check engine light FORD MONDEO 1993 Service Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 146 of 279

Vehicle speed sensor

29Testing of this component is beyond the

scope of the DIY mechanic, and should be left

to a Ford dealer.

Power steering pressure switch

30Unplug the electrical connector from the

sensor.

31Using an ohmmeter, measure the

resistance between the switch terminals. With

the engine switched off, or idling with the

roadwheels in the straight-ahead position,

little or no resistance should be measured.

With the engine running and the steering on

full-lock, the pressure increase in the system

should open the switch contacts, so that

infinite resistance is now measured.

32If the results obtained show the switch to

be faulty, renew it.

Exhaust gas pressure differential

sensor

33Testing of this component is beyond the

scope of the DIY mechanic, and should be left

to a Ford dealer.

Oxygen sensor

34Testing of this component can be done

only by attaching special diagnostic

equipment to the sensor wiring, and checking

that the voltage varies from low to high values

when the engine is running; do notattempt to

“test” any part of the system with anything

other than the correct test equipment. This is

beyond the scope of the DIY mechanic, and

should be left to a Ford dealer.

Removal and refitting

General

35Before disconnecting any of these

components, always disconnect the power by

uncoupling the battery terminals, negative

(earth) lead first - see Section 1 of Chapter 5.

ECU (Electronic Control Unit)

Note:The ECU is fragile. Take care not to

drop it or subject it to any other kind of

impact, and do not subject it to extremes of

temperature, or allow it to get wet.

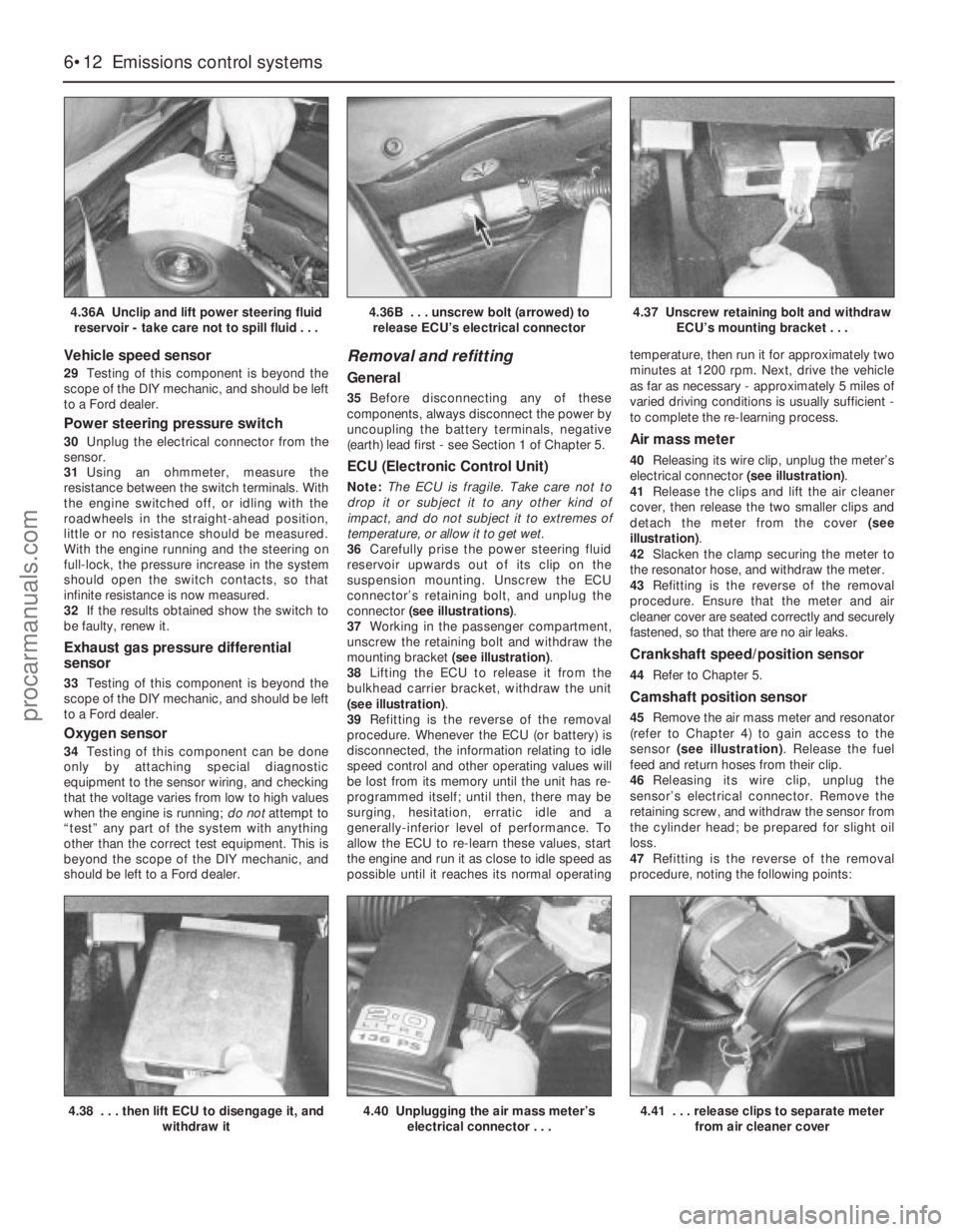

36Carefully prise the power steering fluid

reservoir upwards out of its clip on the

suspension mounting. Unscrew the ECU

connector’s retaining bolt, and unplug the

connector (see illustrations).

37Working in the passenger compartment,

unscrew the retaining bolt and withdraw the

mounting bracket (see illustration).

38Lifting the ECU to release it from the

bulkhead carrier bracket, withdraw the unit

(see illustration).

39Refitting is the reverse of the removal

procedure. Whenever the ECU (or battery) is

disconnected, the information relating to idle

speed control and other operating values will

be lost from its memory until the unit has re-

programmed itself; until then, there may be

surging, hesitation, erratic idle and a

generally-inferior level of performance. To

allow the ECU to re-learn these values, start

the engine and run it as close to idle speed as

possible until it reaches its normal operatingtemperature, then run it for approximately two

minutes at 1200 rpm. Next, drive the vehicle

as far as necessary - approximately 5 miles of

varied driving conditions is usually sufficient -

to complete the re-learning process.

Air mass meter

40Releasing its wire clip, unplug the meter’s

electrical connector (see illustration).

41Release the clips and lift the air cleaner

cover, then release the two smaller clips and

detach the meter from the cover (see

illustration).

42Slacken the clamp securing the meter to

the resonator hose, and withdraw the meter.

43Refitting is the reverse of the removal

procedure. Ensure that the meter and air

cleaner cover are seated correctly and securely

fastened, so that there are no air leaks.

Crankshaft speed/position sensor

44Refer to Chapter 5.

Camshaft position sensor

45Remove the air mass meter and resonator

(refer to Chapter 4) to gain access to the

sensor (see illustration). Release the fuel

feed and return hoses from their clip.

46Releasing its wire clip, unplug the

sensor’s electrical connector. Remove the

retaining screw, and withdraw the sensor from

the cylinder head; be prepared for slight oil

loss.

47Refitting is the reverse of the removal

procedure, noting the following points:

6•12 Emissions control systems

4.36A Unclip and lift power steering fluid

reservoir - take care not to spill fluid . . .4.36B . . . unscrew bolt (arrowed) to

release ECU’s electrical connector4.37 Unscrew retaining bolt and withdraw

ECU’s mounting bracket . . .

4.40 Unplugging the air mass meter’s

electrical connector . . .4.38 . . . then lift ECU to disengage it, and

withdraw it4.41 . . . release clips to separate meter

from air cleaner cover

procarmanuals.com

Page 149 of 279

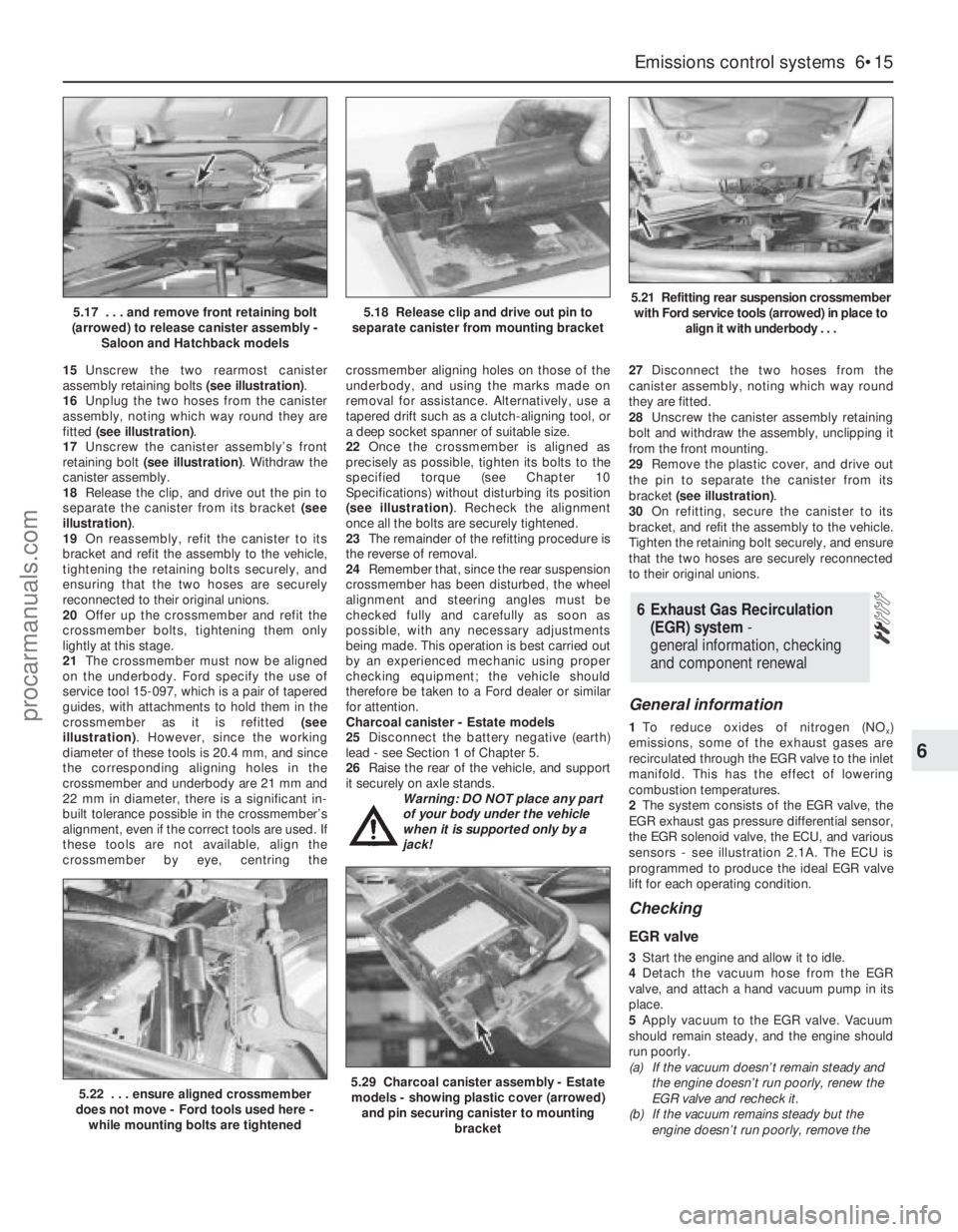

15Unscrew the two rearmost canister

assembly retaining bolts (see illustration).

16Unplug the two hoses from the canister

assembly, noting which way round they are

fitted (see illustration).

17Unscrew the canister assembly’s front

retaining bolt (see illustration). Withdraw the

canister assembly.

18Release the clip, and drive out the pin to

separate the canister from its bracket (see

illustration).

19On reassembly, refit the canister to its

bracket and refit the assembly to the vehicle,

tightening the retaining bolts securely, and

ensuring that the two hoses are securely

reconnected to their original unions.

20Offer up the crossmember and refit the

crossmember bolts, tightening them only

lightly at this stage.

21The crossmember must now be aligned

on the underbody. Ford specify the use of

service tool 15-097, which is a pair of tapered

guides, with attachments to hold them in the

crossmember as it is refitted (see

illustration). However, since the working

diameter of these tools is 20.4 mm, and since

the corresponding aligning holes in the

crossmember and underbody are 21 mm and

22 mm in diameter, there is a significant in-

built tolerance possible in the crossmember’s

alignment, even if the correct tools are used. If

these tools are not available, align the

crossmember by eye, centring thecrossmember aligning holes on those of the

underbody, and using the marks made on

removal for assistance. Alternatively, use a

tapered drift such as a clutch-aligning tool, or

a deep socket spanner of suitable size.

22Once the crossmember is aligned as

precisely as possible, tighten its bolts to the

specified torque (see Chapter 10

Specifications) without disturbing its position

(see illustration). Recheck the alignment

once all the bolts are securely tightened.

23The remainder of the refitting procedure is

the reverse of removal.

24Remember that, since the rear suspension

crossmember has been disturbed, the wheel

alignment and steering angles must be

checked fully and carefully as soon as

possible, with any necessary adjustments

being made. This operation is best carried out

by an experienced mechanic using proper

checking equipment; the vehicle should

therefore be taken to a Ford dealer or similar

for attention.

Charcoal canister - Estate models

25Disconnect the battery negative (earth)

lead - see Section 1 of Chapter 5.

26Raise the rear of the vehicle, and support

it securely on axle stands.

Warning: DO NOT place any part

of your body under the vehicle

when it is supported only by a

jack!27Disconnect the two hoses from the

canister assembly, noting which way round

they are fitted.

28Unscrew the canister assembly retaining

bolt and withdraw the assembly, unclipping it

from the front mounting.

29Remove the plastic cover, and drive out

the pin to separate the canister from its

bracket (see illustration).

30On refitting, secure the canister to its

bracket, and refit the assembly to the vehicle.

Tighten the retaining bolt securely, and ensure

that the two hoses are securely reconnected

to their original unions.

General information

1To reduce oxides of nitrogen (NOx)

emissions, some of the exhaust gases are

recirculated through the EGR valve to the inlet

manifold. This has the effect of lowering

combustion temperatures.

2The system consists of the EGR valve, the

EGR exhaust gas pressure differential sensor,

the EGR solenoid valve, the ECU, and various

sensors - see illustration 2.1A. The ECU is

programmed to produce the ideal EGR valve

lift for each operating condition.

Checking

EGR valve

3Start the engine and allow it to idle.

4Detach the vacuum hose from the EGR

valve, and attach a hand vacuum pump in its

place.

5Apply vacuum to the EGR valve. Vacuum

should remain steady, and the engine should

run poorly.

(a) If the vacuum doesn’t remain steady and

the engine doesn’t run poorly, renew the

EGR valve and recheck it.

(b) If the vacuum remains steady but the

engine doesn’t run poorly, remove the

6 Exhaust Gas Recirculation

(EGR) system-

general information, checking

and component renewal

Emissions control systems 6•15

6

5.22 . . . ensure aligned crossmember

does not move - Ford tools used here -

while mounting bolts are tightened5.29 Charcoal canister assembly - Estate

models - showing plastic cover (arrowed)

and pin securing canister to mounting

bracket

5.17 . . . and remove front retaining bolt

(arrowed) to release canister assembly -

Saloon and Hatchback models5.18 Release clip and drive out pin to

separate canister from mounting bracket5.21 Refitting rear suspension crossmember

with Ford service tools (arrowed) in place to

align it with underbody . . .

procarmanuals.com

Page 160 of 279

11Locate one of the circlips in the outer

groove of the knuckle.

12Press or drive the new bearing into the

knuckle until it contacts the circlip, using a

length of metal tube of diameter slightly less

than the outer race. Do not apply any

pressure to the inner race.

13Locate the remaining circlip in the inner

groove of the knuckle.

14Support the inner race on a length of

metal tube, then press or drive the hub fully

into the bearing.

15Refit the steering knuckle and hub

assembly as described in Section 2.

Removal

1Apply the handbrake, then jack up the front

of the vehicle and support it on axle stands.

Remove the appropriate front wheel.

2Unbolt the brake hose support bracket from

the front of the suspension strut (see

illustration).

3Remove the brake caliper as described in

Chapter 9, but do not disconnect the flexible

hydraulic hose from the caliper. Suspend the

caliper from a suitable point under the wheel

arch, taking care not to strain the hose.

4Extract the split pin from the track rod end

balljoint nut. Unscrew the nut, and detach the

rod from the arm on the steering knuckleusing a conventional balljoint removal tool.

Take care not to damage the balljoint seal.

5Remove the ABS sensor (when fitted) from

the steering knuckle, as described in Chapter 9.

6Remove the clip securing the driveshaft

inner gaiter to the inner CV joint. Disconnect

the gaiter from the CV joint housing.

7Remove the nut and disconnect the anti-roll

bar link from the strut. Note that, on models

fitted with ABS, the ABS wheel sensor wiring

support bracket is located beneath the nut

(see illustration).

8Note which way round the lower arm

balljoint clamp bolt is fitted, then unscrew and

remove it from the knuckle assembly. Lever

the balljoint down from the knuckle; if it is

tight, prise the clamp open carefully using a

large flat-bladed tool. Take care not to

damage the balljoint seal during the

separation procedure.

9Where applicable, disconnect the adaptive

damping wiring multi-plug at the strut, and

unclip the wire.

10Support the strut and steering knuckle on

an axle stand. Working inside the engine

compartment, remove the strut cap (if fitted).

Unscrew and remove the front suspension

strut upper mounting nut, holding the piston

rod stationary with an 8 mm Allen key (see

illustration).

11Lower the suspension strut, together with

the driveshaft and steering knuckle, from

under the wheel arch, withdrawing the tripod

on the inner end of the driveshaft from the CV

joint housing.12Unscrew and remove the pinch-bolt

securing the steering knuckle assembly to the

front suspension strut, noting which way

round it is fitted. Prise open the clamp using a

wedge-shaped tool, and release the knuckle

from the strut (see illustrations).

Refitting

13With the clamp prised open, locate the

front suspension strut on the steering knuckle,

and refit the pinch-bolt with its head facing

forwards. Tighten the bolt to the specified

torque.

14Locate the suspension strut (together with

the driveshaft and steering knuckle) in its

upper mounting, and loosely screw on the

nut.

15Locate the tripod on the inner end of the

driveshaft in the CV joint housing, then

manipulate the gaiter onto the housing, and fit

a new clip.

16Where applicable, reconnect the adaptive

damping multi-plug, and fit the wire in the clip.

17Locate the lower arm balljoint fully in the

bottom of the steering knuckle. Refit the

clamp bolt and tighten it to the specified

torque.

18Reconnect the anti-roll bar link to the

strut, and tighten the nut to the specified

torque. On models fitted with ABS, do not

forget to locate the sensor wiring support

bracket beneath the nut.

19Where fitted, refit the ABS sensor as

described in Chapter 9.

20Refit the track rod end balljoint to the

steering knuckle, and tighten the nut to the

specified torque. Check that the split pin

holes are aligned; if necessary, turn the nut to

the nearest alignment, making sure that the

torque wrench setting is still within the

specified range. Insert a new split pin, and

bend it back to secure.

21Refit the brake caliper as described in

Chapter 9.

22Refit the brake hose support bracket to

the strut, and tighten the bolt.

23Refit the wheel, and lower the vehicle to

the ground. Tighten the wheel nuts to the

specified torque.

24Tighten the suspension strut upper

mounting nut to the specified torque, while

4 Front suspension strut -

removal and refitting

10•6 Suspension and steering systems

4.2 Removing the brake hose support

bracket from the front of the front

suspension strut4.7 Removing the anti-roll bar link and

ABS sensor wiring bracket4.10 Front suspension strut upper

mounting nut

4.12A Steering knuckle-to-strut pinch-bolt4.12B Releasing the knuckle from the strut

procarmanuals.com

Page 174 of 279

15Locate the steering column shaft on the

flexible coupling, swivel the clamp plate

round, then insert the bolt and tighten to the

specified torque.

16Refit the driver’s side lower trim panel.

17Refit the steering column upper and lower

shrouds.

18Reconnect the battery negative lead.

Removal

1Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

2Turn the steering wheel so that the front

wheels are in the straight-ahead position.

Remove the ignition key, then turn the

steering wheel slightly as necessary until the

steering lock engages.

3Unscrew the clamp plate bolt securing the

steering column shaft to the flexible coupling.

Swivel the clamp plate around, and disengage

it from the flexible coupling stub.

4Carefully prise the rubber boot from the

bulkhead, and withdraw it into the passenger

compartment. Take care not to damage the

sealing lip of the boot.

5Using an Allen key, unscrew the clamp bolt

securing the flexible coupling to the pinion

shaft on the steering gear, and withdraw the

coupling from inside the vehicle.

Refitting

6Refitting is a reversal of the removal

procedure, but tighten the clamp bolts to the

specified torque. Make sure that the rubber

boot engages correctly in the bulkhead and

on the flexible coupling.

Removal

1Remove the steering column flexible

coupling as described in Section 29.

2Apply the handbrake, then jack up the frontof the vehicle and support it on axle stands.

Remove both front wheels.

3Working beneath the vehicle, unbolt the

rear engine mounting from the transmission

and underbody.

4Extract the split pins from the track rod end

balljoint nuts, then unscrew the nuts, and

detach the rods from the arms on the steering

knuckles using a conventional balljoint

removal tool. Take care not to damage the

balljoint seals.

5Position a suitable container beneath the

steering gear, then unscrew the union nuts

securing the power steering fluid supply,

return, and cooler lines to the steering gear.

Identify the lines for position, then unbolt the

clamps, disconnect the lines, and allow the

fluid to drain into the container. Cover the

apertures in the steering gear and also the

ends of the fluid pipes, to prevent the ingress

of dust and dirt into the hydraulic circuit.

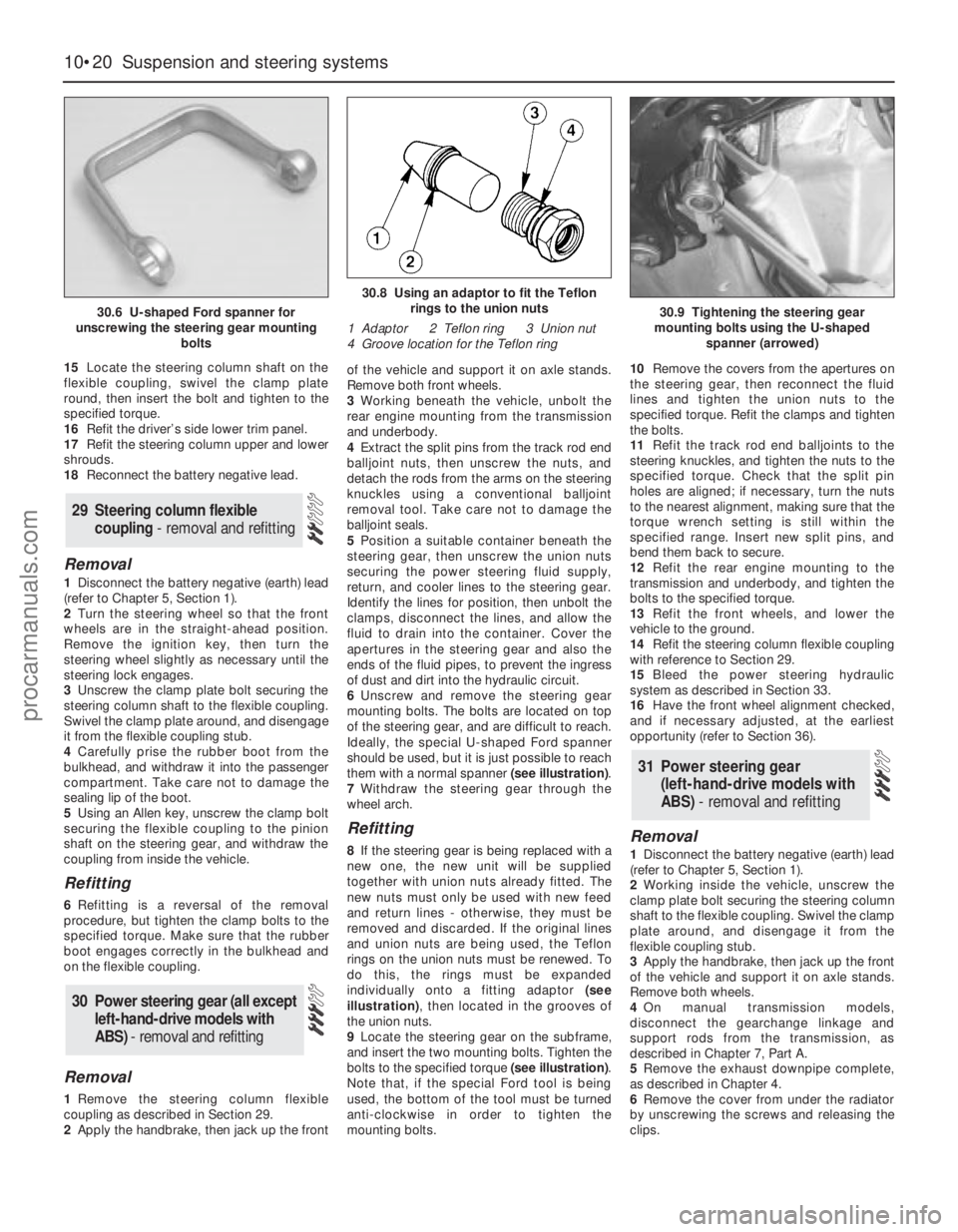

6Unscrew and remove the steering gear

mounting bolts. The bolts are located on top

of the steering gear, and are difficult to reach.

Ideally, the special U-shaped Ford spanner

should be used, but it is just possible to reach

them with a normal spanner (see illustration).

7Withdraw the steering gear through the

wheel arch.

Refitting

8If the steering gear is being replaced with a

new one, the new unit will be supplied

together with union nuts already fitted. The

new nuts must only be used with new feed

and return lines - otherwise, they must be

removed and discarded. If the original lines

and union nuts are being used, the Teflon

rings on the union nuts must be renewed. To

do this, the rings must be expanded

individually onto a fitting adaptor (see

illustration), then located in the grooves of

the union nuts.

9Locate the steering gear on the subframe,

and insert the two mounting bolts. Tighten the

bolts to the specified torque (see illustration).

Note that, if the special Ford tool is being

used, the bottom of the tool must be turned

anti-clockwise in order to tighten the

mounting bolts.10Remove the covers from the apertures on

the steering gear, then reconnect the fluid

lines and tighten the union nuts to the

specified torque. Refit the clamps and tighten

the bolts.

11Refit the track rod end balljoints to the

steering knuckles, and tighten the nuts to the

specified torque. Check that the split pin

holes are aligned; if necessary, turn the nuts

to the nearest alignment, making sure that the

torque wrench setting is still within the

specified range. Insert new split pins, and

bend them back to secure.

12Refit the rear engine mounting to the

transmission and underbody, and tighten the

bolts to the specified torque.

13Refit the front wheels, and lower the

vehicle to the ground.

14Refit the steering column flexible coupling

with reference to Section 29.

15Bleed the power steering hydraulic

system as described in Section 33.

16Have the front wheel alignment checked,

and if necessary adjusted, at the earliest

opportunity (refer to Section 36).Removal

1Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

2Working inside the vehicle, unscrew the

clamp plate bolt securing the steering column

shaft to the flexible coupling. Swivel the clamp

plate around, and disengage it from the

flexible coupling stub.

3Apply the handbrake, then jack up the front

of the vehicle and support it on axle stands.

Remove both wheels.

4On manual transmission models,

disconnect the gearchange linkage and

support rods from the transmission, as

described in Chapter 7, Part A.

5Remove the exhaust downpipe complete,

as described in Chapter 4.

6Remove the cover from under the radiator

by unscrewing the screws and releasing the

clips.

31 Power steering gear

(left-hand-drive models with

ABS) - removal and refitting

30 Power steering gear (all except

left-hand-drive models with

ABS) - removal and refitting

29 Steering column flexible

coupling - removal and refitting

10•20 Suspension and steering systems

30.6 U-shaped Ford spanner for

unscrewing the steering gear mounting

bolts

30.8 Using an adaptor to fit the Teflon

rings to the union nuts

1 Adaptor 2 Teflon ring 3 Union nut

4 Groove location for the Teflon ring

30.9 Tightening the steering gear

mounting bolts using the U-shaped

spanner (arrowed)

procarmanuals.com

Page 179 of 279

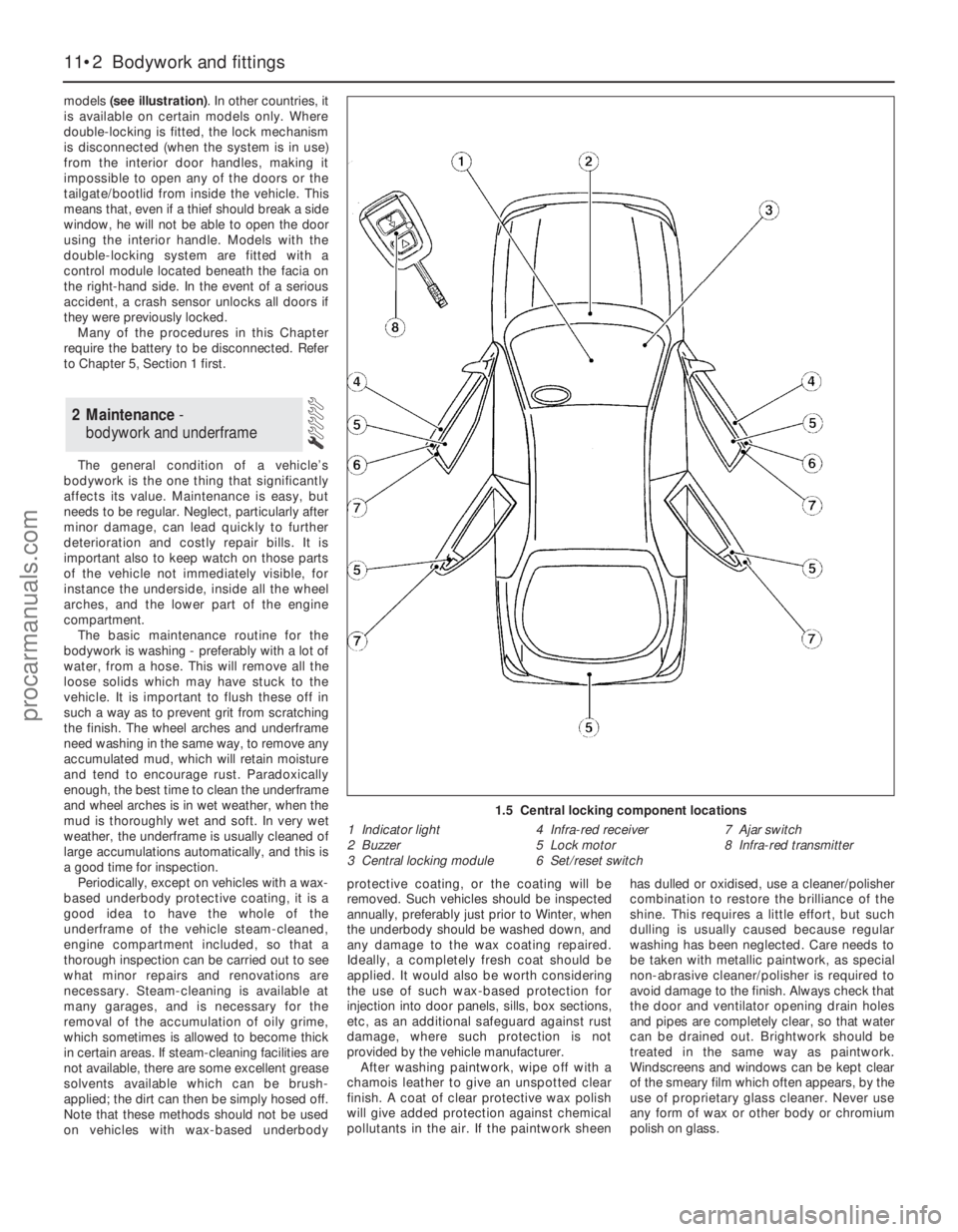

models (see illustration). In other countries, it

is available on certain models only. Where

double-locking is fitted, the lock mechanism

is disconnected (when the system is in use)

from the interior door handles, making it

impossible to open any of the doors or the

tailgate/bootlid from inside the vehicle. This

means that, even if a thief should break a side

window, he will not be able to open the door

using the interior handle. Models with the

double-locking system are fitted with a

control module located beneath the facia on

the right-hand side. In the event of a serious

accident, a crash sensor unlocks all doors if

they were previously locked.

Many of the procedures in this Chapter

require the battery to be disconnected. Refer

to Chapter 5, Section 1 first.

The general condition of a vehicle’s

bodywork is the one thing that significantly

affects its value. Maintenance is easy, but

needs to be regular. Neglect, particularly after

minor damage, can lead quickly to further

deterioration and costly repair bills. It is

important also to keep watch on those parts

of the vehicle not immediately visible, for

instance the underside, inside all the wheel

arches, and the lower part of the engine

compartment.

The basic maintenance routine for the

bodywork is washing - preferably with a lot of

water, from a hose. This will remove all the

loose solids which may have stuck to the

vehicle. It is important to flush these off in

such a way as to prevent grit from scratching

the finish. The wheel arches and underframe

need washing in the same way, to remove any

accumulated mud, which will retain moisture

and tend to encourage rust. Paradoxically

enough, the best time to clean the underframe

and wheel arches is in wet weather, when the

mud is thoroughly wet and soft. In very wet

weather, the underframe is usually cleaned of

large accumulations automatically, and this is

a good time for inspection.

Periodically, except on vehicles with a wax-

based underbody protective coating, it is a

good idea to have the whole of the

underframe of the vehicle steam-cleaned,

engine compartment included, so that a

thorough inspection can be carried out to see

what minor repairs and renovations are

necessary. Steam-cleaning is available at

many garages, and is necessary for the

removal of the accumulation of oily grime,

which sometimes is allowed to become thick

in certain areas. If steam-cleaning facilities are

not available, there are some excellent grease

solvents available which can be brush-

applied; the dirt can then be simply hosed off.

Note that these methods should not be used

on vehicles with wax-based underbodyprotective coating, or the coating will be

removed. Such vehicles should be inspected

annually, preferably just prior to Winter, when

the underbody should be washed down, and

any damage to the wax coating repaired.

Ideally, a completely fresh coat should be

applied. It would also be worth considering

the use of such wax-based protection for

injection into door panels, sills, box sections,

etc, as an additional safeguard against rust

damage, where such protection is not

provided by the vehicle manufacturer.

After washing paintwork, wipe off with a

chamois leather to give an unspotted clear

finish. A coat of clear protective wax polish

will give added protection against chemical

pollutants in the air. If the paintwork sheenhas dulled or oxidised, use a cleaner/polisher

combination to restore the brilliance of the

shine. This requires a little effort, but such

dulling is usually caused because regular

washing has been neglected. Care needs to

be taken with metallic paintwork, as special

non-abrasive cleaner/polisher is required to

avoid damage to the finish. Always check that

the door and ventilator opening drain holes

and pipes are completely clear, so that water

can be drained out. Brightwork should be

treated in the same way as paintwork.

Windscreens and windows can be kept clear

of the smeary film which often appears, by the

use of proprietary glass cleaner. Never use

any form of wax or other body or chromium

polish on glass.

2 Maintenance -

bodywork and underframe

11•2 Bodywork and fittings

1.5 Central locking component locations

1 Indicator light

2 Buzzer

3 Central locking module4 Infra-red receiver

5 Lock motor

6 Set/reset switch7 Ajar switch

8 Infra-red transmitter

procarmanuals.com

Page 202 of 279

Chapter 12 Body electrical system

Air bag clock spring - removal and refitting . . . . . . . . . . . . . . . . . . . 30

Air bag control module - removal and refitting . . . . . . . . . . . . . . . . . 29

Air bag unit (driver’s side) - removal and refitting . . . . . . . . . . . . . . . 28

Anti-theft alarm system - general information . . . . . . . . . . . . . . . . . . 20

Auxiliary warning system - general information and

component renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Battery - check, maintenance and charging . . . . . . . . See Chapter 1

Battery - removal and refitting . . . . . . . . . . . . . . . . . . . See Chapter 5

Bulbs (exterior lights) - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Bulbs (interior lights) - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Clock - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Compact disc player - removal and refitting . . . . . . . . . . . . . . . . . . . 25

Cruise control system - general information . . . . . . . . . . . . . . . . . . . 21

Electrical fault finding - general information . . . . . . . . . . . . . . . . . . . 2

Electrical system check . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Exterior light units - removal and refitting . . . . . . . . . . . . . . . . . . . . . 7

Fuses, relays and timer module - testing and renewal . . . . . . . . . . . 3

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Headlight beam alignment - checking and adjustment . . . . . . . . . . 8

Headlight levelling motor - removal and refitting . . . . . . . . . . . . . . . 9Horn - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Instrument panel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . 10

Instrument panel components - removal and refitting . . . . . . . . . . . 11

Radio aerial - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Radio/cassette player - coding, removal and refitting . . . . . . . . . . . 23

Radio/cassette player power amplifier - removal and refitting . . . . . 24

Speakers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Speedometer drive cable - removal and refitting . . . . . . . . . . . . . . . 12

Stop-light switch - removal and refitting . . . . . . . . . . . See Chapter 9

Switches - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Tailgate wiper motor assembly - removal and refitting . . . . . . . . . . . 17

TCS inhibition switch - removal and refitting . . . . . . . . See Chapter 9

Trip computer module - removal and refitting . . . . . . . . . . . . . . . . . 18

Windscreen/tailgate washer system and wiper blade

check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Windscreen/tailgate washer system components - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Windscreen wiper motor and linkage - removal and refitting . . . . . . 16

Wiper arms - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 15

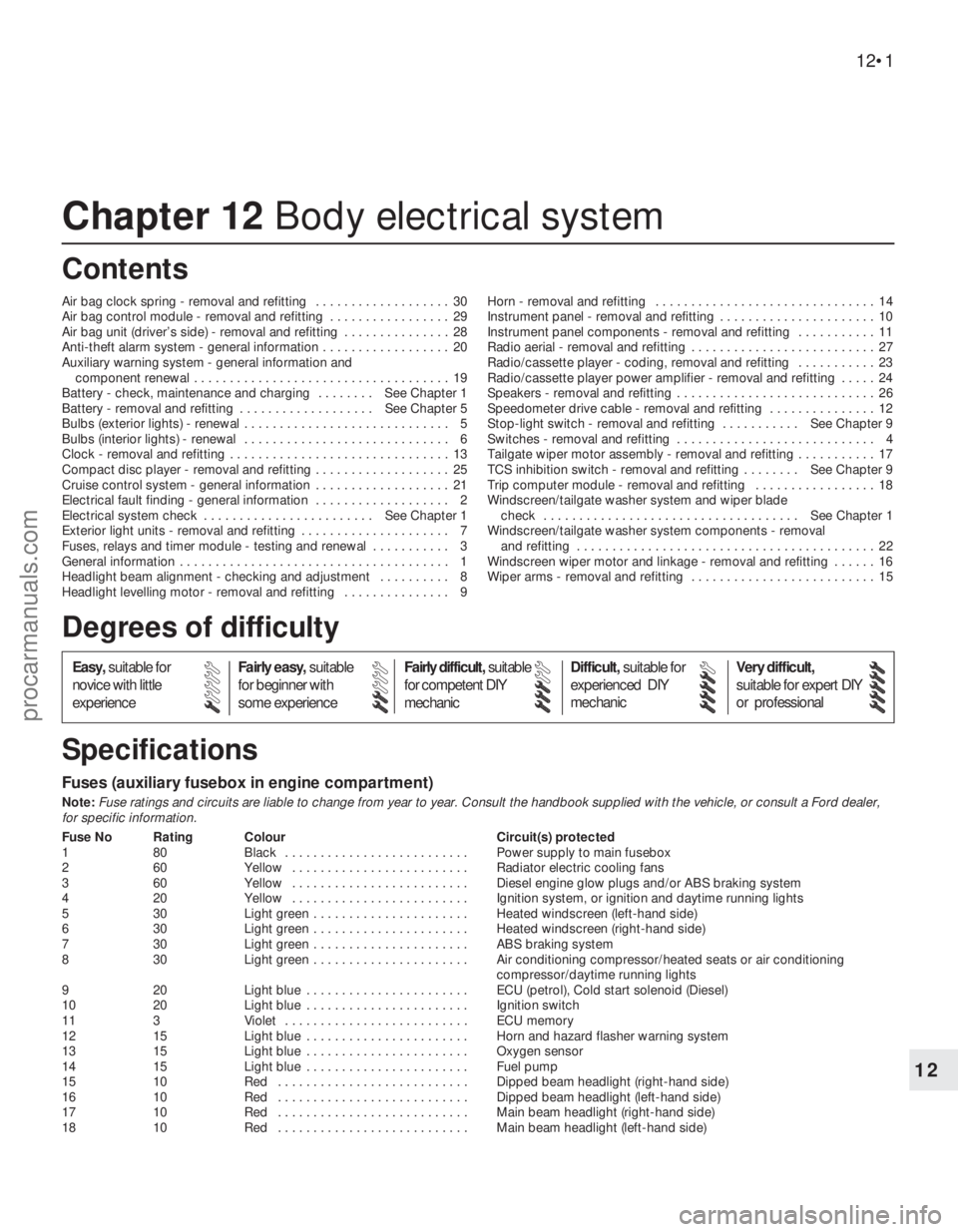

Fuses (auxiliary fusebox in engine compartment)

Note:Fuse ratings and circuits are liable to change from year to year. Consult the handbook supplied with the vehicle, or consult a Ford dealer,

for specific information.

Fuse No Rating Colour Circuit(s) protected

1 80 Black . . . . . . . . . . . . . . . . . . . . . . . . . . Power supply to main fusebox

2 60 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . Radiator electric cooling fans

3 60 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . Diesel engine glow plugs and/or ABS braking system

4 20 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . Ignition system, or ignition and daytime running lights

5 30 Light green . . . . . . . . . . . . . . . . . . . . . . Heated windscreen (left-hand side)

6 30 Light green . . . . . . . . . . . . . . . . . . . . . . Heated windscreen (right-hand side)

7 30 Light green . . . . . . . . . . . . . . . . . . . . . . ABS braking system

8 30 Light green . . . . . . . . . . . . . . . . . . . . . . Air conditioning compressor/heated seats or air conditioning

compressor/daytime running lights

9 20 Light blue . . . . . . . . . . . . . . . . . . . . . . . ECU (petrol), Cold start solenoid (Diesel)

10 20 Light blue . . . . . . . . . . . . . . . . . . . . . . . Ignition switch

11 3 Violet . . . . . . . . . . . . . . . . . . . . . . . . . . ECU memory

12 15 Light blue . . . . . . . . . . . . . . . . . . . . . . . Horn and hazard flasher warning system

13 15 Light blue . . . . . . . . . . . . . . . . . . . . . . . Oxygen sensor

14 15 Light blue . . . . . . . . . . . . . . . . . . . . . . . Fuel pump

15 10 Red . . . . . . . . . . . . . . . . . . . . . . . . . . . Dipped beam headlight (right-hand side)

16 10 Red . . . . . . . . . . . . . . . . . . . . . . . . . . . Dipped beam headlight (left-hand side)

17 10 Red . . . . . . . . . . . . . . . . . . . . . . . . . . . Main beam headlight (right-hand side)

18 10 Red . . . . . . . . . . . . . . . . . . . . . . . . . . . Main beam headlight (left-hand side)

12•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,suitable

for competent DIY

mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

Specifications Contents

12

procarmanuals.com

Page 205 of 279

compartment, but on Estate models, it is on

the right-hand side.

Some models are fitted with a headlight

levelling system, which is controlled by a knob

on the facia. On position “0”, the headlights

are in their base position, and on position “5”,

the headlights are in their maximum inclined

angle.

It should be noted that, when portions of

the electrical system are serviced, the cable

should be disconnected from the battery

negative terminal, to prevent electrical shorts

and fires.

Caution: When disconnecting the

battery for work described in the

following Sections, refer to

Chapter 5, Section 1.

Note:Refer to the precautions given in

“Safety first!” and in Section 1 of this Chapter

before starting work. The following tests relate

to testing of the main electrical circuits, and

should not be used to test delicate electronic

circuits (such as engine management systems,

anti-lock braking systems, etc), particularly

where an electronic control module is used.

Also refer to the precautions given in Chapter

5, Section 1.

General

1A typical electrical circuit consists of an

electrical component, any switches, relays,

motors, fuses, fusible links or circuit breakers

related to that component, and the wiring and

connectors which link the component to both

the battery and the chassis. To help to

pinpoint a problem in an electrical circuit,

wiring diagrams are included at the end of this

manual.

2Before attempting to diagnose an electrical

fault, first study the appropriate wiring

diagram, to obtain a complete understanding

of the components included in the particular

circuit concerned. The possible sources of a

fault can be narrowed down by noting if other

components related to the circuit are

operating properly. If several components or

circuits fail at one time, the problem is likely to

be related to a shared fuse or earth

connection.

3Electrical problems usually stem from

simple causes, such as loose or corroded

connections, a faulty earth connection, a

blown fuse, a melted fusible link, or a faulty

relay (refer to Section 3 for details of testing

relays). Visually inspect the condition of all

fuses, wires and connections in a problem

circuit before testing the components. Use

the wiring diagrams to determine which

terminal connections will need to be checked

in order to pinpoint the trouble-spot.

4The basic tools required for electrical fault-

finding include a circuit tester or voltmeter (a

12-volt bulb with a set of test leads can alsobe used for certain tests); an ohmmeter (to

measure resistance and check for continuity);

a battery and set of test leads; and a jumper

wire, preferably with a circuit breaker or fuse

incorporated, which can be used to bypass

suspect wires or electrical components.

Before attempting to locate a problem with

test instruments, use the wiring diagram to

determine where to make the connections.

5To find the source of an intermittent wiring

fault (usually due to a poor or dirty

connection, or damaged wiring insulation), a

“wiggle” test can be performed on the wiring.

This involves wiggling the wiring by hand to

see if the fault occurs as the wiring is moved.

It should be possible to narrow down the

source of the fault to a particular section of

wiring. This method of testing can be used in

conjunction with any of the tests described in

the following sub-Sections.

6Apart from problems due to poor

connections, two basic types of fault can

occur in an electrical circuit - open-circuit, or

short-circuit.

7Open-circuit faults are caused by a break

somewhere in the circuit, which prevents

current from flowing. An open-circuit fault will

prevent a component from working.

8Short-circuit faults are caused by a “short”

somewhere in the circuit, which allows the

current flowing in the circuit to “escape” along

an alternative route, usually to earth. Short-

circuit faults are normally caused by a

breakdown in wiring insulation, which allows a

feed wire to touch either another wire, or an

earthed component such as the bodyshell. A

short-circuit fault will normally cause the

relevant circuit fuse to blow.

Finding an open-circuit

9To check for an open-circuit, connect one

lead of a circuit tester or the negative lead of a

voltmeter either to the battery negative

terminal or to a known good earth.

10Connect the other lead to a connector in

the circuit being tested, preferably nearest to

the battery or fuse. At this point, battery

voltage should be present, unless the lead

from the battery or the fuse itself is faulty

(bearing in mind that some circuits are live

only when the ignition switch is moved to a

particular position).

11Switch on the circuit, then connect the

tester lead to the connector nearest the circuit

switch on the component side.

12If voltage is present (indicated either by

the tester bulb lighting or a voltmeter reading,

as applicable), this means that the section of

the circuit between the relevant connector

and the switch is problem-free.

13Continue to check the remainder of the

circuit in the same fashion.

14When a point is reached at which no

voltage is present, the problem must lie

between that point and the previous test point

with voltage. Most problems can be traced to

a broken, corroded or loose connection.

Finding a short-circuit

15To check for a short-circuit, first

disconnect the load(s) from the circuit (loads

are the components which draw current from

a circuit, such as bulbs, motors, heating

elements, etc).

16Remove the relevant fuse from the circuit,

and connect a circuit tester or voltmeter to the

fuse connections.

17Switch on the circuit, bearing in mind that

some circuits are live only when the ignition

switch is moved to a particular position.

18If voltage is present (indicated either by

the tester bulb lighting or a voltmeter reading,

as applicable), this means that there is a

short-circuit.

19If no voltage is present during this test,

but the fuse still blows with the load(s)

reconnected, this indicates an internal fault in

the load(s).

Finding an earth fault

20The battery negative terminal is

connected to “earth” - the metal of the

engine/transmission unit and the vehicle body

- and many systems are wired so that they

only receive a positive feed, the current

returning via the metal of the car body. This

means that the component mounting and the

body form part of that circuit. Loose or

corroded mountings can therefore cause a

range of electrical faults, ranging from total

failure of a circuit, to a puzzling partial failure.

In particular, lights may shine dimly (especially

when another circuit sharing the same earth

point is in operation), motors (eg wiper motors

or the radiator cooling fan motor) may run

slowly, and the operation of one circuit may

have an apparently-unrelated effect on

another. Note that on many vehicles, earth

straps are used between certain components,

such as the engine/transmission and the

body, usually where there is no metal-to-

metal contact between components, due to

flexible rubber mountings, etc.

21To check whether a component is

properly earthed, disconnect the battery (refer

to Chapter 5, Section 1) and connect one lead

of an ohmmeter to a known good earth point.

Connect the other lead to the wire or earth

connection being tested. The resistance

reading should be zero; if not, check the

connection as follows.

22If an earth connection is thought to be

faulty, dismantle the connection, and clean

both the bodyshell and the wire terminal (or

the component earth connection mating

surface) back to bare metal. Be careful to

remove all traces of dirt and corrosion, then

use a knife to trim away any paint, so that a

clean metal-to-metal joint is made. On

reassembly, tighten the joint fasteners

securely; if a wire terminal is being refitted,

use serrated washers between the terminal

and the bodyshell, to ensure a clean and

secure connection. When the connection is

2 Electrical fault finding -

general information

12•4 Body electrical system

procarmanuals.com

Page 206 of 279

remade, prevent the onset of corrosion in the

future by applying a coat of petroleum jelly or

silicone-based grease, or by spraying on (at

regular intervals) a proprietary ignition sealer

such as Holts Damp Start, or a water-

dispersant lubricant such as Holts Wet Start.

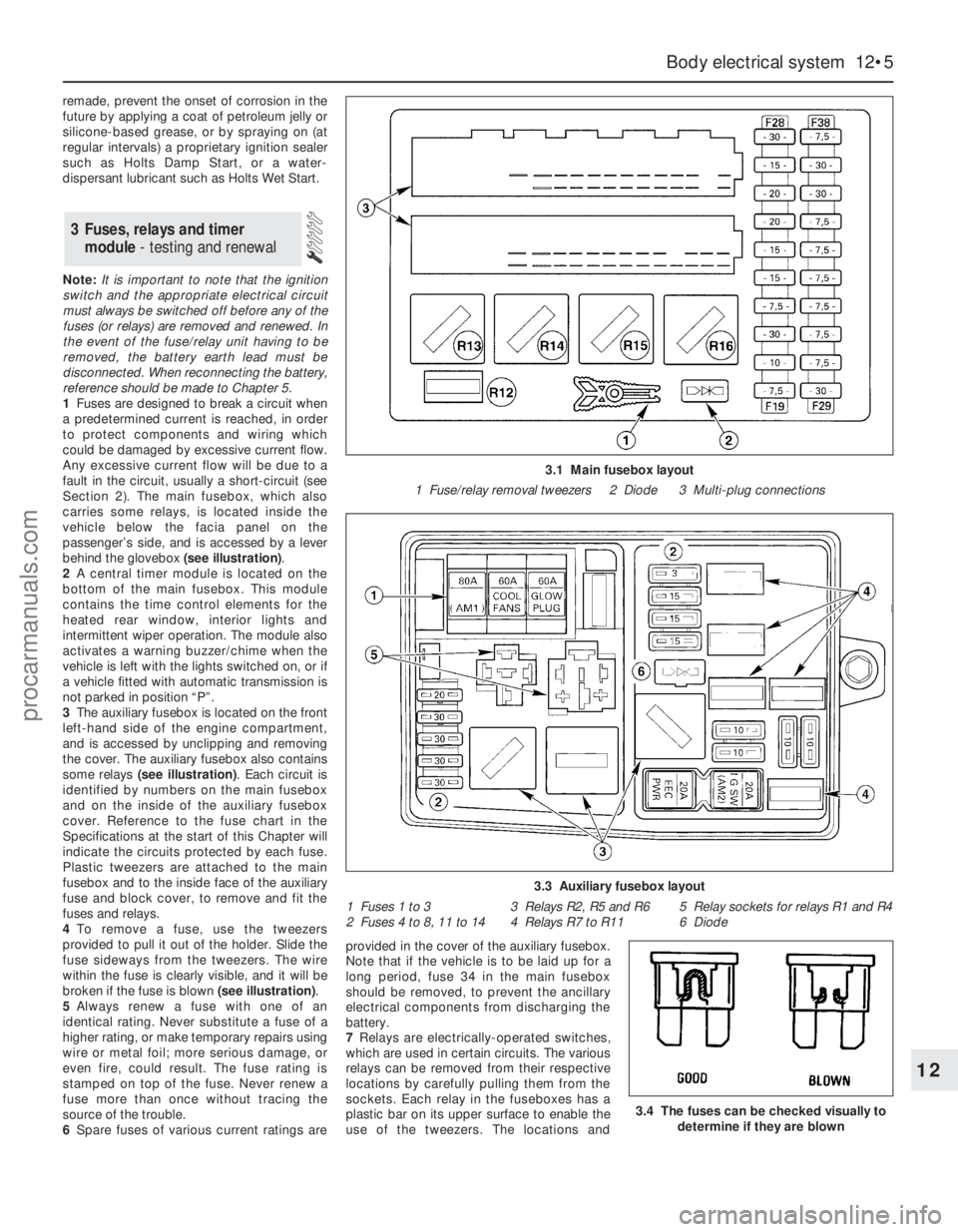

Note:It is important to note that the ignition

switch and the appropriate electrical circuit

must always be switched off before any of the

fuses (or relays) are removed and renewed. In

the event of the fuse/relay unit having to be

removed, the battery earth lead must be

disconnected. When reconnecting the battery,

reference should be made to Chapter 5.

1Fuses are designed to break a circuit when

a predetermined current is reached, in order

to protect components and wiring which

could be damaged by excessive current flow.

Any excessive current flow will be due to a

fault in the circuit, usually a short-circuit (see

Section 2). The main fusebox, which also

carries some relays, is located inside the

vehicle below the facia panel on the

passenger’s side, and is accessed by a lever

behind the glovebox (see illustration).

2A central timer module is located on the

bottom of the main fusebox. This module

contains the time control elements for the

heated rear window, interior lights and

intermittent wiper operation. The module also

activates a warning buzzer/chime when the

vehicle is left with the lights switched on, or if

a vehicle fitted with automatic transmission is

not parked in position “P”.

3The auxiliary fusebox is located on the front

left-hand side of the engine compartment,

and is accessed by unclipping and removing

the cover. The auxiliary fusebox also contains

some relays (see illustration). Each circuit is

identified by numbers on the main fusebox

and on the inside of the auxiliary fusebox

cover. Reference to the fuse chart in the

Specifications at the start of this Chapter will

indicate the circuits protected by each fuse.

Plastic tweezers are attached to the main

fusebox and to the inside face of the auxiliary

fuse and block cover, to remove and fit the

fuses and relays.

4To remove a fuse, use the tweezers

provided to pull it out of the holder. Slide the

fuse sideways from the tweezers. The wire

within the fuse is clearly visible, and it will be

broken if the fuse is blown (see illustration).

5Always renew a fuse with one of an

identical rating. Never substitute a fuse of a

higher rating, or make temporary repairs using

wire or metal foil; more serious damage, or

even fire, could result. The fuse rating is

stamped on top of the fuse. Never renew a

fuse more than once without tracing the

source of the trouble.

6Spare fuses of various current ratings areprovided in the cover of the auxiliary fusebox.

Note that if the vehicle is to be laid up for a

long period, fuse 34 in the main fusebox

should be removed, to prevent the ancillary

electrical components from discharging the

battery.

7Relays are electrically-operated switches,

which are used in certain circuits. The various

relays can be removed from their respective

locations by carefully pulling them from the

sockets. Each relay in the fuseboxes has a

plastic bar on its upper surface to enable the

use of the tweezers. The locations and

3 Fuses, relays and timer

module- testing and renewal

Body electrical system 12•5

12

3.4 The fuses can be checked visually to

determine if they are blown

3.1 Main fusebox layout

1 Fuse/relay removal tweezers 2 Diode 3 Multi-plug connections

3.3 Auxiliary fusebox layout

1 Fuses 1 to 3 3 Relays R2, R5 and R6 5 Relay sockets for relays R1 and R4

2 Fuses 4 to 8, 11 to 14 4 Relays R7 to R11 6 Diode

procarmanuals.com

Page 218 of 279

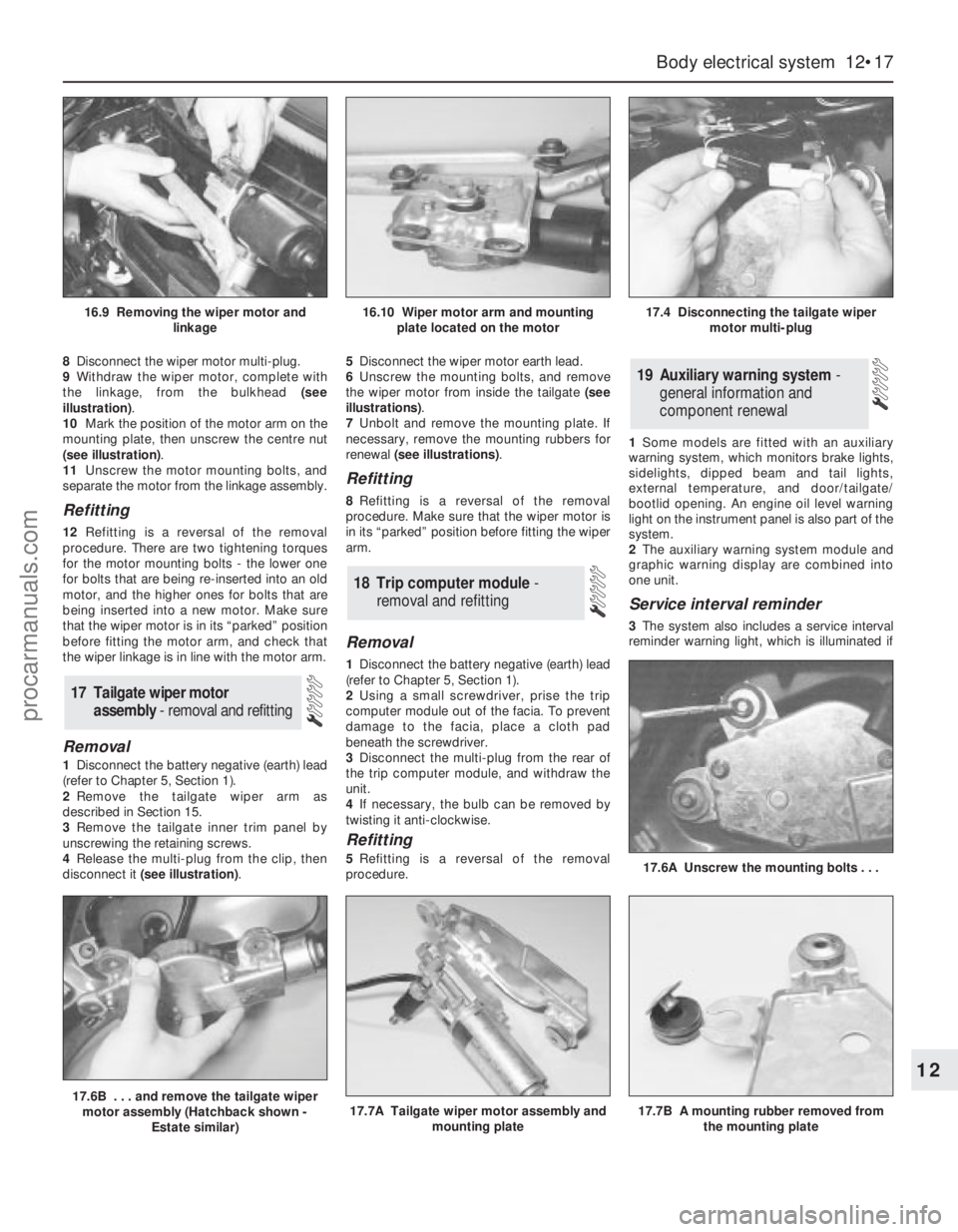

8Disconnect the wiper motor multi-plug.

9Withdraw the wiper motor, complete with

the linkage, from the bulkhead (see

illustration).

10Mark the position of the motor arm on the

mounting plate, then unscrew the centre nut

(see illustration).

11Unscrew the motor mounting bolts, and

separate the motor from the linkage assembly.

Refitting

12Refitting is a reversal of the removal

procedure. There are two tightening torques

for the motor mounting bolts - the lower one

for bolts that are being re-inserted into an old

motor, and the higher ones for bolts that are

being inserted into a new motor. Make sure

that the wiper motor is in its “parked” position

before fitting the motor arm, and check that

the wiper linkage is in line with the motor arm.

Removal

1Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

2Remove the tailgate wiper arm as

described in Section 15.

3Remove the tailgate inner trim panel by

unscrewing the retaining screws.

4Release the multi-plug from the clip, then

disconnect it (see illustration).5Disconnect the wiper motor earth lead.

6Unscrew the mounting bolts, and remove

the wiper motor from inside the tailgate (see

illustrations).

7Unbolt and remove the mounting plate. If

necessary, remove the mounting rubbers for

renewal (see illustrations).

Refitting

8Refitting is a reversal of the removal

procedure. Make sure that the wiper motor is

in its “parked” position before fitting the wiper

arm.

Removal

1Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

2Using a small screwdriver, prise the trip

computer module out of the facia. To prevent

damage to the facia, place a cloth pad

beneath the screwdriver.

3Disconnect the multi-plug from the rear of

the trip computer module, and withdraw the

unit.

4If necessary, the bulb can be removed by

twisting it anti-clockwise.

Refitting

5Refitting is a reversal of the removal

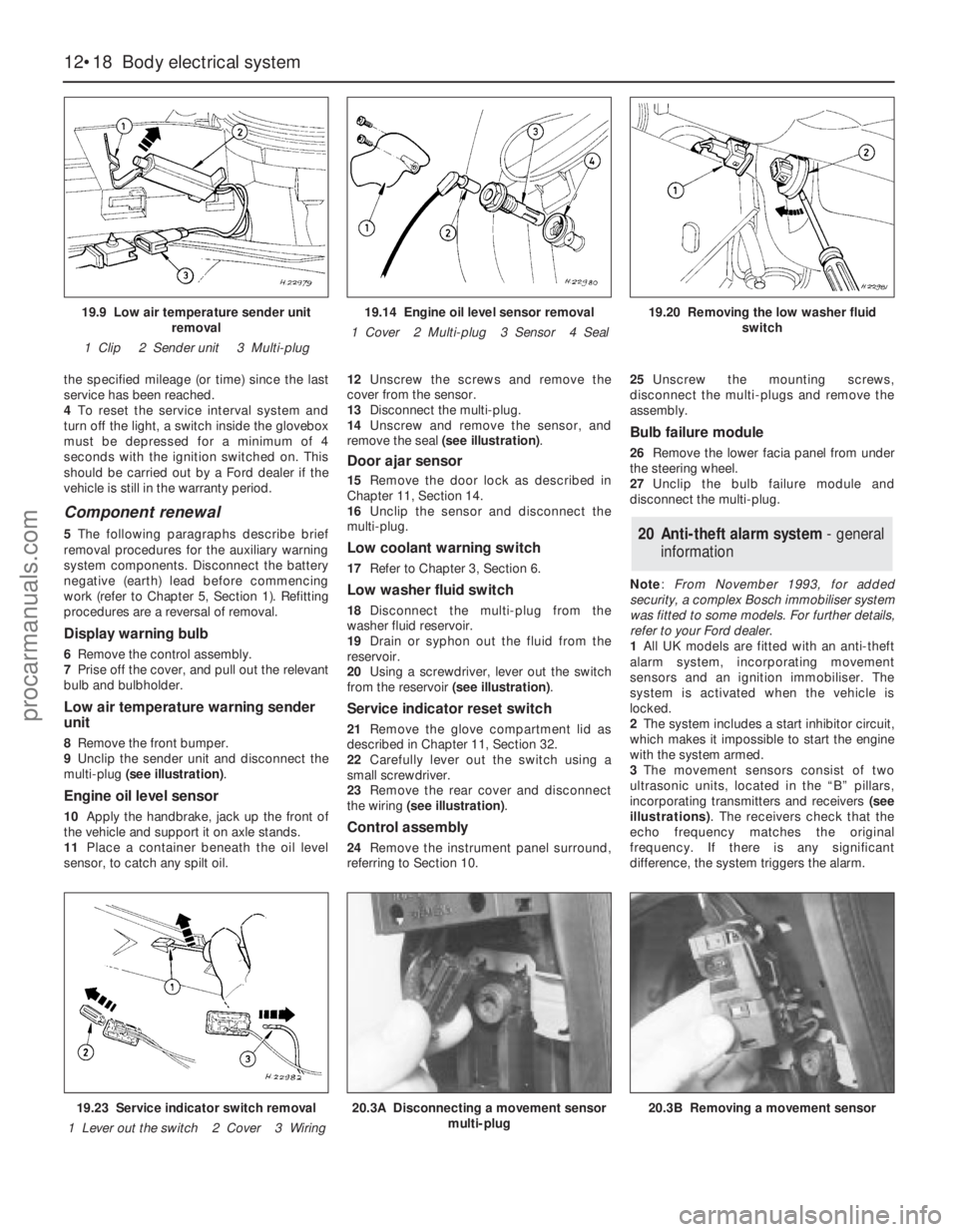

procedure.1Some models are fitted with an auxiliary

warning system, which monitors brake lights,

sidelights, dipped beam and tail lights,

external temperature, and door/tailgate/

bootlid opening. An engine oil level warning

light on the instrument panel is also part of the

system.

2The auxiliary warning system module and

graphic warning display are combined into

one unit.

Service interval reminder

3The system also includes a service interval

reminder warning light, which is illuminated if

19 Auxiliary warning system -

general information and

component renewal

18 Trip computer module-

removal and refitting

17 Tailgate wiper motor

assembly - removal and refitting

Body electrical system 12•17

12

17.6B . . . and remove the tailgate wiper

motor assembly (Hatchback shown -

Estate similar)17.7A Tailgate wiper motor assembly and

mounting plate17.7B A mounting rubber removed from

the mounting plate

17.6A Unscrew the mounting bolts . . .

16.9 Removing the wiper motor and

linkage16.10 Wiper motor arm and mounting

plate located on the motor17.4 Disconnecting the tailgate wiper

motor multi-plug

procarmanuals.com

Page 219 of 279

the specified mileage (or time) since the last

service has been reached.

4To reset the service interval system and

turn off the light, a switch inside the glovebox

must be depressed for a minimum of 4

seconds with the ignition switched on. This

should be carried out by a Ford dealer if the

vehicle is still in the warranty period.

Component renewal

5The following paragraphs describe brief

removal procedures for the auxiliary warning

system components. Disconnect the battery

negative (earth) lead before commencing

work (refer to Chapter 5, Section 1). Refitting

procedures are a reversal of removal.

Display warning bulb

6Remove the control assembly.

7Prise off the cover, and pull out the relevant

bulb and bulbholder.

Low air temperature warning sender

unit

8Remove the front bumper.

9Unclip the sender unit and disconnect the

multi-plug (see illustration).

Engine oil level sensor

10Apply the handbrake, jack up the front of

the vehicle and support it on axle stands.

11Place a container beneath the oil level

sensor, to catch any spilt oil.12Unscrew the screws and remove the

cover from the sensor.

13Disconnect the multi-plug.

14Unscrew and remove the sensor, and

remove the seal (see illustration).

Door ajar sensor

15Remove the door lock as described in

Chapter 11, Section 14.

16Unclip the sensor and disconnect the

multi-plug.

Low coolant warning switch

17Refer to Chapter 3, Section 6.

Low washer fluid switch

18Disconnect the multi-plug from the

washer fluid reservoir.

19Drain or syphon out the fluid from the

reservoir.

20Using a screwdriver, lever out the switch

from the reservoir (see illustration).

Service indicator reset switch

21Remove the glove compartment lid as

described in Chapter 11, Section 32.

22Carefully lever out the switch using a

small screwdriver.

23Remove the rear cover and disconnect

the wiring (see illustration).

Control assembly

24Remove the instrument panel surround,

referring to Section 10.25Unscrew the mounting screws,

disconnect the multi-plugs and remove the

assembly.

Bulb failure module

26Remove the lower facia panel from under

the steering wheel.

27Unclip the bulb failure module and

disconnect the multi-plug.

Note: From November 1993, for added

security, a complex Bosch immobiliser system

was fitted to some models. For further details,

refer to your Ford dealer.

1All UK models are fitted with an anti-theft

alarm system, incorporating movement

sensors and an ignition immobiliser. The

system is activated when the vehicle is

locked.

2The system includes a start inhibitor circuit,

which makes it impossible to start the engine

with the system armed.

3The movement sensors consist of two

ultrasonic units, located in the “B” pillars,

incorporating transmitters and receivers (see

illustrations). The receivers check that the

echo frequency matches the original

frequency. If there is any significant

difference, the system triggers the alarm.

20 Anti-theft alarm system- general

information

12•18 Body electrical system

19.9 Low air temperature sender unit

removal

1 Clip 2 Sender unit 3 Multi-plug19.14 Engine oil level sensor removal

1 Cover 2 Multi-plug 3 Sensor 4 Seal19.20 Removing the low washer fluid

switch

19.23 Service indicator switch removal

1 Lever out the switch 2 Cover 3 Wiring20.3A Disconnecting a movement sensor

multi-plug20.3B Removing a movement sensor

procarmanuals.com