auxiliary battery FORD MONDEO 1993 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 15 of 279

Chapter 1 Routine maintenance and servicing

Air conditioning system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Air filter element renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Automatic transmission fluid level check . . . . . . . . . . . . . . . . . . . . . 7

Automatic transmission linkage lubrication . . . . . . . . . . . . . . . . . . . 18

Auxiliary drivebelt check and renewal . . . . . . . . . . . . . . . . . . . . . . . . 11

Battery check, maintenance and charging . . . . . . . . . . . . . . . . . . . . 9

Brake check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Brake fluid renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Clutch pedal adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Coolant renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2, 28

Door and bonnet check and lubrication . . . . . . . . . . . . . . . . . . . . . . 24

Driveshaft rubber gaiter and CV joint check . . . . . . . . . . . . . . . . . . . 20

Electrical system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Engine compartment wiring check . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Engine oil and filter change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fluid level checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fuel filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Idle speed and mixture check and adjustment . . . . . . See Chapter 4Ignition timing check . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Manual transmission oil level check . . . . . . . . . . . . . . . . . . . . . . . . . 16

Positive Crankcase Ventilation (PCV) system check

and filter cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Power steering fluid level check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Road test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Roadwheel nut tightness check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Seat belt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Spark plug renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . See end of Chapter

Steering, suspension and roadwheel check . . . . . . . . . . . . . . . . . . . 19

Timing belt renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Tyre and tyre pressure checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Underbody and fuel/brake line check . . . . . . . . . . . . . . . . . . . . . . . . 22

Underbonnet check for fluid leaks and hose condition . . . . . . . . . . 12

Ventilation system pollen filter renewal . . . . . . . . . . . . . . . . . . . . . . . 27

Windscreen/tailgate washer system and wiper blade check . . . . . . 6

1•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,suitable

for competent DIY

mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty Contents

1

procarmanuals.com

Page 17 of 279

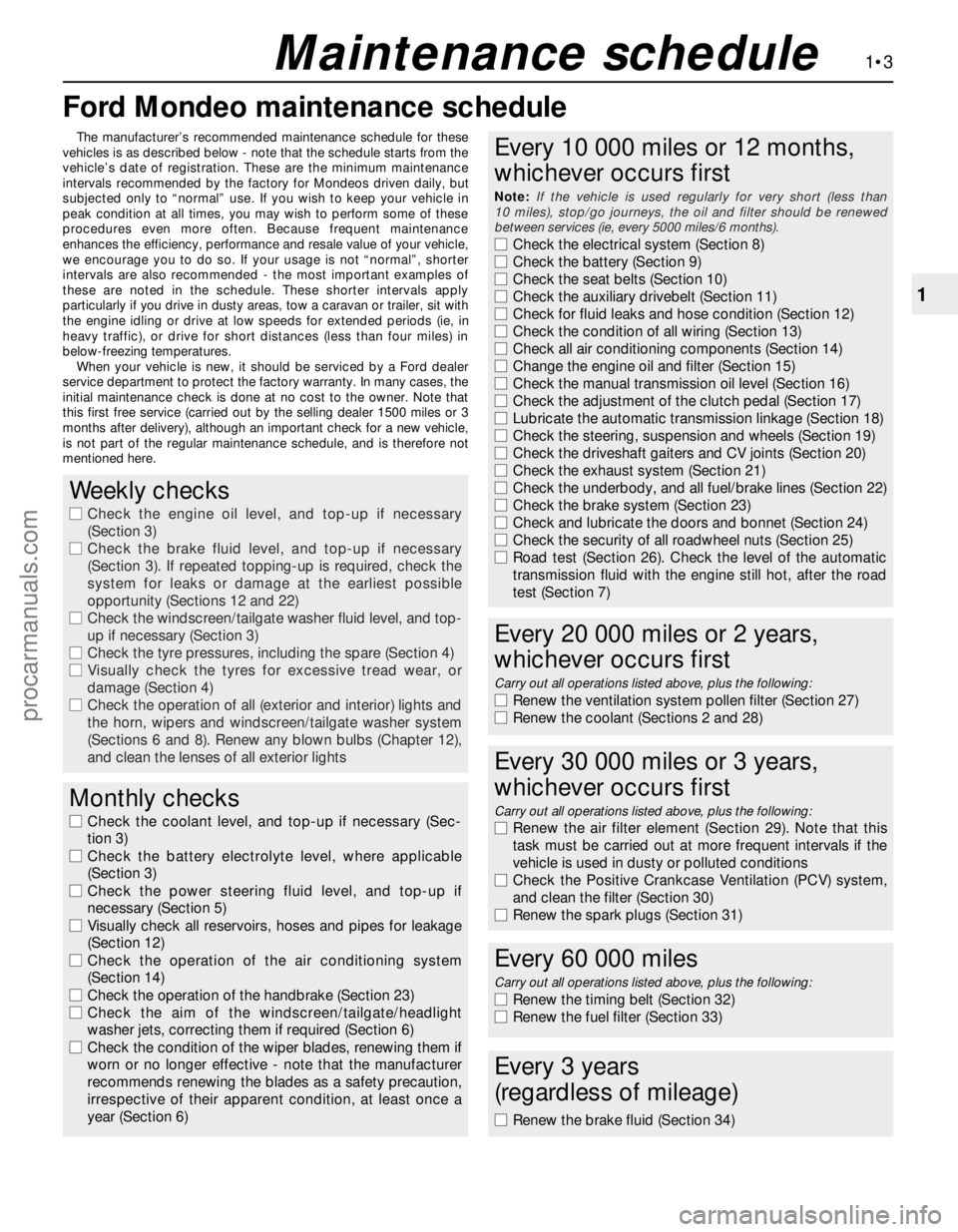

Ford Mondeo maintenance schedule

1•3

1

Maintenance schedule

The manufacturer’s recommended maintenance schedule for these

vehicles is as described below - note that the schedule starts from the

vehicle’s date of registration. These are the minimum maintenance

intervals recommended by the factory for Mondeos driven daily, but

subjected only to “normal” use. If you wish to keep your vehicle in

peak condition at all times, you may wish to perform some of these

procedures even more often. Because frequent maintenance

enhances the efficiency, performance and resale value of your vehicle,

we encourage you to do so. If your usage is not “normal”, shorter

intervals are also recommended - the most important examples of

these are noted in the schedule. These shorter intervals apply

particularly if you drive in dusty areas, tow a caravan or trailer, sit with

the engine idling or drive at low speeds for extended periods (ie, in

heavy traffic), or drive for short distances (less than four miles) in

below-freezing temperatures.

When your vehicle is new, it should be serviced by a Ford dealer

service department to protect the factory warranty. In many cases, the

initial maintenance check is done at no cost to the owner. Note that

this first free service (carried out by the selling dealer 1500 miles or 3

months after delivery), although an important check for a new vehicle,

is not part of the regular maintenance schedule, and is therefore not

mentioned here.

Weekly checks

m mCheck the engine oil level, and top-up if necessary

(Section 3)

m mCheck the brake fluid level, and top-up if necessary

(Section 3). If repeated topping-up is required, check the

system for leaks or damage at the earliest possible

opportunity (Sections 12 and 22)

m mCheck the windscreen/tailgate washer fluid level, and top-

up if necessary (Section 3)

m mCheck the tyre pressures, including the spare (Section 4)

m mVisually check the tyres for excessive tread wear, or

damage (Section 4)

m mCheck the operation of all (exterior and interior) lights and

the horn, wipers and windscreen/tailgate washer system

(Sections 6 and 8). Renew any blown bulbs (Chapter 12),

and clean the lenses of all exterior lights

Monthly checks

m mCheck the coolant level, and top-up if necessary (Sec-

tion 3)

m mCheck the battery electrolyte level, where applicable

(Section 3)

m mCheck the power steering fluid level, and top-up if

necessary (Section 5)

m mVisually check all reservoirs, hoses and pipes for leakage

(Section 12)

m mCheck the operation of the air conditioning system

(Section 14)

m mCheck the operation of the handbrake (Section 23)

m mCheck the aim of the windscreen/tailgate/headlight

washer jets, correcting them if required (Section 6)

m mCheck the condition of the wiper blades, renewing them if

worn or no longer effective - note that the manufacturer

recommends renewing the blades as a safety precaution,

irrespective of their apparent condition, at least once a

year (Section 6)

Every 10 000 miles or 12 months,

whichever occurs first

Note:If the vehicle is used regularly for very short (less than

10 miles), stop/go journeys, the oil and filter should be renewed

between services (ie, every 5000 miles/6 months).

m mCheck the electrical system (Section 8)

m mCheck the battery (Section 9)

m mCheck the seat belts (Section 10)

m mCheck the auxiliary drivebelt (Section 11)

m mCheck for fluid leaks and hose condition (Section 12)

m mCheck the condition of all wiring (Section 13)

m mCheck all air conditioning components (Section 14)

m mChange the engine oil and filter (Section 15)

m mCheck the manual transmission oil level (Section 16)

m mCheck the adjustment of the clutch pedal (Section 17)

m mLubricate the automatic transmission linkage (Section 18)

m mCheck the steering, suspension and wheels (Section 19)

m mCheck the driveshaft gaiters and CV joints (Section 20)

m mCheck the exhaust system (Section 21)

m mCheck the underbody, and all fuel/brake lines (Section 22)

m mCheck the brake system (Section 23)

m mCheck and lubricate the doors and bonnet (Section 24)

m mCheck the security of all roadwheel nuts (Section 25)

m mRoad test (Section 26). Check the level of the automatic

transmission fluid with the engine still hot, after the road

test (Section 7)

Every 20 000 miles or 2 years,

whichever occurs first

Carry out all operations listed above, plus the following:

m mRenew the ventilation system pollen filter (Section 27)

m mRenew the coolant (Sections 2 and 28)

Every 30 000 miles or 3 years,

whichever occurs first

Carry out all operations listed above, plus the following:

m mRenew the air filter element (Section 29). Note that this

task must be carried out at more frequent intervals if the

vehicle is used in dusty or polluted conditions

m mCheck the Positive Crankcase Ventilation (PCV) system,

and clean the filter (Section 30)

m mRenew the spark plugs (Section 31)

Every 60 000 miles

Carry out all operations listed above, plus the following:

m

mRenew the timing belt (Section 32)

m mRenew the fuel filter (Section 33)

Every 3 years

(regardless of mileage)

m mRenew the brake fluid (Section 34)

procarmanuals.com

Page 18 of 279

1•4

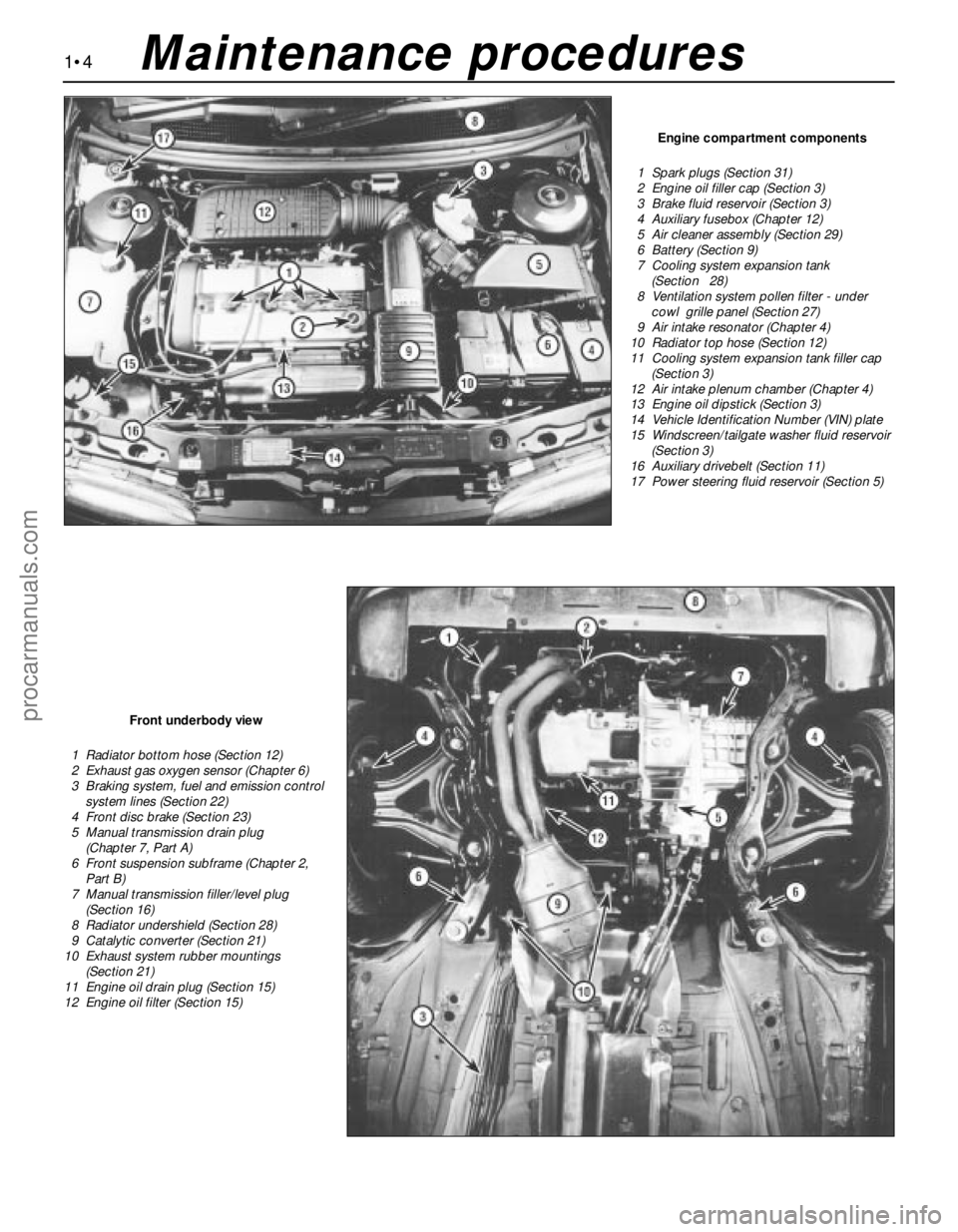

Engine compartment components

1 Spark plugs (Section 31)

2 Engine oil filler cap (Section 3)

3 Brake fluid reservoir (Section 3)

4 Auxiliary fusebox (Chapter 12)

5 Air cleaner assembly (Section 29)

6 Battery (Section 9)

7 Cooling system expansion tank

(Section 28)

8 Ventilation system pollen filter - under

cowl grille panel (Section 27)

9 Air intake resonator (Chapter 4)

10 Radiator top hose (Section 12)

11 Cooling system expansion tank filler cap

(Section 3)

12 Air intake plenum chamber (Chapter 4)

13 Engine oil dipstick (Section 3)

14 Vehicle Identification Number (VIN) plate

15 Windscreen/tailgate washer fluid reservoir

(Section 3)

16 Auxiliary drivebelt (Section 11)

17 Power steering fluid reservoir (Section 5)

Front underbody view

1 Radiator bottom hose (Section 12)

2 Exhaust gas oxygen sensor (Chapter 6)

3 Braking system, fuel and emission control

system lines (Section 22)

4 Front disc brake (Section 23)

5 Manual transmission drain plug

(Chapter 7, Part A)

6 Front suspension subframe (Chapter 2,

Part B)

7 Manual transmission filler/level plug

(Section 16)

8 Radiator undershield (Section 28)

9 Catalytic converter (Section 21)

10 Exhaust system rubber mountings

(Section 21)

11 Engine oil drain plug (Section 15)

12 Engine oil filter (Section 15)

Maintenance procedures

procarmanuals.com

Page 27 of 279

amperage charger, but don’t use one rated

more than 1/10th the amp/hour rating of the

battery (ie no more than 5 amps, typically).

Rapid boost charges that claim to restore the

power of the battery in one to two hours are

hardest on the battery, and can damage

batteries not in good condition. This type of

charging should only be used in emergency

situations.

14The average time necessary to charge a

battery should be listed in the instructions that

come with the charger. As a general rule, a

trickle charger will charge a battery in 12 to

16 hours.

1Check the seat belts for satisfactory

operation and condition. Inspect the webbing

for fraying and cuts. Check that they retract

smoothly and without binding into their reels.

2Check that the seat belt mounting bolts are

tight, and if necessary tighten them to the

specified torque wrench setting.

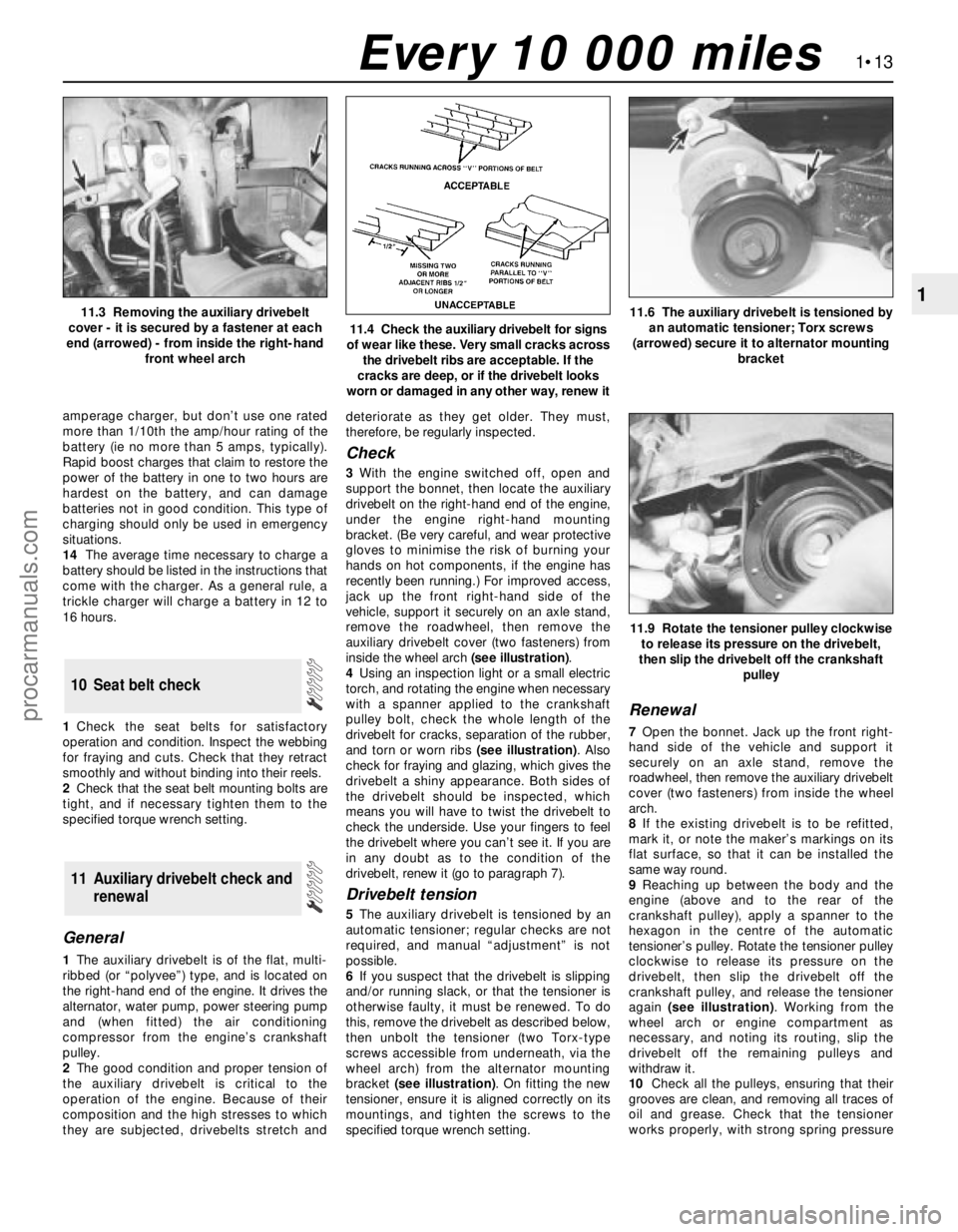

General

1The auxiliary drivebelt is of the flat, multi-

ribbed (or “polyvee”) type, and is located on

the right-hand end of the engine. It drives the

alternator, water pump, power steering pump

and (when fitted) the air conditioning

compressor from the engine’s crankshaft

pulley.

2The good condition and proper tension of

the auxiliary drivebelt is critical to the

operation of the engine. Because of their

composition and the high stresses to which

they are subjected, drivebelts stretch anddeteriorate as they get older. They must,

therefore, be regularly inspected.

Check

3With the engine switched off, open and

support the bonnet, then locate the auxiliary

drivebelt on the right-hand end of the engine,

under the engine right-hand mounting

bracket. (Be very careful, and wear protective

gloves to minimise the risk of burning your

hands on hot components, if the engine has

recently been running.) For improved access,

jack up the front right-hand side of the

vehicle, support it securely on an axle stand,

remove the roadwheel, then remove the

auxiliary drivebelt cover (two fasteners) from

inside the wheel arch (see illustration).

4Using an inspection light or a small electric

torch, and rotating the engine when necessary

with a spanner applied to the crankshaft

pulley bolt, check the whole length of the

drivebelt for cracks, separation of the rubber,

and torn or worn ribs (see illustration). Also

check for fraying and glazing, which gives the

drivebelt a shiny appearance. Both sides of

the drivebelt should be inspected, which

means you will have to twist the drivebelt to

check the underside. Use your fingers to feel

the drivebelt where you can’t see it. If you are

in any doubt as to the condition of the

drivebelt, renew it (go to paragraph 7).

Drivebelt tension

5The auxiliary drivebelt is tensioned by an

automatic tensioner; regular checks are not

required, and manual “adjustment” is not

possible.

6If you suspect that the drivebelt is slipping

and/or running slack, or that the tensioner is

otherwise faulty, it must be renewed. To do

this, remove the drivebelt as described below,

then unbolt the tensioner (two Torx-type

screws accessible from underneath, via the

wheel arch) from the alternator mounting

bracket (see illustration). On fitting the new

tensioner, ensure it is aligned correctly on its

mountings, and tighten the screws to the

specified torque wrench setting.

Renewal

7Open the bonnet. Jack up the front right-

hand side of the vehicle and support it

securely on an axle stand, remove the

roadwheel, then remove the auxiliary drivebelt

cover (two fasteners) from inside the wheel

arch.

8If the existing drivebelt is to be refitted,

mark it, or note the maker’s markings on its

flat surface, so that it can be installed the

same way round.

9Reaching up between the body and the

engine (above and to the rear of the

crankshaft pulley), apply a spanner to the

hexagon in the centre of the automatic

tensioner’s pulley. Rotate the tensioner pulley

clockwise to release its pressure on the

drivebelt, then slip the drivebelt off the

crankshaft pulley, and release the tensioner

again (see illustration). Working from the

wheel arch or engine compartment as

necessary, and noting its routing, slip the

drivebelt off the remaining pulleys and

withdraw it.

10Check all the pulleys, ensuring that their

grooves are clean, and removing all traces of

oil and grease. Check that the tensioner

works properly, with strong spring pressure

11 Auxiliary drivebelt check and

renewal

10 Seat belt check

1•13

1

11.9 Rotate the tensioner pulley clockwise

to release its pressure on the drivebelt,

then slip the drivebelt off the crankshaft

pulley

11.3 Removing the auxiliary drivebelt

cover - it is secured by a fastener at each

end (arrowed) - from inside the right-hand

front wheel arch

11.4 Check the auxiliary drivebelt for signs

of wear like these. Very small cracks across

the drivebelt ribs are acceptable. If the

cracks are deep, or if the drivebelt looks

worn or damaged in any other way, renew it

11.6 The auxiliary drivebelt is tensioned by

an automatic tensioner; Torx screws

(arrowed) secure it to alternator mounting

bracket

Every 10 000 miles

procarmanuals.com

Page 29 of 279

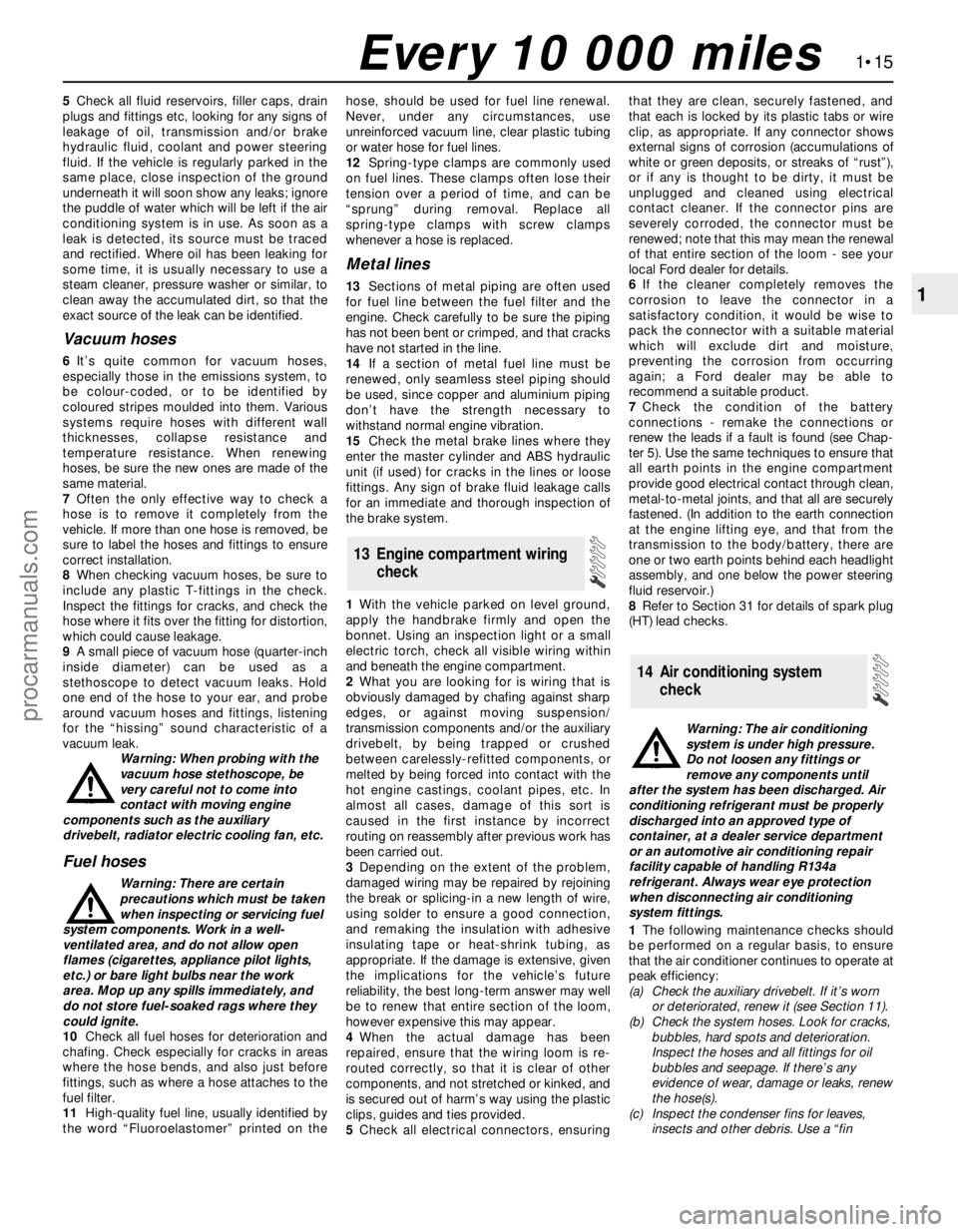

5Check all fluid reservoirs, filler caps, drain

plugs and fittings etc, looking for any signs of

leakage of oil, transmission and/or brake

hydraulic fluid, coolant and power steering

fluid. If the vehicle is regularly parked in the

same place, close inspection of the ground

underneath it will soon show any leaks; ignore

the puddle of water which will be left if the air

conditioning system is in use. As soon as a

leak is detected, its source must be traced

and rectified. Where oil has been leaking for

some time, it is usually necessary to use a

steam cleaner, pressure washer or similar, to

clean away the accumulated dirt, so that the

exact source of the leak can be identified.

Vacuum hoses

6It’s quite common for vacuum hoses,

especially those in the emissions system, to

be colour-coded, or to be identified by

coloured stripes moulded into them. Various

systems require hoses with different wall

thicknesses, collapse resistance and

temperature resistance. When renewing

hoses, be sure the new ones are made of the

same material.

7Often the only effective way to check a

hose is to remove it completely from the

vehicle. If more than one hose is removed, be

sure to label the hoses and fittings to ensure

correct installation.

8When checking vacuum hoses, be sure to

include any plastic T-fittings in the check.

Inspect the fittings for cracks, and check the

hose where it fits over the fitting for distortion,

which could cause leakage.

9A small piece of vacuum hose (quarter-inch

inside diameter) can be used as a

stethoscope to detect vacuum leaks. Hold

one end of the hose to your ear, and probe

around vacuum hoses and fittings, listening

for the “hissing” sound characteristic of a

vacuum leak.

Warning: When probing with the

vacuum hose stethoscope, be

very careful not to come into

contact with moving engine

components such as the auxiliary

drivebelt, radiator electric cooling fan, etc.

Fuel hoses

Warning: There are certain

precautions which must be taken

when inspecting or servicing fuel

system components. Work in a well-

ventilated area, and do not allow open

flames (cigarettes, appliance pilot lights,

etc.) or bare light bulbs near the work

area. Mop up any spills immediately, and

do not store fuel-soaked rags where they

could ignite.

10Check all fuel hoses for deterioration and

chafing. Check especially for cracks in areas

where the hose bends, and also just before

fittings, such as where a hose attaches to the

fuel filter.

11High-quality fuel line, usually identified by

the word “Fluoroelastomer” printed on thehose, should be used for fuel line renewal.

Never, under any circumstances, use

unreinforced vacuum line, clear plastic tubing

or water hose for fuel lines.

12Spring-type clamps are commonly used

on fuel lines. These clamps often lose their

tension over a period of time, and can be

“sprung” during removal. Replace all

spring-type clamps with screw clamps

whenever a hose is replaced.

Metal lines

13Sections of metal piping are often used

for fuel line between the fuel filter and the

engine. Check carefully to be sure the piping

has not been bent or crimped, and that cracks

have not started in the line.

14If a section of metal fuel line must be

renewed, only seamless steel piping should

be used, since copper and aluminium piping

don’t have the strength necessary to

withstand normal engine vibration.

15Check the metal brake lines where they

enter the master cylinder and ABS hydraulic

unit (if used) for cracks in the lines or loose

fittings. Any sign of brake fluid leakage calls

for an immediate and thorough inspection of

the brake system.

1With the vehicle parked on level ground,

apply the handbrake firmly and open the

bonnet. Using an inspection light or a small

electric torch, check all visible wiring within

and beneath the engine compartment.

2What you are looking for is wiring that is

obviously damaged by chafing against sharp

edges, or against moving suspension/

transmission components and/or the auxiliary

drivebelt, by being trapped or crushed

between carelessly-refitted components, or

melted by being forced into contact with the

hot engine castings, coolant pipes, etc. In

almost all cases, damage of this sort is

caused in the first instance by incorrect

routing on reassembly after previous work has

been carried out.

3Depending on the extent of the problem,

damaged wiring may be repaired by rejoining

the break or splicing-in a new length of wire,

using solder to ensure a good connection,

and remaking the insulation with adhesive

insulating tape or heat-shrink tubing, as

appropriate. If the damage is extensive, given

the implications for the vehicle’s future

reliability, the best long-term answer may well

be to renew that entire section of the loom,

however expensive this may appear.

4When the actual damage has been

repaired, ensure that the wiring loom is re-

routed correctly, so that it is clear of other

components, and not stretched or kinked, and

is secured out of harm’s way using the plastic

clips, guides and ties provided.

5Check all electrical connectors, ensuringthat they are clean, securely fastened, and

that each is locked by its plastic tabs or wire

clip, as appropriate. If any connector shows

external signs of corrosion (accumulations of

white or green deposits, or streaks of “rust”),

or if any is thought to be dirty, it must be

unplugged and cleaned using electrical

contact cleaner. If the connector pins are

severely corroded, the connector must be

renewed; note that this may mean the renewal

of that entire section of the loom - see your

local Ford dealer for details.

6If the cleaner completely removes the

corrosion to leave the connector in a

satisfactory condition, it would be wise to

pack the connector with a suitable material

which will exclude dirt and moisture,

preventing the corrosion from occurring

again; a Ford dealer may be able to

recommend a suitable product.

7Check the condition of the battery

connections - remake the connections or

renew the leads if a fault is found (see Chap-

ter 5). Use the same techniques to ensure that

all earth points in the engine compartment

provide good electrical contact through clean,

metal-to-metal joints, and that all are securely

fastened. (In addition to the earth connection

at the engine lifting eye, and that from the

transmission to the body/battery, there are

one or two earth points behind each headlight

assembly, and one below the power steering

fluid reservoir.)

8Refer to Section 31 for details of spark plug

(HT) lead checks.

Warning: The air conditioning

system is under high pressure.

Do not loosen any fittings or

remove any components until

after the system has been discharged. Air

conditioning refrigerant must be properly

discharged into an approved type of

container, at a dealer service department

or an automotive air conditioning repair

facility capable of handling R134a

refrigerant. Always wear eye protection

when disconnecting air conditioning

system fittings.

1The following maintenance checks should

be performed on a regular basis, to ensure

that the air conditioner continues to operate at

peak efficiency:

(a) Check the auxiliary drivebelt. If it’s worn

or deteriorated, renew it (see Section 11).

(b) Check the system hoses. Look for cracks,

bubbles, hard spots and deterioration.

Inspect the hoses and all fittings for oil

bubbles and seepage. If there’s any

evidence of wear, damage or leaks, renew

the hose(s).

(c) Inspect the condenser fins for leaves,

insects and other debris. Use a “fin

14 Air conditioning system

check

13 Engine compartment wiring

check

1•15

1

Every 10 000 miles

procarmanuals.com

Page 46 of 279

specifications were available from Ford, but a

typical reading would be in excess of 12 bars.

All cylinders should produce very similar

pressures; any difference greater than 10%

indicates the existence of a fault. Note that the

compression should build up quickly in a

healthy engine; low compression on the first

stroke, followed by gradually-increasing

pressure on successive strokes, indicates worn

piston rings. A low compression reading on the

first stroke, which does not build up during

successive strokes, indicates leaking valves or a

blown head gasket (a cracked head could also

be the cause). Deposits on the undersides of the

valve heads can also cause low compression.

8If the pressure in any cylinder is

considerably lower than the others, introduce

a teaspoonful of clean oil into that cylinder

through its spark plug hole, and repeat the

test.

9If the addition of oil temporarily improves

the compression pressure, this indicates that

bore or piston wear is responsible for the

pressure loss. No improvement suggests that

leaking or burnt valves, or a blown head

gasket, may be to blame.

10A low reading from two adjacent cylinders

is almost certainly due to the head gasket

having blown between them; the presence of

coolant in the engine oil will confirm this.

11If one cylinder is about 20 percent lower

than the others and the engine has a slightly

rough idle, a worn camshaft lobe or faulty

hydraulic tappet could be the cause.

12If the compression is unusually high, the

combustion chambers are probably coated

with carbon deposits. If this is the case, the

cylinder head should be removed and

decarbonised.

13On completion of the test, refit the spark

plugs, then reconnect the ignition system and

fuel pump.

General

1Top Dead Centre (TDC) is the highest point

in its travel up-and-down its cylinder bore

that each piston reaches as the crankshaftrotates. While each piston reaches TDC both

at the top of the compression stroke and

again at the top of the exhaust stroke, for the

purpose of timing the engine, TDC refers to

the piston position (usually No 1 piston) at the

top of its compression stroke.

2It is useful for several servicing procedures

to be able to position the engine at TDC.

3No 1 piston and cylinder are at the right-

hand (timing belt) end of the engine (right-

and left-hand are always quoted as seen from

the driver’s seat). Note that the crankshaft

rotates clockwise when viewed from the

right-hand side of the vehicle.

Locating TDC

4Remove all the spark plugs (Chapter 1).

5Disconnect both battery leads - see

Chapter 5, Section 1 - unless the starter

motor is to be used to turn the engine.

6Apply the handbrake and ensure that the

transmission is in neutral, then jack up the

front right-hand side of the vehicle and

support on an axle stand. Remove the

roadwheel.

7Remove the auxiliary drivebelt cover (see

Chapter 1) to expose the crankshaft pulley

and timing marks.

8It is best to rotate the crankshaft using a

spanner applied to the crankshaft pulley bolt;

however, it is possible also to use the starter

motor (switched on either by an assistant

using the ignition key, or by using a remote

starter switch) to bring the engine close to

TDC, then finish with a spanner. If the starter

is used, be sure to disconnect the battery

leads immediately it is no longer required.

9Note the two pairs of notches in the inner

and outer rims of the crankshaft pulley. In the

normal direction of crankshaft rotation

(clockwise, seen from the right-hand side of the

vehicle) the first pair of notches are irrelevant to

the vehicles covered in this manual, while the

second pair indicate TDC when aligned with

the rear edge of the raised mark on the sump.

Rotate the crankshaft clockwise until the

second pair of notches align with the edge of

the sump mark; use a straight edge extended

out from the sump if greater accuracy is

required (see illustrations).10Nos 1 and 4 cylinders are now at TDC,

one of them on the compression stroke.

Remove the oil filler cap; if No 4 cylinder

exhaust cam lobe is pointing to the rear of the

vehicle and slightly downwards, it is No 1

cylinder that is correctly positioned. If the

lobe is pointing horizontally forwards, rotate

the crankshaft one full turn (360°) clockwise

until the pulley notches align again, and the

lobe is pointing to the rear and slightly down.

No 1 cylinder will then be at TDC on the

compression stroke.

11Once No 1 cylinder has been positioned

at TDC on the compression stroke, TDC for

any of the other cylinders can then be located

by rotating the crankshaft clockwise 180° at a

time and following the firing order (see

Specifications).

12An alternative method of locating TDC is

to remove the cylinder head cover (see

Section 5) and to rotate the crankshaft

(clockwise, as described in paragraph 8

above) until the inlet valves for the cylinder

concerned have opened and just closed

again. Insert a length of wooden dowel

(approximately 150 mm/6 in long) or similar

into the spark plug hole until it rests on the

piston crown, and slowly further rotate the

crankshaft (taking care not to allow the dowel

to be trapped in the cylinder) until the dowel

stops rising - the piston is now at the top of

its compression stroke, and the dowel can be

removed.

13There is a “dead” area around TDC (as

the piston stops rising, pauses and then

begins to descend) which makes difficult the

exact location of TDC by this method; if

accuracy is required, either establish carefully

the exact mid-point of the dead area, or refer

to the timing marks (paragraph 9 above).

1Unplug the two electrical connectors and

disconnect the vacuum hose (where fitted),

then remove the air cleaner assembly cover

with the air mass meter, the resonator and the

plenum chamber (see Chapter 4).

2Disconnect the accelerator cable from the

5 Cylinder head cover-

removal and refitting

4 Top Dead Centre (TDC) for

No 1 piston - locating

2A•6 In-car engine repair procedures

4.9A Do not use crankshaft pulley’s first

pair of notches “A” - align second pair of

notches “B” with raised rib on sump “C” . . .4.9B . . . using a straight edge extended

out from the sump (arrowed) if greater

accuracy is required5.4 Disconnecting crankcase breather

hose from cylinder head cover union

procarmanuals.com

Page 51 of 279

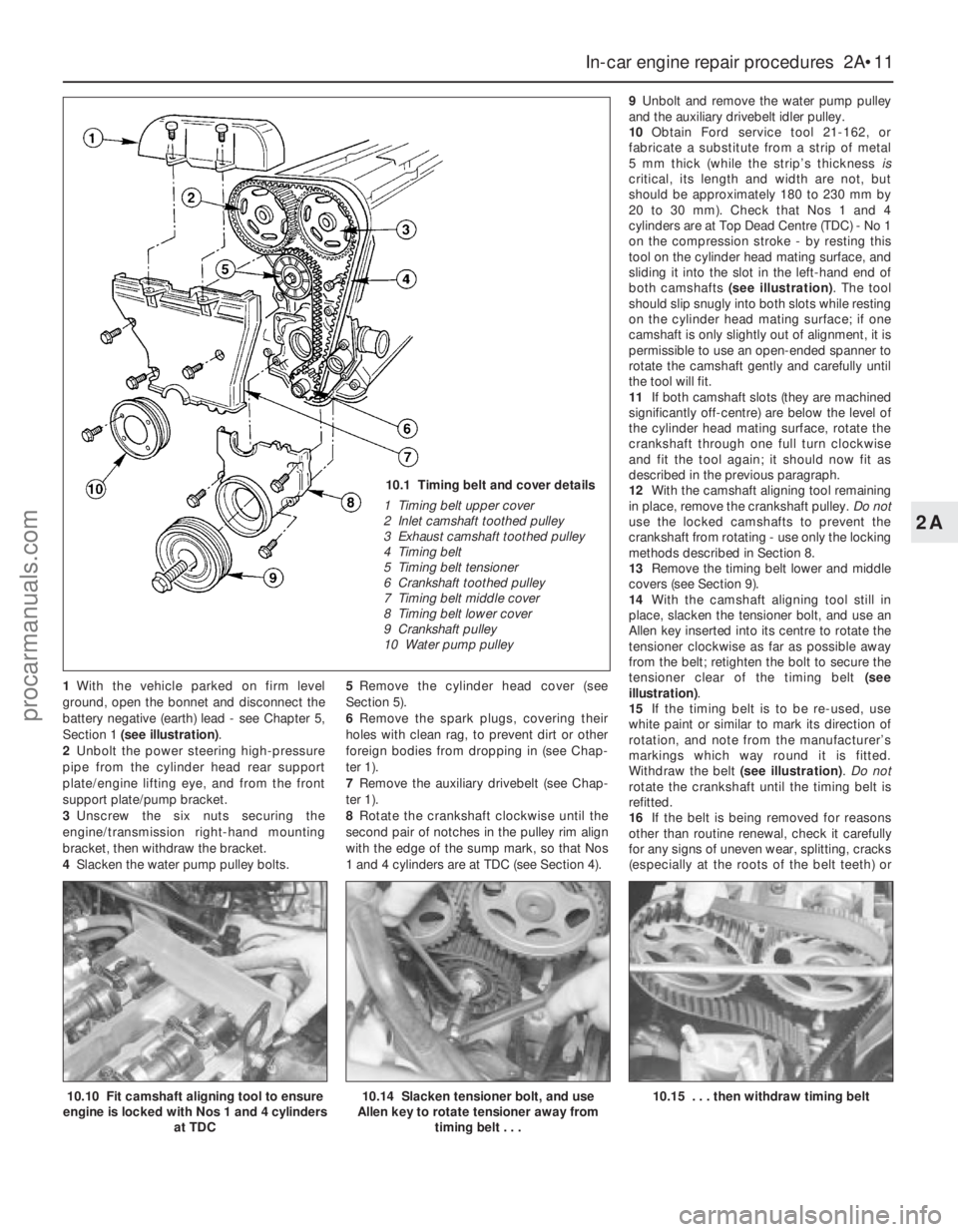

1With the vehicle parked on firm level

ground, open the bonnet and disconnect the

battery negative (earth) lead - see Chapter 5,

Section 1 (see illustration).

2Unbolt the power steering high-pressure

pipe from the cylinder head rear support

plate/engine lifting eye, and from the front

support plate/pump bracket.

3Unscrew the six nuts securing the

engine/transmission right-hand mounting

bracket, then withdraw the bracket.

4Slacken the water pump pulley bolts.5Remove the cylinder head cover (see

Section 5).

6Remove the spark plugs, covering their

holes with clean rag, to prevent dirt or other

foreign bodies from dropping in (see Chap-

ter 1).

7Remove the auxiliary drivebelt (see Chap-

ter 1).

8Rotate the crankshaft clockwise until the

second pair of notches in the pulley rim align

with the edge of the sump mark, so that Nos

1 and 4 cylinders are at TDC (see Section 4).9Unbolt and remove the water pump pulley

and the auxiliary drivebelt idler pulley.

10Obtain Ford service tool 21-162, or

fabricate a substitute from a strip of metal

5 mm thick (while the strip’s thickness is

critical, its length and width are not, but

should be approximately 180 to 230 mm by

20 to 30 mm). Check that Nos 1 and 4

cylinders are at Top Dead Centre (TDC) - No 1

on the compression stroke - by resting this

tool on the cylinder head mating surface, and

sliding it into the slot in the left-hand end of

both camshafts (see illustration). The tool

should slip snugly into both slots while resting

on the cylinder head mating surface; if one

camshaft is only slightly out of alignment, it is

permissible to use an open-ended spanner to

rotate the camshaft gently and carefully until

the tool will fit.

11If both camshaft slots (they are machined

significantly off-centre) are below the level of

the cylinder head mating surface, rotate the

crankshaft through one full turn clockwise

and fit the tool again; it should now fit as

described in the previous paragraph.

12With the camshaft aligning tool remaining

in place, remove the crankshaft pulley. Do not

use the locked camshafts to prevent the

crankshaft from rotating - use only the locking

methods described in Section 8.

13Remove the timing belt lower and middle

covers (see Section 9).

14With the camshaft aligning tool still in

place, slacken the tensioner bolt, and use an

Allen key inserted into its centre to rotate the

tensioner clockwise as far as possible away

from the belt; retighten the bolt to secure the

tensioner clear of the timing belt (see

illustration).

15If the timing belt is to be re-used, use

white paint or similar to mark its direction of

rotation, and note from the manufacturer’s

markings which way round it is fitted.

Withdraw the belt (see illustration). Do not

rotate the crankshaft until the timing belt is

refitted.

16If the belt is being removed for reasons

other than routine renewal, check it carefully

for any signs of uneven wear, splitting, cracks

(especially at the roots of the belt teeth) or

In-car engine repair procedures 2A•11

2A

10.10 Fit camshaft aligning tool to ensure

engine is locked with Nos 1 and 4 cylinders

at TDC10.14 Slacken tensioner bolt, and use

Allen key to rotate tensioner away from

timing belt . . .10.15 . . . then withdraw timing belt

10.1 Timing belt and cover details

1 Timing belt upper cover

2 Inlet camshaft toothed pulley

3 Exhaust camshaft toothed pulley

4 Timing belt

5 Timing belt tensioner

6 Crankshaft toothed pulley

7 Timing belt middle cover

8 Timing belt lower cover

9 Crankshaft pulley

10 Water pump pulley

procarmanuals.com

Page 59 of 279

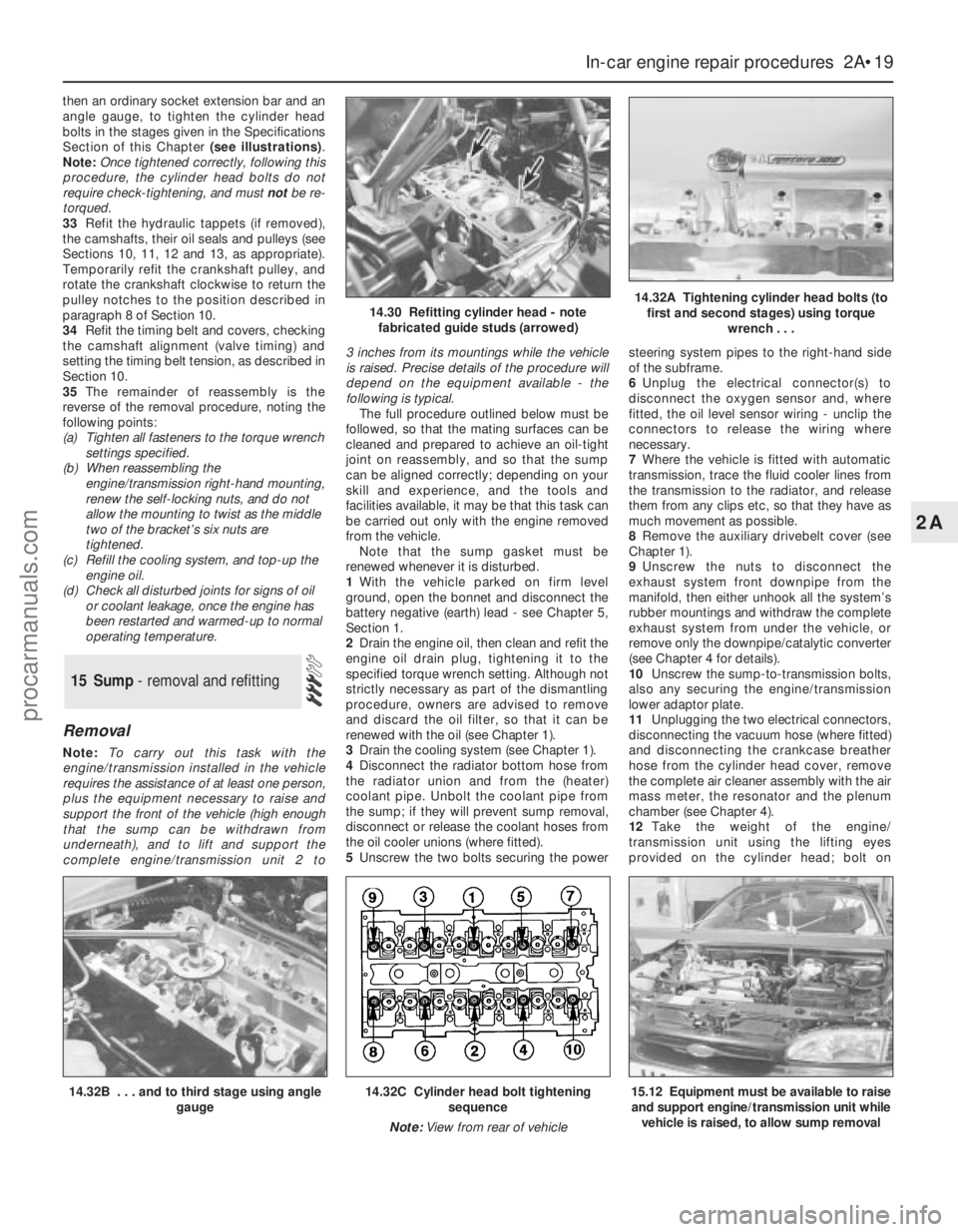

then an ordinary socket extension bar and an

angle gauge, to tighten the cylinder head

bolts in the stages given in the Specifications

Section of this Chapter (see illustrations).

Note:Once tightened correctly, following this

procedure, the cylinder head bolts do not

require check-tightening, and must notbe re-

torqued.

33Refit the hydraulic tappets (if removed),

the camshafts, their oil seals and pulleys (see

Sections 10, 11, 12 and 13, as appropriate).

Temporarily refit the crankshaft pulley, and

rotate the crankshaft clockwise to return the

pulley notches to the position described in

paragraph 8 of Section 10.

34Refit the timing belt and covers, checking

the camshaft alignment (valve timing) and

setting the timing belt tension, as described in

Section 10.

35The remainder of reassembly is the

reverse of the removal procedure, noting the

following points:

(a) Tighten all fasteners to the torque wrench

settings specified.

(b) When reassembling the

engine/transmission right-hand mounting,

renew the self-locking nuts, and do not

allow the mounting to twist as the middle

two of the bracket’s six nuts are

tightened.

(c) Refill the cooling system, and top-up the

engine oil.

(d) Check all disturbed joints for signs of oil

or coolant leakage, once the engine has

been restarted and warmed-up to normal

operating temperature.

Removal

Note:To carry out this task with the

engine/transmission installed in the vehicle

requires the assistance of at least one person,

plus the equipment necessary to raise and

support the front of the vehicle (high enough

that the sump can be withdrawn from

underneath), and to lift and support the

complete engine/transmission unit 2 to 3 inches from its mountings while the vehicle

is raised. Precise details of the procedure will

depend on the equipment available - the

following is typical.

The full procedure outlined below must be

followed, so that the mating surfaces can be

cleaned and prepared to achieve an oil-tight

joint on reassembly, and so that the sump

can be aligned correctly; depending on your

skill and experience, and the tools and

facilities available, it may be that this task can

be carried out only with the engine removed

from the vehicle.

Note that the sump gasket must be

renewed whenever it is disturbed.

1With the vehicle parked on firm level

ground, open the bonnet and disconnect the

battery negative (earth) lead - see Chapter 5,

Section 1.

2Drain the engine oil, then clean and refit the

engine oil drain plug, tightening it to the

specified torque wrench setting. Although not

strictly necessary as part of the dismantling

procedure, owners are advised to remove

and discard the oil filter, so that it can be

renewed with the oil (see Chapter 1).

3Drain the cooling system (see Chapter 1).

4Disconnect the radiator bottom hose from

the radiator union and from the (heater)

coolant pipe. Unbolt the coolant pipe from

the sump; if they will prevent sump removal,

disconnect or release the coolant hoses from

the oil cooler unions (where fitted).

5Unscrew the two bolts securing the powersteering system pipes to the right-hand side

of the subframe.

6Unplug the electrical connector(s) to

disconnect the oxygen sensor and, where

fitted, the oil level sensor wiring - unclip the

connectors to release the wiring where

necessary.

7Where the vehicle is fitted with automatic

transmission, trace the fluid cooler lines from

the transmission to the radiator, and release

them from any clips etc, so that they have as

much movement as possible.

8Remove the auxiliary drivebelt cover (see

Chapter 1).

9Unscrew the nuts to disconnect the

exhaust system front downpipe from the

manifold, then either unhook all the system’s

rubber mountings and withdraw the complete

exhaust system from under the vehicle, or

remove only the downpipe/catalytic converter

(see Chapter 4 for details).

10Unscrew the sump-to-transmission bolts,

also any securing the engine/transmission

lower adaptor plate.

11Unplugging the two electrical connectors,

disconnecting the vacuum hose (where fitted)

and disconnecting the crankcase breather

hose from the cylinder head cover, remove

the complete air cleaner assembly with the air

mass meter, the resonator and the plenum

chamber (see Chapter 4).

12Take the weight of the engine/

transmission unit using the lifting eyes

provided on the cylinder head; bolt on

15 Sump - removal and refitting

In-car engine repair procedures 2A•19

2A

14.32B . . . and to third stage using angle

gauge14.32C Cylinder head bolt tightening

sequence

Note:View from rear of vehicle15.12 Equipment must be available to raise

and support engine/transmission unit while

vehicle is raised, to allow sump removal

14.30 Refitting cylinder head - note

fabricated guide studs (arrowed)14.32A Tightening cylinder head bolts (to

first and second stages) using torque

wrench . . .

procarmanuals.com

Page 91 of 279

4If a hose proves stubborn, try to release it

by rotating it on its unions before attempting

to work it off. Gently prise the end of the hose

with a blunt instrument (such as a flat-bladed

screwdriver), but do not apply too much force,

and take care not to damage the pipe stubs or

hoses. Note in particular that the radiator hose

unions are fragile; do not use excessive force

when attempting to remove the hoses. If all

else fails, cut the hose with a sharp knife, then

slit it so that it can be peeled off in two pieces.

While expensive, this is preferable to buying a

new radiator. Check first, however, that a new

hose is readily available.

5When refitting a hose, first slide the clampsonto the hose, then work the hose onto its

unions. If the hose is stiff, use soap (or

washing-up liquid) as a lubricant, or soften it

by soaking it in boiling water, but take care to

prevent scalding.

6Work each hose end fully onto its union,

then check that the hose is settled correctly

and is properly routed. Slide each clip along

the hose until it is behind the union flared end,

before tightening it securely.

7Refill the system with coolant (see Chap-

ter 1).

8Check carefully for leaks as soon as

possible after disturbing any part of the

cooling system.Note:Refer to the warnings given in Section 1

of this Chapter before starting work.

Removal

1Disconnect the battery negative (earth) lead

(see Chapter 5, Section 1).

2Unbolt the resonator support bracket from

the engine compartment front crossmember.

Slacken the two clamp screws securing the

resonator to the air mass meter and plenum

chamber hoses, then swing the resonator up

clear of the thermostat housing (see Chap-

ter 4).

3Drain the cooling system (see Chapter 1). If

the coolant is relatively new or in good

condition, drain it into a clean container and

re-use it.

4Disconnect the expansion tank coolant

hose and the radiator top hose from the

thermostat housing’s water outlet.

5Unbolt the water outlet and withdraw the

thermostat (see illustration). Note the

position of the air bleed valve, and how the

thermostat is installed (which end is facing

outwards).

Testing

General check

6Before assuming the thermostat is to blame

for a cooling system problem, check the

coolant level, auxiliary drivebelt tension and

condition (see Chapter 1) and temperature

gauge operation.

7If the engine seems to be taking a long time

to warm up (based on heater output or

temperature gauge operation), the thermostat

is probably stuck open. Renew the

thermostat.

8If the engine runs hot, use your hand to

check the temperature of the radiator top

hose. If the hose isn’t hot, but the engine is,

the thermostat is probably stuck closed,

preventing the coolant inside the engine from

escaping to the radiator - renew the

thermostat.

4 Thermostat -

removal, testing and refitting

Cooling, heating and air conditioning systems 3•3

3

4.5 Unbolt water outlet to withdraw

thermostat

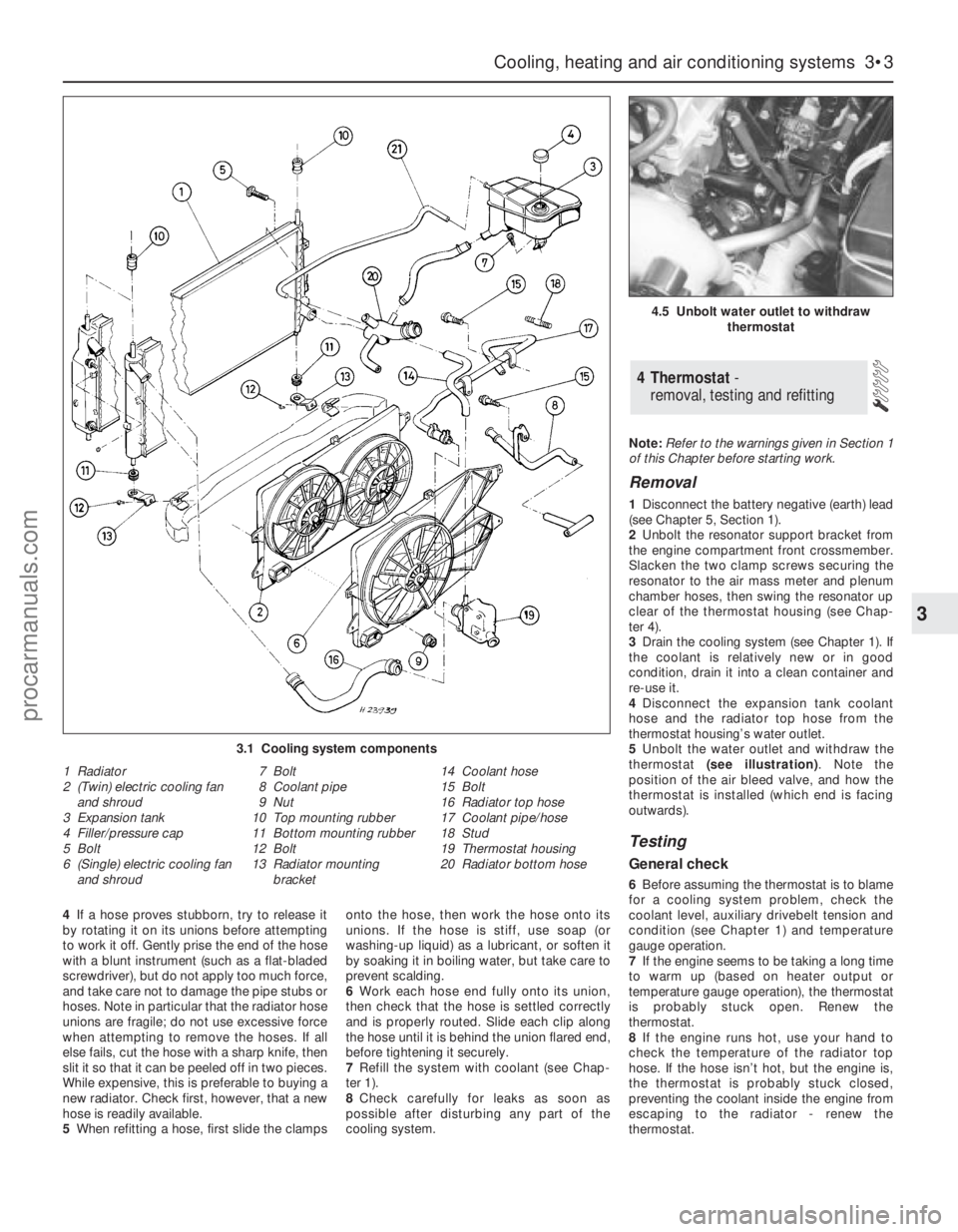

3.1 Cooling system components

1 Radiator

2 (Twin) electric cooling fan

and shroud

3 Expansion tank

4 Filler/pressure cap

5 Bolt

6 (Single) electric cooling fan

and shroud7 Bolt

8 Coolant pipe

9 Nut

10 Top mounting rubber

11 Bottom mounting rubber

12 Bolt

13 Radiator mounting

bracket14 Coolant hose

15 Bolt

16 Radiator top hose

17 Coolant pipe/hose

18 Stud

19 Thermostat housing

20 Radiator bottom hose

procarmanuals.com

Page 93 of 279

sender’s electrical connector, and use a

jumper wire to connect the white/red wire to a

clean earth point (bare metal) on the engine.

Switch on the ignition without starting the

engine. If the gauge now indicates Hot, renew

the sender.

5If the gauge still does not work, the circuit

may be open, or the gauge may be faulty. See

Chapter 12 for additional information.

Removal

6Unbolt the resonator support bracket from

the engine compartment front crossmember.

Slacken the two clamp screws securing the

resonator to the air mass meter and plenum

chamber hoses, then swing the resonator up

clear of the thermostat housing (see Chap-

ter 4).

7Drain the cooling system (see Chapter 1).

8Disconnect the expansion tank coolant

hose and the radiator top hose from the

thermostat housing’s water outlet, then

disconnect the metal coolant pipe/hose from

the thermostat.

9Unplug the electrical connector from the

sender (see illustration).

10Unscrew the sender and withdraw it.

Refitting

11Clean as thoroughly as possible the

opening in the thermostat housing, then apply

a light coat of sealant to the sender’s threads.

Screw in the sender and tighten it to the

specified torque wrench setting, and plug in

its electrical connector.

12Reconnect the hoses and refit the

resonator, top-up the cooling system (see

Chapter 1) and run the engine. Check for

leaks and proper gauge operation.

Coolant temperature sensor

Testing

13Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

14Unbolt the resonator support bracket

from the engine compartment front

crossmember. Slacken the two clamp screws

securing the resonator to the air mass meter

and plenum chamber hoses, then swing the

resonator up clear of the thermostat housing

(see Chapter 4).

15Unplug the electrical connector from the

sensor (see illustration).

16Using an ohmmeter, measure the

resistance between the sensor terminals.

Depending on the temperature of the sensor

tip, the resistance measured will vary, but

should be within the broad limits given in the

Specifications Section of this Chapter. If the

sensor’s temperature is varied - by removing

it (see below) and placing it in a freezer for a

while, or by warming it gently - its resistance

should alter accordingly.

17If the results obtained show the sensor to

be faulty, renew it.

18On completion, plug in the connector and

refit the resonator.

Removal

19Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

20Unbolt the resonator support bracket

from the engine compartment front

crossmember. Slacken the two clamp screws

securing the resonator to the air mass meter

and plenum chamber hoses, then swing the

resonator up clear of the thermostat housing

(see Chapter 4).

21With the engine completely cool, remove

the expansion tank filler cap to release any

pressure, then refit the cap. Provided you

work swiftly and plug the opening as soon as

the sensor is unscrewed, coolant loss will thus

be minimised; this will avoid the draining of

the complete cooling system which would

otherwise be necessary (see Chapter 1).

22Unplug the electrical connector from the

sensor.

23Unscrew the sensor and withdraw it. If the

cooling system has not been drained, plug the

opening as quickly as possible.

Refitting

24Clean as thoroughly as possible the

opening in the thermostat housing, then apply

a light coat of sealant to the sensor’s threads.

Remove the material used to plug the sensor

hole (where applicable), and quickly install the

sensor to prevent coolant loss. Tighten the

sensor to the specified torque wrench setting,

and plug in its electrical connector.

25Refit the resonator, top-up the cooling

system (see Chapter 1) and run the engine,

checking for leaks.

Coolant low level switch

Testing

26The switch is a reed-type unit mounted in

the bottom of the cooling system expansion

tank, activated by a magnetic float. If the

coolant level falls to the “MIN” level or less,

the appropriate bulb lights in the warning

display.

27If the bulb fails to light during the 5-

second bulb test, check the bulb, and renew if

necessary as described in Chapter 12.

28To check the switch itself, unplug its

electrical connector, and use an ohmmeter to

measure the resistance across the switchterminals. With the float up, a resistance of

90 ohms should be measured; when it is

down, the resistance should increase to

approximately 150 kilohms.

29If the results obtained from the check are

significantly different from those expected,

the switch is faulty, and must be renewed.

30If the switch and bulb are proven to be

sound, the fault must be in the wiring or in the

auxiliary warning control assembly (see

Chapter 12).

Removal

31Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

32Remove the expansion tank (see Sec-

tion 7).

33Unplug the switch electrical connector.

34Release the switch by twisting its retainer

anti-clockwise, then withdraw it.

Refitting

35Refitting is the reverse of the removal

procedure. Refill the cooling system (see

Chapter 1). Start the engine, and check for

coolant leaks when it is fully warmed-up.

Note:Refer to the warnings given in Section 1

of this Chapter before starting work.

Radiator

Removal

Note:If leakage is the reason for removing the

radiator, bear in mind that minor leaks can

often be cured using a radiator sealant with

the radiator in situ.

1Remove the radiator fan and shroud

assembly (see Section 5).

2Disconnect the bottom hose from the

radiator.

3If the vehicle has automatic transmission,

disconnect the fluid cooler lines, and plug the

lines and fittings.

4If the vehicle has air conditioning, unscrew

the condenser mounting nuts or bolts, detach

the condenser from the radiator, and tie it to

the engine compartment front crossmember.

7 Radiator and expansion tank -

removal, inspection and refitting

Cooling, heating and air conditioning systems 3•5

3

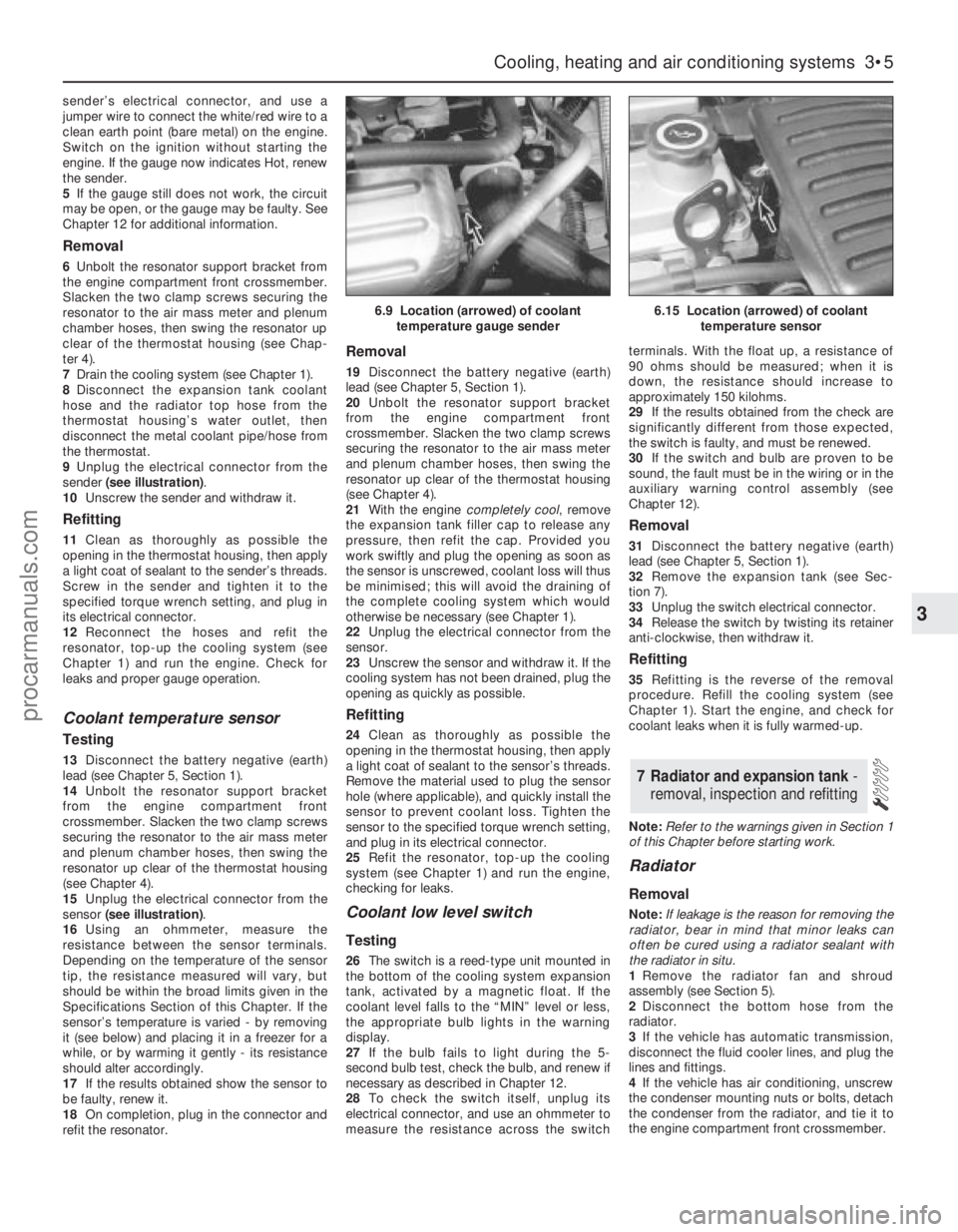

6.9 Location (arrowed) of coolant

temperature gauge sender6.15 Location (arrowed) of coolant

temperature sensor

procarmanuals.com