clock FORD MONDEO 1993 Service User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 58 of 279

14Unscrew the two nuts to disconnect the

exhaust system front downpipe from the

manifold (Chapter 4); disconnect the oxygen

sensor wiring, so that it is not strained by the

weight of the exhaust system.

15Remove the auxiliary drivebelt (see

Chapter 1).

16Support the weight of the

engine/transmission using a trolley jack, with

a wooden spacer to prevent damage to the

sump.

17Unscrew the six nuts securing the

engine/transmission right-hand mounting

bracket, then withdraw the bracket. Unbolt

the auxiliary drivebelt’s idler pulley (see

illustration).

18Unbolt the cylinder head front and rear

support plates (see illustrations).

19Remove the timing belt and both

camshafts (see Sections 10 and 13); if the

cylinder head is to be dismantled, withdraw

the hydraulic tappets.

20Remove the timing belt inner shield (see

Section 9).

21Working in the reverseof the sequence

shown in illustration 14.32C, slacken the ten

cylinder head bolts progressively and by one

turn at a time; a Torx key (TX 55 size) will be

required. Remove each bolt in turn, and

ensure that new replacements are obtained

for reassembly; these bolts are subjected to

severe stresses and so must be renewed,

regardless of their apparent condition,

whenever they are disturbed.22Lift the cylinder head away; use

assistance if possible, as it is a heavy

assembly (see illustration). Remove the

gasket, noting the two dowels, and discard it.

Refitting

23The mating faces of the cylinder head and

cylinder block must be perfectly clean before

refitting the head. Use a hard plastic or wood

scraper to remove all traces of gasket and

carbon; also clean the piston crowns. Take

particular care, as the soft aluminium alloy is

easily damaged. Also, make sure that the

carbon is not allowed to enter the oil and

water passages - this is particularly important

for the lubrication system, as carbon could

block the oil supply to any of the engine’s

components. Using adhesive tape and paper,

seal the water, oil and bolt holes in the

cylinder block. Clean all the pistons in the

same way.24Check the mating surfaces of the cylinder

block and the cylinder head for nicks, deep

scratches and other damage. If slight, they

may be removed carefully with a file, but if

excessive, machining may be the only

alternative to renewal.

25If warpage of the cylinder head gasket

surface is suspected, use a straight edge to

check it for distortion. Refer to Part B of this

Chapter, Section 7, if necessary.

26Wipe clean the mating surfaces of the

cylinder head and cylinder block. Check that

the two locating dowels are in position in the

cylinder block, and that all cylinder head bolt

holes are free from oil.

27Position a new gasket over the dowels on

the cylinder block surface, so that the

“TOP/OBEN” mark is uppermost, and the

tooth (or teeth, according to engine size)

protruding from one edge point to the front of

the vehicle (see illustration).

28Temporarily refit the crankshaft pulley,

and rotate the crankshaft anti-clockwise so

that No 1 cylinder’s piston is lowered to

approximately 20 mm before TDC, thus

avoiding any risk of valve/piston contact and

damage during reassembly.

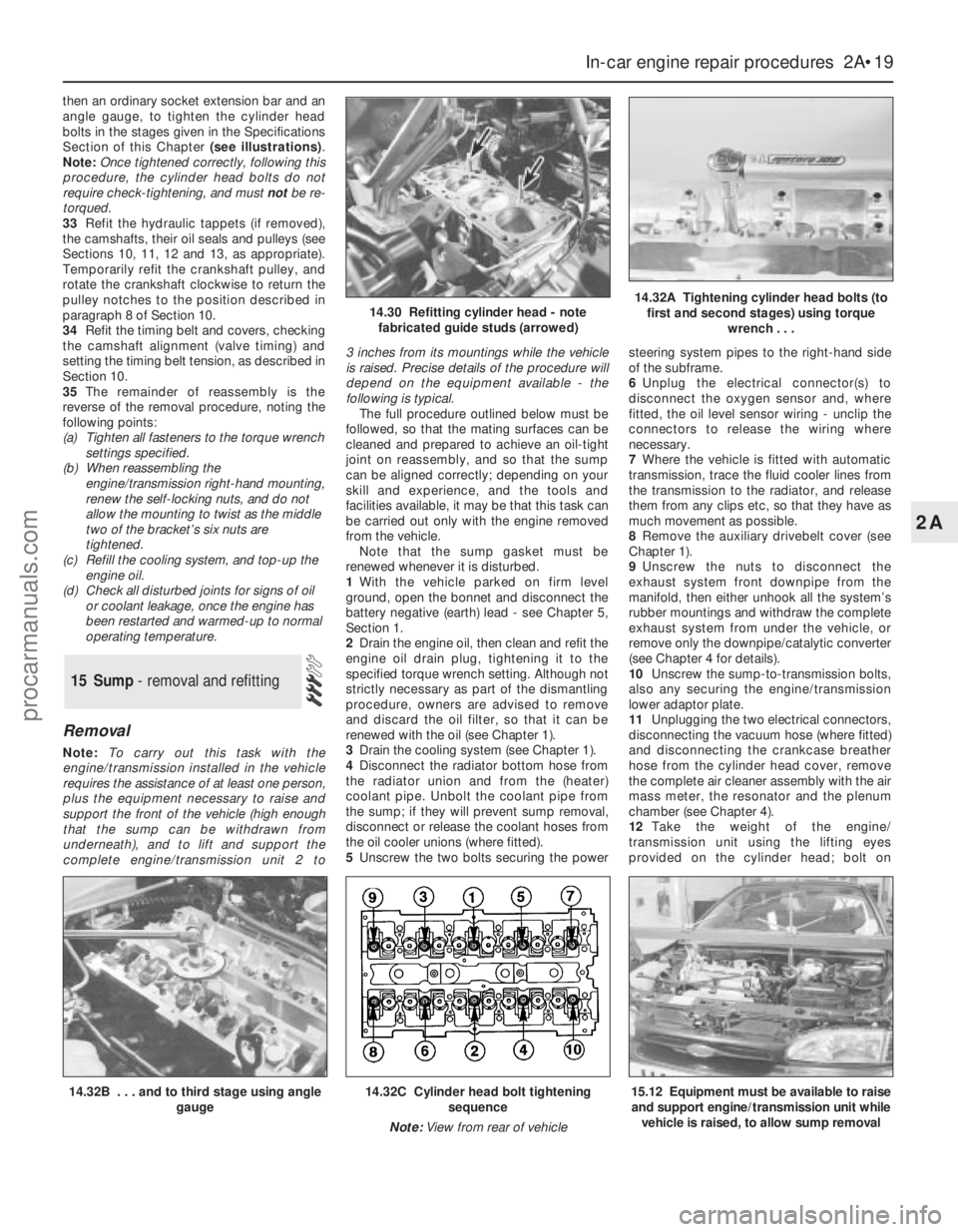

29As the cylinder head is such a heavy and

awkward assembly to refit with manifolds, it is

helpful to make up a pair of guide studs from

two 10 mm (thread size) studs approximately

90 mm long, with a screwdriver slot cut in one

end - two old cylinder head bolts with their

heads cut off would make a good starting

point. Screw these guide studs, screwdriver

slot upwards to permit removal, into the bolt

holes at diagonally-opposite corners of the

cylinder block surface (or into those where

the locating dowels are fitted, as shown);

ensure that approximately 70 mm of stud

protrudes above the gasket.

30Refit the cylinder head, sliding it down the

guide studs (if used) and locating it on the

dowels (see illustration). Unscrew the guide

studs (if used) when the head is in place.

31Fit the new cylinder head bolts dry (do not

oiltheir threads); carefully enter each into its

hole and screw it in, by hand only, until finger-

tight.

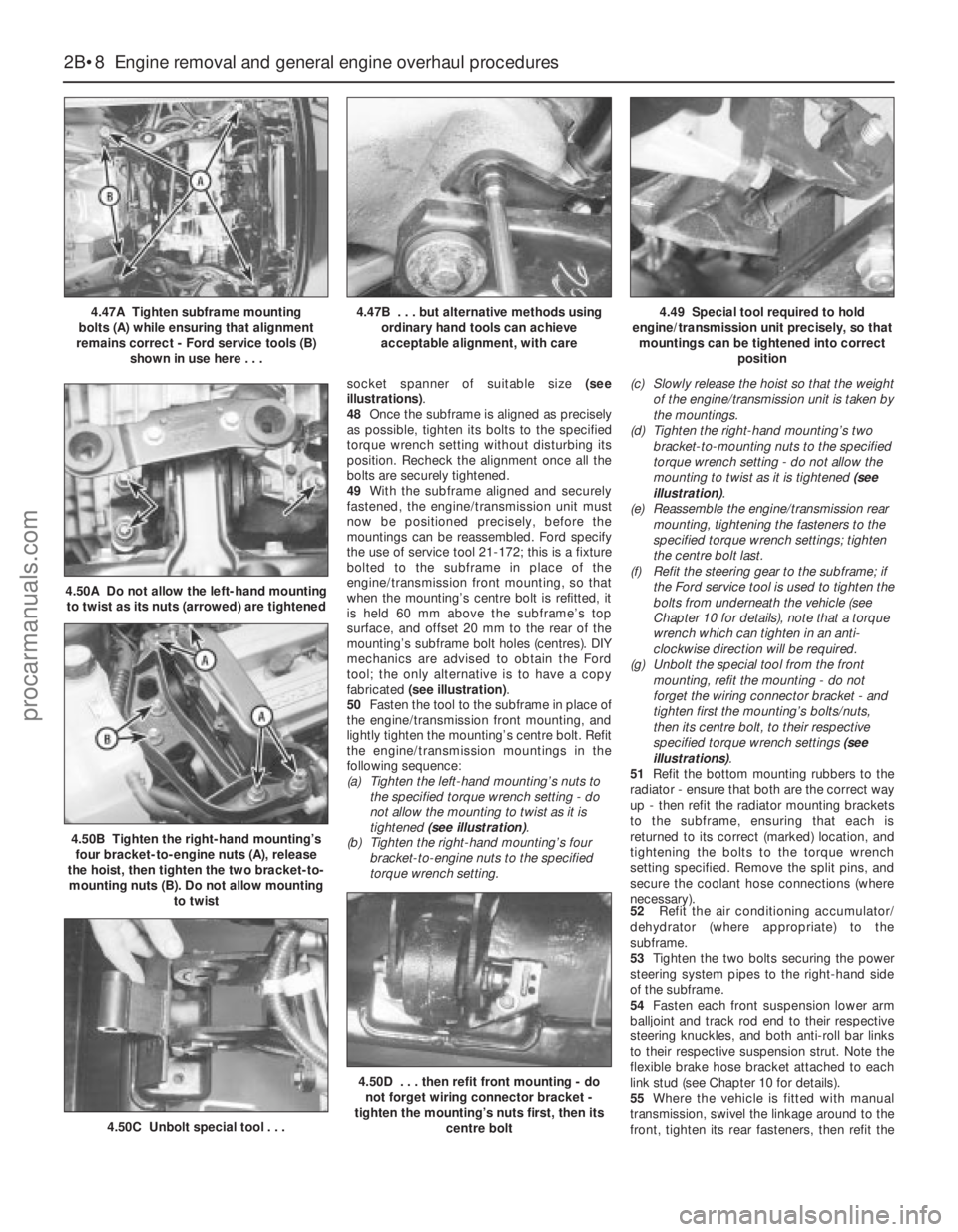

32Working progressively and in the

sequence shown, use first a torque wrench,

2A•18 In-car engine repair procedures

14.17 Unbolt auxiliary drivebelt idler pulley14 18A Remove cylinder head front . . .14.18B . . . and rear support plates

14.22 Using an engine hoist to lift off the

cylinder head complete with manifolds

14.27 Ensuring protruding tooth (or teeth)

“A” are at front and marking “B” is

upwards, locate new cylinder head gasket

on dowels “C”

To prevent carbon entering

the gap between the pistons

and bores, smear a little

grease in the gap. After

cleaning each piston, use a small brush

to remove all traces of grease and

carbon from the gap, then wipe away

the remainder with a clean rag.

procarmanuals.com

Page 59 of 279

then an ordinary socket extension bar and an

angle gauge, to tighten the cylinder head

bolts in the stages given in the Specifications

Section of this Chapter (see illustrations).

Note:Once tightened correctly, following this

procedure, the cylinder head bolts do not

require check-tightening, and must notbe re-

torqued.

33Refit the hydraulic tappets (if removed),

the camshafts, their oil seals and pulleys (see

Sections 10, 11, 12 and 13, as appropriate).

Temporarily refit the crankshaft pulley, and

rotate the crankshaft clockwise to return the

pulley notches to the position described in

paragraph 8 of Section 10.

34Refit the timing belt and covers, checking

the camshaft alignment (valve timing) and

setting the timing belt tension, as described in

Section 10.

35The remainder of reassembly is the

reverse of the removal procedure, noting the

following points:

(a) Tighten all fasteners to the torque wrench

settings specified.

(b) When reassembling the

engine/transmission right-hand mounting,

renew the self-locking nuts, and do not

allow the mounting to twist as the middle

two of the bracket’s six nuts are

tightened.

(c) Refill the cooling system, and top-up the

engine oil.

(d) Check all disturbed joints for signs of oil

or coolant leakage, once the engine has

been restarted and warmed-up to normal

operating temperature.

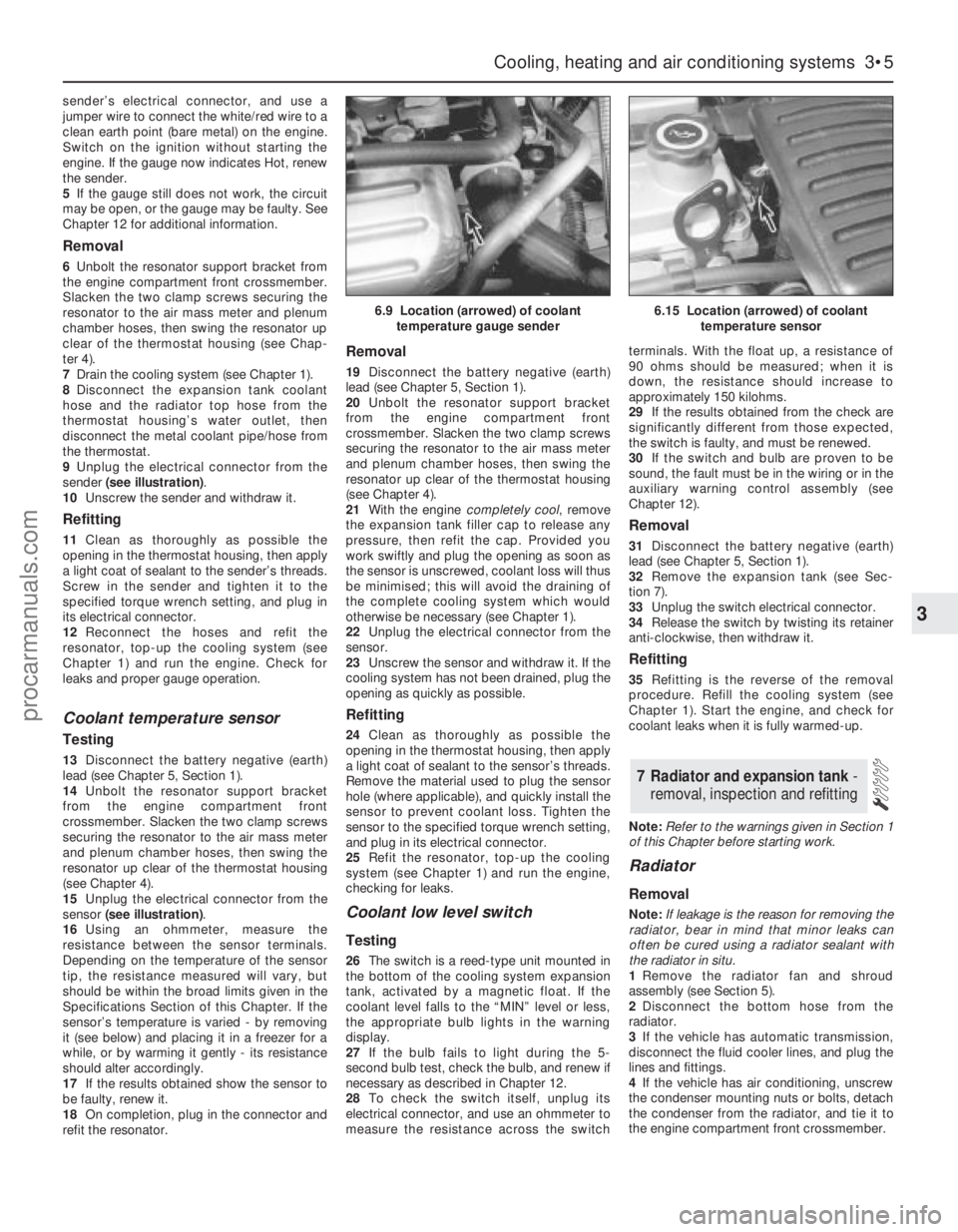

Removal

Note:To carry out this task with the

engine/transmission installed in the vehicle

requires the assistance of at least one person,

plus the equipment necessary to raise and

support the front of the vehicle (high enough

that the sump can be withdrawn from

underneath), and to lift and support the

complete engine/transmission unit 2 to 3 inches from its mountings while the vehicle

is raised. Precise details of the procedure will

depend on the equipment available - the

following is typical.

The full procedure outlined below must be

followed, so that the mating surfaces can be

cleaned and prepared to achieve an oil-tight

joint on reassembly, and so that the sump

can be aligned correctly; depending on your

skill and experience, and the tools and

facilities available, it may be that this task can

be carried out only with the engine removed

from the vehicle.

Note that the sump gasket must be

renewed whenever it is disturbed.

1With the vehicle parked on firm level

ground, open the bonnet and disconnect the

battery negative (earth) lead - see Chapter 5,

Section 1.

2Drain the engine oil, then clean and refit the

engine oil drain plug, tightening it to the

specified torque wrench setting. Although not

strictly necessary as part of the dismantling

procedure, owners are advised to remove

and discard the oil filter, so that it can be

renewed with the oil (see Chapter 1).

3Drain the cooling system (see Chapter 1).

4Disconnect the radiator bottom hose from

the radiator union and from the (heater)

coolant pipe. Unbolt the coolant pipe from

the sump; if they will prevent sump removal,

disconnect or release the coolant hoses from

the oil cooler unions (where fitted).

5Unscrew the two bolts securing the powersteering system pipes to the right-hand side

of the subframe.

6Unplug the electrical connector(s) to

disconnect the oxygen sensor and, where

fitted, the oil level sensor wiring - unclip the

connectors to release the wiring where

necessary.

7Where the vehicle is fitted with automatic

transmission, trace the fluid cooler lines from

the transmission to the radiator, and release

them from any clips etc, so that they have as

much movement as possible.

8Remove the auxiliary drivebelt cover (see

Chapter 1).

9Unscrew the nuts to disconnect the

exhaust system front downpipe from the

manifold, then either unhook all the system’s

rubber mountings and withdraw the complete

exhaust system from under the vehicle, or

remove only the downpipe/catalytic converter

(see Chapter 4 for details).

10Unscrew the sump-to-transmission bolts,

also any securing the engine/transmission

lower adaptor plate.

11Unplugging the two electrical connectors,

disconnecting the vacuum hose (where fitted)

and disconnecting the crankcase breather

hose from the cylinder head cover, remove

the complete air cleaner assembly with the air

mass meter, the resonator and the plenum

chamber (see Chapter 4).

12Take the weight of the engine/

transmission unit using the lifting eyes

provided on the cylinder head; bolt on

15 Sump - removal and refitting

In-car engine repair procedures 2A•19

2A

14.32B . . . and to third stage using angle

gauge14.32C Cylinder head bolt tightening

sequence

Note:View from rear of vehicle15.12 Equipment must be available to raise

and support engine/transmission unit while

vehicle is raised, to allow sump removal

14.30 Refitting cylinder head - note

fabricated guide studs (arrowed)14.32A Tightening cylinder head bolts (to

first and second stages) using torque

wrench . . .

procarmanuals.com

Page 74 of 279

socket spanner of suitable size (see

illustrations).

48Once the subframe is aligned as precisely

as possible, tighten its bolts to the specified

torque wrench setting without disturbing its

position. Recheck the alignment once all the

bolts are securely tightened.

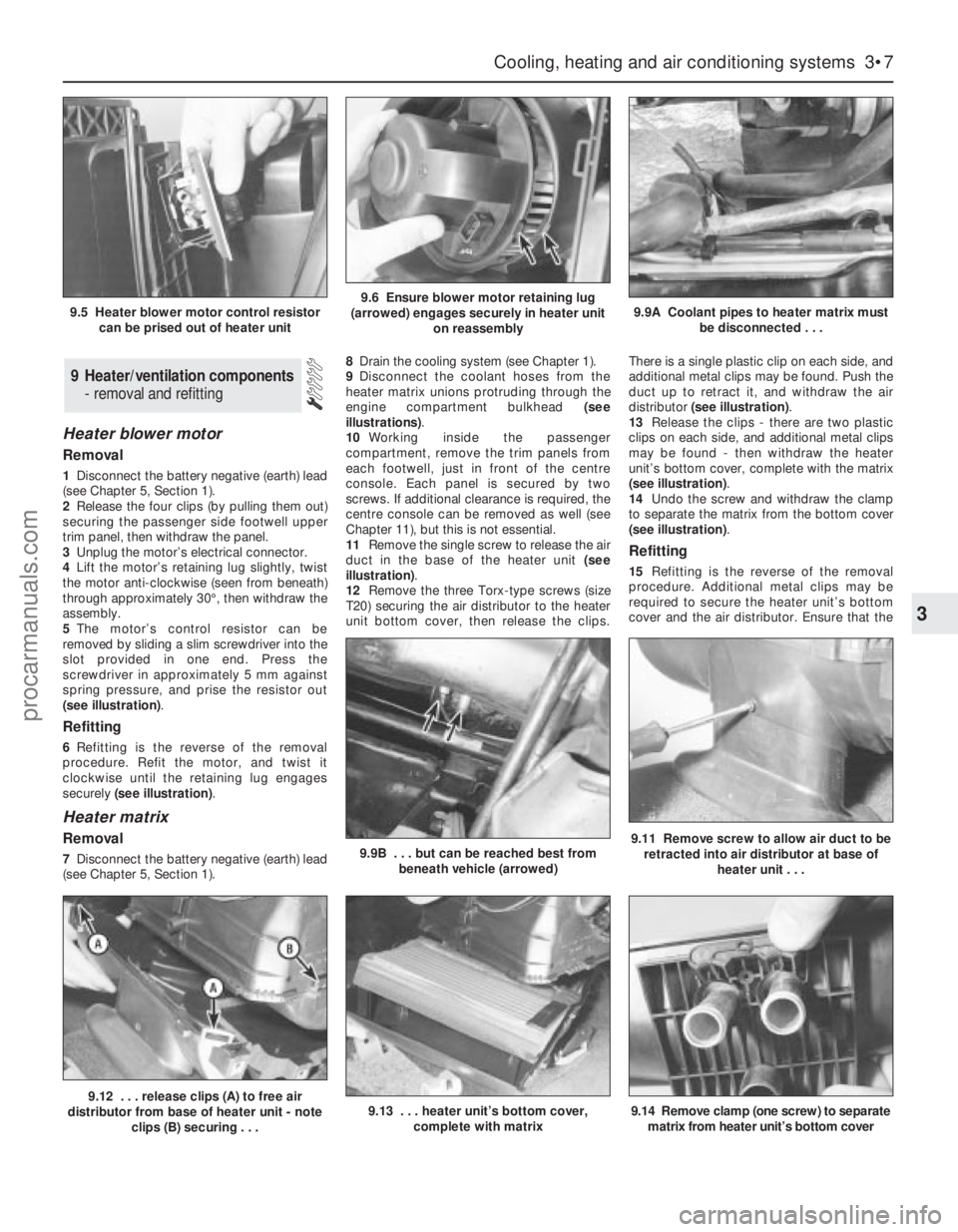

49With the subframe aligned and securely

fastened, the engine/transmission unit must

now be positioned precisely, before the

mountings can be reassembled. Ford specify

the use of service tool 21-172; this is a fixture

bolted to the subframe in place of the

engine/transmission front mounting, so that

when the mounting’s centre bolt is refitted, it

is held 60 mm above the subframe’s top

surface, and offset 20 mm to the rear of the

mounting’s subframe bolt holes (centres). DIY

mechanics are advised to obtain the Ford

tool; the only alternative is to have a copy

fabricated (see illustration).

50Fasten the tool to the subframe in place of

the engine/transmission front mounting, and

lightly tighten the mounting’s centre bolt. Refit

the engine/transmission mountings in the

following sequence:

(a) Tighten the left-hand mounting’s nuts to

the specified torque wrench setting - do

not allow the mounting to twist as it is

tightened (see illustration).

(b) Tighten the right-hand mounting’s four

bracket-to-engine nuts to the specified

torque wrench setting.(c) Slowly release the hoist so that the weight

of the engine/transmission unit is taken by

the mountings.

(d) Tighten the right-hand mounting’s two

bracket-to-mounting nuts to the specified

torque wrench setting - do not allow the

mounting to twist as it is tightened (see

illustration).

(e) Reassemble the engine/transmission rear

mounting, tightening the fasteners to the

specified torque wrench settings; tighten

the centre bolt last.

(f) Refit the steering gear to the subframe; if

the Ford service tool is used to tighten the

bolts from underneath the vehicle (see

Chapter 10 for details), note that a torque

wrench which can tighten in an anti-

clockwise direction will be required.

(g) Unbolt the special tool from the front

mounting, refit the mounting - do not

forget the wiring connector bracket - and

tighten first the mounting’s bolts/nuts,

then its centre bolt, to their respective

specified torque wrench settings (see

illustrations).

51Refit the bottom mounting rubbers to the

radiator - ensure that both are the correct way

up - then refit the radiator mounting brackets

to the subframe, ensuring that each is

returned to its correct (marked) location, and

tightening the bolts to the torque wrench

setting specified. Remove the split pins, and

secure the coolant hose connections (where

necessary).

52Refit the air conditioning accumulator/

dehydrator (where appropriate) to the

subframe.

53Tighten the two bolts securing the power

steering system pipes to the right-hand side

of the subframe.

54Fasten each front suspension lower arm

balljoint and track rod end to their respective

steering knuckles, and both anti-roll bar links

to their respective suspension strut. Note the

flexible brake hose bracket attached to each

link stud (see Chapter 10 for details).

55Where the vehicle is fitted with manual

transmission, swivel the linkage around to the

front, tighten its rear fasteners, then refit the

2B•8 Engine removal and general engine overhaul procedures

4.47A Tighten subframe mounting

bolts (A) while ensuring that alignment

remains correct - Ford service tools (B)

shown in use here . . .4.47B . . . but alternative methods using

ordinary hand tools can achieve

acceptable alignment, with care4.49 Special tool required to hold

engine/transmission unit precisely, so that

mountings can be tightened into correct

position

4.50B Tighten the right-hand mounting’s

four bracket-to-engine nuts (A), release

the hoist, then tighten the two bracket-to-

mounting nuts (B). Do not allow mounting

to twist

4.50A Do not allow the left-hand mounting

to twist as its nuts (arrowed) are tightened

4.50C Unbolt special tool . . .

4.50D . . . then refit front mounting - do

not forget wiring connector bracket -

tighten the mounting’s nuts first, then its

centre bolt

procarmanuals.com

Page 93 of 279

sender’s electrical connector, and use a

jumper wire to connect the white/red wire to a

clean earth point (bare metal) on the engine.

Switch on the ignition without starting the

engine. If the gauge now indicates Hot, renew

the sender.

5If the gauge still does not work, the circuit

may be open, or the gauge may be faulty. See

Chapter 12 for additional information.

Removal

6Unbolt the resonator support bracket from

the engine compartment front crossmember.

Slacken the two clamp screws securing the

resonator to the air mass meter and plenum

chamber hoses, then swing the resonator up

clear of the thermostat housing (see Chap-

ter 4).

7Drain the cooling system (see Chapter 1).

8Disconnect the expansion tank coolant

hose and the radiator top hose from the

thermostat housing’s water outlet, then

disconnect the metal coolant pipe/hose from

the thermostat.

9Unplug the electrical connector from the

sender (see illustration).

10Unscrew the sender and withdraw it.

Refitting

11Clean as thoroughly as possible the

opening in the thermostat housing, then apply

a light coat of sealant to the sender’s threads.

Screw in the sender and tighten it to the

specified torque wrench setting, and plug in

its electrical connector.

12Reconnect the hoses and refit the

resonator, top-up the cooling system (see

Chapter 1) and run the engine. Check for

leaks and proper gauge operation.

Coolant temperature sensor

Testing

13Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

14Unbolt the resonator support bracket

from the engine compartment front

crossmember. Slacken the two clamp screws

securing the resonator to the air mass meter

and plenum chamber hoses, then swing the

resonator up clear of the thermostat housing

(see Chapter 4).

15Unplug the electrical connector from the

sensor (see illustration).

16Using an ohmmeter, measure the

resistance between the sensor terminals.

Depending on the temperature of the sensor

tip, the resistance measured will vary, but

should be within the broad limits given in the

Specifications Section of this Chapter. If the

sensor’s temperature is varied - by removing

it (see below) and placing it in a freezer for a

while, or by warming it gently - its resistance

should alter accordingly.

17If the results obtained show the sensor to

be faulty, renew it.

18On completion, plug in the connector and

refit the resonator.

Removal

19Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

20Unbolt the resonator support bracket

from the engine compartment front

crossmember. Slacken the two clamp screws

securing the resonator to the air mass meter

and plenum chamber hoses, then swing the

resonator up clear of the thermostat housing

(see Chapter 4).

21With the engine completely cool, remove

the expansion tank filler cap to release any

pressure, then refit the cap. Provided you

work swiftly and plug the opening as soon as

the sensor is unscrewed, coolant loss will thus

be minimised; this will avoid the draining of

the complete cooling system which would

otherwise be necessary (see Chapter 1).

22Unplug the electrical connector from the

sensor.

23Unscrew the sensor and withdraw it. If the

cooling system has not been drained, plug the

opening as quickly as possible.

Refitting

24Clean as thoroughly as possible the

opening in the thermostat housing, then apply

a light coat of sealant to the sensor’s threads.

Remove the material used to plug the sensor

hole (where applicable), and quickly install the

sensor to prevent coolant loss. Tighten the

sensor to the specified torque wrench setting,

and plug in its electrical connector.

25Refit the resonator, top-up the cooling

system (see Chapter 1) and run the engine,

checking for leaks.

Coolant low level switch

Testing

26The switch is a reed-type unit mounted in

the bottom of the cooling system expansion

tank, activated by a magnetic float. If the

coolant level falls to the “MIN” level or less,

the appropriate bulb lights in the warning

display.

27If the bulb fails to light during the 5-

second bulb test, check the bulb, and renew if

necessary as described in Chapter 12.

28To check the switch itself, unplug its

electrical connector, and use an ohmmeter to

measure the resistance across the switchterminals. With the float up, a resistance of

90 ohms should be measured; when it is

down, the resistance should increase to

approximately 150 kilohms.

29If the results obtained from the check are

significantly different from those expected,

the switch is faulty, and must be renewed.

30If the switch and bulb are proven to be

sound, the fault must be in the wiring or in the

auxiliary warning control assembly (see

Chapter 12).

Removal

31Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

32Remove the expansion tank (see Sec-

tion 7).

33Unplug the switch electrical connector.

34Release the switch by twisting its retainer

anti-clockwise, then withdraw it.

Refitting

35Refitting is the reverse of the removal

procedure. Refill the cooling system (see

Chapter 1). Start the engine, and check for

coolant leaks when it is fully warmed-up.

Note:Refer to the warnings given in Section 1

of this Chapter before starting work.

Radiator

Removal

Note:If leakage is the reason for removing the

radiator, bear in mind that minor leaks can

often be cured using a radiator sealant with

the radiator in situ.

1Remove the radiator fan and shroud

assembly (see Section 5).

2Disconnect the bottom hose from the

radiator.

3If the vehicle has automatic transmission,

disconnect the fluid cooler lines, and plug the

lines and fittings.

4If the vehicle has air conditioning, unscrew

the condenser mounting nuts or bolts, detach

the condenser from the radiator, and tie it to

the engine compartment front crossmember.

7 Radiator and expansion tank -

removal, inspection and refitting

Cooling, heating and air conditioning systems 3•5

3

6.9 Location (arrowed) of coolant

temperature gauge sender6.15 Location (arrowed) of coolant

temperature sensor

procarmanuals.com

Page 95 of 279

Heater blower motor

Removal

1Disconnect the battery negative (earth) lead

(see Chapter 5, Section 1).

2Release the four clips (by pulling them out)

securing the passenger side footwell upper

trim panel, then withdraw the panel.

3Unplug the motor’s electrical connector.

4Lift the motor’s retaining lug slightly, twist

the motor anti-clockwise (seen from beneath)

through approximately 30°, then withdraw the

assembly.

5The motor’s control resistor can be

removed by sliding a slim screwdriver into the

slot provided in one end. Press the

screwdriver in approximately 5 mm against

spring pressure, and prise the resistor out

(see illustration).

Refitting

6Refitting is the reverse of the removal

procedure. Refit the motor, and twist it

clockwise until the retaining lug engages

securely (see illustration).

Heater matrix

Removal

7Disconnect the battery negative (earth) lead

(see Chapter 5, Section 1).8Drain the cooling system (see Chapter 1).

9Disconnect the coolant hoses from the

heater matrix unions protruding through the

engine compartment bulkhead (see

illustrations).

10Working inside the passenger

compartment, remove the trim panels from

each footwell, just in front of the centre

console. Each panel is secured by two

screws. If additional clearance is required, the

centre console can be removed as well (see

Chapter 11), but this is not essential.

11Remove the single screw to release the air

duct in the base of the heater unit (see

illustration).

12Remove the three Torx-type screws (size

T20) securing the air distributor to the heater

unit bottom cover, then release the clips.There is a single plastic clip on each side, and

additional metal clips may be found. Push the

duct up to retract it, and withdraw the air

distributor (see illustration).

13Release the clips - there are two plastic

clips on each side, and additional metal clips

may be found - then withdraw the heater

unit’s bottom cover, complete with the matrix

(see illustration).

14Undo the screw and withdraw the clamp

to separate the matrix from the bottom cover

(see illustration).

Refitting

15Refitting is the reverse of the removal

procedure. Additional metal clips may be

required to secure the heater unit’s bottom

cover and the air distributor. Ensure that the

9 Heater/ventilation components

- removal and refitting

Cooling, heating and air conditioning systems 3•7

3

9.12 . . . release clips (A) to free air

distributor from base of heater unit - note

clips (B) securing . . .9.13 . . . heater unit’s bottom cover,

complete with matrix9.14 Remove clamp (one screw) to separate

matrix from heater unit’s bottom cover

9.5 Heater blower motor control resistor

can be prised out of heater unit9.6 Ensure blower motor retaining lug

(arrowed) engages securely in heater unit

on reassembly9.9A Coolant pipes to heater matrix must

be disconnected . . .

9.9B . . . but can be reached best from

beneath vehicle (arrowed)9.11 Remove screw to allow air duct to be

retracted into air distributor at base of

heater unit . . .

procarmanuals.com

Page 103 of 279

which pulley, disconnect the first cable end

nipple from the throttle actuator’s upper

pulley, then slide the cable outer upwards out

of the actuator housing. Disconnect the

second cable in the same way from the

actuator’s lower pulley.

6Working in the passenger compartment,

reach up to the top of the accelerator pedal.

Pull the end fitting and collar out of the pedal,

then release the cable inner wire through the

slot in the pedal. Tie a length of string to the

end of the cable.

7Returning to the engine compartment, pull

the cable through the bulkhead until the string

can be untied and the pedal-to-actuator cable

removed.

Refitting

8Refitting is the reverse of the removal

procedure. Use the string to draw the pedal-

to-actuator cable through the bulkhead.

Ensure that each cable end is connected to

the correct actuator pulley.

9Adjust both cables as described below.

Adjustment

Note:Both sections of the cable must be

adjusted together, even if only one has been

disturbed.

10Remove the plenum chamber (see

Section 4).

11Remove the metal clip from the adjuster

of each cable section (see illustration), and

lubricate the adjusters’ grommets with soapy

water.

12Remove any slack by pulling both cable

outers as far as possible out of their

respective adjusters.

13Unplug the TCS throttle actuator’s

electrical connector, and prise off its cover.

Lock both pulleys together by pushing a

locking pin (a pin punch or a similar tool of

suitable size) into their alignment holes.

Disconnect the actuator-to-throttle housing

cable’s end nipple from the throttle linkage.

14Have an assistant depress the accelerator

pedal fully. The pedal-to-actuator cable outer

will move back into the adjuster; hold it there,

and refit the clip.

15Connect the actuator-to-throttle housing

cable end nipple to the throttle linkage, andcheck that the cable outer’s grommet is

correctly secured in the housing bracket.

16Again have the assistant depress the

accelerator pedal fully. The actuator-to-

throttle housing cable outer will move back

into the adjuster; hold it there, and refit the

clip.

17Remove the locking pin from the pulleys.

Check that the throttle valve moves smoothly

and easily from the fully-closed to the fully-

open position and back again, as the

assistant depresses and releases the

accelerator pedal. Re-adjust the cable(s) if

required.

18When the setting is correct, refit the TCS

throttle actuator’s cover and electrical

connector, then refit the plenum chamber (see

Section 4).

1Disconnect the cable inner wire from the

pedal - see Section 5 or 6, as appropriate.

2Undo the retaining nuts and bolt, then

withdraw the pedal assembly (see

illustration).

3Refitting is the reverse of the removal

procedure. Adjust the cable(s) as described in

the relevant Section of this Chapter.

Warning: Petrol is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area. Don’t work in a

garage where a natural gas-type appliance

(such as a water heater or clothes dryer)

with a pilot light is present. If you spill any

fuel on your skin, rinse it off immediately

with soap and water. When you perform

any kind of work on the fuel system, wear

safety glasses, and have a Class B type

fire extinguisher on hand.

Fuel pump operation check

1Switch on the ignition and listen for the fuel

pump (the sound of an electric motor running,

audible from beneath the rear seats). Assuming

there is sufficient fuel in the tank, the pump

should start and run for approximately one or

two seconds, then stop, each time the ignition

is switched on. Note:If the pump runs

continuously all the time the ignition is switched

on, the electronic control system is running in

the backup (or “limp-home”) mode referred to

by Ford as “Limited Operation Strategy” (LOS).

This almost certainly indicates a fault in the

ECU itself, and the vehicle should therefore be

taken to a Ford dealer for a full test of the

complete system, using the correct diagnostic

equipment; do not waste time trying to test the

system without such facilities.

2Listen for fuel return noises from the fuel

pressure regulator. It should be possible to

feel the fuel pulsing in the regulator and in the

feed hose from the fuel filter.

3If the pump does not run at all, check the

fuse, relay and wiring (see Chapter 6).

Fuel pressure check

3A fuel pressure gauge, equipped with an

adaptor to suit the Schrader-type valve on the

fuel rail pressure test/release fitting

(identifiable by its blue plastic cap, and

located on the union of the fuel feed line and

the fuel rail) is required for the following

procedure. If the Ford special tool 29-033 is

available (see Section 2), the tool can be

attached to the valve, and a conventional-type

pressure gauge attached to the tool.

4If using the service tool, ensure that its tap

is turned fully anti-clockwise, then attach it to

the valve. Connect the pressure gauge to the

service tool. If using a fuel pressure gauge

with its own adaptor, connect it in accordance

with its maker’s instructions (see illustration).

5Start the engine and allow it to idle. Note

the gauge reading as soon as the pressure

stabilises, and compare it with the pressure

listed in this Chapter’s Specifications.

(a) If the pressure is high, check for a

restricted fuel return line. If the line is

clear, renew the pressure regulator.

8 Fuel pump/fuel pressure -

check

7 Accelerator pedal -

removal and refitting

Fuel and exhaust systems 4•5

4

6.11 Location of TCS throttle actuator-to-

throttle housing cable adjuster (arrowed)7.2 Removing the accelerator pedal

assembly8.4 A fuel pressure gauge, equipped with

an adaptor to suit the Schrader-type valve

on the fuel rail pressure test/release fitting,

is needed to check fuel pressure

procarmanuals.com

Page 104 of 279

(b) If the pressure is low, pinch the fuel return

line. If the pressure now goes up, renew

the fuel pressure regulator. If the pressure

does not increase, check the fuel feed

line, the fuel pump and the fuel filter.

6Detach the vacuum hose from the fuel

pressure regulator; the pressure shown on the

gauge should increase. Note the increase in

pressure, and compare it with that listed in

this Chapter’s Specifications. If the pressure

increase is not as specified, check the

vacuum hose and pressure regulator.

7Reconnect the regulator vacuum hose, and

switch off the engine. Verify that the fuel

pressure stays at the specified level for five

minutes after the engine is turned off.

8Carefully disconnect the fuel pressure

gauge. Be sure to cover the fitting with a rag

before slackening it. Mop up any spilt petrol.

9Run the engine, and check that there are no

fuel leaks.

Warning: Petrol is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t smoke,

or allow open flames or bare light bulbs,

near the work area. Don’t work in a garage

where a natural gas-type appliance (such

as a water heater or clothes dryer) with a

pilot light is present. If you spill any fuel on

your skin, rinse it off immediately with

soap and water. When you perform any

kind of work on the fuel system, wear

safety glasses, and have a Class B type

fire extinguisher on hand.

Note: Ford specify the use of their service tool

23-038 (a large box spanner with projecting teeth

to engage the fuel pump/sender unit retaining

ring’s slots) for this task. While alternatives are

possible, as shown below, in view of the difficulty

experienced in removing and refitting the

pump/sender unit, owners are strongly advised

to obtain this tool before starting work. The help

of an assistant will be required.

1Relieve the residual pressure in the fuel

system (see Section 2), and equalise tank

pressure by removing the fuel filler cap. Warning: This procedure will

merely relieve the increased

pressure necessary for the

engine to run - remember that

fuel will still be present in the system

components, and take precautions

accordingly before disconnecting any of

them.

2Disconnect the battery negative (earth) lead

- see Chapter 5, Section 1.

3Unbolt or fold forwards (as appropriate) the

rear seat base cushion (see Chapter 11).

Withdraw from the vehicle’s floor the grommet

covering the fuel pump/sender unit. Wash off

any dirt from the tank’s top surface, and dry it;

use a vacuum cleaner to clean the immediate

surroundings of the vehicle’s interior, to

reduce the risk of introducing water, dirt and

dust into the tank while it is open.

4Unplug the fuel pump/sender unit’s

electrical connector (see illustration).

5To disconnect the fuel feed and return

pipes from the unit, release each pipe’s

coupling, by squeezing together the

protruding locking lugs on each union and

carefully pulling the coupling apart. Use rag to

soak up any spilt fuel. Where the couplings

are difficult to separate, use a pair of pliers

and a block of wood as shown, to lever the

pipe out of the union. Considerable force maybe required, but be as careful as possible to

avoid damaging any of the components (see

illustration).

6Release the fuel pump/sender unit’s

retaining ring by turning it anti-clockwise. As

noted above, Ford recommend the use of

service tool 23-038. For those without access

to such equipment, a hammer and drift, or a

pair of slip-jointed pliers, will serve as an

adequate substitute - at least for removal (see

illustration).

7Withdraw the fuel pump/fuel gauge sender

unit, taking care not to bend the float arm. The

float arm is mounted on a spring-loaded

extension, to hold it closely against the

bottom of the tank. Note the sealing ring; this

must be renewed whenever it is disturbed

(see illustrations).

8On refitting, use a new sealing ring, and

ensure that the gauze filter over the base of

the pump pick-up is clean.

9Align the pump/sender unit with the tank

opening, and refit it, ensuring that the float

arm is not bent. Insert the unit so that the float

arm slides correctly up the extension, until the

unit’s top mounting plate can be aligned with

the tank opening and pressed onto the sealing

ring. This may require a considerable amount

of pressure; if so, be careful to avoid

damaging any of the components. The Ford

service tool provides the best way of holding

9 Fuel pump/fuel gauge sender

unit- removal and refitting

4•6 Fuel and exhaust systems

9.4 Unplugging the fuel pump/fuel gauge

sender unit electrical connector (arrowed)9.5 If fuel couplings are difficult to release,

use pliers and a block of wood as shown

to prise pipe end out of union - be careful

not to damage pipes or unions9.6 Fuel pump/fuel gauge sender unit’s

retaining ring can be released using

ordinary tools as shown. Correct service

tool will probably be required on refitting

9.7A Removing fuel pump/fuel gauge

sender unit - take care not to bend float

arm, and note how it is fitted on spring-

loaded extension9.7B Fuel pump/fuel gauge sender unit’s

sealing ring must be renewed whenever it

is disturbed

procarmanuals.com

Page 105 of 279

the ring square to the tank and turning it at the

same time.

10Maintain the pressure while an assistant

refits and engages the retaining ring. When

the ring is engaged in the tank lugs, turn it

clockwise to tighten it until it is secured.

11The remainder of the refitting procedure is

the reverse of removal. Observe the colour-

coding to ensure that the fuel pipes are

reconnected to the correct unions.

Warning: The fuel system pressure

must be released before any part

of the system is disturbed - see

Section 2. Petrol is extremely

flammable, so take extra precautions when

you work on any part of the fuel system.

Don’t smoke, or allow open flames or bare

light bulbs, near the work area. Don’t work

in a garage where a natural gas-type

appliance (such as a water heater or clothes

dryer) with a pilot light is present. If you spill

any fuel on your skin, rinse it off

immediately with soap and water. When you

perform any kind of work on the fuel

system, wear safety glasses, and have a

Class B type fire extinguisher on hand.

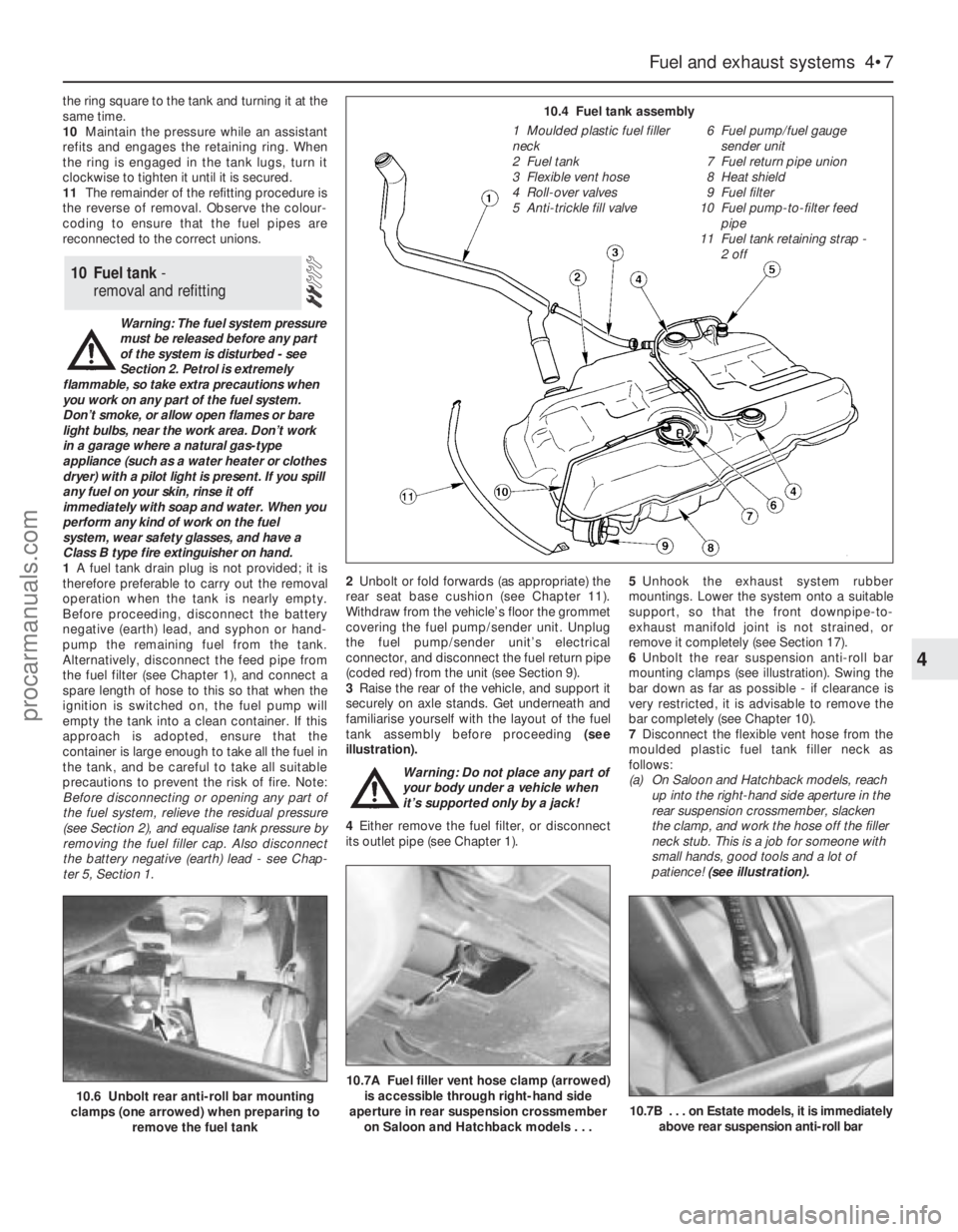

1A fuel tank drain plug is not provided; it is

therefore preferable to carry out the removal

operation when the tank is nearly empty.

Before proceeding, disconnect the battery

negative (earth) lead, and syphon or hand-

pump the remaining fuel from the tank.

Alternatively, disconnect the feed pipe from

the fuel filter (see Chapter 1), and connect a

spare length of hose to this so that when the

ignition is switched on, the fuel pump will

empty the tank into a clean container. If this

approach is adopted, ensure that the

container is large enough to take all the fuel in

the tank, and be careful to take all suitable

precautions to prevent the risk of fire. Note:

Before disconnecting or opening any part of

the fuel system, relieve the residual pressure

(see Section 2), and equalise tank pressure by

removing the fuel filler cap. Also disconnect

the battery negative (earth) lead - see Chap-

ter 5, Section 1.2Unbolt or fold forwards (as appropriate) the

rear seat base cushion (see Chapter 11).

Withdraw from the vehicle’s floor the grommet

covering the fuel pump/sender unit. Unplug

the fuel pump/sender unit’s electrical

connector, and disconnect the fuel return pipe

(coded red) from the unit (see Section 9).

3Raise the rear of the vehicle, and support it

securely on axle stands. Get underneath and

familiarise yourself with the layout of the fuel

tank assembly before proceeding (see

illustration).

Warning: Do not place any part of

your body under a vehicle when

it’s supported only by a jack!

4Either remove the fuel filter, or disconnect

its outlet pipe (see Chapter 1).5Unhook the exhaust system rubber

mountings. Lower the system onto a suitable

support, so that the front downpipe-to-

exhaust manifold joint is not strained, or

remove it completely (see Section 17).

6Unbolt the rear suspension anti-roll bar

mounting clamps (see illustration). Swing the

bar down as far as possible - if clearance is

very restricted, it is advisable to remove the

bar completely (see Chapter 10).

7Disconnect the flexible vent hose from the

moulded plastic fuel tank filler neck as

follows:

(a) On Saloon and Hatchback models, reach

up into the right-hand side aperture in the

rear suspension crossmember, slacken

the clamp, and work the hose off the filler

neck stub. This is a job for someone with

small hands, good tools and a lot of

patience! (see illustration).

10 Fuel tank -

removal and refitting

Fuel and exhaust systems 4•7

4

10.6 Unbolt rear anti-roll bar mounting

clamps (one arrowed) when preparing to

remove the fuel tank10.7A Fuel filler vent hose clamp (arrowed)

is accessible through right-hand side

aperture in rear suspension crossmember

on Saloon and Hatchback models . . .

10.7B . . . on Estate models, it is immediately

above rear suspension anti-roll bar

10.4 Fuel tank assembly

1 Moulded plastic fuel filler

neck

2 Fuel tank

3 Flexible vent hose

4 Roll-over valves

5 Anti-trickle fill valve6 Fuel pump/fuel gauge

sender unit

7 Fuel return pipe union

8 Heat shield

9 Fuel filter

10 Fuel pump-to-filter feed

pipe

11 Fuel tank retaining strap -

2 off

procarmanuals.com

Page 112 of 279

General information

The engine electrical systems include all

ignition, charging and starting components.

Because of their engine-related functions,

these components are discussed separately

from body electrical devices such as the

lights, the instruments, etc (which are

included in Chapter 12).

Precautions

Always observe the following precautions

when working on the electrical system:

(a) Be extremely careful when servicing

engine electrical components. They are

easily damaged if checked, connected or

handled improperly.

(b) Never leave the ignition switched on for

long periods of time when the engine is

not running.

(c) Don’t disconnect the battery leads while

the engine is running.

(d) Maintain correct polarity when connecting

a battery lead from another vehicle during

jump starting - see the “Booster battery

(jump) starting” section at the front of this

manual.

(e) Always disconnect the negative lead first,

and reconnect it last, or the battery may

be shorted by the tool being used to

loosen the lead clamps (see illustration).

It’s also a good idea to review the safety-

related information regarding the engine

electrical systems located in the “Safety first!”

section at the front of this manual, before

beginning any operation included in this Chapter.

Battery disconnection

Several systems fitted to the vehicle require

battery power to be available at all times, either

to ensure their continued operation (such as

the clock) or to maintain control unit memories

(such as that in the engine management

system’s ECU) which would be wiped if the

battery were to be disconnected. Whenever thebattery is to be disconnected therefore, first

note the following, to ensure that there are no

unforeseen consequences of this action:

(a) First, on any vehicle with central locking, it

is a wise precaution to remove the key

from the ignition, and to keep it with you,

so that it does not get locked in if the

central locking should engage accidentally

when the battery is reconnected!

(b) The engine management system’s ECU will

lose the information stored in its memory -

referred to by Ford as the “KAM” (Keep-

Alive Memory) - when the battery is

disconnected. This includes idling and

operating values, and any fault codes

detected - in the case of the fault codes, if it

is thought likely that the system has

developed a fault for which the

corresponding code has been logged, the

vehicle must be taken to a Ford dealer for

the codes to be read, using the special

diagnostic equipment necessary for this (see

Chapter 6). Whenever the battery is

disconnected, the information relating to idle

speed control and other operating values will

have to be re-programmed into the unit’s

memory. The ECU does this by itself, but

until then, there may be surging, hesitation,

erratic idle and a generally inferior level of

performance. To allow the ECU to relearn

these values, start the engine and run it as

close to idle speed as possible until it

reaches its normal operating temperature,

then run it for approximately two minutes at

1200 rpm. Next, drive the vehicle as far as

necessary - approximately 5 miles of varied

driving conditions is usually sufficient - to

complete the relearning process.

(c) If the battery is disconnected while the

alarm system is armed or activated, the

alarm will remain in the same state when

the battery is reconnected. The same

applies to the engine immobiliser system

(where fitted).

(d) If a trip computer is in use, any

information stored in memory will be lost.

(e) If a Ford “Keycode” audio unit is fitted,

and the unit and/or the battery is

disconnected, the unit will not function

again on reconnection until the correct

security code is entered. Details of thisprocedure, which varies according to the

unit and model year, are given in the

“Ford Audio Systems Operating Guide”

supplied with the vehicle when new, with

the code itself being given in a “Radio

Passport” and/or a “Keycode Label” at

the same time. Ensure you have the

correct code before you disconnect the

battery. For obvious security reasons, the

procedure is not given in this manual. If

you do not have the code or details of the

correct procedure, but can supply proof

of ownership and a legitimate reason for

wanting this information, the vehicle’s

selling dealer may be able to help.

Devices known as “memory-savers” (or

“code-savers”) can be used to avoid some of

the above problems. Precise details vary

according to the device used. Typically, it is

plugged into the cigarette lighter, and is

connected by its own wires to a spare battery;

the vehicle’s own battery is then disconnected

from the electrical system, leaving the

“memory-saver” to pass sufficient current to

maintain audio unit security codes and ECU

memory values, and also to run permanently-

live circuits such as the clock, all the while

isolating the battery in the event of a short-

circuit occurring while work is carried out.

Warning: Some of these devices

allow a considerable amount of

current to pass, which can mean

that many of the vehicle’s systems are still

operational when the main battery is

disconnected. If a “memory-saver” is used,

ensure that the circuit concerned is

actually “dead” before carrying out any

work on it!

Note:See also the relevant Sections of

Chapter 1.

1Disconnect the battery leads, negative

(earth) lead first - see Section 1.

2Remove the battery hold-down clamp (see

illustrations).

3Lift out the battery. Be careful - it’s heavy.

4While the battery is out, inspect the tray for

corrosion (see Chapter 1).

2 Battery- removal and refitting

1 General information,

precautions and battery

disconnection

5•2 Engine electrical systems

1.2 Always disconnect battery - negative

(earth) lead first - to prevent the possibility

of short-circuits2.2A Unscrew hold-down nuts (one of two

arrowed) . . .2.2B . . . and withdraw hold-down clamp

to release battery

procarmanuals.com

Page 120 of 279

Torque wrench settingsNm lbf ft

Front caliper bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 89

Rear caliper bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 44

Front caliper guide bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 21

Rear caliper guide bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 30

Rear drum brake backplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 37

Vacuum servo unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 30

Master cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 17

ABS hydraulic unit to bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

Roadwheel nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 63

9•2 Braking system

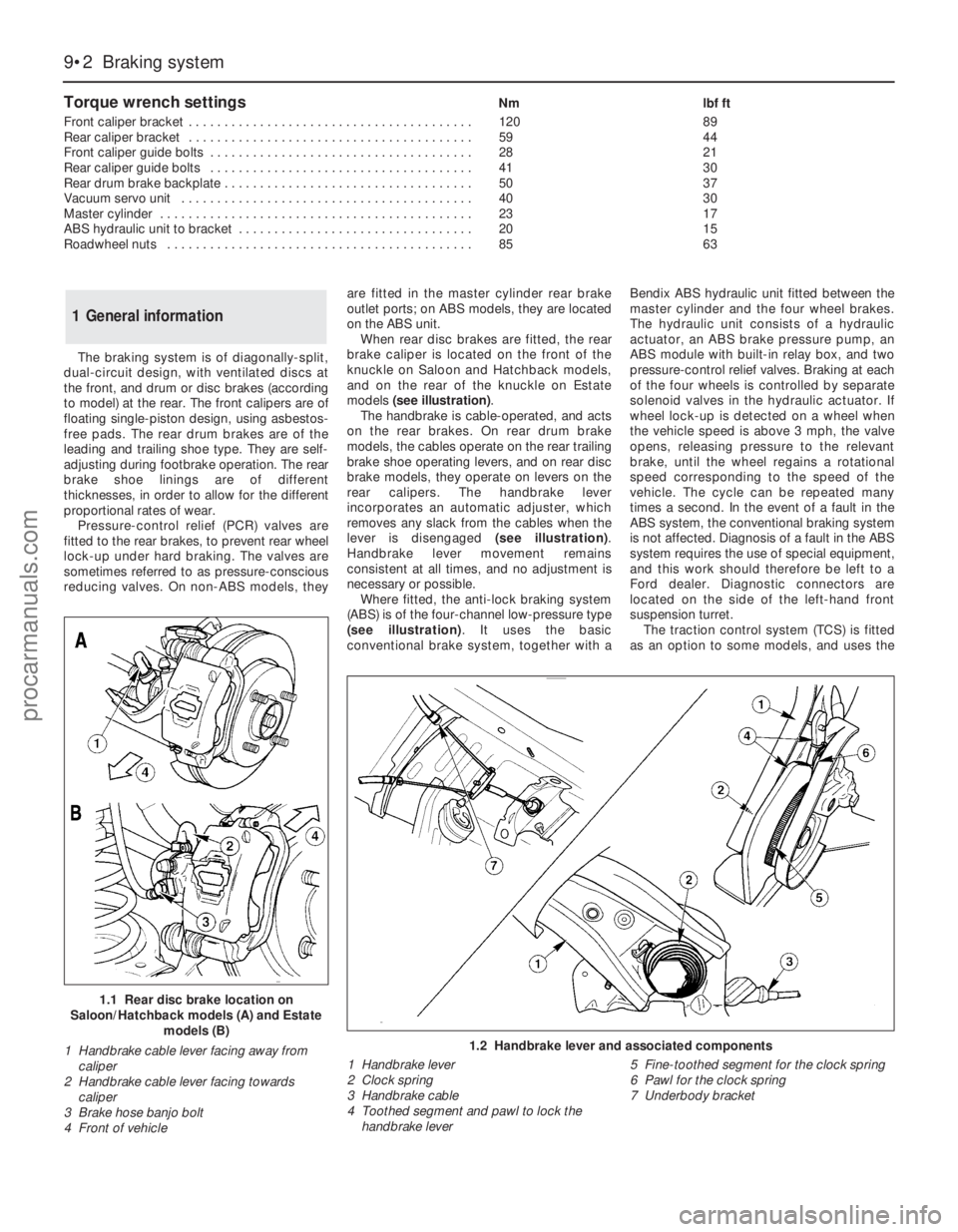

1.2 Handbrake lever and associated components

1 Handbrake lever

2 Clock spring

3 Handbrake cable

4 Toothed segment and pawl to lock the

handbrake lever5 Fine-toothed segment for the clock spring

6 Pawl for the clock spring

7 Underbody bracket

The braking system is of diagonally-split,

dual-circuit design, with ventilated discs at

the front, and drum or disc brakes (according

to model) at the rear. The front calipers are of

floating single-piston design, using asbestos-

free pads. The rear drum brakes are of the

leading and trailing shoe type. They are self-

adjusting during footbrake operation. The rear

brake shoe linings are of different

thicknesses, in order to allow for the different

proportional rates of wear.

Pressure-control relief (PCR) valves are

fitted to the rear brakes, to prevent rear wheel

lock-up under hard braking. The valves are

sometimes referred to as pressure-conscious

reducing valves. On non-ABS models, theyare fitted in the master cylinder rear brake

outlet ports; on ABS models, they are located

on the ABS unit.

When rear disc brakes are fitted, the rear

brake caliper is located on the front of the

knuckle on Saloon and Hatchback models,

and on the rear of the knuckle on Estate

models (see illustration).

The handbrake is cable-operated, and acts

on the rear brakes. On rear drum brake

models, the cables operate on the rear trailing

brake shoe operating levers, and on rear disc

brake models, they operate on levers on the

rear calipers. The handbrake lever

incorporates an automatic adjuster, which

removes any slack from the cables when the

lever is disengaged (see illustration).

Handbrake lever movement remains

consistent at all times, and no adjustment is

necessary or possible.

Where fitted, the anti-lock braking system

(ABS) is of the four-channel low-pressure type

(see illustration). It uses the basic

conventional brake system, together with aBendix ABS hydraulic unit fitted between the

master cylinder and the four wheel brakes.

The hydraulic unit consists of a hydraulic

actuator, an ABS brake pressure pump, an

ABS module with built-in relay box, and two

pressure-control relief valves. Braking at each

of the four wheels is controlled by separate

solenoid valves in the hydraulic actuator. If

wheel lock-up is detected on a wheel when

the vehicle speed is above 3 mph, the valve

opens, releasing pressure to the relevant

brake, until the wheel regains a rotational

speed corresponding to the speed of the

vehicle. The cycle can be repeated many

times a second. In the event of a fault in the

ABS system, the conventional braking system

is not affected. Diagnosis of a fault in the ABS

system requires the use of special equipment,

and this work should therefore be left to a

Ford dealer. Diagnostic connectors are

located on the side of the left-hand front

suspension turret.

The traction control system (TCS) is fitted

as an option to some models, and uses the

1 General information

1.1 Rear disc brake location on

Saloon/Hatchback models (A) and Estate

models (B)

1 Handbrake cable lever facing away from

caliper

2 Handbrake cable lever facing towards

caliper

3 Brake hose banjo bolt

4 Front of vehicle

procarmanuals.com