loss of

lubricant, together with dirt and water entry,

resulting in rapid deterioration of the balljoints

or steering gear.

3Check the power-assisted steering fluid

hoses for chafing or deterioration, and the

pipe and hose unions for fluid leaks. Also

check for signs of fluid leakage under

pressure from the steering gear rubber

gaiters, which would indicate failed fluid seals

within the steering gear.

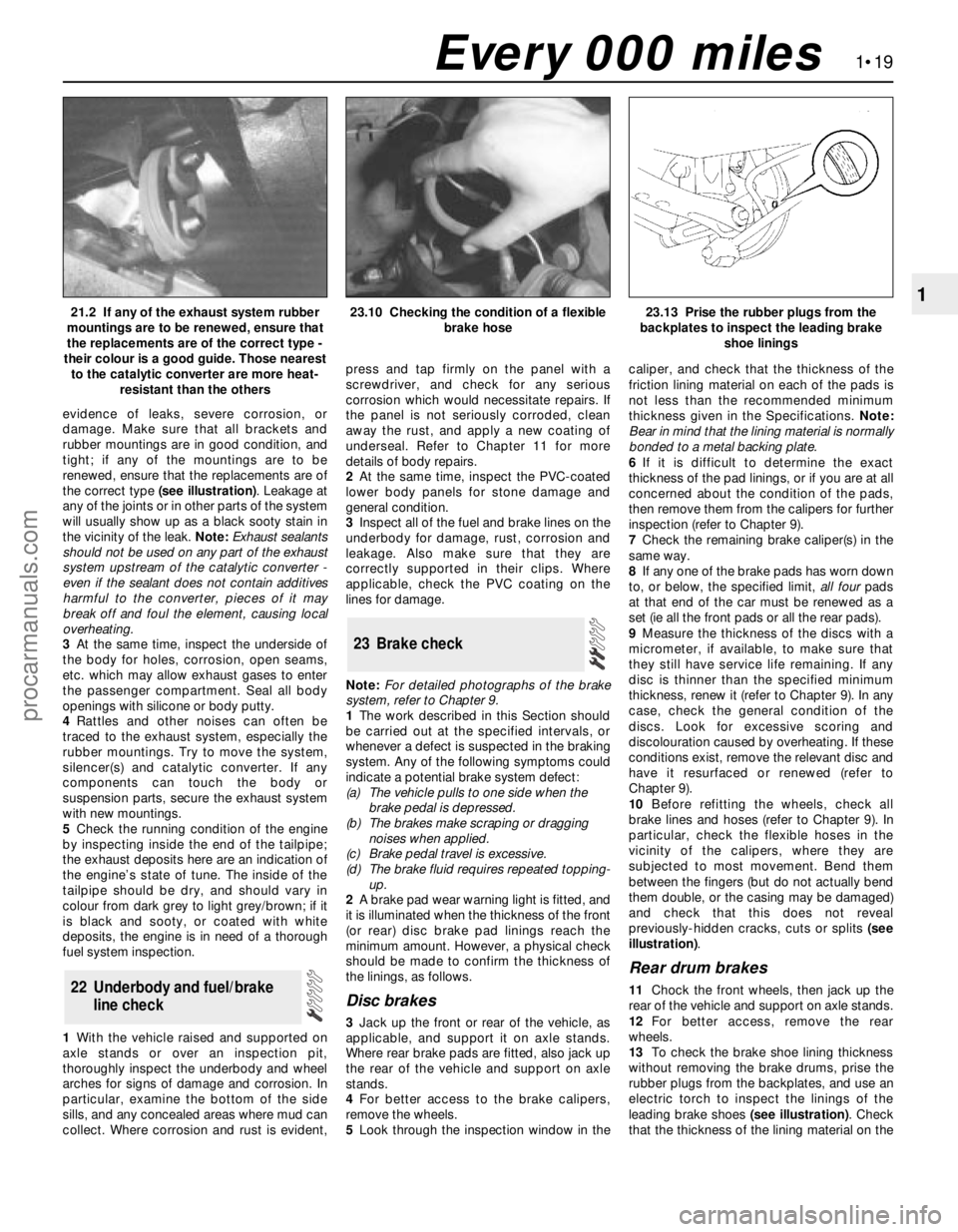

4Grasp the roadwheel at the 12 o’clock and

6 o’clock positions, and try to rock it (see

illustration). Very slight free play may be felt,

but if the movement is appreciable, further

investigation is necessary to determine the

source. Continue rocking the wheel while an

assistant depresses the footbrake. If the

movement is now eliminated or significantly

reduced, it is likely that the hub bearings are

at fault. If the free play is still evident with the

footbrake depressed, then there is wear in the

suspension joints or mountings.

5Now grasp the wheel at the 9 o’clock and

3 o’clock positions, and try to rock it as

before. Any movement felt now may again be

caused by wear in the hub bearings or the

steering track rod balljoints. If the outer track

rod balljoint is worn, the visual movement will

be obvious. If the inner joint is suspect, it can

be felt by placing a hand over the rack-and-

pinion rubber gaiter, and gripping the track

rod. If the wheel is now rocked, movement will

be felt at the inner joint if wear has taken

place.

6Using a large screwdriver or flat bar, check

for wear in the suspension mounting bushes

by levering between the relevant suspension

component and its attachment point. Some

movement is to be expected as the mountings

are made of rubber, but excessive wear

should be obvious. Also check the condition

of any visible rubber bushes, looking for splits,

cracks or contamination of the rubber.

7With the vehicle standing on its wheels,

have an assistant turn the steering wheel

back-and-forth, about an eighth of a turn each

way. There should be very little, if any, lost

movement between the steering wheel and

roadwheels. If this is not the case, closely

observe the joints and mountings previouslydescribed, but in addition, check the steering

column universal joints for wear, and also

check the rack-and-pinion steering gear itself.

Rear suspension check

8Chock the front wheels, then raise the rear

of the vehicle and support it on axle stands.

9Check the rear hub bearings for wear, using

the method described for the front hub

bearings (paragraph 4).

10Using a large screwdriver or flat bar,

check for wear in the suspension mounting

bushes by levering between the relevant

suspension component and its attachment

point. Some movement is to be expected as

the mountings are made of rubber, but

excessive wear should be obvious.

Roadwheel check and balancing

11Periodically remove the roadwheels, and

clean any dirt or mud from the inside and

outside surfaces. Examine the wheel rims for

signs of rusting, corrosion or other damage.

Light alloy wheels are easily damaged by

“kerbing” whilst parking, and similarly, steel

wheels may become dented or buckled.

Renewal of the wheel is very often the only

course of remedial action possible.

12The balance of each wheel and tyre

assembly should be maintained, not only to

avoid excessive tyre wear, but also to avoid

wear in the steering and suspension

components. Wheel imbalance is normally

signified by vibration through the vehicle’s

bodyshell, although in many cases it is

particularly noticeable through the steering

wheel. Conversely, it should be noted that

wear or damage in suspension or steering

components may cause excessive tyre wear.

Out-of-round or out-of-true tyres, damaged

wheels and wheel bearing wear/

maladjustment also fall into this category.

Balancing will not usually cure vibration

caused by such wear.

13Wheel balancing may be carried out with

the wheel either on or off the vehicle. If

balanced on the vehicle, ensure that the

wheel-to-hub relationship is marked in some

way prior to subsequent wheel removal, so

that it may be refitted in its original position.1The driveshaft rubber gaiters are very

important, because they prevent dirt, water

and foreign material from entering and

damaging the constant velocity (CV) joints.

External contamination can cause the gaiter

material to deteriorate prematurely, so it’s a

good idea to wash the gaiters with soap and

water occasionally.

2With the vehicle raised and securely

supported on axle stands, turn the steering

onto full-lock, then slowly rotate each front

wheel in turn. Inspect the condition of the

outer constant velocity (CV) joint rubber

gaiters, squeezing the gaiters to open out the

folds. Check for signs of cracking, splits, or

deterioration of the rubber, which may allow

the escape of grease, and lead to the ingress

of water and grit into the joint (see

illustration). Also check the security and

condition of the retaining clips. Repeat these

checks on the inner CV joints. If any damage

or deterioration is found, the gaiters should be

renewed as described in Chapter 8.

3At the same time, check the general

condition of the outer CV joints themselves,

by first holding the driveshaft and attempting

to rotate the wheels. Repeat this check on the

inner joints, by holding the inner joint yoke

and attempting to rotate the driveshaft.

4Any appreciable movement in the CV joint

indicates wear in the joint, wear in the

driveshaft splines, or a loose driveshaft

retaining nut.

1With the engine cold (at least three hours

after the vehicle has been driven), check the

complete exhaust system, from its starting

point at the engine to the end of the tailpipe.

Ideally, this should be done on a hoist, where

unrestricted access is available; if a hoist is

not available, raise and support the vehicle on

axle stands.

2Check the pipes and connections for

21 Exhaust system check

20 Driveshaft rubber gaiter and

CV joint check

1•18

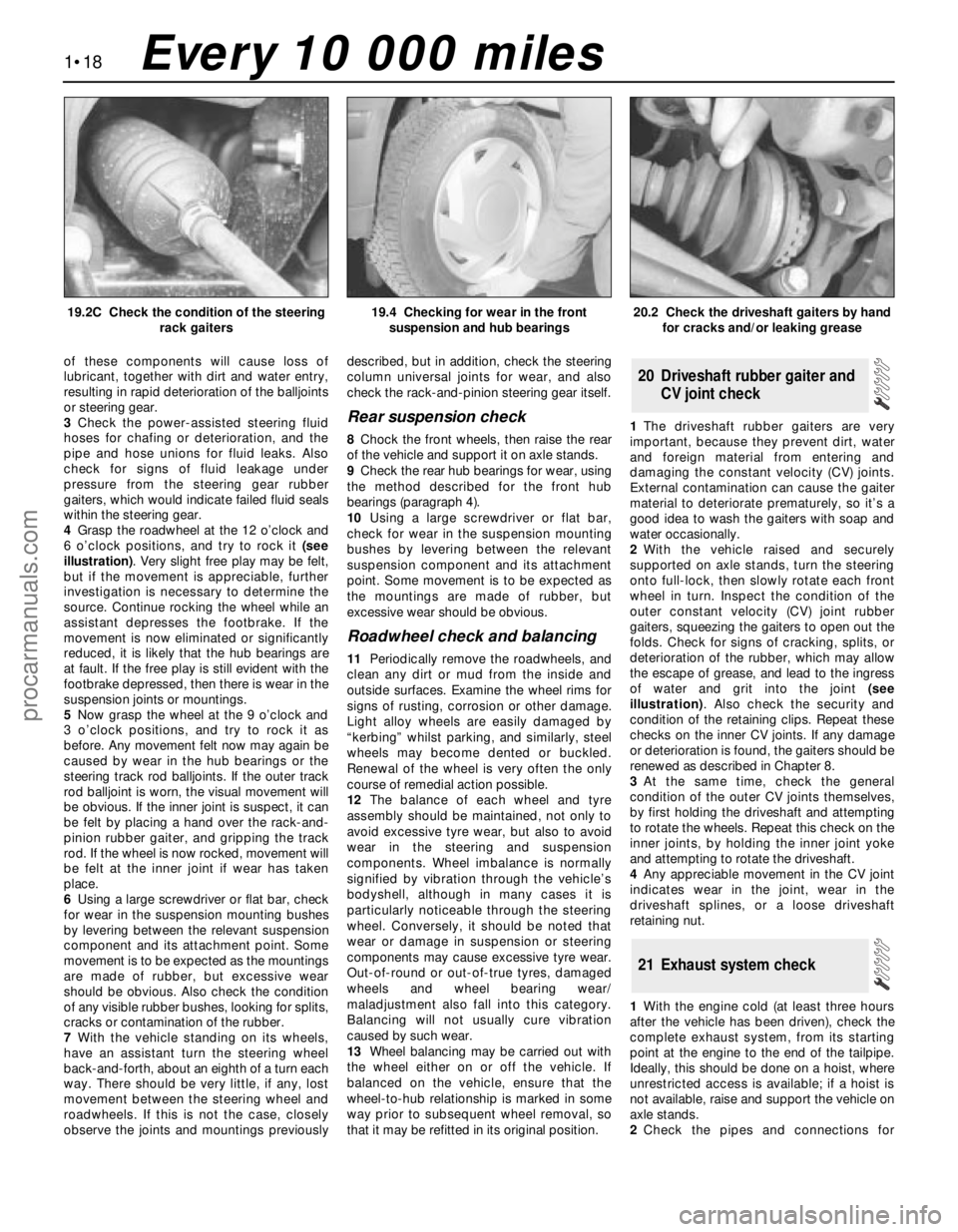

19.2C Check the condition of the steering

rack gaiters19.4 Checking for wear in the front

suspension and hub bearings20.2 Check the driveshaft gaiters by hand

for cracks and/or leaking grease

Every 10 000 miles

procarmanuals.com

Page 33 of 279

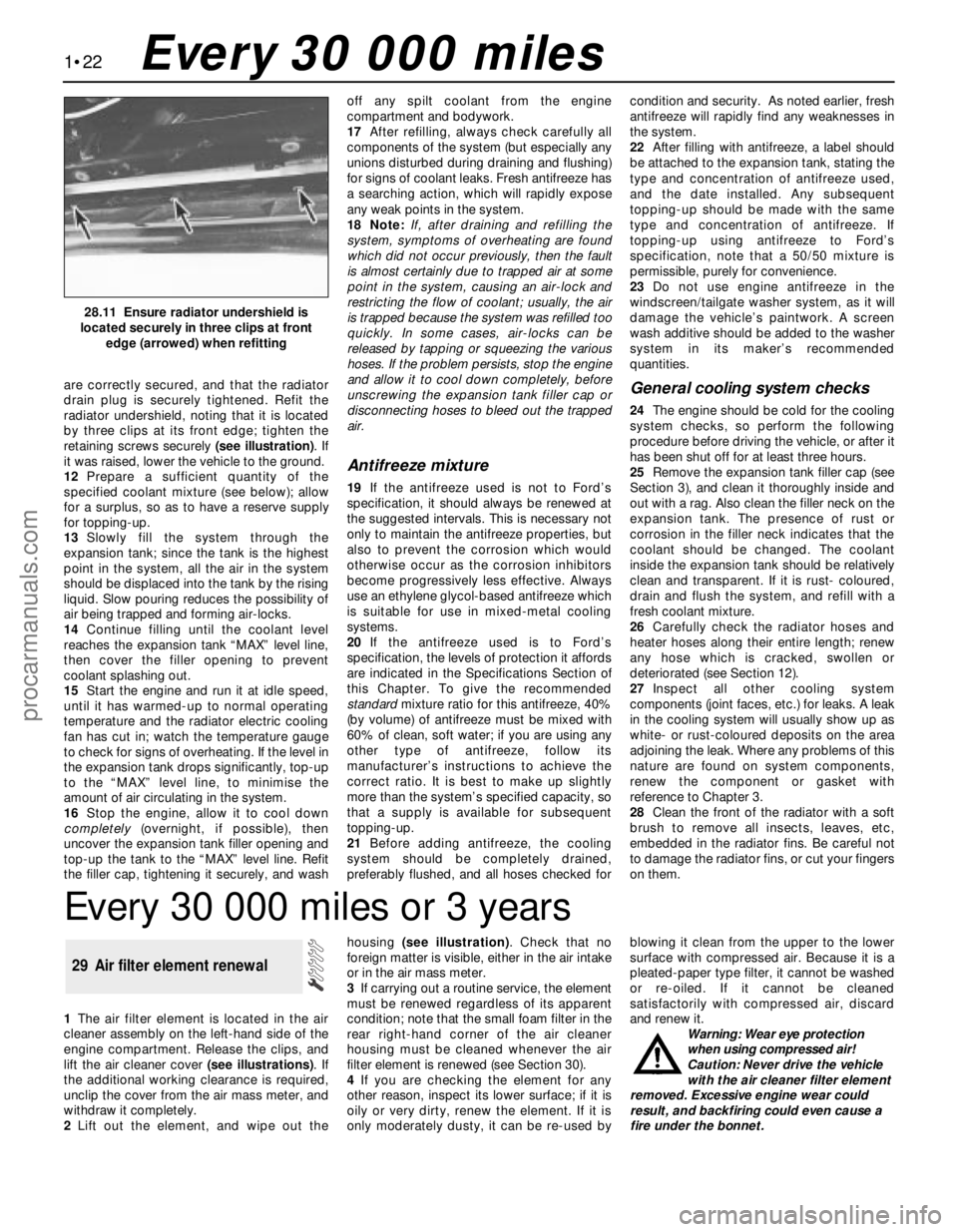

evidence of leaks, severe corrosion, or

damage. Make sure that all brackets and

rubber mountings are in good condition, and

tight; if any of the mountings are to be

renewed, ensure that the replacements are of

the correct type (see illustration). Leakage at

any of the joints or in other parts of the system

will usually show up as a black sooty stain in

the vicinity of the leak. Note:Exhaust sealants

should not be used on any part of the exhaust

system upstream of the catalytic converter -

even if the sealant does not contain additives

harmful to the converter, pieces of it may

break off and foul the element, causing local

overheating.

3At the same time, inspect the underside of

the body for holes, corrosion, open seams,

etc. which may allow exhaust gases to enter

the passenger compartment. Seal all body

openings with silicone or body putty.

4Rattles and other noises can often be

traced to the exhaust system, especially the

rubber mountings. Try to move the system,

silencer(s) and catalytic converter. If any

components can touch the body or

suspension parts, secure the exhaust system

with new mountings.

5Check the running condition of the engine

by inspecting inside the end of the tailpipe;

the exhaust deposits here are an indication of

the engine’s state of tune. The inside of the

tailpipe should be dry, and should vary in

colour from dark grey to light grey/brown; if it

is black and sooty, or coated with white

deposits, the engine is in need of a thorough

fuel system inspection.

1With the vehicle raised and supported on

axle stands or over an inspection pit,

thoroughly inspect the underbody and wheel

arches for signs of damage and corrosion. In

particular, examine the bottom of the side

sills, and any concealed areas where mud can

collect. Where corrosion and rust is evident,press and tap firmly on the panel with a

screwdriver, and check for any serious

corrosion which would necessitate repairs. If

the panel is not seriously corroded, clean

away the rust, and apply a new coating of

underseal. Refer to Chapter 11 for more

details of body repairs.

2At the same time, inspect the PVC-coated

lower body panels for stone damage and

general condition.

3Inspect all of the fuel and brake lines on the

underbody for damage, rust, corrosion and

leakage. Also make sure that they are

correctly supported in their clips. Where

applicable, check the PVC coating on the

lines for damage.

Note:For detailed photographs of the brake

system, refer to Chapter 9.

1The work described in this Section should

be carried out at the specified intervals, or

whenever a defect is suspected in the braking

system. Any of the following symptoms could

indicate a potential brake system defect:

(a) The vehicle pulls to one side when the

brake pedal is depressed.

(b) The brakes make scraping or dragging

noises when applied.

(c) Brake pedal travel is excessive.

(d) The brake fluid requires repeated topping-

up.

2A brake pad wear warning light is fitted, and

it is illuminated when the thickness of the front

(or rear) disc brake pad linings reach the

minimum amount. However, a physical check

should be made to confirm the thickness of

the linings, as follows.

Disc brakes

3Jack up the front or rear of the vehicle, as

applicable, and support it on axle stands.

Where rear brake pads are fitted, also jack up

the rear of the vehicle and support on axle

stands.

4For better access to the brake calipers,

remove the wheels.

5Look through the inspection window in thecaliper, and check that the thickness of the

friction lining material on each of the pads is

not less than the recommended minimum

thickness given in the Specifications. Note:

Bear in mind that the lining material is normally

bonded to a metal backing plate.

6If it is difficult to determine the exact

thickness of the pad linings, or if you are at all

concerned about the condition of the pads,

then remove them from the calipers for further

inspection (refer to Chapter 9).

7Check the remaining brake caliper(s) in the

same way.

8If any one of the brake pads has worn down

to, or below, the specified limit, all fourpads

at that end of the car must be renewed as a

set (ie all the front pads or all the rear pads).

9Measure the thickness of the discs with a

micrometer, if available, to make sure that

they still have service life remaining. If any

disc is thinner than the specified minimum

thickness, renew it (refer to Chapter 9). In any

case, check the general condition of the

discs. Look for excessive scoring and

discolouration caused by overheating. If these

conditions exist, remove the relevant disc and

have it resurfaced or renewed (refer to

Chapter 9).

10Before refitting the wheels, check all

brake lines and hoses (refer to Chapter 9). In

particular, check the flexible hoses in the

vicinity of the calipers, where they are

subjected to most movement. Bend them

between the fingers (but do not actually bend

them double, or the casing may be damaged)

and check that this does not reveal

previously-hidden cracks, cuts or splits (see

illustration).

Rear drum brakes

11Chock the front wheels, then jack up the

rear of the vehicle and support on axle stands.

12For better access, remove the rear

wheels.

13To check the brake shoe lining thickness

without removing the brake drums, prise the

rubber plugs from the backplates, and use an

electric torch to inspect the linings of the

leading brake shoes (see illustration). Check

that the thickness of the lining material on the

23 Brake check

22 Underbody and fuel/brake

line check

1•19

121.2 If any of the exhaust system rubber

mountings are to be renewed, ensure that

the replacements are of the correct type -

their colour is a good guide. Those nearest

to the catalytic converter are more heat-

resistant than the others23.10 Checking the condition of a flexible

brake hose23.13 Prise the rubber plugs from the

backplates to inspect the leading brake

shoe linings

Every 000 miles

procarmanuals.com

Page 36 of 279

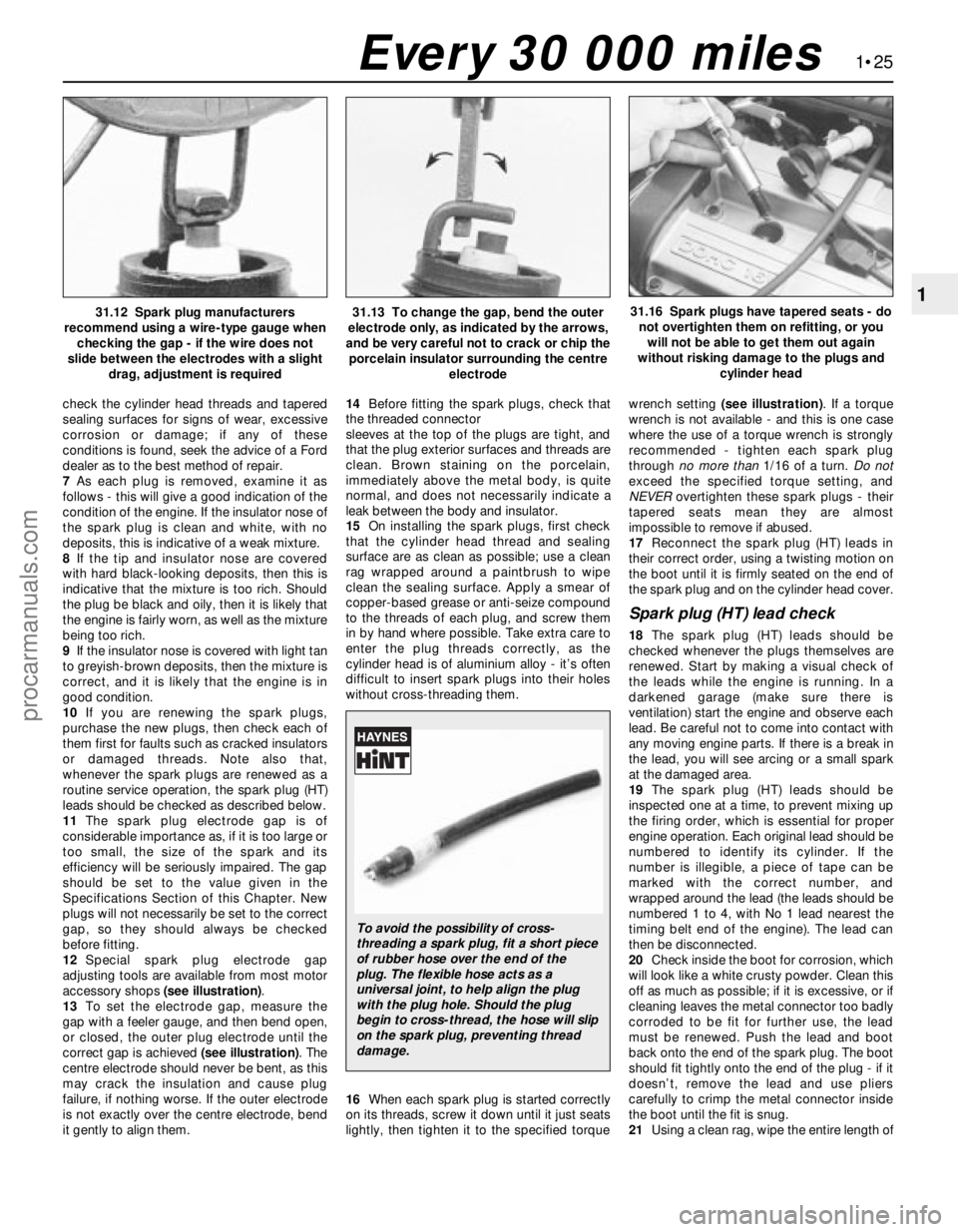

are correctly secured, and that the radiator

drain plug is securely tightened. Refit the

radiator undershield, noting that it is located

by three clips at its front edge; tighten the

retaining screws securely (see illustration). If

it was raised, lower the vehicle to the ground.

12Prepare a sufficient quantity of the

specified coolant mixture (see below); allow

for a surplus, so as to have a reserve supply

for topping-up.

13Slowly fill the system through the

expansion tank; since the tank is the highest

point in the system, all the air in the system

should be displaced into the tank by the rising

liquid. Slow pouring reduces the possibility of

air being trapped and forming air-locks.

14Continue filling until the coolant level

reaches the expansion tank “MAX” level line,

then cover the filler opening to prevent

coolant splashing out.

15Start the engine and run it at idle speed,

until it has warmed-up to normal operating

temperature and the radiator electric cooling

fan has cut in; watch the temperature gauge

to check for signs of overheating. If the level in

the expansion tank drops significantly, top-up

to the “MAX” level line, to minimise the

amount of air circulating in the system.

16Stop the engine, allow it to cool down

completely(overnight, if possible), then

uncover the expansion tank filler opening and

top-up the tank to the “MAX” level line. Refit

the filler cap, tightening it securely, and washoff any spilt coolant from the engine

compartment and bodywork.

17After refilling, always check carefully all

components of the system (but especially any

unions disturbed during draining and flushing)

for signs of coolant leaks. Fresh antifreeze has

a searching action, which will rapidly expose

any weak points in the system.

18 Note:If, after draining and refilling the

system, symptoms of overheating are found

which did not occur previously, then the fault

is almost certainly due to trapped air at some

point in the system, causing an air-lock and

restricting the flow of coolant; usually, the air

is trapped because the system was refilled too

quickly. In some cases, air-locks can be

released by tapping or squeezing the various

hoses. If the problem persists, stop the engine

and allow it to cool down completely, before

unscrewing the expansion tank filler cap or

disconnecting hoses to bleed out the trapped

air.

Antifreeze mixture

19If the antifreeze used is not to Ford’s

specification, it should always be renewed at

the suggested intervals. This is necessary not

only to maintain the antifreeze properties, but

also to prevent the corrosion which would

otherwise occur as the corrosion inhibitors

become progressively less effective. Always

use an ethylene glycol-based antifreeze which

is suitable for use in mixed-metal cooling

systems.

20If the antifreeze used is to Ford’s

specification, the levels of protection it affords

are indicated in the Specifications Section of

this Chapter. To give the recommended

standardmixture ratio for this antifreeze, 40%

(by volume) of antifreeze must be mixed with

60% of clean, soft water; if you are using any

other type of antifreeze, follow its

manufacturer’s instructions to achieve the

correct ratio. It is best to make up slightly

more than the system’s specified capacity, so

that a supply is available for subsequent

topping-up.

21Before adding antifreeze, the cooling

system should be completely drained,

preferably flushed, and all hoses checked forcondition and security. As noted earlier, fresh

antifreeze will rapidly find any weaknesses in

the system.

22After filling with antifreeze, a label should

be attached to the expansion tank, stating the

type and concentration of antifreeze used,

and the date installed. Any subsequent

topping-up should be made with the same

type and concentration of antifreeze. If

topping-up using antifreeze to Ford’s

specification, note that a 50/50 mixture is

permissible, purely for convenience.

23Do not use engine antifreeze in the

windscreen/tailgate washer system, as it will

damage the vehicle’s paintwork. A screen

wash additive should be added to the washer

system in its maker’s recommended

quantities.

General cooling system checks

24The engine should be cold for the cooling

system checks, so perform the following

procedure before driving the vehicle, or after it

has been shut off for at least three hours.

25Remove the expansion tank filler cap (see

Section 3), and clean it thoroughly inside and

out with a rag. Also clean the filler neck on the

expansion tank. The presence of rust or

corrosion in the filler neck indicates that the

coolant should be changed. The coolant

inside the expansion tank should be relatively

clean and transparent. If it is rust- coloured,

drain and flush the system, and refill with a

fresh coolant mixture.

26Carefully check the radiator hoses and

heater hoses along their entire length; renew

any hose which is cracked, swollen or

deteriorated (see Section 12).

27Inspect all other cooling system

components (joint faces, etc.) for leaks. A leak

in the cooling system will usually show up as

white- or rust-coloured deposits on the area

adjoining the leak. Where any problems of this

nature are found on system components,

renew the component or gasket with

reference to Chapter 3.

28Clean the front of the radiator with a soft

brush to remove all insects, leaves, etc,

embedded in the radiator fins. Be careful not

to damage the radiator fins, or cut your fingers

on them.

1•22

28.11 Ensure radiator undershield is

located securely in three clips at front

edge (arrowed) when refitting

Every 30 000 miles

Every 30 000 miles or 3 years

1The air filter element is located in the air

cleaner assembly on the left-hand side of the

engine compartment. Release the clips, and

lift the air cleaner cover (see illustrations). If

the additional working clearance is required,

unclip the cover from the air mass meter, and

withdraw it completely.

2Lift out the element, and wipe out thehousing (see illustration). Check that no

foreign matter is visible, either in the air intake

or in the air mass meter.

3If carrying out a routine service, the element

must be renewed regardless of its apparent

condition; note that the small foam filter in the

rear right-hand corner of the air cleaner

housing must be cleaned whenever the air

filter element is renewed (see Section 30).

4If you are checking the element for any

other reason, inspect its lower surface; if it is

oily or very dirty, renew the element. If it is

only moderately dusty, it can be re-used byblowing it clean from the upper to the lower

surface with compressed air. Because it is a

pleated-paper type filter, it cannot be washed

or re-oiled. If it cannot be cleaned

satisfactorily with compressed air, discard

and renew it.

Warning: Wear eye protection

when using compressed air!

Caution: Never drive the vehicle

with the air cleaner filter element

removed. Excessive engine wear could

result, and backfiring could even cause a

fire under the bonnet.

29 Air filter element renewal

procarmanuals.com

Page 39 of 279

check the cylinder head threads and tapered

sealing surfaces for signs of wear, excessive

corrosion or damage; if any of these

conditions is found, seek the advice of a Ford

dealer as to the best method of repair.

7As each plug is removed, examine it as

follows - this will give a good indication of the

condition of the engine. If the insulator nose of

the spark plug is clean and white, with no

deposits, this is indicative of a weak mixture.

8If the tip and insulator nose are covered

with hard black-looking deposits, then this is

indicative that the mixture is too rich. Should

the plug be black and oily, then it is likely that

the engine is fairly worn, as well as the mixture

being too rich.

9If the insulator nose is covered with light tan

to greyish-brown deposits, then the mixture is

correct, and it is likely that the engine is in

good condition.

10If you are renewing the spark plugs,

purchase the new plugs, then check each of

them first for faults such as cracked insulators

or damaged threads. Note also that,

whenever the spark plugs are renewed as a

routine service operation, the spark plug (HT)

leads should be checked as described below.

11The spark plug electrode gap is of

considerable importance as, if it is too large or

too small, the size of the spark and its

efficiency will be seriously impaired. The gap

should be set to the value given in the

Specifications Section of this Chapter. New

plugs will not necessarily be set to the correct

gap, so they should always be checked

before fitting.

12Special spark plug electrode gap

adjusting tools are available from most motor

accessory shops (see illustration).

13To set the electrode gap, measure the

gap with a feeler gauge, and then bend open,

or closed, the outer plug electrode until the

correct gap is achieved (see illustration). The

centre electrode should never be bent, as this

may crack the insulation and cause plug

failure, if nothing worse. If the outer electrode

is not exactly over the centre electrode, bend

it gently to align them.14Before fitting the spark plugs, check that

the threaded connector

sleeves at the top of the plugs are tight, and

that the plug exterior surfaces and threads are

clean. Brown staining on the porcelain,

immediately above the metal body, is quite

normal, and does not necessarily indicate a

leak between the body and insulator.

15On installing the spark plugs, first check

that the cylinder head thread and sealing

surface are as clean as possible; use a clean

rag wrapped around a paintbrush to wipe

clean the sealing surface. Apply a smear of

copper-based grease or anti-seize compound

to the threads of each plug, and screw them

in by hand where possible. Take extra care to

enter the plug threads correctly, as the

cylinder head is of aluminium alloy - it’s often

difficult to insert spark plugs into their holes

without cross-threading them.

16When each spark plug is started correctly

on its threads, screw it down until it just seats

lightly, then tighten it to the specified torquewrench setting (see illustration). If a torque

wrench is not available - and this is one case

where the use of a torque wrench is strongly

recommended - tighten each spark plug

through no more than1/16 of a turn. Do not

exceed the specified torque setting, and

NEVERovertighten these spark plugs - their

tapered seats mean they are almost

impossible to remove if abused.

17Reconnect the spark plug (HT) leads in

their correct order, using a twisting motion on

the boot until it is firmly seated on the end of

the spark plug and on the cylinder head cover.

Spark plug (HT) lead check

18The spark plug (HT) leads should be

checked whenever the plugs themselves are

renewed. Start by making a visual check of

the leads while the engine is running. In a

darkened garage (make sure there is

ventilation) start the engine and observe each

lead. Be careful not to come into contact with

any moving engine parts. If there is a break in

the lead, you will see arcing or a small spark

at the damaged area.

19The spark plug (HT) leads should be

inspected one at a time, to prevent mixing up

the firing order, which is essential for proper

engine operation. Each original lead should be

numbered to identify its cylinder. If the

number is illegible, a piece of tape can be

marked with the correct number, and

wrapped around the lead (the leads should be

numbered 1 to 4, with No 1 lead nearest the

timing belt end of the engine). The lead can

then be disconnected.

20Check inside the boot for corrosion, which

will look like a white crusty powder. Clean this

off as much as possible; if it is excessive, or if

cleaning leaves the metal connector too badly

corroded to be fit for further use, the lead

must be renewed. Push the lead and boot

back onto the end of the spark plug. The boot

should fit tightly onto the end of the plug - if it

doesn’t, remove the lead and use pliers

carefully to crimp the metal connector inside

the boot until the fit is snug.

21Using a clean rag, wipe the entire length of

1•25

1

Every 30 000 miles

31.12 Spark plug manufacturers

recommend using a wire-type gauge when

checking the gap - if the wire does not

slide between the electrodes with a slight

drag, adjustment is required31.13 To change the gap, bend the outer

electrode only, as indicated by the arrows,

and be very careful not to crack or chip the

porcelain insulator surrounding the centre

electrode31.16 Spark plugs have tapered seats - do

not overtighten them on refitting, or you

will not be able to get them out again

without risking damage to the plugs and

cylinder head

To avoid the possibility of cross-

threading a spark plug, fit a short piece

of rubber hose over the end of the

plug. The flexible hose acts as a

universal joint, to help align the plug

with the plug hole. Should the plug

begin to cross-thread, the hose will slip

on the spark plug, preventing thread

damage.

procarmanuals.com

Page 40 of 279

1•26Every 60 000 miles

Every 60 000 miles

Refer to Chapter 2, Part A.

Warning: Petrol is extremely

flammable, so extra precautions

must be taken when working on

any part of the fuel system. Do not smoke,

or allow open flames or bare light bulbs,

near the work area. Also, do not work in a

garage if a gas appliance with a pilot light is

present. While performing any work on the

fuel system, wear safety glasses, and have

a suitable (Class B) fire extinguisher on

hand. If you spill any fuel on your skin, rinse

it off immediately with soap and water.

1The fuel filter is located at the front right-

hand corner of the fuel tank, just forward of

the vehicle’s right-hand rear jacking point. The

filter performs a vital role in keeping dirt and

other foreign matter out of the fuel system,

and so must be renewed at regular intervals,or whenever you have reason to suspect that

it may be clogged. It is always unpleasant

working under a vehicle - pressure-washing or

hosing clean the underbody in the filter’s

vicinity will make working conditions more

tolerable, and will reduce the risk of getting

dirt into the fuel system.

2Relieve any residual pressure in the system

by removing the fuel pump fuse (No 14) and

starting the engine; allow the engine to idle until

it dies. Turn the engine over once or twice on

the starter, to ensure that all pressure is

released, then switch off the ignition.

Warning: This procedure will

merely relieve the pressure

necessary for the engine to run -

remember that fuel will still be present in

the system components, and take

precautions before disconnecting them.

3Noting the comments made in Section 1 of

Chapter 5, disconnect the battery earth terminal.

4Jack up the rear right-hand side of the

vehicle, and support it securely on an axle stand.

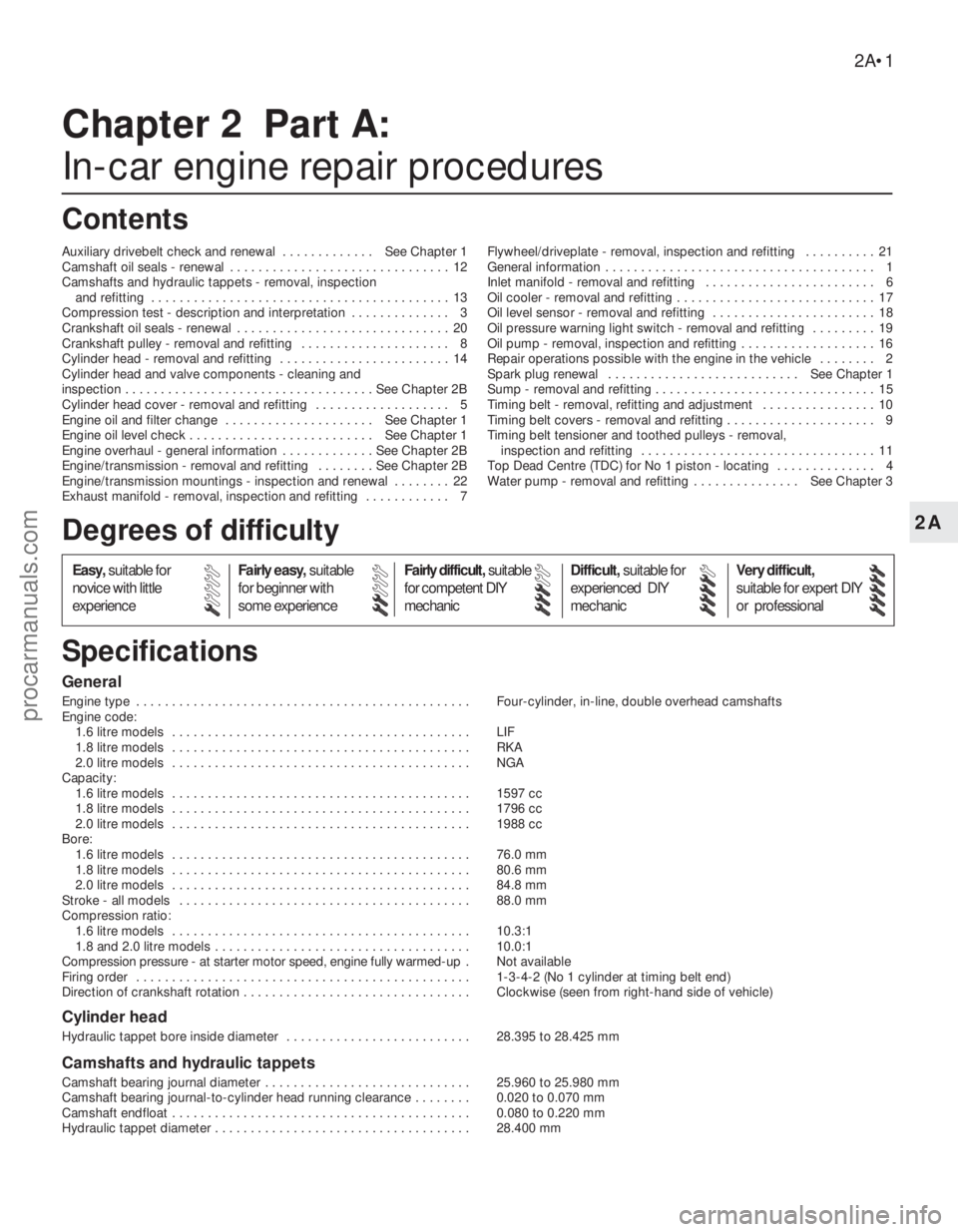

5Using rag to soak up any spilt fuel, release

the fuel feed and outlet pipe unions from the

filter, by squeezing together the protruding

locking lugs on each union, and carefully

pulling the union off the filter stub (seeillustration). Where the unions are colour-

coded, the feed and outlet pipes cannot be

confused; where both unions are the same

colour, note carefully which pipe is connected

to which filter stub, and ensure that they are

correctly reconnected on refitting.

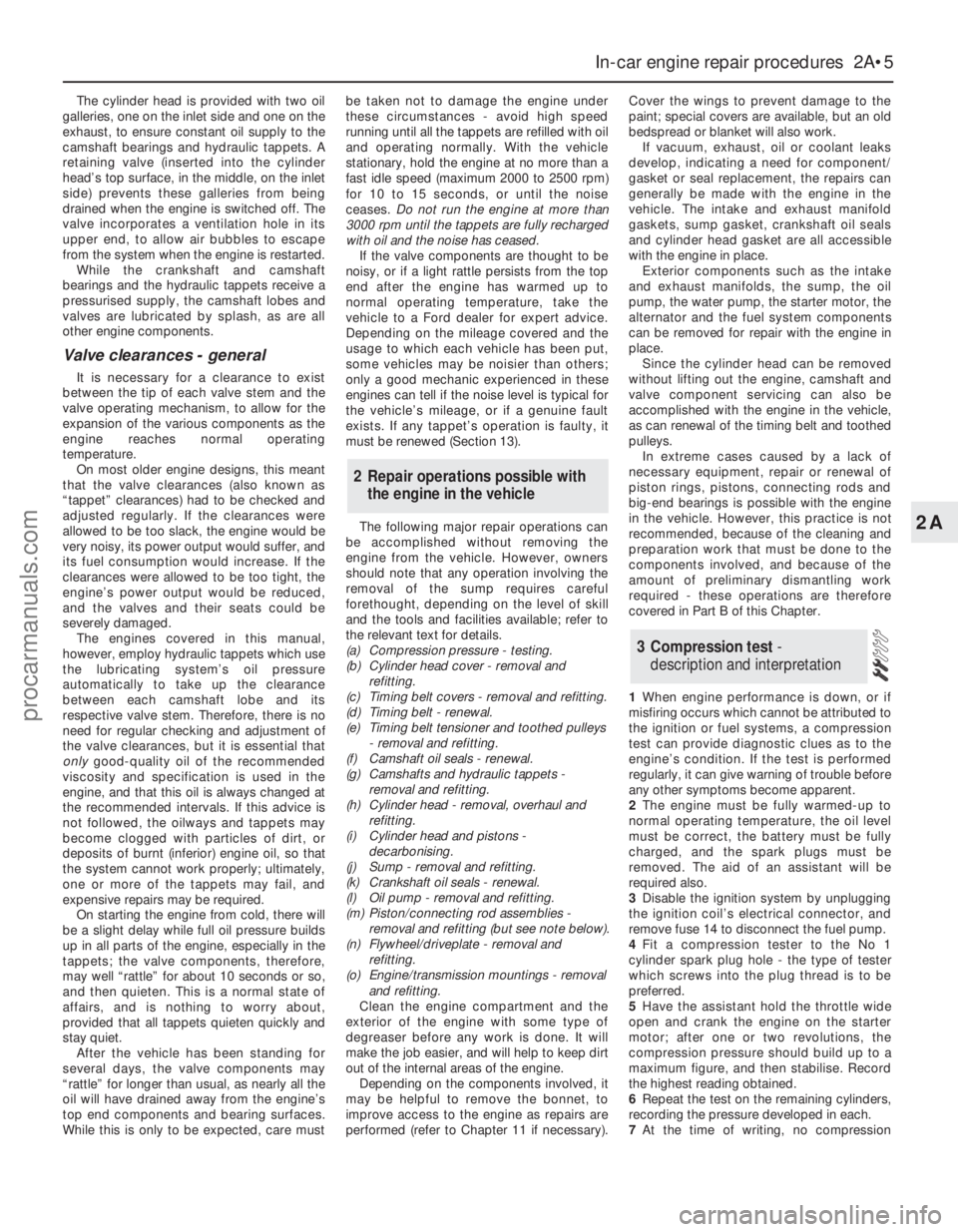

6Noting the arrows and/or other markings on

the filter showing the direction of fuel flow

(towards the engine), slacken the filter clamp

screw and withdraw the filter. Note that the

filter will still contain fuel; care should be

taken, to avoid spillage and to minimise the

risk of fire.

7On installation, slide the filter into its clamp

so that the arrow marked on it faces the

correct way, then slide each pipe union on to

its (correct) respective filter stub, and press it

down until the locking lugs click into their

groove (see illustrations). Tighten the clamp

screw carefully, until the filter is just prevented

from moving; do not overtighten the clamp

screw, or the filter casing may be crushed.

8Refit the fuel pump fuse and reconnect the

battery earth terminal, then switch the ignition

on and off five times, to pressurise the

system. Check for any sign of fuel leakage

around the filter unions before lowering the

vehicle to the ground and starting the engine.

33 Fuel filter renewal

32 Timing belt renewal

33.5 Squeeze together fuel filter pipe union

locking lugs, then pull pipes off filter stubs -

ensure pipes are correctly reconnected33.7A When installing the new filter,

ensure the arrow showing direction of fuel

flow points towards the engine . . .

Every 3 years

The procedure is similar to that for the

bleeding of the hydraulic system as described

in Chapter 9, except that the brake fluid

reservoir should be emptied by syphoning,and allowance should be made for the old

fluid to be removed from the circuit when

bleeding a section of the circuit.

34 Brake fluid renewal

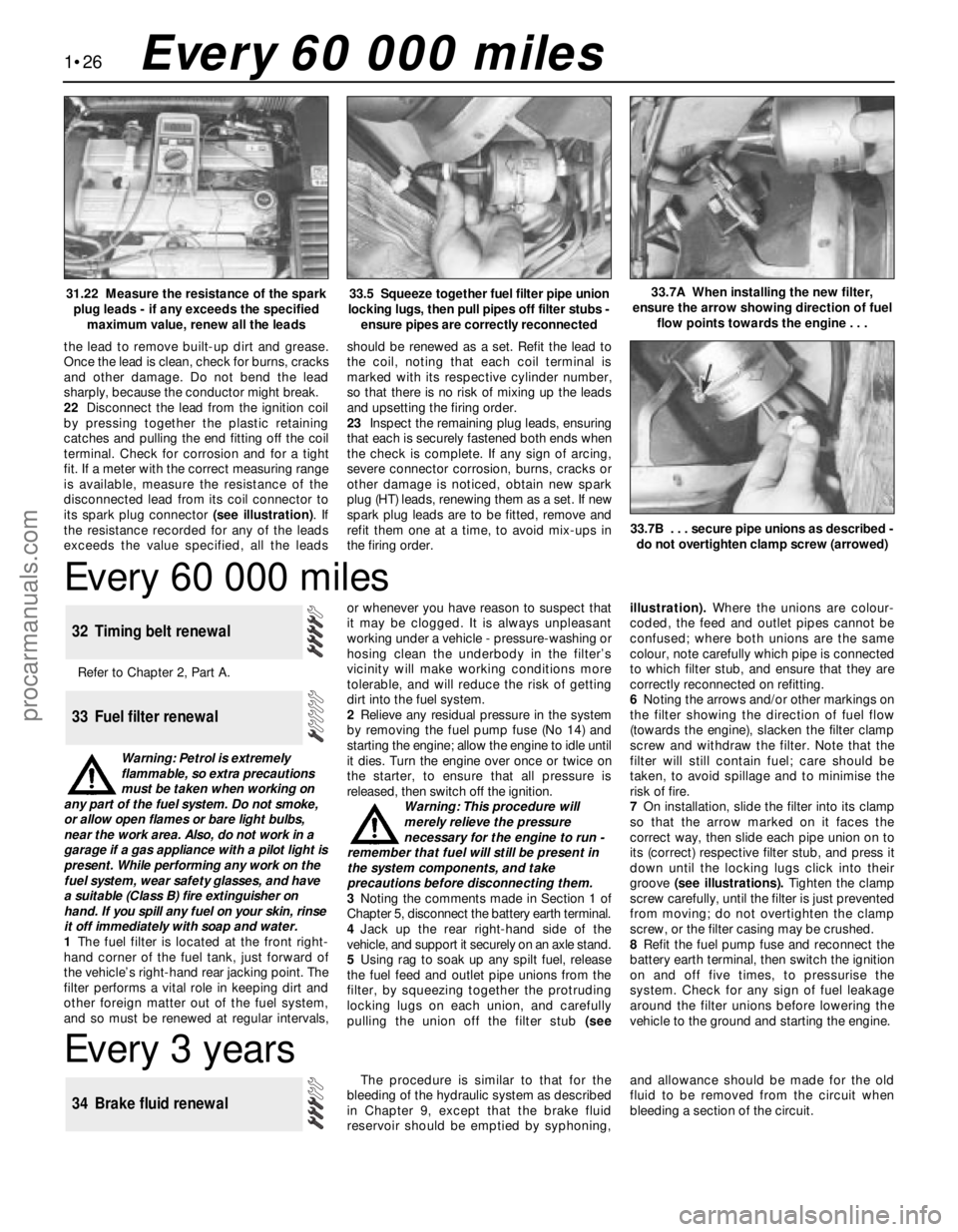

31.22 Measure the resistance of the spark

plug leads - if any exceeds the specified

maximum value, renew all the leads

the lead to remove built-up dirt and grease.

Once the lead is clean, check for burns, cracks

and other damage. Do not bend the lead

sharply, because the conductor might break.

22Disconnect the lead from the ignition coil

by pressing together the plastic retaining

catches and pulling the end fitting off the coil

terminal. Check for corrosion and for a tight

fit. If a meter with the correct measuring range

is available, measure the resistance of the

disconnected lead from its coil connector to

its spark plug connector (see illustration). If

the resistance recorded for any of the leads

exceeds the value specified, all the leadsshould be renewed as a set. Refit the lead to

the coil, noting that each coil terminal is

marked with its respective cylinder number,

so that there is no risk of mixing up the leads

and upsetting the firing order.

23Inspect the remaining plug leads, ensuring

that each is securely fastened both ends when

the check is complete. If any sign of arcing,

severe connector corrosion, burns, cracks or

other damage is noticed, obtain new spark

plug (HT) leads, renewing them as a set. If new

spark plug leads are to be fitted, remove and

refit them one at a time, to avoid mix-ups in

the firing order.

33.7B . . . secure pipe unions as described -

do not overtighten clamp screw (arrowed)

procarmanuals.com

Page 41 of 279

Chapter 2 Part A:

In-car engine repair procedures

Auxiliary drivebelt check and renewal . . . . . . . . . . . . . See Chapter 1

Camshaft oil seals - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Camshafts and hydraulic tappets - removal, inspection

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Compression test - description and interpretation . . . . . . . . . . . . . . 3

Crankshaft oil seals - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Crankshaft pulley - removal and refitting . . . . . . . . . . . . . . . . . . . . . 8

Cylinder head - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 14

Cylinder head and valve components - cleaning and

inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 2B

Cylinder head cover - removal and refitting . . . . . . . . . . . . . . . . . . . 5

Engine oil and filter change . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Engine oil level check . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Engine overhaul - general information . . . . . . . . . . . . . See Chapter 2B

Engine/transmission - removal and refitting . . . . . . . . See Chapter 2B

Engine/transmission mountings - inspection and renewal . . . . . . . . 22

Exhaust manifold - removal, inspection and refitting . . . . . . . . . . . . 7Flywheel/driveplate - removal, inspection and refitting . . . . . . . . . . 21

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Inlet manifold - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 6

Oil cooler - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Oil level sensor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 18

Oil pressure warning light switch - removal and refitting . . . . . . . . . 19

Oil pump - removal, inspection and refitting . . . . . . . . . . . . . . . . . . . 16

Repair operations possible with the engine in the vehicle . . . . . . . . 2

Spark plug renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Timing belt - removal, refitting and adjustment . . . . . . . . . . . . . . . . 10

Timing belt covers - removal and refitting . . . . . . . . . . . . . . . . . . . . . 9

Timing belt tensioner and toothed pulleys - removal,

inspection and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Top Dead Centre (TDC) for No 1 piston - locating . . . . . . . . . . . . . . 4

Water pump - removal and refitting . . . . . . . . . . . . . . . See Chapter 3

General

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Four-cylinder, in-line, double overhead camshafts

Engine code:

1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LIF

1.8 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RKA

2.0 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NGA

Capacity:

1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1597 cc

1.8 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1796 cc

2.0 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1988 cc

Bore:

1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76.0 mm

1.8 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80.6 mm

2.0 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84.8 mm

Stroke - all models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88.0 mm

Compression ratio:

1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.3:1

1.8 and 2.0 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.0:1

Compression pressure - at starter motor speed, engine fully warmed-up .Not available

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-4-2 (No 1 cylinder at timing belt end)

Direction of crankshaft rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clockwise (seen from right-hand side of vehicle)

Cylinder head

Hydraulic tappet bore inside diameter . . . . . . . . . . . . . . . . . . . . . . . . . . 28.395 to 28.425 mm

Camshafts and hydraulic tappets

Camshaft bearing journal diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.960 to 25.980 mm

Camshaft bearing journal-to-cylinder head running clearance . . . . . . . . 0.020 to 0.070 mm

Camshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.080 to 0.220 mm

Hydraulic tappet diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.400 mm

2A•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,suitable

for competent DIY

mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

Specifications Contents2A

procarmanuals.com

Page 45 of 279

The cylinder head is provided with two oil

galleries, one on the inlet side and one on the

exhaust, to ensure constant oil supply to the

camshaft bearings and hydraulic tappets. A

retaining valve (inserted into the cylinder

head’s top surface, in the middle, on the inlet

side) prevents these galleries from being

drained when the engine is switched off. The

valve incorporates a ventilation hole in its

upper end, to allow air bubbles to escape

from the system when the engine is restarted.

While the crankshaft and camshaft

bearings and the hydraulic tappets receive a

pressurised supply, the camshaft lobes and

valves are lubricated by splash, as are all

other engine components.

Valve clearances - general

It is necessary for a clearance to exist

between the tip of each valve stem and the

valve operating mechanism, to allow for the

expansion of the various components as the

engine reaches normal operating

temperature.

On most older engine designs, this meant

that the valve clearances (also known as

“tappet” clearances) had to be checked and

adjusted regularly. If the clearances were

allowed to be too slack, the engine would be

very noisy, its power output would suffer, and

its fuel consumption would increase. If the

clearances were allowed to be too tight, the

engine’s power output would be reduced,

and the valves and their seats could be

severely damaged.

The engines covered in this manual,

however, employ hydraulic tappets which use

the lubricating system’s oil pressure

automatically to take up the clearance

between each camshaft lobe and its

respective valve stem. Therefore, there is no

need for regular checking and adjustment of

the valve clearances, but it is essential that

onlygood-quality oil of the recommended

viscosity and specification is used in the

engine, and that this oil is always changed at

the recommended intervals. If this advice is

not followed, the oilways and tappets may

become clogged with particles of dirt, or

deposits of burnt (inferior) engine oil, so that

the system cannot work properly; ultimately,

one or more of the tappets may fail, and

expensive repairs may be required.

On starting the engine from cold, there will

be a slight delay while full oil pressure builds

up in all parts of the engine, especially in the

tappets; the valve components, therefore,

may well “rattle” for about 10 seconds or so,

and then quieten. This is a normal state of

affairs, and is nothing to worry about,

provided that all tappets quieten quickly and

stay quiet.

After the vehicle has been standing for

several days, the valve components may

“rattle” for longer than usual, as nearly all the

oil will have drained away from the engine’s

top end components and bearing surfaces.

While this is only to be expected, care mustbe taken not to damage the engine under

these circumstances - avoid high speed

running until all the tappets are refilled with oil

and operating normally. With the vehicle

stationary, hold the engine at no more than a

fast idle speed (maximum 2000 to 2500 rpm)

for 10 to 15 seconds, or until the noise

ceases. Do not run the engine at more than

3000 rpm until the tappets are fully recharged

with oil and the noise has ceased.

If the valve components are thought to be

noisy, or if a light rattle persists from the top

end after the engine has warmed up to

normal operating temperature, take the

vehicle to a Ford dealer for expert advice.

Depending on the mileage covered and the

usage to which each vehicle has been put,

some vehicles may be noisier than others;

only a good mechanic experienced in these

engines can tell if the noise level is typical for

the vehicle’s mileage, or if a genuine fault

exists. If any tappet’s operation is faulty, it

must be renewed (Section 13).

The following major repair operations can

be accomplished without removing the

engine from the vehicle. However, owners

should note that any operation involving the

removal of the sump requires careful

forethought, depending on the level of skill

and the tools and facilities available; refer to

the relevant text for details.

(a) Compression pressure - testing.

(b) Cylinder head cover - removal and

refitting.

(c) Timing belt covers - removal and refitting.

(d) Timing belt - renewal.

(e) Timing belt tensioner and toothed pulleys

- removal and refitting.

(f) Camshaft oil seals - renewal.

(g) Camshafts and hydraulic tappets -

removal and refitting.

(h) Cylinder head - removal, overhaul and

refitting.

(i) Cylinder head and pistons -

decarbonising.

(j) Sump - removal and refitting.

(k) Crankshaft oil seals - renewal.

(l) Oil pump - removal and refitting.

(m) Piston/connecting rod assemblies -

removal and refitting (but see note below).

(n) Flywheel/driveplate - removal and

refitting.

(o) Engine/transmission mountings - removal

and refitting.

Clean the engine compartment and the

exterior of the engine with some type of

degreaser before any work is done. It will

make the job easier, and will help to keep dirt

out of the internal areas of the engine.

Depending on the components involved, it

may be helpful to remove the bonnet, to

improve access to the engine as repairs are

performed (refer to Chapter 11 if necessary).Cover the wings to prevent damage to the

paint; special covers are available, but an old

bedspread or blanket will also work.

If vacuum, exhaust, oil or coolant leaks

develop, indicating a need for component/

gasket or seal replacement, the repairs can

generally be made with the engine in the

vehicle. The intake and exhaust manifold

gaskets, sump gasket, crankshaft oil seals

and cylinder head gasket are all accessible

with the engine in place.

Exterior components such as the intake

and exhaust manifolds, the sump, the oil

pump, the water pump, the starter motor, the

alternator and the fuel system components

can be removed for repair with the engine in

place.

Since the cylinder head can be removed

without lifting out the engine, camshaft and

valve component servicing can also be

accomplished with the engine in the vehicle,

as can renewal of the timing belt and toothed

pulleys.

In extreme cases caused by a lack of

necessary equipment, repair or renewal of

piston rings, pistons, connecting rods and

big-end bearings is possible with the engine

in the vehicle. However, this practice is not

recommended, because of the cleaning and

preparation work that must be done to the

components involved, and because of the

amount of preliminary dismantling work

required - these operations are therefore

covered in Part B of this Chapter.

1When engine performance is down, or if

misfiring occurs which cannot be attributed to

the ignition or fuel systems, a compression

test can provide diagnostic clues as to the

engine’s condition. If the test is performed

regularly, it can give warning of trouble before

any other symptoms become apparent.

2The engine must be fully warmed-up to

normal operating temperature, the oil level

must be correct, the battery must be fully

charged, and the spark plugs must be

removed. The aid of an assistant will be

required also.

3Disable the ignition system by unplugging

the ignition coil’s electrical connector, and

remove fuse 14 to disconnect the fuel pump.

4Fit a compression tester to the No 1

cylinder spark plug hole - the type of tester

which screws into the plug thread is to be

preferred.

5Have the assistant hold the throttle wide

open and crank the engine on the starter

motor; after one or two revolutions, the

compression pressure should build up to a

maximum figure, and then stabilise. Record

the highest reading obtained.

6Repeat the test on the remaining cylinders,

recording the pressure developed in each.

7At the time of writing, no compression

3 Compression test -

description and interpretation

2 Repair operations possible with

the engine in the vehicle

In-car engine repair procedures 2A•5

2A

procarmanuals.com

Page 47 of 279

throttle linkage as described in Chapter 4.

Where fitted, disconnect also the cruise

control actuator cable (see Chapter 12).

3Remove the timing belt upper cover (see

Section 9).

4Disconnect the crankcase breather hose

from the cylinder head cover union (see

illustration).

5Unplug the HT leads from the spark plugs

and withdraw them, unclipping the leads from

the cover.

6Working progressively, unscrew the

cylinder head cover retaining bolts, noting the

spacer sleeve and rubber seal at each, then

withdraw the cover (see illustration).

7Discard the cover gasket; this mustbe

renewed whenever it is disturbed. Check that

the sealing faces are undamaged, and that

the rubber seal at each retaining bolt is

serviceable; renew any worn or damaged

seals.

8On refitting, clean the cover and cylinder

head gasket faces carefully, then fit a new

gasket to the cover, ensuring that it locates

correctly in the cover grooves (see

illustration).

9Refit the cover to the cylinder head, then

insert the rubber seal and spacer sleeve at

each bolt location (see illustration). Start all

bolts finger-tight, ensuring that the gasket

remains seated in its groove.

10Working in a diagonal sequence from the

centre outwards, and in two stages (see

Specifications), tighten the cover bolts to the

specified torque wrench setting.

11Refit the HT leads, clipping them into

place so that they are correctly routed; each

is numbered, and can also be identified by

the numbering on its respective coil terminal.

12Reconnect the crankcase breather hose,

and refit the timing belt upper cover.

Reconnect and adjust the accelerator cable,

then refit the air cleaner assembly cover with

the air mass meter, the resonator and the

plenum chamber (see Chapter 4).

Warning: Petrol is extremely

flammable, so take extra

precautions when disconnecting

any part of the fuel system. Don’t smoke,

or allow naked flames or bare light bulbs in

or near the work area. Don’t work in a

garage where a natural gas appliance

(such as a clothes dryer or water heater) is

installed. If you spill petrol on your skin,

rinse it off immediately. Have a fire

extinguisher rated for petrol fires handy,

and know how to use it.

Removal

1Park the vehicle on firm, level ground,

apply the handbrake firmly, and slacken the

nuts securing the right-hand front roadwheel.

2Relieve the fuel system pressure (see

Chapter 4).3Disconnect the battery negative (earth) lead

- see Chapter 5, Section 1.

4Unplugging the two electrical connectors

and disconnecting the vacuum hose (where

fitted), remove the air cleaner assembly cover

with the air mass meter, the resonator and the

plenum chamber (see Chapter 4).

5Disconnect the accelerator cable from the

throttle linkage as described in Chapter 4 -

where fitted, disconnect also the cruise

control actuator cable (see Chapter 12).

6Disconnect the crankcase breather hose

from the cylinder head cover union.

7Unbolt the upper part of the exhaust

manifold heat shield; unclip the coolant hose

to allow it to be withdrawn. Slacken the

sleeve nut securing the EGR pipe to the

manifold, remove the two screws securing

the pipe to the ignition coil bracket, then

unscrew the sleeve nut securing the pipe to

the EGR valve - see Chapter 6 for full details if

required.

8Remove the two screws securing the wiring

“rail” to the top of the manifold - this is simply

so that it can be moved as required to reach

the manifold bolts. Unplug their electrical

connectors to disconnect the camshaft

position sensor and the coolant temperature

sensor, then unclip the wiring from the ignition

coil bracket, and secure it to the manifold.

9Remove the three screws securing the

wiring “rail” to the rear of the manifold.

Releasing its wire clip, unplug the large

electrical connector (next to the fuel pressure

regulator) to disconnect the wiring of themanifold components from the engine wiring

loom.

10Marking or labelling them as they are

unplugged, disconnect the vacuum hoses as

follows:

(a) One from the rear of the throttle housing

(only the one hose - there is no need to

disconnect the second hose running to

the fuel pressure regulator).

(b) One from the union on the manifold’s left-

hand end.

(c) The braking system vacuum servo unit

hose (see Chapter 9 for details).

(d) One from the Exhaust Gas Recirculation

(EGR) valve.

11Equalise the pressure in the fuel tank by

removing the filler cap, then undo the fuel

feed and return lines connecting the engine to

the chassis (see Chapter 4). Plug or cap all

open fittings.

12Unbolt the power steering high-pressure

pipe and the earth lead from the cylinder

head rear support plate/engine lifting eye,

then unscrew the bolt securing the support

plate/lifting eye to the alternator mounting

bracket.

13Unscrew the six nuts securing the

engine/transmission right-hand mounting

bracket, then withdraw the bracket.

14Remove the alternator (see Chapter 5).

15Unbolt the alternator mounting bracket

from the rear of the cylinder block and

withdraw it, together with the cylinder head

rear support plate/engine lifting eye (see

illustration).

6 Inlet manifold -

removal and refitting

In-car engine repair procedures 2A•7

2A

5.8 Ensure gasket is located correctly in

cover groove5.6 Removing cylinder head cover

5.9 Ensure rubber seal is fitted to each

cover bolt spacer, as shown6.15 Alternator mounting bracket must be

unbolted from rear of cylinder block to

permit access to inlet manifold nut

procarmanuals.com

Page 51 of 279

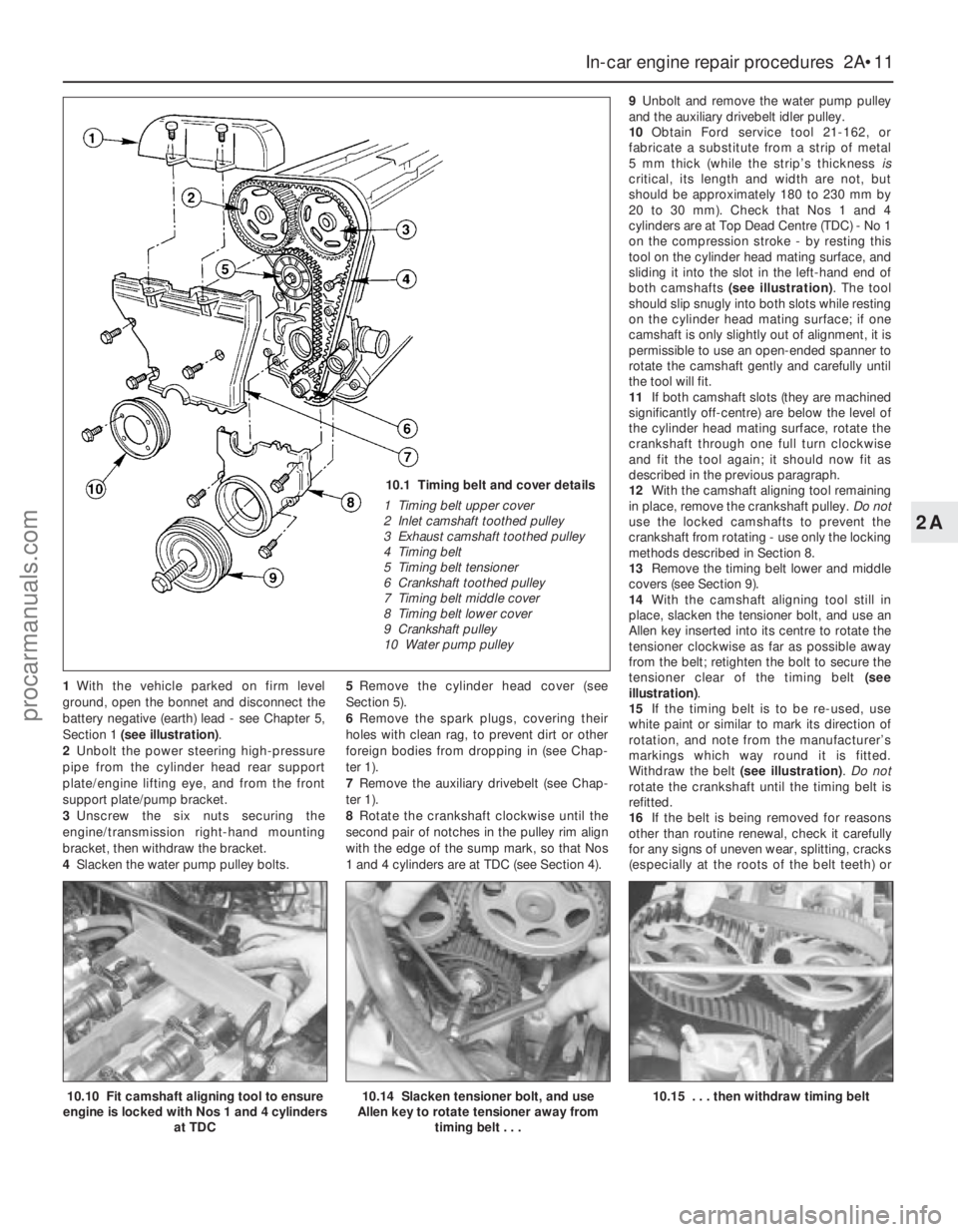

1With the vehicle parked on firm level

ground, open the bonnet and disconnect the

battery negative (earth) lead - see Chapter 5,

Section 1 (see illustration).

2Unbolt the power steering high-pressure

pipe from the cylinder head rear support

plate/engine lifting eye, and from the front

support plate/pump bracket.

3Unscrew the six nuts securing the

engine/transmission right-hand mounting

bracket, then withdraw the bracket.

4Slacken the water pump pulley bolts.5Remove the cylinder head cover (see

Section 5).

6Remove the spark plugs, covering their

holes with clean rag, to prevent dirt or other

foreign bodies from dropping in (see Chap-

ter 1).

7Remove the auxiliary drivebelt (see Chap-

ter 1).

8Rotate the crankshaft clockwise until the

second pair of notches in the pulley rim align

with the edge of the sump mark, so that Nos

1 and 4 cylinders are at TDC (see Section 4).9Unbolt and remove the water pump pulley

and the auxiliary drivebelt idler pulley.

10Obtain Ford service tool 21-162, or

fabricate a substitute from a strip of metal

5 mm thick (while the strip’s thickness is

critical, its length and width are not, but

should be approximately 180 to 230 mm by

20 to 30 mm). Check that Nos 1 and 4

cylinders are at Top Dead Centre (TDC) - No 1

on the compression stroke - by resting this

tool on the cylinder head mating surface, and

sliding it into the slot in the left-hand end of

both camshafts (see illustration). The tool

should slip snugly into both slots while resting

on the cylinder head mating surface; if one

camshaft is only slightly out of alignment, it is

permissible to use an open-ended spanner to

rotate the camshaft gently and carefully until

the tool will fit.

11If both camshaft slots (they are machined

significantly off-centre) are below the level of

the cylinder head mating surface, rotate the

crankshaft through one full turn clockwise

and fit the tool again; it should now fit as

described in the previous paragraph.

12With the camshaft aligning tool remaining

in place, remove the crankshaft pulley. Do not

use the locked camshafts to prevent the

crankshaft from rotating - use only the locking

methods described in Section 8.

13Remove the timing belt lower and middle

covers (see Section 9).

14With the camshaft aligning tool still in

place, slacken the tensioner bolt, and use an

Allen key inserted into its centre to rotate the

tensioner clockwise as far as possible away

from the belt; retighten the bolt to secure the

tensioner clear of the timing belt (see

illustration).

15If the timing belt is to be re-used, use

white paint or similar to mark its direction of

rotation, and note from the manufacturer’s

markings which way round it is fitted.

Withdraw the belt (see illustration). Do not

rotate the crankshaft until the timing belt is

refitted.

16If the belt is being removed for reasons

other than routine renewal, check it carefully

for any signs of uneven wear, splitting, cracks

(especially at the roots of the belt teeth) or

In-car engine repair procedures 2A•11

2A

10.10 Fit camshaft aligning tool to ensure

engine is locked with Nos 1 and 4 cylinders

at TDC10.14 Slacken tensioner bolt, and use

Allen key to rotate tensioner away from

timing belt . . .10.15 . . . then withdraw timing belt

10.1 Timing belt and cover details

1 Timing belt upper cover

2 Inlet camshaft toothed pulley

3 Exhaust camshaft toothed pulley

4 Timing belt

5 Timing belt tensioner

6 Crankshaft toothed pulley

7 Timing belt middle cover

8 Timing belt lower cover

9 Crankshaft pulley

10 Water pump pulley

procarmanuals.com

Page 52 of 279

contamination with oil or coolant. Renew the

belt if there is the slightest doubt about its

condition. As a safety measure, the belt must

be renewed as a matter of course at the

intervals given in Chapter 1; if its history is

unknown, the belt should be renewed

irrespective of its apparent condition

whenever the engine is overhauled. Similarly,

check the tensioner spring (where fitted),

renewing it if there is any doubt about its

condition. Check also the toothed pulleys for

signs of wear or damage, and ensure that the

tensioner and guide pulleys rotate smoothly

on their bearings; renew any worn or

damaged components. If signs of oil or

coolant contamination are found, trace the

source of the leak and rectify it, then wash

down the engine timing belt area and related

components, to remove all traces of oil or

coolant.

17On reassembly, temporarily refit the

crankshaft pulley, to check that the pulley

notches and sump rib are aligned as

described in paragraph 8 above, then ensure

that both camshafts are aligned at TDC by

the special tool (paragraph 10). If the engine

is being reassembled after major dismantling,

both camshaft toothed pulleys should be free

to rotate on their respective camshafts; if the

timing belt alone is being renewed, both

pulleys should still be securely fastened.

18A holding tool will be required to prevent

the camshaft toothed pulleys from rotating

while their bolts are slackened and

retightened; either obtain Ford service tool15-030A, or fabricate a substitute as follows.

Find two lengths of steel strip, one

approximately 600 mm long and the other

about 200 mm, and three bolts with nuts and

washers; one nut and bolt forming the pivot of

a forked tool, with the remaining nuts and

bolts at the tips of the “forks”, to engage with

the pulley spokes as shown in the

accompanying illustrations. Note:Do not use

the camshaft aligning tool (whether genuine

Ford or not) to prevent rotation while the

camshaft toothed pulley bolts are slackened

or tightened; the risk of damage to the

camshaft concerned and to the cylinder head

is far too great. Use only a forked holding tool

applied directly to the pulleys, as described.

19If it is being fitted for the first time, screw

the timing belt tensioner spring retaining pin

into the cylinder head, tightening it to the

specified torque wrench setting. Unbolt the

tensioner, hook the spring on to the pin and

the tensioner backplate, then refit the

tensioner, engaging its backplate on the

locating peg (see illustrations).

20In all cases, slacken the tensioner bolt (if

necessary), and use an Allen key inserted into

its centre to rotate the tensioner clockwise as

far as possible against spring tension, then

retighten the bolt to secure the tensioner (see

illustration).

21Fit the timing belt; if the original is being

refitted, ensure that the marks and notes

made on removal are followed, so that the

belt is refitted the same way round, and to run

in the same direction. Starting at thecrankshaft toothed pulley, work anti-

clockwise around the camshaft toothed

pulleys and tensioner, finishing off at the rear

guide pulley. The front run, between the

crankshaft and the exhaust camshaft toothed

pulleys, mustbe kept taut, without altering

the position either of the crankshaft or of the

camshaft(s) - if necessary, the position of the

camshaft toothed pulleys can be altered by

rotating each on its camshaft (which remains

fixed by the aligning tool). Where the pulley is

still fastened, use the holding tool described

in paragraph 18 above to prevent the pulley

from rotating while its retaining bolt is

slackened - the pulley can then be rotated on

the camshaft until the belt will slip into place;

retighten the pulley bolt.

22When the belt is in place, slacken the

tensioner bolt gently until the spring pulls the

tensioner against the belt; the tensioner

should be retained correctly against the

timing belt inner shield and cylinder head, but

must be just free to respond to changes in

belt tension (see illustration).

23Tighten both camshaft toothed pulley

bolts (or check that they are tight, as

applicable) and remove the camshaft aligning

tool. Temporarily refit the crankshaft pulley,

and rotate the crankshaft through two full

turns clockwise to settle and tension the

timing belt, returning the crankshaft (pulley

notches) to the position described in

paragraph 8 above. Refit the camshaft

aligning tool; it should slip into place as

described in paragraph 10. If all is well,

proceed to paragraph 26 below.

24If one camshaft is only just out of line, fit

the forked holding tool to its toothed pulley,

adjust its position as required, and check that

any slack created has been taken up by the

tensioner; rotate the crankshaft through two

further turns clockwise, and refit the camshaft

aligning tool to check that it now fits as it

should. If all is well, proceed to paragraph 26

below.

25If either camshaft is significantly out of

line, use the holding tool described in

paragraph 18 above to prevent its pulley from

rotating while its retaining bolt is slackened -

the camshaft can then be rotated (gently and

carefully, using an open-ended spanner) until

2A•12 In-car engine repair procedures

10.19A Fitting tensioner spring retaining

pin10.19B Hook spring onto tensioner and

refit as shown - engage tensioner

backplate on locating peg (arrowed) . . .10.20 . . . then use Allen key to position

tensioner so that timing belt can be refitted

10.22 Slacken tensioner bolt to give initial

belt tension10.25 Using forked holding tool while

camshaft toothed pulley bolt is tightened

procarmanuals.com