fuse FORD MONDEO 1993 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 18 of 279

1•4

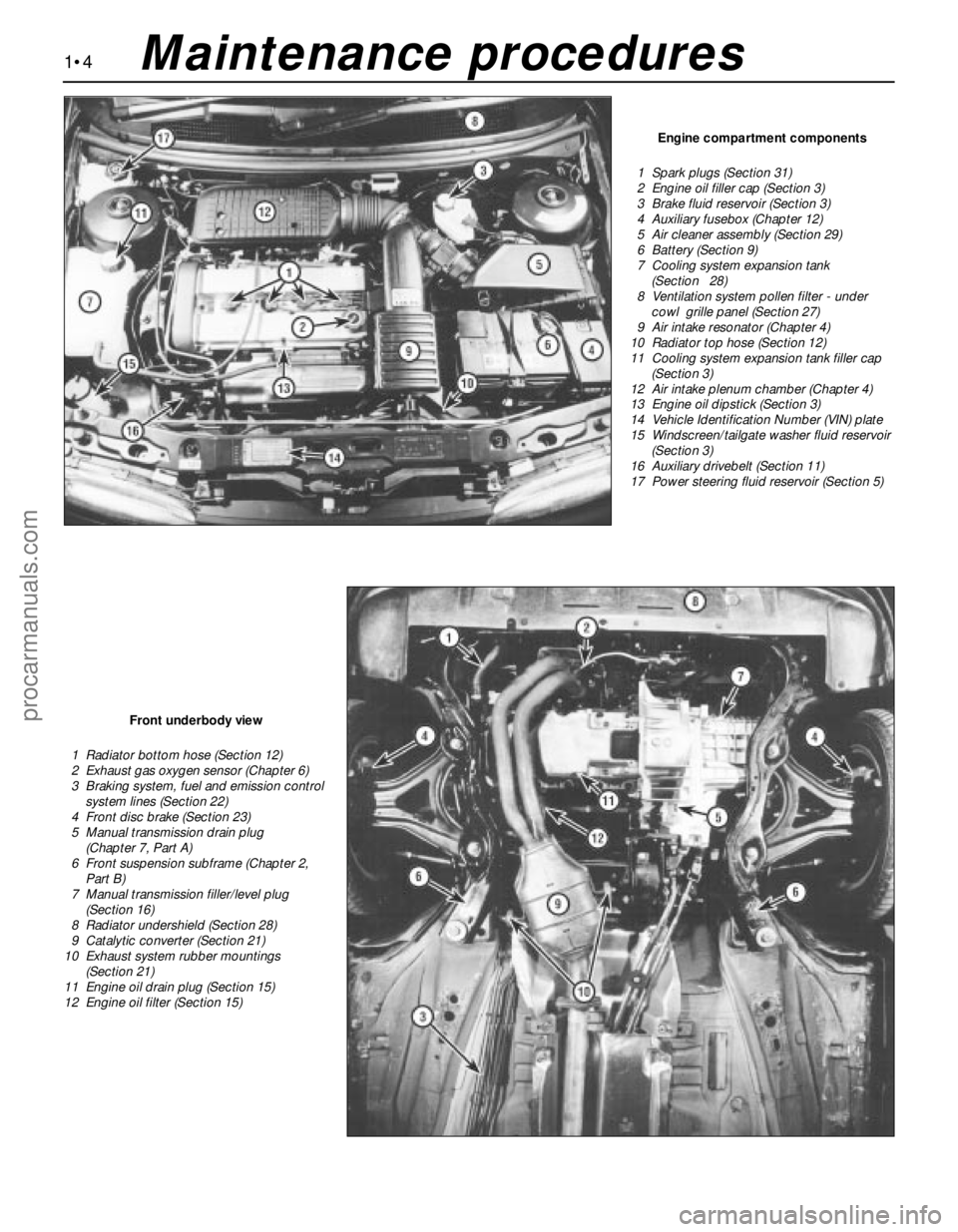

Engine compartment components

1 Spark plugs (Section 31)

2 Engine oil filler cap (Section 3)

3 Brake fluid reservoir (Section 3)

4 Auxiliary fusebox (Chapter 12)

5 Air cleaner assembly (Section 29)

6 Battery (Section 9)

7 Cooling system expansion tank

(Section 28)

8 Ventilation system pollen filter - under

cowl grille panel (Section 27)

9 Air intake resonator (Chapter 4)

10 Radiator top hose (Section 12)

11 Cooling system expansion tank filler cap

(Section 3)

12 Air intake plenum chamber (Chapter 4)

13 Engine oil dipstick (Section 3)

14 Vehicle Identification Number (VIN) plate

15 Windscreen/tailgate washer fluid reservoir

(Section 3)

16 Auxiliary drivebelt (Section 11)

17 Power steering fluid reservoir (Section 5)

Front underbody view

1 Radiator bottom hose (Section 12)

2 Exhaust gas oxygen sensor (Chapter 6)

3 Braking system, fuel and emission control

system lines (Section 22)

4 Front disc brake (Section 23)

5 Manual transmission drain plug

(Chapter 7, Part A)

6 Front suspension subframe (Chapter 2,

Part B)

7 Manual transmission filler/level plug

(Section 16)

8 Radiator undershield (Section 28)

9 Catalytic converter (Section 21)

10 Exhaust system rubber mountings

(Section 21)

11 Engine oil drain plug (Section 15)

12 Engine oil filter (Section 15)

Maintenance procedures

procarmanuals.com

Page 40 of 279

1•26Every 60 000 miles

Every 60 000 miles

Refer to Chapter 2, Part A.

Warning: Petrol is extremely

flammable, so extra precautions

must be taken when working on

any part of the fuel system. Do not smoke,

or allow open flames or bare light bulbs,

near the work area. Also, do not work in a

garage if a gas appliance with a pilot light is

present. While performing any work on the

fuel system, wear safety glasses, and have

a suitable (Class B) fire extinguisher on

hand. If you spill any fuel on your skin, rinse

it off immediately with soap and water.

1The fuel filter is located at the front right-

hand corner of the fuel tank, just forward of

the vehicle’s right-hand rear jacking point. The

filter performs a vital role in keeping dirt and

other foreign matter out of the fuel system,

and so must be renewed at regular intervals,or whenever you have reason to suspect that

it may be clogged. It is always unpleasant

working under a vehicle - pressure-washing or

hosing clean the underbody in the filter’s

vicinity will make working conditions more

tolerable, and will reduce the risk of getting

dirt into the fuel system.

2Relieve any residual pressure in the system

by removing the fuel pump fuse (No 14) and

starting the engine; allow the engine to idle until

it dies. Turn the engine over once or twice on

the starter, to ensure that all pressure is

released, then switch off the ignition.

Warning: This procedure will

merely relieve the pressure

necessary for the engine to run -

remember that fuel will still be present in

the system components, and take

precautions before disconnecting them.

3Noting the comments made in Section 1 of

Chapter 5, disconnect the battery earth terminal.

4Jack up the rear right-hand side of the

vehicle, and support it securely on an axle stand.

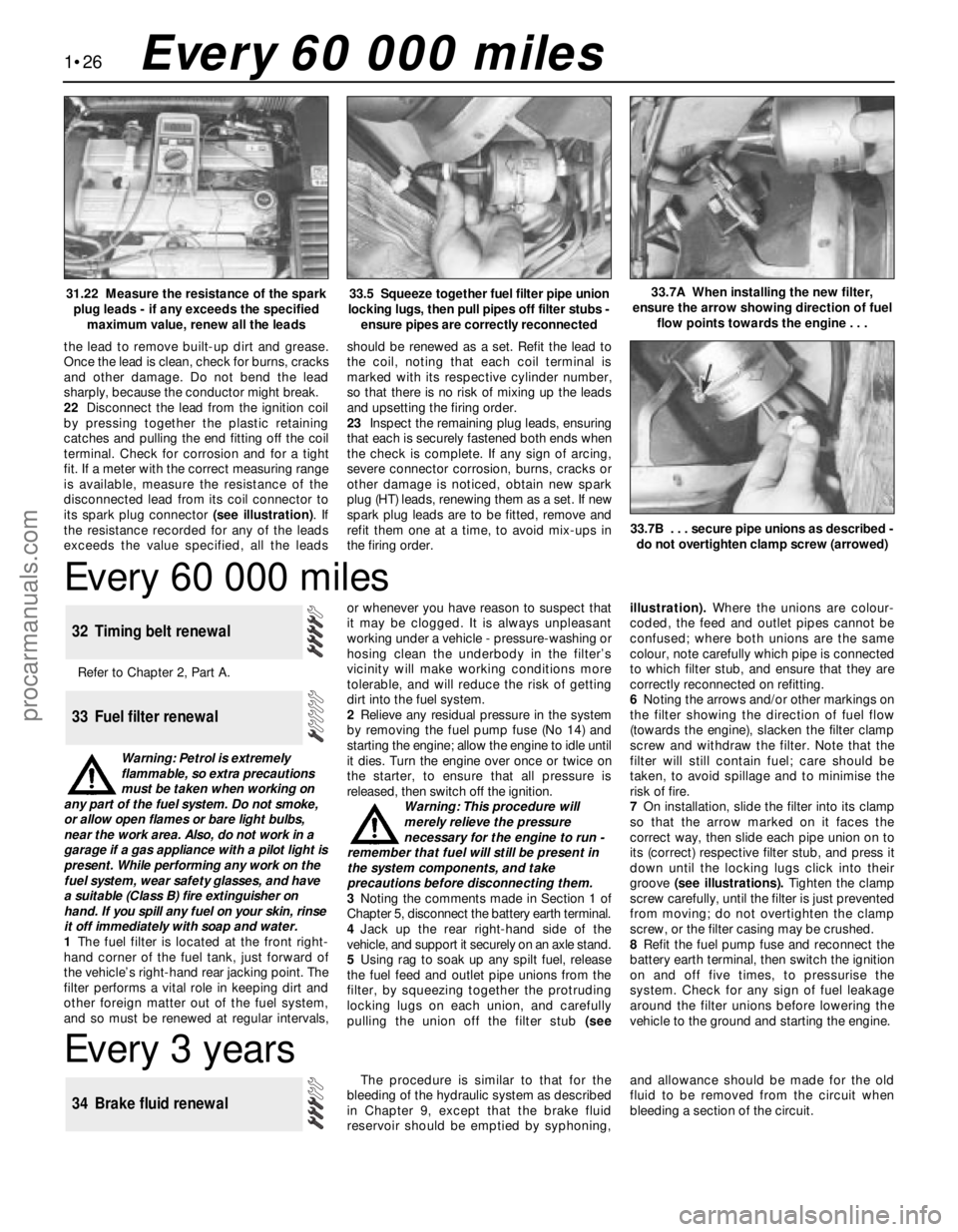

5Using rag to soak up any spilt fuel, release

the fuel feed and outlet pipe unions from the

filter, by squeezing together the protruding

locking lugs on each union, and carefully

pulling the union off the filter stub (seeillustration). Where the unions are colour-

coded, the feed and outlet pipes cannot be

confused; where both unions are the same

colour, note carefully which pipe is connected

to which filter stub, and ensure that they are

correctly reconnected on refitting.

6Noting the arrows and/or other markings on

the filter showing the direction of fuel flow

(towards the engine), slacken the filter clamp

screw and withdraw the filter. Note that the

filter will still contain fuel; care should be

taken, to avoid spillage and to minimise the

risk of fire.

7On installation, slide the filter into its clamp

so that the arrow marked on it faces the

correct way, then slide each pipe union on to

its (correct) respective filter stub, and press it

down until the locking lugs click into their

groove (see illustrations). Tighten the clamp

screw carefully, until the filter is just prevented

from moving; do not overtighten the clamp

screw, or the filter casing may be crushed.

8Refit the fuel pump fuse and reconnect the

battery earth terminal, then switch the ignition

on and off five times, to pressurise the

system. Check for any sign of fuel leakage

around the filter unions before lowering the

vehicle to the ground and starting the engine.

33 Fuel filter renewal

32 Timing belt renewal

33.5 Squeeze together fuel filter pipe union

locking lugs, then pull pipes off filter stubs -

ensure pipes are correctly reconnected33.7A When installing the new filter,

ensure the arrow showing direction of fuel

flow points towards the engine . . .

Every 3 years

The procedure is similar to that for the

bleeding of the hydraulic system as described

in Chapter 9, except that the brake fluid

reservoir should be emptied by syphoning,and allowance should be made for the old

fluid to be removed from the circuit when

bleeding a section of the circuit.

34 Brake fluid renewal

31.22 Measure the resistance of the spark

plug leads - if any exceeds the specified

maximum value, renew all the leads

the lead to remove built-up dirt and grease.

Once the lead is clean, check for burns, cracks

and other damage. Do not bend the lead

sharply, because the conductor might break.

22Disconnect the lead from the ignition coil

by pressing together the plastic retaining

catches and pulling the end fitting off the coil

terminal. Check for corrosion and for a tight

fit. If a meter with the correct measuring range

is available, measure the resistance of the

disconnected lead from its coil connector to

its spark plug connector (see illustration). If

the resistance recorded for any of the leads

exceeds the value specified, all the leadsshould be renewed as a set. Refit the lead to

the coil, noting that each coil terminal is

marked with its respective cylinder number,

so that there is no risk of mixing up the leads

and upsetting the firing order.

23Inspect the remaining plug leads, ensuring

that each is securely fastened both ends when

the check is complete. If any sign of arcing,

severe connector corrosion, burns, cracks or

other damage is noticed, obtain new spark

plug (HT) leads, renewing them as a set. If new

spark plug leads are to be fitted, remove and

refit them one at a time, to avoid mix-ups in

the firing order.

33.7B . . . secure pipe unions as described -

do not overtighten clamp screw (arrowed)

procarmanuals.com

Page 45 of 279

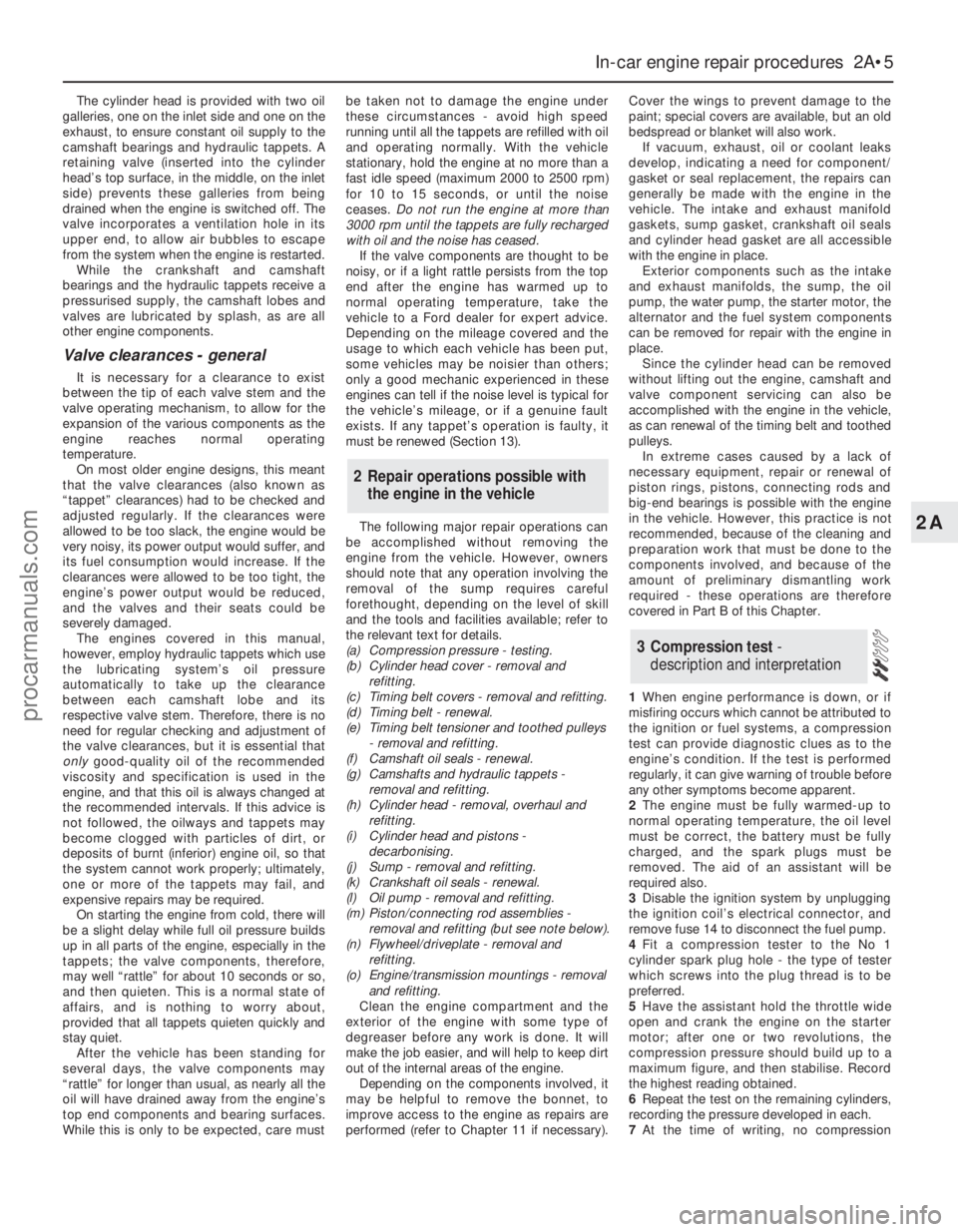

The cylinder head is provided with two oil

galleries, one on the inlet side and one on the

exhaust, to ensure constant oil supply to the

camshaft bearings and hydraulic tappets. A

retaining valve (inserted into the cylinder

head’s top surface, in the middle, on the inlet

side) prevents these galleries from being

drained when the engine is switched off. The

valve incorporates a ventilation hole in its

upper end, to allow air bubbles to escape

from the system when the engine is restarted.

While the crankshaft and camshaft

bearings and the hydraulic tappets receive a

pressurised supply, the camshaft lobes and

valves are lubricated by splash, as are all

other engine components.

Valve clearances - general

It is necessary for a clearance to exist

between the tip of each valve stem and the

valve operating mechanism, to allow for the

expansion of the various components as the

engine reaches normal operating

temperature.

On most older engine designs, this meant

that the valve clearances (also known as

“tappet” clearances) had to be checked and

adjusted regularly. If the clearances were

allowed to be too slack, the engine would be

very noisy, its power output would suffer, and

its fuel consumption would increase. If the

clearances were allowed to be too tight, the

engine’s power output would be reduced,

and the valves and their seats could be

severely damaged.

The engines covered in this manual,

however, employ hydraulic tappets which use

the lubricating system’s oil pressure

automatically to take up the clearance

between each camshaft lobe and its

respective valve stem. Therefore, there is no

need for regular checking and adjustment of

the valve clearances, but it is essential that

onlygood-quality oil of the recommended

viscosity and specification is used in the

engine, and that this oil is always changed at

the recommended intervals. If this advice is

not followed, the oilways and tappets may

become clogged with particles of dirt, or

deposits of burnt (inferior) engine oil, so that

the system cannot work properly; ultimately,

one or more of the tappets may fail, and

expensive repairs may be required.

On starting the engine from cold, there will

be a slight delay while full oil pressure builds

up in all parts of the engine, especially in the

tappets; the valve components, therefore,

may well “rattle” for about 10 seconds or so,

and then quieten. This is a normal state of

affairs, and is nothing to worry about,

provided that all tappets quieten quickly and

stay quiet.

After the vehicle has been standing for

several days, the valve components may

“rattle” for longer than usual, as nearly all the

oil will have drained away from the engine’s

top end components and bearing surfaces.

While this is only to be expected, care mustbe taken not to damage the engine under

these circumstances - avoid high speed

running until all the tappets are refilled with oil

and operating normally. With the vehicle

stationary, hold the engine at no more than a

fast idle speed (maximum 2000 to 2500 rpm)

for 10 to 15 seconds, or until the noise

ceases. Do not run the engine at more than

3000 rpm until the tappets are fully recharged

with oil and the noise has ceased.

If the valve components are thought to be

noisy, or if a light rattle persists from the top

end after the engine has warmed up to

normal operating temperature, take the

vehicle to a Ford dealer for expert advice.

Depending on the mileage covered and the

usage to which each vehicle has been put,

some vehicles may be noisier than others;

only a good mechanic experienced in these

engines can tell if the noise level is typical for

the vehicle’s mileage, or if a genuine fault

exists. If any tappet’s operation is faulty, it

must be renewed (Section 13).

The following major repair operations can

be accomplished without removing the

engine from the vehicle. However, owners

should note that any operation involving the

removal of the sump requires careful

forethought, depending on the level of skill

and the tools and facilities available; refer to

the relevant text for details.

(a) Compression pressure - testing.

(b) Cylinder head cover - removal and

refitting.

(c) Timing belt covers - removal and refitting.

(d) Timing belt - renewal.

(e) Timing belt tensioner and toothed pulleys

- removal and refitting.

(f) Camshaft oil seals - renewal.

(g) Camshafts and hydraulic tappets -

removal and refitting.

(h) Cylinder head - removal, overhaul and

refitting.

(i) Cylinder head and pistons -

decarbonising.

(j) Sump - removal and refitting.

(k) Crankshaft oil seals - renewal.

(l) Oil pump - removal and refitting.

(m) Piston/connecting rod assemblies -

removal and refitting (but see note below).

(n) Flywheel/driveplate - removal and

refitting.

(o) Engine/transmission mountings - removal

and refitting.

Clean the engine compartment and the

exterior of the engine with some type of

degreaser before any work is done. It will

make the job easier, and will help to keep dirt

out of the internal areas of the engine.

Depending on the components involved, it

may be helpful to remove the bonnet, to

improve access to the engine as repairs are

performed (refer to Chapter 11 if necessary).Cover the wings to prevent damage to the

paint; special covers are available, but an old

bedspread or blanket will also work.

If vacuum, exhaust, oil or coolant leaks

develop, indicating a need for component/

gasket or seal replacement, the repairs can

generally be made with the engine in the

vehicle. The intake and exhaust manifold

gaskets, sump gasket, crankshaft oil seals

and cylinder head gasket are all accessible

with the engine in place.

Exterior components such as the intake

and exhaust manifolds, the sump, the oil

pump, the water pump, the starter motor, the

alternator and the fuel system components

can be removed for repair with the engine in

place.

Since the cylinder head can be removed

without lifting out the engine, camshaft and

valve component servicing can also be

accomplished with the engine in the vehicle,

as can renewal of the timing belt and toothed

pulleys.

In extreme cases caused by a lack of

necessary equipment, repair or renewal of

piston rings, pistons, connecting rods and

big-end bearings is possible with the engine

in the vehicle. However, this practice is not

recommended, because of the cleaning and

preparation work that must be done to the

components involved, and because of the

amount of preliminary dismantling work

required - these operations are therefore

covered in Part B of this Chapter.

1When engine performance is down, or if

misfiring occurs which cannot be attributed to

the ignition or fuel systems, a compression

test can provide diagnostic clues as to the

engine’s condition. If the test is performed

regularly, it can give warning of trouble before

any other symptoms become apparent.

2The engine must be fully warmed-up to

normal operating temperature, the oil level

must be correct, the battery must be fully

charged, and the spark plugs must be

removed. The aid of an assistant will be

required also.

3Disable the ignition system by unplugging

the ignition coil’s electrical connector, and

remove fuse 14 to disconnect the fuel pump.

4Fit a compression tester to the No 1

cylinder spark plug hole - the type of tester

which screws into the plug thread is to be

preferred.

5Have the assistant hold the throttle wide

open and crank the engine on the starter

motor; after one or two revolutions, the

compression pressure should build up to a

maximum figure, and then stabilise. Record

the highest reading obtained.

6Repeat the test on the remaining cylinders,

recording the pressure developed in each.

7At the time of writing, no compression

3 Compression test -

description and interpretation

2 Repair operations possible with

the engine in the vehicle

In-car engine repair procedures 2A•5

2A

procarmanuals.com

Page 76 of 279

2Remove the cylinder head (Part A of this

Chapter, Section 14).

3Using a valve spring compressor, compress

each valve spring in turn until the split collets

can be removed. A special valve spring

compressor will be required, to reach into the

deep wells in the cylinder head without risk of

damaging the hydraulic tappet bores; such

compressors are now widely available from

most good motor accessory shops. Release

the compressor, and lift off the spring upper

seat and spring (see illustrations).

4If, when the valve spring compressor is

screwed down, the spring upper seat refuses

to free and expose the split collets, gently tap

the top of the tool, directly over the upper

seat, with a light hammer. This will free the

seat.

5Withdraw the valve through the combustionchamber. If it binds in the guide (won’t pull

through), push it back in, and de-burr the area

around the collet groove with a fine file or

whetstone; take care not to mark the

hydraulic tappet bores.

6Ford recommend the use of their service

tool 21-160 to extract the valve spring lower

seat/stem oil seals; while this is almost

indispensable if the seals are to be removed

without risk of (extremely expensive) damage

to the cylinder head, we found that a

serviceable substitute can be made from a

strong spring of suitable size. Screw on the

tool or spring so that it bites into the seal, then

draw the seal off the valve guide (see

illustrations).

7It is essential that the valves are kept

together with their collets, spring seats and

springs, and in their correct sequence (unless

they are so badly worn that they are to be

renewed). If they are going to be kept and

used again, place them in a labelled polythene

bag or similar small container (see

illustration). Note that No 1 valve is nearest to

the timing belt end of the engine.

8If the oil-retaining valve is to be removed (to

flush out the cylinder head oil galleries

thoroughly), seek the advice of a Ford dealer

as to how it can be extracted; it may be that

the only course of action involves destroying

the valve as follows. Screw a self-tapping

screw into its ventilation hole, and use the

screw to provide purchase with which the

valve can be drawn out; a new valve must be

purchased and pressed into place on

reassembly (see illustration).Note:Always check first what replacement

parts are available before planning any

overhaul operation; refer to Section 1 of this

Part. A Ford dealer, or a good engine

reconditioning specialist/automotive parts

supplier, may be able to suggest alternatives

which will enable you to overcome the lack of

replacement parts.

1Thorough cleaning of the cylinder head and

valve components, followed by a detailed

inspection, will enable you to decide how

much valve service work must be carried out

during the engine overhaul. Note:If the

engine has been severely overheated, it is best

to assume that the cylinder head is warped,

and to check carefully for signs of this.

Cleaning

2Scrape away all traces of old gasket

material and sealing compound from the

cylinder head (see Part A of this Chapter,

Section 14 for details).

3Scrape away the carbon from the

combustion chambers and ports, then wash

the cylinder head thoroughly with paraffin or a

suitable solvent.

7 Cylinder head and valve

components-

cleaning and inspection

2B•10 Engine removal and general engine overhaul procedures

6.3A Standard valve spring compressor

modified as shown . . .6.3B . . . or purpose-built special version,

is required to compress valve springs

without damaging cylinder head . . .

6.3C . . . so that both valve split collets

can be removed from the valve’s stem -

small magnetic pick-up tool prevents loss

of small metal components on removal

and refitting

6.6B . . . can be replaced by home-made

tool if suitable spring can be found

6.6A Ford service tool in use to remove

valve spring lower seat/stem oil seals . . .

6.7 Use clearly-marked containers to

identify components and to keep matched

assemblies together6.8 Cylinder head oil-retaining valve

(arrowed)

procarmanuals.com

Page 86 of 279

(see illustration). Next, install the upper side

rail in the same manner.

8After the three oil ring components have

been installed, check that both the upper and

lower side rails can be turned smoothly in the

ring groove.

9The second compression (middle) ring is

installed next, followed by the top

compression ring - ensure their marks are

uppermost, and be careful not to confuse

them. Don’t expand either ring any more than

necessary to slide it over the top of the piston.

10With all the rings in position, space the

ring gaps (including the elements of the oil

control ring) uniformly around the piston at

120° intervals. Repeat the procedure for the

remaining pistons and rings.

1Crankshaft refitting is the first major step in

engine reassembly. It is assumed at this point

that the cylinder block/crankcase and

crankshaft have been cleaned, inspected and

repaired or reconditioned as necessary.

Position the engine upside-down.

2Remove the main bearing cap bolts, and liftout the caps. Lay the caps out in the proper

order, to ensure correct installation.

3If they’re still in place, remove the old

bearing shells from the block and the main

bearing caps. Wipe the bearing recesses of

the block and caps with a clean, lint-free

cloth. They must be kept spotlessly-clean!

Main bearing running clearance

check

4Clean the backs of the new main bearing

shells. Fit the shells with an oil groove in each

main bearing location in the block; note the

thrustwashers integral with the No 3 (centre)

main bearing upper shell. Fit the other shell

from each bearing set in the corresponding

main bearing cap. Make sure the tab on each

bearing shell fits into the notch in the block or

cap. Also, the oil holes in the block must line

up with the oil holes in the bearing shell (see

illustration).

Caution: Don’t hammer the shells

into place, and don’t nick or gouge

the bearing faces. No lubrication

should be used at this time.

5Clean the bearing surfaces of the shells inthe block and the crankshaft main bearing

journals with a clean, lint-free cloth. Check or

clean the oil holes in the crankshaft, as any

dirt here can go only one way - straight

through the new bearings.

6Once you’re certain the crankshaft is clean,

carefully lay it in position in the main bearings.

Trim several pieces of the appropriate-size

Plastigage (they must be slightly shorter than

the width of the main bearings), and place one

piece on each crankshaft main bearing

journal, parallel with the crankshaft centre-line

(see illustration).

7Clean the bearing surfaces of the cap

shells, and install the caps in their respective

positions (don’t mix them up) with the arrows

pointing to the timing belt end of the engine.

Don’t disturb the Plastigage (see illustration).

8Working on one cap at a time, from the

centre main bearing outwards (and ensuring

that each cap is tightened down squarely and

evenly onto the block), tighten the main

bearing cap bolts to the specified torque

wrench setting. Don’t rotate the crankshaft at

any time during this operation!

9Remove the bolts, and carefully lift off the

main bearing caps. Keep them in order. Don’t

disturb the Plastigage or rotate the

crankshaft. If any of the main bearing caps are

difficult to remove, tap them gently from side-

to-side with a soft-faced mallet to loosen

them.

10Compare the width of the crushed

Plastigage on each journal with the scale

printed on the Plastigage envelope to obtain

the main bearing running clearance (see

illustration). Check the Specifications to

make sure that the clearance is correct.

11If the clearance is not as specified, seek

the advice of a Ford dealer or similar engine

reconditioning specialist - if the crankshaft

journals are in good condition (see Sec-

tion 13), it may be possible simply to renew

the shells to achieve the correct clearance. If

this is not possible, the crankshaft must be

reground by a specialist who can supply the

necessary undersized shells. First though,

17 Crankshaft-

refitting and main bearing

running clearance check

2B•20 Engine removal and general engine overhaul procedures

16.7B DO NOT use a piston ring

installation tool when installing the oil ring

side rails17.4 Tab on each bearing shell must

engage with notch in block or cap, and oil

holes in upper shells must align with block

oilways17.6 Lay the Plastigage strips (arrowed) on

the main bearing journals, parallel to the

crankshaft centre-line

17.7 Refit the main bearing caps and

tighten the bolts as specified

17.10 Compare the width of the crushed

Plastigage to the scale on the envelope to

determine the main bearing oil clearance

(always take the measurement at the

widest point of the Plastigage). Be sure to

use the correct scale; Imperial and metric

scales are included

procarmanuals.com

Page 88 of 279

rod’s big-end onto the crankpin. The piston

rings may try to pop out of the ring

compressor just before entering the cylinder

bore, so keep some pressure on the ring

compressor. Work slowly, and if any

resistance is felt as the piston enters the

cylinder, stop immediately. Find out what’s

binding, and fix it before proceeding. Do not,

for any reason, force the piston into the

cylinder - you might break a ring and/or the

piston.

10To check the big-end bearing running

clearance, cut a piece of the appropriate-size

Plastigage slightly shorter than the width of

the connecting rod bearing, and lay it in place

on the No 1 crankpin (big-end) journal, parallel

with the crankshaft centre-line (see illus-

tration 17.6).

11Clean the connecting rod-to-cap mating

surfaces, and refit the big-end bearing cap.

Make sure the etched number on the cap is

on the same side as that on the rod (see

illustration). Tighten the cap bolts evenly -

first use a torque wrench to tighten the bolts

to the specified (first stage) torque setting,

then use an ordinary socket extension bar

and an angle gauge to tighten the bolts

further through the specified (second stage)

angle. Use a thin-wall socket, to avoid

erroneous torque readings that can result if

the socket is wedged between the cap and

nut. If the socket tends to wedge itself

between the nut and the cap, lift up on it

slightly until it no longer contacts the cap.

Don’t rotate the crankshaft at any time during

this operation!

12Unscrew the bolts and detach the cap,

being very careful not to disturb the

Plastigage.

13Compare the width of the crushed

Plastigage to the scale printed on the

Plastigage envelope, to obtain the running

clearance (see illustration 17.10). Compare it

to the Specifications, to make sure the

clearance is correct.

14If the clearance is not as specified, seek

the advice of a Ford dealer or similar engine

reconditioning specialist - if the crankshaft

journals are in good condition (see Sec-

tion 13), it may be possible simply to renew

the shells to achieve the correct clearance. If

this is not possible, the crankshaft must bereground by a specialist, who can also supply

the necessary undersized shells. First though,

make sure that no dirt or oil was trapped

between the bearing shells and the

connecting rod or cap when the clearance

was measured. Also, recheck the crankpin

diameter. If the Plastigage was wider at one

end than the other, the crankpin journal may

be tapered (see Section 13).

15Carefully scrape all traces of the

Plastigage material off the journal and the

bearing surface. Be very careful not to scratch

the bearing - use your fingernail or the edge of

a credit card.

Final piston/connecting rod

refitting

16Make sure the bearing surfaces are

perfectly clean, then apply a uniform layer of

clean molybdenum disulphide-based grease,

engine assembly lubricant, or clean engine oil,

to both of them. You’ll have to push the piston

into the cylinder to expose the bearing surface

of the shell in the connecting rod.

17Slide the connecting rod back into place

on the crankpin (big-end) journal, refit the big-

end bearing cap, and then tighten the bolts in

two stages, as described above.

18Repeat the entire procedure for the

remaining piston/connecting rod assemblies.

19The important points to remember are:

(a) Keep the backs of the bearing shells and

the recesses of the connecting rods and

caps perfectly clean when assembling

them.

(b) Make sure you have the correct

piston/rod assembly for each cylinder -

use the etched cylinder numbers to

identify the front-facing side of both the

rod and its cap.

(c) The arrow on the piston crown must face

the timing belt end of the engine.

(d) Lubricate the cylinder bores with clean

engine oil.

(e) Lubricate the bearing surfaces when

refitting the big-end bearing caps after the

running clearance has been checked.

20After all the piston/connecting rod

assemblies have been properly installed,

rotate the crankshaft a number of times by

hand, to check for any obvious binding.1With the engine refitted in the vehicle,

double-check the engine oil and coolant

levels. Make a final check that everything has

been reconnected, and that there are no tools

or rags left in the engine compartment.

2With the spark plugs removed and the

ignition system disabled by unplugging the

ignition coil’s electrical connector, remove

fuse 14 to disconnect the fuel pump. Turn the

engine on the starter until the oil pressure

warning light goes out.

3Refit the spark plugs, and connect all the

spark plug (HT) leads (Chapter 1). Reconnect

the ignition coil wiring, refit the fuel pump fuse,

then switch on the ignition and listen for the fuel

pump; it will run for a little longer than usual,

due to the lack of pressure in the system.

4Start the engine, noting that this also may

take a little longer than usual, due to the fuel

system components being empty.

5While the engine is idling, check for fuel,

coolant and oil leaks. Don’t be alarmed if

there are some odd smells and smoke from

parts getting hot and burning off oil deposits.

If the hydraulic tappets have been disturbed,

some valve gear noise may be heard at first;

this should disappear as the oil circulates fully

around the engine, and normal pressure is

restored in the tappets.

6Keep the engine idling until hot water is felt

circulating through the top hose, check that it

idles reasonably smoothly and at the usual

speed, then switch it off.

7After a few minutes, recheck the oil and

coolant levels, and top-up as necessary

(Chapter 1).

8If they were tightened as described, there is

no need to re-tighten the cylinder head bolts

once the engine has first run after reassembly

- in fact, Ford state that the bolts must notbe

re-tightened.

9If new components such as pistons, rings

or crankshaft bearings have been fitted, the

engine must be run-in for the first 500 miles

(800 km). Do not operate the engine at full-

throttle, or allow it to labour in any gear during

this period. It is recommended that the oil and

filter be changed at the end of this period.

19 Engine -

initial start-up after overhaul

2B•22 Engine removal and general engine overhaul procedures

procarmanuals.com

Page 92 of 279

Caution: Don’t drive the vehicle

without a thermostat. The lack of

a thermostat will slow warm-up

time. The engine management system’s

ECU will then stay in warm-up mode for

longer than necessary, causing emissions

and fuel economy to suffer.

9If the radiator top hose is hot, it means that

the coolant is flowing and the thermostat is

open. Consult the “Fault diagnosis”section at

the front of this manual to assist in tracing

possible cooling system faults.

Thermostat test

10If the thermostat remains in the open

position at room temperature, it is faulty, and

must be renewed as a matter of course.

11To test it fully, suspend the (closed)

thermostat on a length of string in a container

of cold water, with a thermometer beside it;

ensure that neither touches the side of the

container.

12Heat the water, and check the

temperature at which the thermostat begins to

open; compare this value with that specified.

Continue to heat the water until the

thermostat is fully open; the temperature at

which this should happen is stamped in the

unit’s end. Remove the thermostat and allow

it to cool down; check that it closes fully.

13If the thermostat does not open and close

as described, if it sticks in either position, or if

it does not open at the specified temperature,

it must be renewed.

Refitting

14Refitting is the reverse of the removal

procedure. Clean the mating surfaces

carefully, renew the thermostat’s sealing ring

if it is worn or damaged, then refit the

thermostat with its air bleed valve uppermost

(see illustration). Tighten the water outlet

bolts to the specified torque wrench setting.

15Refill the cooling system (see Chapter 1).

16Start the engine and allow it to reach

normal operating temperature, then check for

leaks and proper thermostat operation.

Note:Refer to the warnings given in Section 1

of this Chapter before starting work.

Testing

1The radiator cooling fan is controlled by the

engine management system’s ECU, acting on

the information received from the coolant

temperature sensor. Where twin fans or two-

speed fans are fitted, control is through a

resistor assembly, secured to the bottom left-

hand corner of the fan shroud - this can be

renewed separately if faulty.

2First, check the relevant fuses and relays

(see Chapter 12).

3To test the fan motor, unplug the electrical

connector, and use fused jumper wires to

connect the fan directly to the battery. If the

fan still does not work, renew the motor.

4If the motor proved sound, the fault lies in

the coolant temperature sensor (see Section 6

for testing details), in the wiring loom (see

Chapter 12 for testing details) or in the engine

management system (see Chapter 6).

Removal and refitting

5Disconnect the battery negative (earth) lead

(see Chapter 5, Section 1).

6Unbolt the resonator support bracket from

the engine compartment front crossmember.

Slacken the two clamp screws securing the

resonator to the air mass meter and plenum

chamber hoses, then swing the resonator up

clear of the thermostat housing (see Chapter 4).7Drain the cooling system (see Chapter 1).

8Remove the radiator top hose completely.

Disconnect the metal coolant pipe/hose from

the thermostat, and unbolt the coolant pipe

from the exhaust manifold heat shield.

9Unplug the cooling fan electrical

connector(s), then release all wiring and hoses

from the fan shroud.

10Unscrew the two nuts securing the fan

shroud, then lift the assembly to disengage it

from its bottom mountings and from the

radiator top edge (see illustrations).

11Withdraw the fan and shroud as an

assembly (see illustration).

12At the time of writing, the fan, motor and

shroud are available only as a complete

assembly, and must be renewed together if

faulty.

13Refitting is the reverse of the removal

procedure. Ensure that the shroud is settled

correctly at all four mounting points before

refitting and tightening the nuts.

Note:Refer to the warnings given in Section 1

of this Chapter before starting work.

Coolant temperature gauge

sender

Testing

1If the coolant temperature gauge is inopera-

tive, check the fuses first (see Chapter 12).

2If the gauge indicates Hot at any time,

consult the “Fault finding”section at the end

of this manual, to assist in tracing possible

cooling system faults.

3If the gauge indicates Hot shortly after the

engine is started from cold, unplug the

coolant temperature sender’s electrical

connector. If the gauge reading now drops,

renew the sender. If the reading remains high,

the wire to the gauge may be shorted to earth,

or the gauge is faulty.

4If the gauge fails to indicate after the engine

has been warmed up (approximately

10 minutes) and the fuses are known to be

sound, switch off the engine. Unplug the

6 Cooling system electrical

switches and sensors-

testing, removal and refitting

5 Radiator electric cooling

fan(s)- testing,

removal and refitting

3•4 Cooling, heating and air conditioning systems

4.14 Ensure thermostat is refitted as

shown

5.10A Fan shroud is secured at top by

mounting nut (A), at bottom by clip (B) . . .5.10B . . . and is hooked over radiator top

edge (one point arrowed)5.11 Removing radiator electric cooling

fan and shroud assembly

procarmanuals.com

Page 100 of 279

This Chapter is concerned with those

features of the engine management system

that supply clean fuel and air to the engine,

meter it in the required proportions, and

dispose of the results. Since the emission

control sub-systems modify the functions of

both the fuel and exhaust sub-systems, all of

which are integral parts of the whole engine

management system, there are many cross-

references to Chapters 5 and 6. Information

on the electronic control system, its fault

diagnosis, sensors and actuators, is given in

Chapter 6.

The air intake system consists of several

plastics components designed to eliminate

induction roar as much as possible. The air

intake tube (opening behind the direction

indicator/headlight assembly) is connected,

via small and large resonators located under

the front left-hand wing, to the air cleaner

assembly in the engine compartment. Once it

has passed through the filter element and the

air mass meter, the air enters the plenum

chamber mounted above the throttle housing

and inlet manifold; the resonator mounted in

the engine compartment further reduces noise

levels.

The fuel system consists of a plastic tank

(mounted under the body, beneath the rear

seats), combined metal and plastic fuel hoses,

an electric fuel pump mounted in the fuel tank,

and an electronic fuel injection system.

The exhaust system consists of an exhaust

manifold, the front downpipe and catalytic

converter and, on production-fit systems, a

rear section incorporating two or three

silencers and the tailpipe assembly. The

service replacement exhaust system consists

of three or four sections: the front

downpipe/catalytic converter, the

intermediate pipe and front silencer, and the

tailpipe and rear silencer. On some versions,

the tailpipe is in two pieces, with two rear

silencers. The system is suspended

throughout its entire length by rubber

mountings.

Extreme caution should be exercised when

dealing with either the fuel or exhaust

systems. Fuel is a primary element for

combustion. Be very careful! The exhaust

system is an area for exercising caution, as it

operates at very high temperatures. Serious

burns can result from even momentary

contact with any part of the exhaust system,

and the fire risk is ever-present. The catalytic

converter in particular runs at very high

temperatures - refer to the information in

Chapter 6.

Warning: Many of the procedures

in this Chapter require the

removal of fuel lines and

connections, which may result in

some fuel spillage. Petrol is extremely

flammable, so take extra precautionswhen you work on any part of the fuel

system. Don’t smoke, or allow open flames

or bare light bulbs, near the work area.

Don’t work in a garage where a natural

gas-type appliance (such as a water

heater or clothes dryer) with a pilot light is

present. If you spill any fuel on your skin,

rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses,

and have a Class B type fire extinguisher

on hand. Before carrying out any operation

on the fuel system, refer also to the

precautions given in “Safety first!” at the

beginning of this manual, and follow them

implicitly. Petrol is a highly-dangerous and

volatile liquid, and the precautions

necessary when handling it cannot be

overstressed.

Warning: The fuel system will

remain pressurised for long

periods of time after the engine is

switched off - this pressure must

be released before any part of the system

is disturbed. Petrol is extremely

flammable, so take extra precautions

when you work on any part of the fuel

system. Don’t smoke, or allow open flames

or bare light bulbs, near the work area.

Don’t work in a garage where a natural

gas-type appliance (such as a water

heater or clothes dryer) with a pilot light is

present. If you spill any fuel on your skin,

rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses,

and have a Class B type fire extinguisher

on hand.

1The fuel system referred to in this Chapter

is defined as the fuel tank and tank-mounted

fuel pump/fuel gauge sender unit, the fuel

filter, the fuel injectors and the pressure

regulator in the injector rail, and the metal

pipes and flexible hoses of the fuel lines

between these components. All these contain

fuel, which will be under pressure while the

engine is running and/or while the ignition is

switched on.

2The pressure will remain for some time after

the ignition has been switched off, and must

be relieved before any of these components is

disturbed for servicing work.

3The simplest method is simply to

disconnect the fuel pump’s electrical supply

while the engine is running - either by

removing the fuel pump fuse (number 14), or

by lifting the red button on the fuel cut-off

switch (see Section 13) - and to allow the

engine to idle until it dies through lack of fuel

pressure. Turn the engine over once or twice

on the starter to ensure that all pressure is

released, then switch off the ignition; do not

forget to refit the fuse (or depress the redbutton, as appropriate) when work is

complete.

4The Ford method of depressurisation is to

use service tool 29-033 fitted to the fuel rail

pressure test/release fitting - a Schrader-type

valve with a blue plastic cap, located on the

union of the fuel feed line and the fuel rail - to

release the pressure, using a suitable

container and wads of rag to catch the spilt

fuel. Do notsimply depress the valve core to

release fuel pressure - droplets of fuel will

spray out, with a consequent risk of fire, and

of personal injury through fuel getting into

your eyes.

Warning: Either procedure will

merely relieve the increased

pressure necessary for the

engine to run. Remember that

fuel will still be present in the system

components, and take precautions

accordingly before disconnecting any of

them.

5Note that, once the fuel system has been

depressurised and drained (even partially), it

will take significantly longer to restart the

engine - perhaps several seconds of cranking

- before the system is refilled and pressure

restored.

Warning: The fuel system

pressure must be released before

any part of the system is

disturbed - see Section 2. Petrol

is extremely flammable, so take extra

precautions when you work on any part of

the fuel system. Don’t smoke, or allow

open flames or bare light bulbs, near the

work area. Don’t work in a garage where a

natural gas-type appliance (such as a

water heater or clothes dryer) with a pilot

light is present. If you spill any fuel on your

skin, rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses,

and have a Class B type fire extinguisher

on hand.

Disconnecting and connecting

quick-release couplings

1Quick-release couplings are employed at all

unions in the fuel feed and return lines.

2Before disconnecting any fuel system

component, relieve the residual pressure in

the system (see Section 2), and equalise tank

pressure by removing the fuel filler cap.

Warning: This procedure will

merely relieve the increased

pressure necessary for the

engine to run - remember that

fuel will still be present in the system

components, and take precautions

accordingly before disconnecting any of

them.

3 Fuel lines and fittings-

general information

2 Fuel system - depressurisation

1 General information and

precautions

4•2 Fuel and exhaust systems

procarmanuals.com

Page 101 of 279

3Release the protruding locking lugs on each

union, by squeezing them together and

carefully pulling the coupling apart. Use rag to

soak up any spilt fuel. Where the unions are

colour-coded, the pipes cannot be confused.

Where both unions are the same colour, note

carefully which pipe is connected to which,

and ensure that they are correctly

reconnected on refitting (see illustration).

4To reconnect one of these couplings, press

them together until the locking lugs snap into

their groove. Switch the ignition on and off

five times to pressurise the system, and check

for any sign of fuel leakage around the

disturbed coupling before attempting to start

the engine.

Checking

5Checking procedures for the fuel lines are

included in Chapter 1.

Component renewal

6If you must renew any damaged sections,

use original-equipment replacement hoses or

pipes, constructed from exactly the same

material as the section you are replacing. Do

not install substitutes constructed from

inferior or inappropriate material, or you could

cause a fuel leak or a fire.

7Before detaching or disconnecting any part

of the fuel system, note the routing of all

hoses and pipes, and the orientation of all

clamps and clips. Replacement sections must

be installed in exactly the same manner.8Before disconnecting any part of the fuel

system, be sure to relieve the fuel system

pressure (see Section 2), and equalise tank

pressure by removing the fuel filler cap. Also

disconnect the battery negative (earth) lead -

see Chapter 5, Section 1. Cover the fitting

being disconnected with a rag, to absorb any

fuel that may spray out.

Air cleaner assembly

1Disconnect the battery negative (earth) lead

- see Chapter 5, Section 1.

2Unclip the air mass meter from the air

cleaner cover (see Chapter 6).

3Disconnect the crankcase breather hose,

either from the air cleaner housing or from the

cylinder head cover union (see illustration).

4Remove the rubber retaining band (see

illustration). Withdraw the air cleaner

assembly, lifting it upwards out of its

grommets, and releasing it from the rubber

connector sleeve in the inner wing panel.

5Refitting is the reverse of the removal

procedure. Ensure that the housing pegs seat

correctly in their grommets, and that the

intake mouth is fully engaged inside the

connector sleeve (see illustration).

Air intake components

Note:Depending on the reason for removal,

these components can be removed either

individually, or as one assembly. For example,

unplugging the two electrical connectors and

disconnecting the vacuum hose (where fitted),

will allow the air cleaner assembly cover to be

removed with the air mass meter, the

resonator and the plenum chamber.

Air mass meter

6Refer to Section 4 of Chapter 6.

Resonator (engine compartment)

7Unbolt the resonator support bracket from

the engine compartment front crossmember.

Slacken the two clamp screws securing the

resonator to the air mass meter and plenum

chamber hoses. Swing the resonator clear of

the thermostat housing, and unplug the intake

air temperature sensor’s electrical connector

(see illustration). Withdraw the resonator.

8Refitting is the reverse of the removal

procedure.

Plenum chamber

9Prising out the rubber plugs covering them,

undo the chamber’s fasteners (see

illustration). Slacken the clamp screw

securing the chamber to the resonator hose.

10Lift the chamber and (where fitted)

disconnect the vacuum hose from its

underside. Withdraw the chamber - note the

two rubber spacers (one on each throttle

4 Air cleaner assembly and air

intake components -

removal and refitting

Fuel and exhaust systems 4•3

4

4.5 Ensure air filter housing intake mouth

is fully engaged inside connector sleeve4.7 Unplugging intake air temperature

sensor’s electrical connector4.9 Plenum chamber fasteners (arrowed) -

four shown here, some vehicles may only

have three

3.3 Disconnect fuel line quick-release

couplings by squeezing together protruding

locking lugs and pulling coupling apart4.3 Disconnecting the crankcase breather

hose from the cylinder head union4.4 Remove rubber retaining band to

withdraw air cleaner assembly

procarmanuals.com

Page 103 of 279

which pulley, disconnect the first cable end

nipple from the throttle actuator’s upper

pulley, then slide the cable outer upwards out

of the actuator housing. Disconnect the

second cable in the same way from the

actuator’s lower pulley.

6Working in the passenger compartment,

reach up to the top of the accelerator pedal.

Pull the end fitting and collar out of the pedal,

then release the cable inner wire through the

slot in the pedal. Tie a length of string to the

end of the cable.

7Returning to the engine compartment, pull

the cable through the bulkhead until the string

can be untied and the pedal-to-actuator cable

removed.

Refitting

8Refitting is the reverse of the removal

procedure. Use the string to draw the pedal-

to-actuator cable through the bulkhead.

Ensure that each cable end is connected to

the correct actuator pulley.

9Adjust both cables as described below.

Adjustment

Note:Both sections of the cable must be

adjusted together, even if only one has been

disturbed.

10Remove the plenum chamber (see

Section 4).

11Remove the metal clip from the adjuster

of each cable section (see illustration), and

lubricate the adjusters’ grommets with soapy

water.

12Remove any slack by pulling both cable

outers as far as possible out of their

respective adjusters.

13Unplug the TCS throttle actuator’s

electrical connector, and prise off its cover.

Lock both pulleys together by pushing a

locking pin (a pin punch or a similar tool of

suitable size) into their alignment holes.

Disconnect the actuator-to-throttle housing

cable’s end nipple from the throttle linkage.

14Have an assistant depress the accelerator

pedal fully. The pedal-to-actuator cable outer

will move back into the adjuster; hold it there,

and refit the clip.

15Connect the actuator-to-throttle housing

cable end nipple to the throttle linkage, andcheck that the cable outer’s grommet is

correctly secured in the housing bracket.

16Again have the assistant depress the

accelerator pedal fully. The actuator-to-

throttle housing cable outer will move back

into the adjuster; hold it there, and refit the

clip.

17Remove the locking pin from the pulleys.

Check that the throttle valve moves smoothly

and easily from the fully-closed to the fully-

open position and back again, as the

assistant depresses and releases the

accelerator pedal. Re-adjust the cable(s) if

required.

18When the setting is correct, refit the TCS

throttle actuator’s cover and electrical

connector, then refit the plenum chamber (see

Section 4).

1Disconnect the cable inner wire from the

pedal - see Section 5 or 6, as appropriate.

2Undo the retaining nuts and bolt, then

withdraw the pedal assembly (see

illustration).

3Refitting is the reverse of the removal

procedure. Adjust the cable(s) as described in

the relevant Section of this Chapter.

Warning: Petrol is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area. Don’t work in a

garage where a natural gas-type appliance

(such as a water heater or clothes dryer)

with a pilot light is present. If you spill any

fuel on your skin, rinse it off immediately

with soap and water. When you perform

any kind of work on the fuel system, wear

safety glasses, and have a Class B type

fire extinguisher on hand.

Fuel pump operation check

1Switch on the ignition and listen for the fuel

pump (the sound of an electric motor running,

audible from beneath the rear seats). Assuming

there is sufficient fuel in the tank, the pump

should start and run for approximately one or

two seconds, then stop, each time the ignition

is switched on. Note:If the pump runs

continuously all the time the ignition is switched

on, the electronic control system is running in

the backup (or “limp-home”) mode referred to

by Ford as “Limited Operation Strategy” (LOS).

This almost certainly indicates a fault in the

ECU itself, and the vehicle should therefore be

taken to a Ford dealer for a full test of the

complete system, using the correct diagnostic

equipment; do not waste time trying to test the

system without such facilities.

2Listen for fuel return noises from the fuel

pressure regulator. It should be possible to

feel the fuel pulsing in the regulator and in the

feed hose from the fuel filter.

3If the pump does not run at all, check the

fuse, relay and wiring (see Chapter 6).

Fuel pressure check

3A fuel pressure gauge, equipped with an

adaptor to suit the Schrader-type valve on the

fuel rail pressure test/release fitting

(identifiable by its blue plastic cap, and

located on the union of the fuel feed line and

the fuel rail) is required for the following

procedure. If the Ford special tool 29-033 is

available (see Section 2), the tool can be

attached to the valve, and a conventional-type

pressure gauge attached to the tool.

4If using the service tool, ensure that its tap

is turned fully anti-clockwise, then attach it to

the valve. Connect the pressure gauge to the

service tool. If using a fuel pressure gauge

with its own adaptor, connect it in accordance

with its maker’s instructions (see illustration).

5Start the engine and allow it to idle. Note

the gauge reading as soon as the pressure

stabilises, and compare it with the pressure

listed in this Chapter’s Specifications.

(a) If the pressure is high, check for a

restricted fuel return line. If the line is

clear, renew the pressure regulator.

8 Fuel pump/fuel pressure -

check

7 Accelerator pedal -

removal and refitting

Fuel and exhaust systems 4•5

4

6.11 Location of TCS throttle actuator-to-

throttle housing cable adjuster (arrowed)7.2 Removing the accelerator pedal

assembly8.4 A fuel pressure gauge, equipped with

an adaptor to suit the Schrader-type valve

on the fuel rail pressure test/release fitting,

is needed to check fuel pressure

procarmanuals.com