boot FORD MONDEO 1993 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 34 of 279

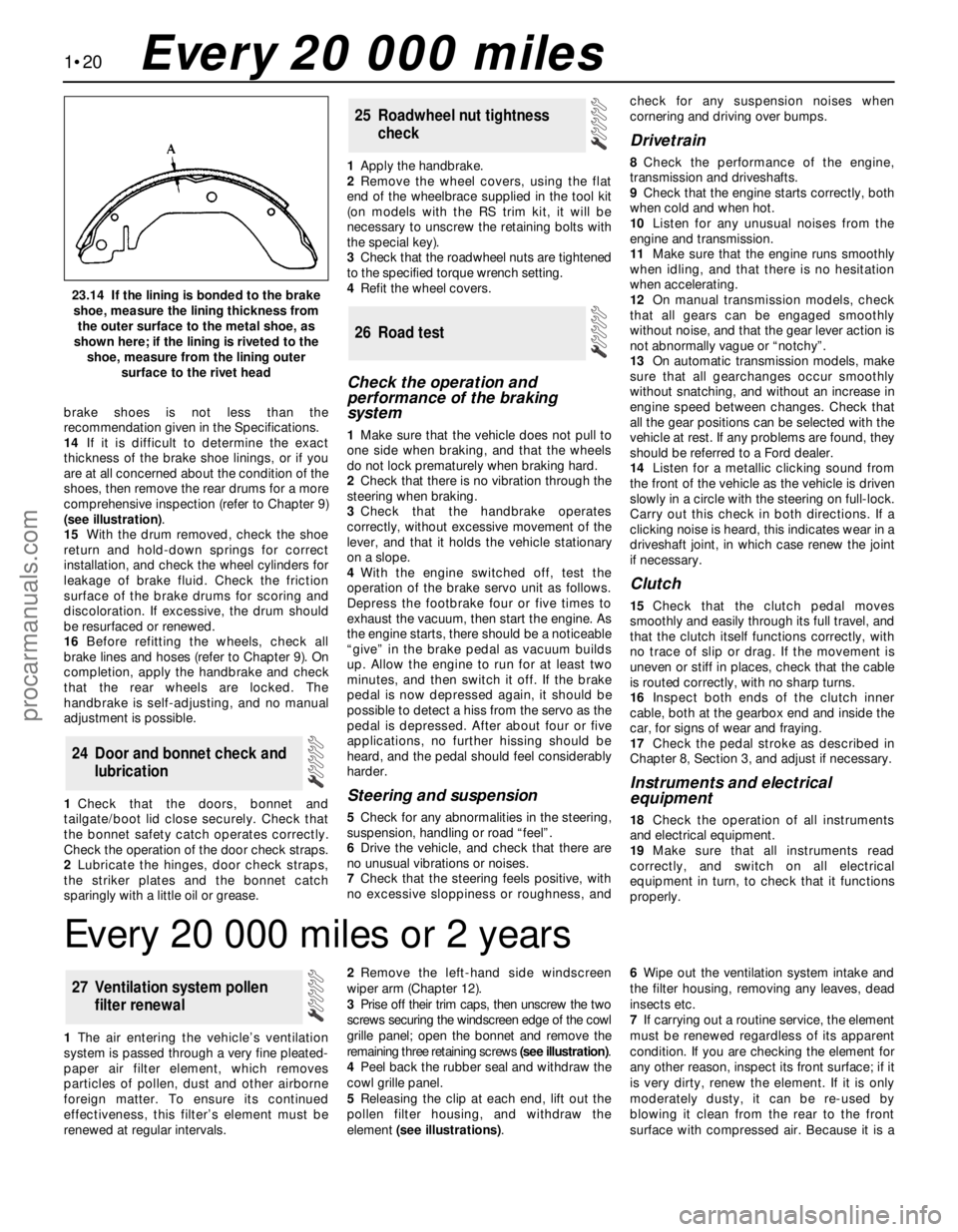

brake shoes is not less than the

recommendation given in the Specifications.

14If it is difficult to determine the exact

thickness of the brake shoe linings, or if you

are at all concerned about the condition of the

shoes, then remove the rear drums for a more

comprehensive inspection (refer to Chapter 9)

(see illustration).

15With the drum removed, check the shoe

return and hold-down springs for correct

installation, and check the wheel cylinders for

leakage of brake fluid. Check the friction

surface of the brake drums for scoring and

discoloration. If excessive, the drum should

be resurfaced or renewed.

16Before refitting the wheels, check all

brake lines and hoses (refer to Chapter 9). On

completion, apply the handbrake and check

that the rear wheels are locked. The

handbrake is self-adjusting, and no manual

adjustment is possible.

1Check that the doors, bonnet and

tailgate/boot lid close securely. Check that

the bonnet safety catch operates correctly.

Check the operation of the door check straps.

2Lubricate the hinges, door check straps,

the striker plates and the bonnet catch

sparingly with a little oil or grease.1Apply the handbrake.

2Remove the wheel covers, using the flat

end of the wheelbrace supplied in the tool kit

(on models with the RS trim kit, it will be

necessary to unscrew the retaining bolts with

the special key).

3Check that the roadwheel nuts are tightened

to the specified torque wrench setting.

4Refit the wheel covers.

Check the operation and

performance of the braking

system

1Make sure that the vehicle does not pull to

one side when braking, and that the wheels

do not lock prematurely when braking hard.

2Check that there is no vibration through the

steering when braking.

3Check that the handbrake operates

correctly, without excessive movement of the

lever, and that it holds the vehicle stationary

on a slope.

4With the engine switched off, test the

operation of the brake servo unit as follows.

Depress the footbrake four or five times to

exhaust the vacuum, then start the engine. As

the engine starts, there should be a noticeable

“give” in the brake pedal as vacuum builds

up. Allow the engine to run for at least two

minutes, and then switch it off. If the brake

pedal is now depressed again, it should be

possible to detect a hiss from the servo as the

pedal is depressed. After about four or five

applications, no further hissing should be

heard, and the pedal should feel considerably

harder.

Steering and suspension

5Check for any abnormalities in the steering,

suspension, handling or road “feel”.

6Drive the vehicle, and check that there are

no unusual vibrations or noises.

7Check that the steering feels positive, with

no excessive sloppiness or roughness, andcheck for any suspension noises when

cornering and driving over bumps.

Drivetrain

8Check the performance of the engine,

transmission and driveshafts.

9Check that the engine starts correctly, both

when cold and when hot.

10Listen for any unusual noises from the

engine and transmission.

11Make sure that the engine runs smoothly

when idling, and that there is no hesitation

when accelerating.

12On manual transmission models, check

that all gears can be engaged smoothly

without noise, and that the gear lever action is

not abnormally vague or “notchy”.

13On automatic transmission models, make

sure that all gearchanges occur smoothly

without snatching, and without an increase in

engine speed between changes. Check that

all the gear positions can be selected with the

vehicle at rest. If any problems are found, they

should be referred to a Ford dealer.

14Listen for a metallic clicking sound from

the front of the vehicle as the vehicle is driven

slowly in a circle with the steering on full-lock.

Carry out this check in both directions. If a

clicking noise is heard, this indicates wear in a

driveshaft joint, in which case renew the joint

if necessary.

Clutch

15Check that the clutch pedal moves

smoothly and easily through its full travel, and

that the clutch itself functions correctly, with

no trace of slip or drag. If the movement is

uneven or stiff in places, check that the cable

is routed correctly, with no sharp turns.

16Inspect both ends of the clutch inner

cable, both at the gearbox end and inside the

car, for signs of wear and fraying.

17Check the pedal stroke as described in

Chapter 8, Section 3, and adjust if necessary.

Instruments and electrical

equipment

18Check the operation of all instruments

and electrical equipment.

19Make sure that all instruments read

correctly, and switch on all electrical

equipment in turn, to check that it functions

properly.

26 Road test

25 Roadwheel nut tightness

check

24 Door and bonnet check and

lubrication

1•20

23.14 If the lining is bonded to the brake

shoe, measure the lining thickness from

the outer surface to the metal shoe, as

shown here; if the lining is riveted to the

shoe, measure from the lining outer

surface to the rivet head

Every 20 000 miles

Every 20 000 miles or 2 years

1The air entering the vehicle’s ventilation

system is passed through a very fine pleated-

paper air filter element, which removes

particles of pollen, dust and other airborne

foreign matter. To ensure its continued

effectiveness, this filter’s element must be

renewed at regular intervals.2Remove the left-hand side windscreen

wiper arm (Chapter 12).

3Prise off their trim caps, then unscrew the two

screws securing the windscreen edge of the cowl

grille panel; open the bonnet and remove the

remaining three retaining screws (see illustration).

4Peel back the rubber seal and withdraw the

cowl grille panel.

5Releasing the clip at each end, lift out the

pollen filter housing, and withdraw the

element (see illustrations).6Wipe out the ventilation system intake and

the filter housing, removing any leaves, dead

insects etc.

7If carrying out a routine service, the element

must be renewed regardless of its apparent

condition. If you are checking the element for

any other reason, inspect its front surface; if it

is very dirty, renew the element. If it is only

moderately dusty, it can be re-used by

blowing it clean from the rear to the front

surface with compressed air. Because it is a

27 Ventilation system pollen

filter renewal

procarmanuals.com

Page 38 of 279

To prevent the possibility of mixing up spark

plug (HT) leads, it is a good idea to try to work

on one spark plug at a time.

4If the marks on the original-equipment

spark plug (HT) leads cannot be seen, mark

the leads 1 to 4, to correspond to the cylinder

the lead serves (No 1 cylinder is at the timing

belt end of the engine). Pull the leads from the

plugs by gripping the rubber boot sealing thecylinder head cover opening, not the lead,

otherwise the lead connection may be

fractured.

5It is advisable to soak up any water in the

spark plug recesses with a rag, and to remove

any dirt from them using a clean brush,

vacuum cleaner or compressed air before

removing the plugs, to prevent any dirt or

water from dropping into the cylinders. Warning: Wear eye protection

when using compressed air!

6Unscrew the spark plugs, ensuring that the

socket is kept in alignment with each plug - if

the socket is forcibly moved to either side, the

porcelain top of the plug may be broken off. If

any undue difficulty is encountered when

unscrewing any of the spark plugs, carefully

1•24Every 30 000 miles

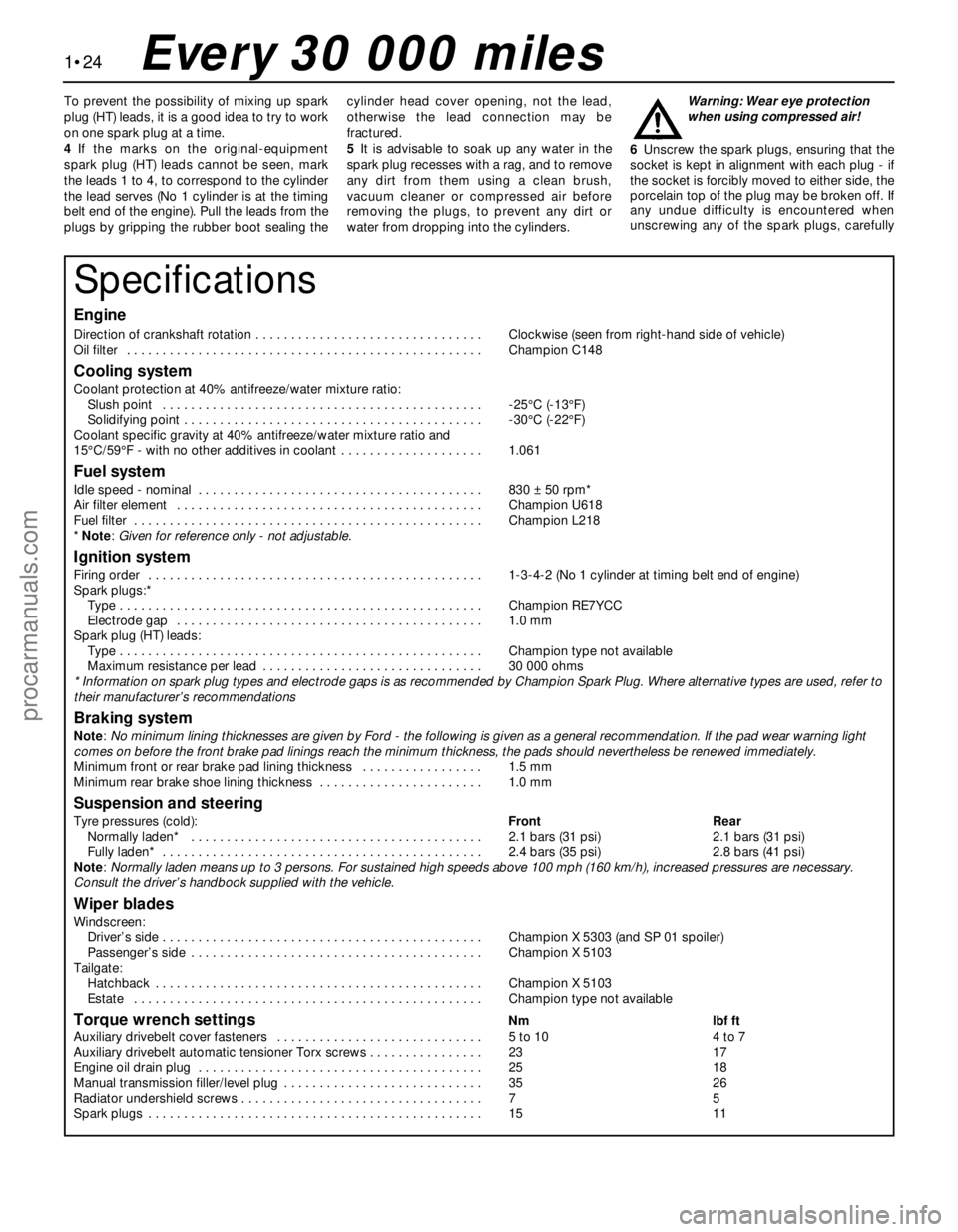

Specifications

Engine

Direction of crankshaft rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clockwise (seen from right-hand side of vehicle)

Oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C148

Cooling system

Coolant protection at 40% antifreeze/water mixture ratio:

Slush point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -25°C (-13°F)

Solidifying point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -30°C (-22°F)

Coolant specific gravity at 40% antifreeze/water mixture ratio and

15°C/59°F - with no other additives in coolant . . . . . . . . . . . . . . . . . . . . 1.061

Fuel system

Idle speed - nominal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 830 ± 50 rpm*

Air filter element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion U618

Fuel filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion L218

* Note: Given for reference only - not adjustable.

Ignition system

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-4-2 (No 1 cylinder at timing belt end of engine)

Spark plugs:*

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion RE7YCC

Electrode gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 mm

Spark plug (HT) leads:

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion type not available

Maximum resistance per lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 000 ohms

* Information on spark plug types and electrode gaps is as recommended by Champion Spark Plug. Where alternative types are used, refer to

their manufacturer’s recommendations

Braking system

Note: No minimum lining thicknesses are given by Ford - the following is given as a general recommendation. If the pad wear warning light

comes on before the front brake pad linings reach the minimum thickness, the pads should nevertheless be renewed immediately.

Minimum front or rear brake pad lining thickness . . . . . . . . . . . . . . . . . 1.5 mm

Minimum rear brake shoe lining thickness . . . . . . . . . . . . . . . . . . . . . . . 1.0 mm

Suspension and steering

Tyre pressures (cold):Front Rear

Normally laden* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 bars (31 psi) 2.1 bars (31 psi)

Fully laden* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.4 bars (35 psi) 2.8 bars (41 psi)

Note: Normally laden means up to 3 persons. For sustained high speeds above 100 mph (160 km/h), increased pressures are necessary.

Consult the driver’s handbook supplied with the vehicle.

Wiper blades

Windscreen:

Driver’s side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X 5303 (and SP 01 spoiler)

Passenger’s side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X 5103

Tailgate:

Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X 5103

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion type not available

Torque wrench settingsNm lbf ft

Auxiliary drivebelt cover fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 to 10 4 to 7

Auxiliary drivebelt automatic tensioner Torx screws . . . . . . . . . . . . . . . . 23 17

Engine oil drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 18

Manual transmission filler/level plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 26

Radiator undershield screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 5

Spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 11

procarmanuals.com

Page 39 of 279

check the cylinder head threads and tapered

sealing surfaces for signs of wear, excessive

corrosion or damage; if any of these

conditions is found, seek the advice of a Ford

dealer as to the best method of repair.

7As each plug is removed, examine it as

follows - this will give a good indication of the

condition of the engine. If the insulator nose of

the spark plug is clean and white, with no

deposits, this is indicative of a weak mixture.

8If the tip and insulator nose are covered

with hard black-looking deposits, then this is

indicative that the mixture is too rich. Should

the plug be black and oily, then it is likely that

the engine is fairly worn, as well as the mixture

being too rich.

9If the insulator nose is covered with light tan

to greyish-brown deposits, then the mixture is

correct, and it is likely that the engine is in

good condition.

10If you are renewing the spark plugs,

purchase the new plugs, then check each of

them first for faults such as cracked insulators

or damaged threads. Note also that,

whenever the spark plugs are renewed as a

routine service operation, the spark plug (HT)

leads should be checked as described below.

11The spark plug electrode gap is of

considerable importance as, if it is too large or

too small, the size of the spark and its

efficiency will be seriously impaired. The gap

should be set to the value given in the

Specifications Section of this Chapter. New

plugs will not necessarily be set to the correct

gap, so they should always be checked

before fitting.

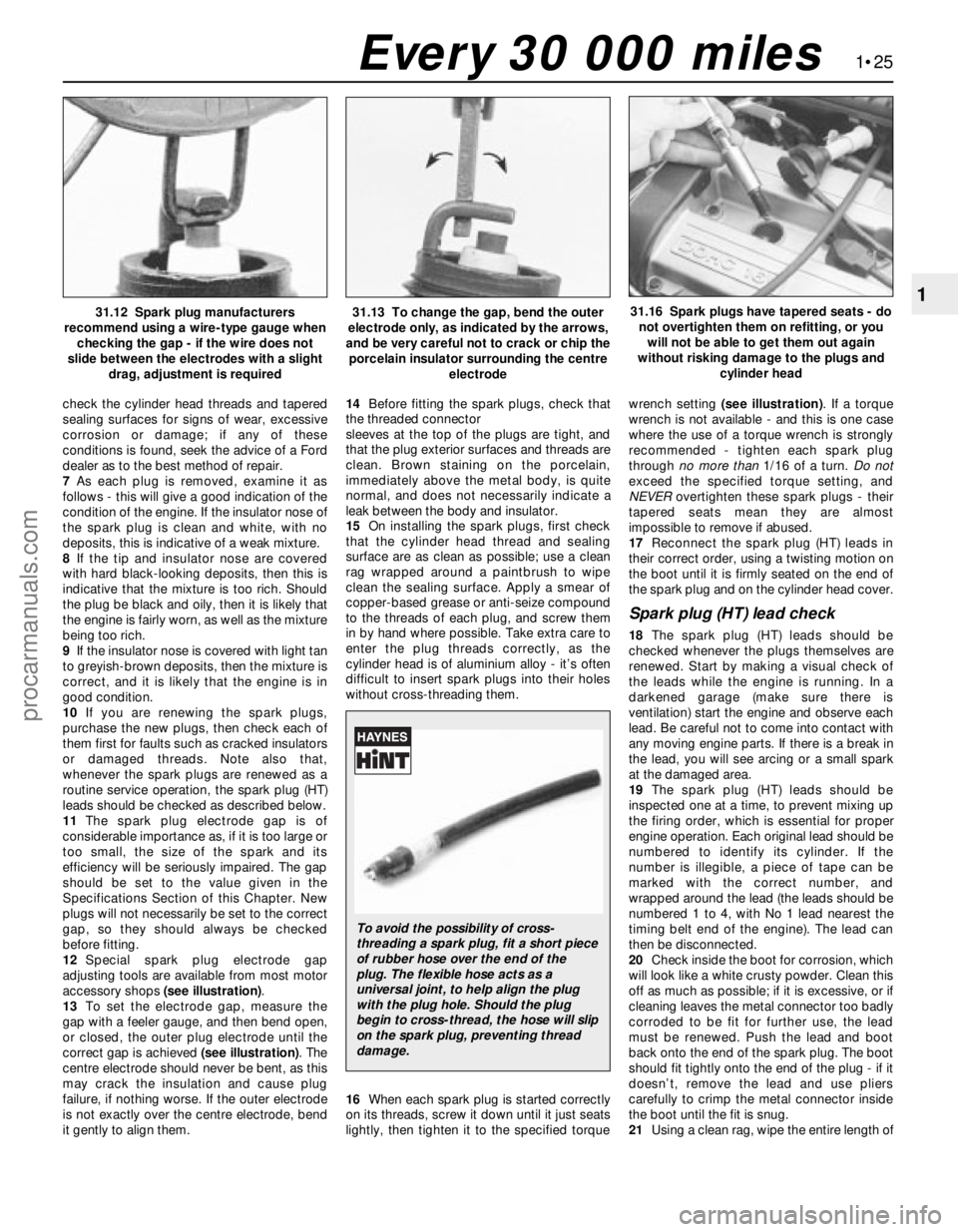

12Special spark plug electrode gap

adjusting tools are available from most motor

accessory shops (see illustration).

13To set the electrode gap, measure the

gap with a feeler gauge, and then bend open,

or closed, the outer plug electrode until the

correct gap is achieved (see illustration). The

centre electrode should never be bent, as this

may crack the insulation and cause plug

failure, if nothing worse. If the outer electrode

is not exactly over the centre electrode, bend

it gently to align them.14Before fitting the spark plugs, check that

the threaded connector

sleeves at the top of the plugs are tight, and

that the plug exterior surfaces and threads are

clean. Brown staining on the porcelain,

immediately above the metal body, is quite

normal, and does not necessarily indicate a

leak between the body and insulator.

15On installing the spark plugs, first check

that the cylinder head thread and sealing

surface are as clean as possible; use a clean

rag wrapped around a paintbrush to wipe

clean the sealing surface. Apply a smear of

copper-based grease or anti-seize compound

to the threads of each plug, and screw them

in by hand where possible. Take extra care to

enter the plug threads correctly, as the

cylinder head is of aluminium alloy - it’s often

difficult to insert spark plugs into their holes

without cross-threading them.

16When each spark plug is started correctly

on its threads, screw it down until it just seats

lightly, then tighten it to the specified torquewrench setting (see illustration). If a torque

wrench is not available - and this is one case

where the use of a torque wrench is strongly

recommended - tighten each spark plug

through no more than1/16 of a turn. Do not

exceed the specified torque setting, and

NEVERovertighten these spark plugs - their

tapered seats mean they are almost

impossible to remove if abused.

17Reconnect the spark plug (HT) leads in

their correct order, using a twisting motion on

the boot until it is firmly seated on the end of

the spark plug and on the cylinder head cover.

Spark plug (HT) lead check

18The spark plug (HT) leads should be

checked whenever the plugs themselves are

renewed. Start by making a visual check of

the leads while the engine is running. In a

darkened garage (make sure there is

ventilation) start the engine and observe each

lead. Be careful not to come into contact with

any moving engine parts. If there is a break in

the lead, you will see arcing or a small spark

at the damaged area.

19The spark plug (HT) leads should be

inspected one at a time, to prevent mixing up

the firing order, which is essential for proper

engine operation. Each original lead should be

numbered to identify its cylinder. If the

number is illegible, a piece of tape can be

marked with the correct number, and

wrapped around the lead (the leads should be

numbered 1 to 4, with No 1 lead nearest the

timing belt end of the engine). The lead can

then be disconnected.

20Check inside the boot for corrosion, which

will look like a white crusty powder. Clean this

off as much as possible; if it is excessive, or if

cleaning leaves the metal connector too badly

corroded to be fit for further use, the lead

must be renewed. Push the lead and boot

back onto the end of the spark plug. The boot

should fit tightly onto the end of the plug - if it

doesn’t, remove the lead and use pliers

carefully to crimp the metal connector inside

the boot until the fit is snug.

21Using a clean rag, wipe the entire length of

1•25

1

Every 30 000 miles

31.12 Spark plug manufacturers

recommend using a wire-type gauge when

checking the gap - if the wire does not

slide between the electrodes with a slight

drag, adjustment is required31.13 To change the gap, bend the outer

electrode only, as indicated by the arrows,

and be very careful not to crack or chip the

porcelain insulator surrounding the centre

electrode31.16 Spark plugs have tapered seats - do

not overtighten them on refitting, or you

will not be able to get them out again

without risking damage to the plugs and

cylinder head

To avoid the possibility of cross-

threading a spark plug, fit a short piece

of rubber hose over the end of the

plug. The flexible hose acts as a

universal joint, to help align the plug

with the plug hole. Should the plug

begin to cross-thread, the hose will slip

on the spark plug, preventing thread

damage.

procarmanuals.com

Page 125 of 279

Braking system 9•7

9

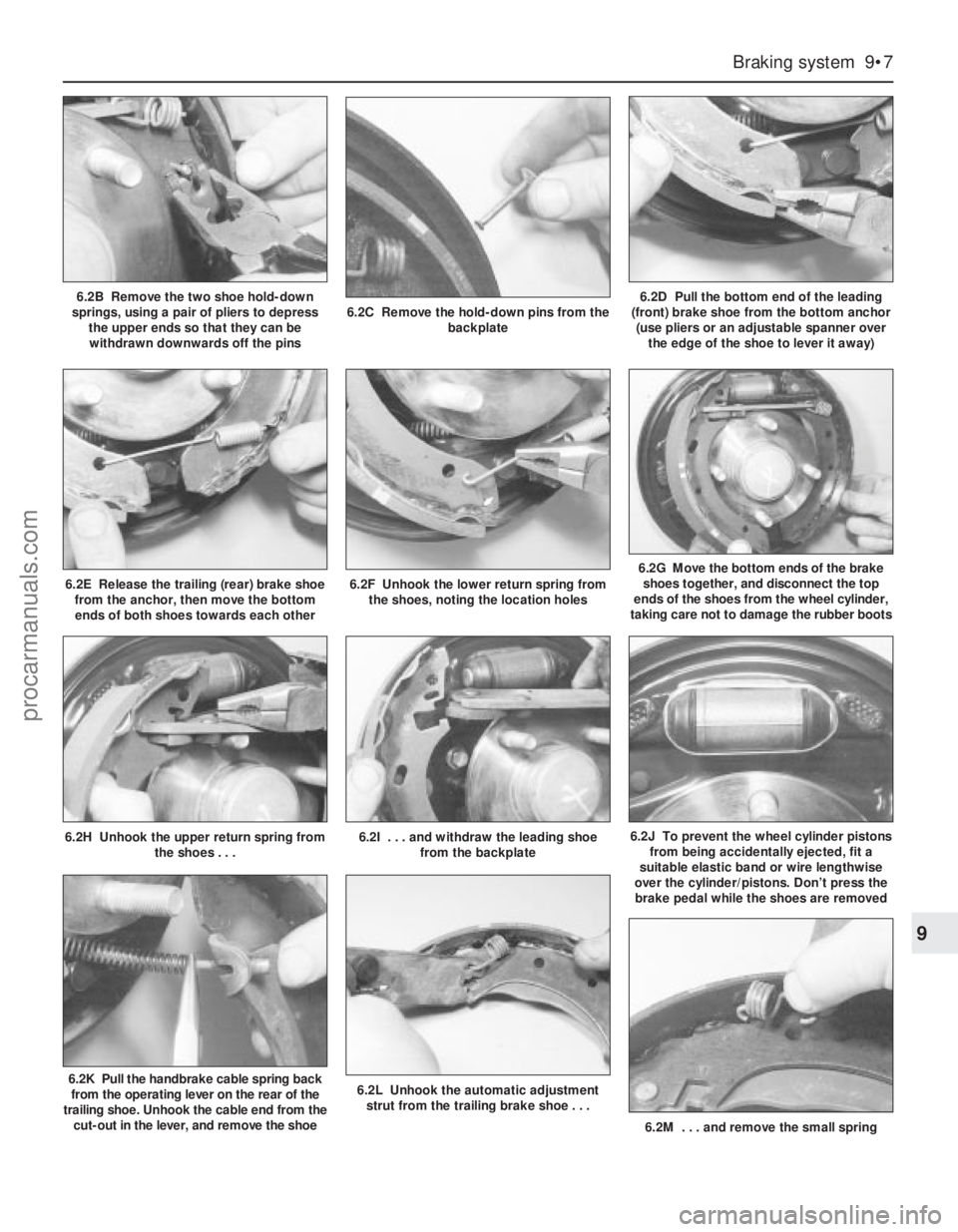

6.2K Pull the handbrake cable spring back

from the operating lever on the rear of the

trailing shoe. Unhook the cable end from the

cut-out in the lever, and remove the shoe6.2L Unhook the automatic adjustment

strut from the trailing brake shoe . . .

6.2M . . . and remove the small spring

6.2B Remove the two shoe hold-down

springs, using a pair of pliers to depress

the upper ends so that they can be

withdrawn downwards off the pins6.2C Remove the hold-down pins from the

backplate6.2D Pull the bottom end of the leading

(front) brake shoe from the bottom anchor

(use pliers or an adjustable spanner over

the edge of the shoe to lever it away)

6.2E Release the trailing (rear) brake shoe

from the anchor, then move the bottom

ends of both shoes towards each other6.2F Unhook the lower return spring from

the shoes, noting the location holes6.2G Move the bottom ends of the brake

shoes together, and disconnect the top

ends of the shoes from the wheel cylinder,

taking care not to damage the rubber boots

6.2H Unhook the upper return spring from

the shoes . . .6.2I . . . and withdraw the leading shoe

from the backplate6.2J To prevent the wheel cylinder pistons

from being accidentally ejected, fit a

suitable elastic band or wire lengthwise

over the cylinder/pistons. Don’t press the

brake pedal while the shoes are removed

procarmanuals.com

Page 163 of 279

Refitting

12Locate the lower arm on the subframe,

and insert the mounting bolts. Fit the nuts and

tighten them in stages, first to the specified

torque and then through the angle specified.

13If removed, locate the tripod on the inner

end of the driveshaft in the CV joint housing,

then refit the gaiter, together with a new clip.

14Refit the front suspension lower arm

balljoint to the knuckle assembly, and insert

the clamp bolt with its head facing forwards.

Refit the nut and tighten to the specified

torque.

15Refit the track rod end balljoint to the

steering knuckle, and tighten the nut to the

specified torque. Check that the split pin

holes are aligned; if necessary, turn the nut to

align the holes, making sure that the torque

wrench setting is still within the specified

range. Insert a new split pin, and bend it back

to secure.

16Swivel the anti-roll bar down, then

reconnect the links to the bar and tighten the

nuts to the specified torque.

17If working on the right-hand side, refit the

auxiliary drivebelt cover where necessary.

18Refit the wheel, and lower the vehicle to

the ground.

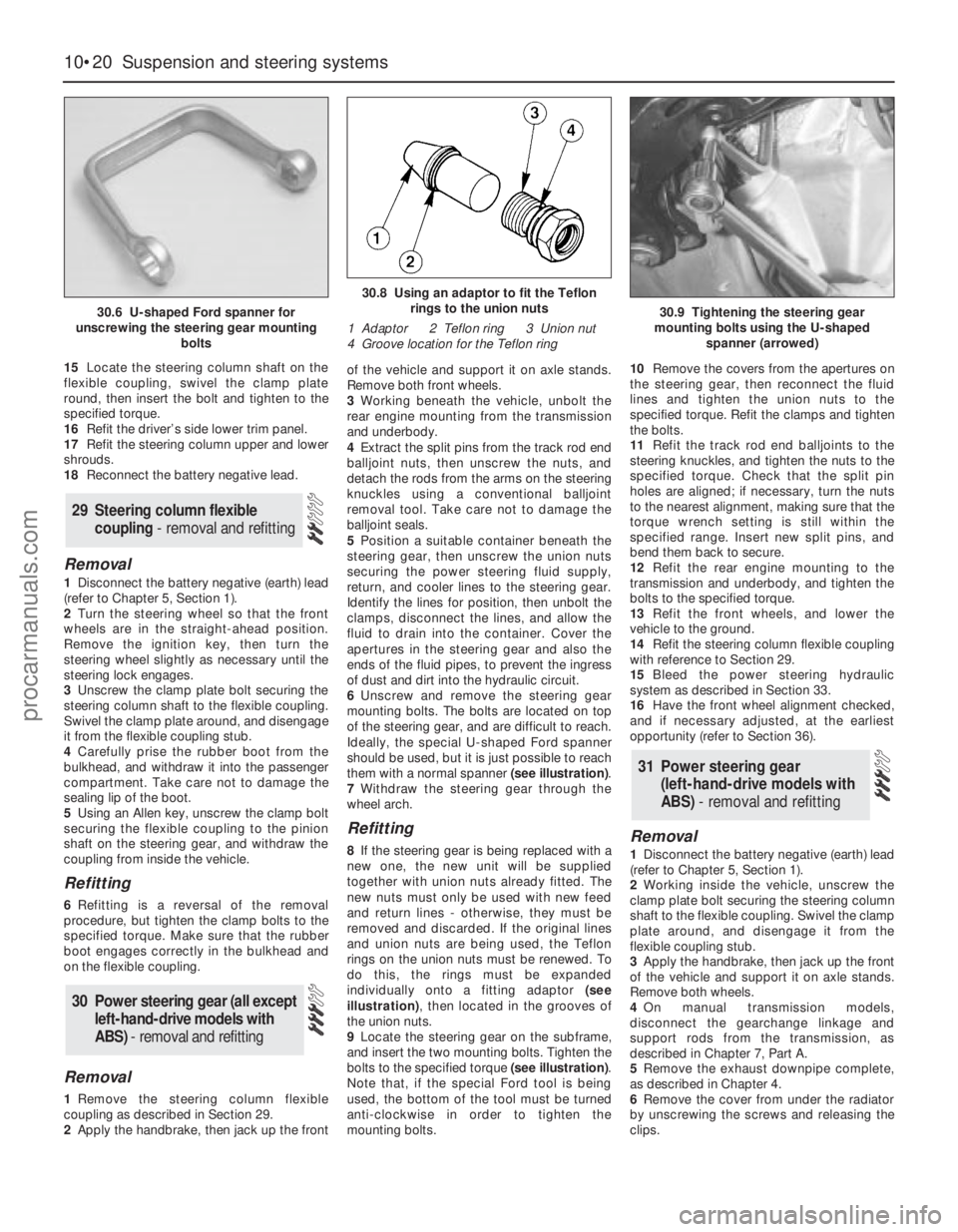

Note:If the lower arm balljoint is worn, either

the complete lower arm or the balljoint alone

can be renewed. If the balljoint has already

been renewed, it will be bolted in position; if

the original balljoint is being renewed, then it

will be riveted in position (see illustration).

This Section describes the renewal of a

riveted balljoint.1Remove the front suspension lower arm as

described in Section 7. It is not recommended

that the balljoint be replaced with the lower

arm in position on the vehicle; the accurate

drilling necessary may not be possible, and

the holes in the arm may be enlarged.

2With the lower arm on the bench, use a

3 mm drill to make a pilot hole through each of

the three rivets. Now use a 9 mm drill to drill

the rivets to a depth of 12 mm, then use a 7 or

8 mm drift to drive the rivets out of the arm.

3Clean any rust or dirt from the rivet holes.

4The new balljoint is supplied with a

protective plastic cover over the rubber boot

and stub, and it is recommended that this

remains in position until it is time to connect

the balljoint to the steering knuckle.

5Locate the new balljoint on the lower arm,

and use three new bolts to secure it, inserting

the bolts from the top of the arm. Tighten the

nuts to the specified torque. Make sure that

the location lug on the balljoint engages the

hole in the lower arm (see illustration).

6Refit the front suspension lower arm as

described in Section 7.

Note:Removal of the rear hub damages the

bearings, and renders them unserviceable for

future use. The hub and bearing assembly

mustalways be renewed if it is removed.

Inspection

1The rear hub bearings are non-adjustable,

and are supplied complete with the hub. It is

not possible to renew the bearings separately

from the hub.

2To check the bearings for excessive wear,chock the front wheels, then jack up the rear

of the vehicle and support it on axle stands.

Fully release the handbrake.

3Grip the rear wheel at the top and bottom,

and attempt to rock it. If excessive movement

is noted, or if there is any roughness or

vibration felt when the wheel is spun, it is

indicative that the hub bearings are worn.

Renewal

4Remove the rear wheel.

5On models fitted with rear brake drums,

remove the rear brake drum as described in

Chapter 9.

6On models fitted with rear brake discs,

remove the rear brake disc as described in

Chapter 9.

7On all models, tap off the dust cap and

unscrew the hub nut. Note that the nut is of

special laminated design, and should only be

re-used a maximum of 5 times. It is a good

idea to mark the nut with a file every time it is

removed. Obtain a new one if necessary.

8Using a suitable puller, draw the hub and

bearing assembly off the stub axle. Note that

this procedure renders the bearings

unserviceable for future use.

9Locate the new rear hub and bearing

assembly on the stub axle, then refit the hub

nut and tighten it to the specified torque.

10Tap the dust cap fully onto the hub.

11Refit the rear brake disc or drum as

applicable, as described in Chapter 9.

12Refit the rear wheel, and lower the vehicle

to the ground.

9 Rear hub and bearings

(Saloon/Hatchback models)-

inspection and renewal

8 Front suspension lower arm

balljoint - renewal

Suspension and steering systems 10•9

10

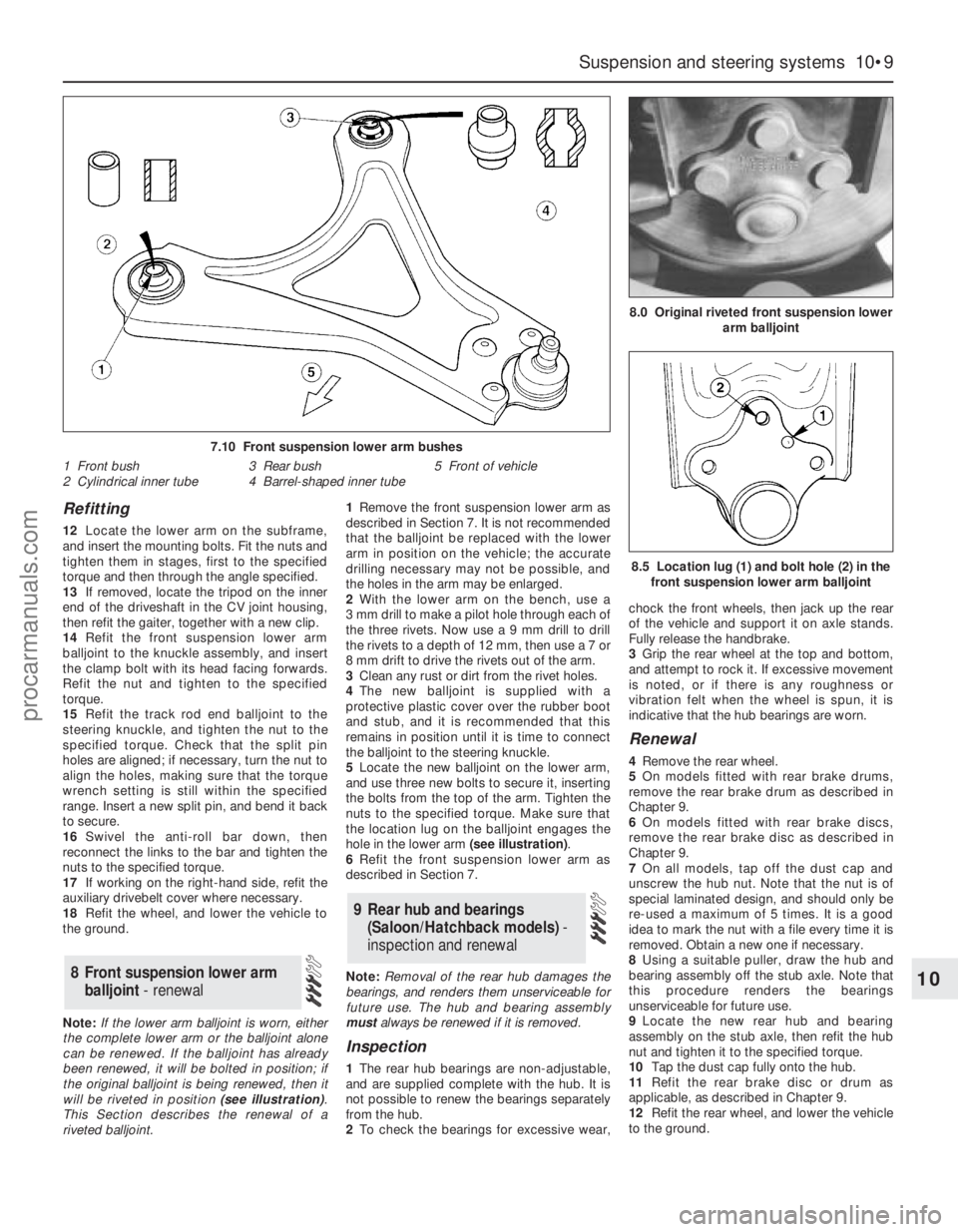

7.10 Front suspension lower arm bushes

1 Front bush

2 Cylindrical inner tube3 Rear bush

4 Barrel-shaped inner tube5 Front of vehicle

8.5 Location lug (1) and bolt hole (2) in the

front suspension lower arm balljoint

8.0 Original riveted front suspension lower

arm balljoint

procarmanuals.com

Page 174 of 279

15Locate the steering column shaft on the

flexible coupling, swivel the clamp plate

round, then insert the bolt and tighten to the

specified torque.

16Refit the driver’s side lower trim panel.

17Refit the steering column upper and lower

shrouds.

18Reconnect the battery negative lead.

Removal

1Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

2Turn the steering wheel so that the front

wheels are in the straight-ahead position.

Remove the ignition key, then turn the

steering wheel slightly as necessary until the

steering lock engages.

3Unscrew the clamp plate bolt securing the

steering column shaft to the flexible coupling.

Swivel the clamp plate around, and disengage

it from the flexible coupling stub.

4Carefully prise the rubber boot from the

bulkhead, and withdraw it into the passenger

compartment. Take care not to damage the

sealing lip of the boot.

5Using an Allen key, unscrew the clamp bolt

securing the flexible coupling to the pinion

shaft on the steering gear, and withdraw the

coupling from inside the vehicle.

Refitting

6Refitting is a reversal of the removal

procedure, but tighten the clamp bolts to the

specified torque. Make sure that the rubber

boot engages correctly in the bulkhead and

on the flexible coupling.

Removal

1Remove the steering column flexible

coupling as described in Section 29.

2Apply the handbrake, then jack up the frontof the vehicle and support it on axle stands.

Remove both front wheels.

3Working beneath the vehicle, unbolt the

rear engine mounting from the transmission

and underbody.

4Extract the split pins from the track rod end

balljoint nuts, then unscrew the nuts, and

detach the rods from the arms on the steering

knuckles using a conventional balljoint

removal tool. Take care not to damage the

balljoint seals.

5Position a suitable container beneath the

steering gear, then unscrew the union nuts

securing the power steering fluid supply,

return, and cooler lines to the steering gear.

Identify the lines for position, then unbolt the

clamps, disconnect the lines, and allow the

fluid to drain into the container. Cover the

apertures in the steering gear and also the

ends of the fluid pipes, to prevent the ingress

of dust and dirt into the hydraulic circuit.

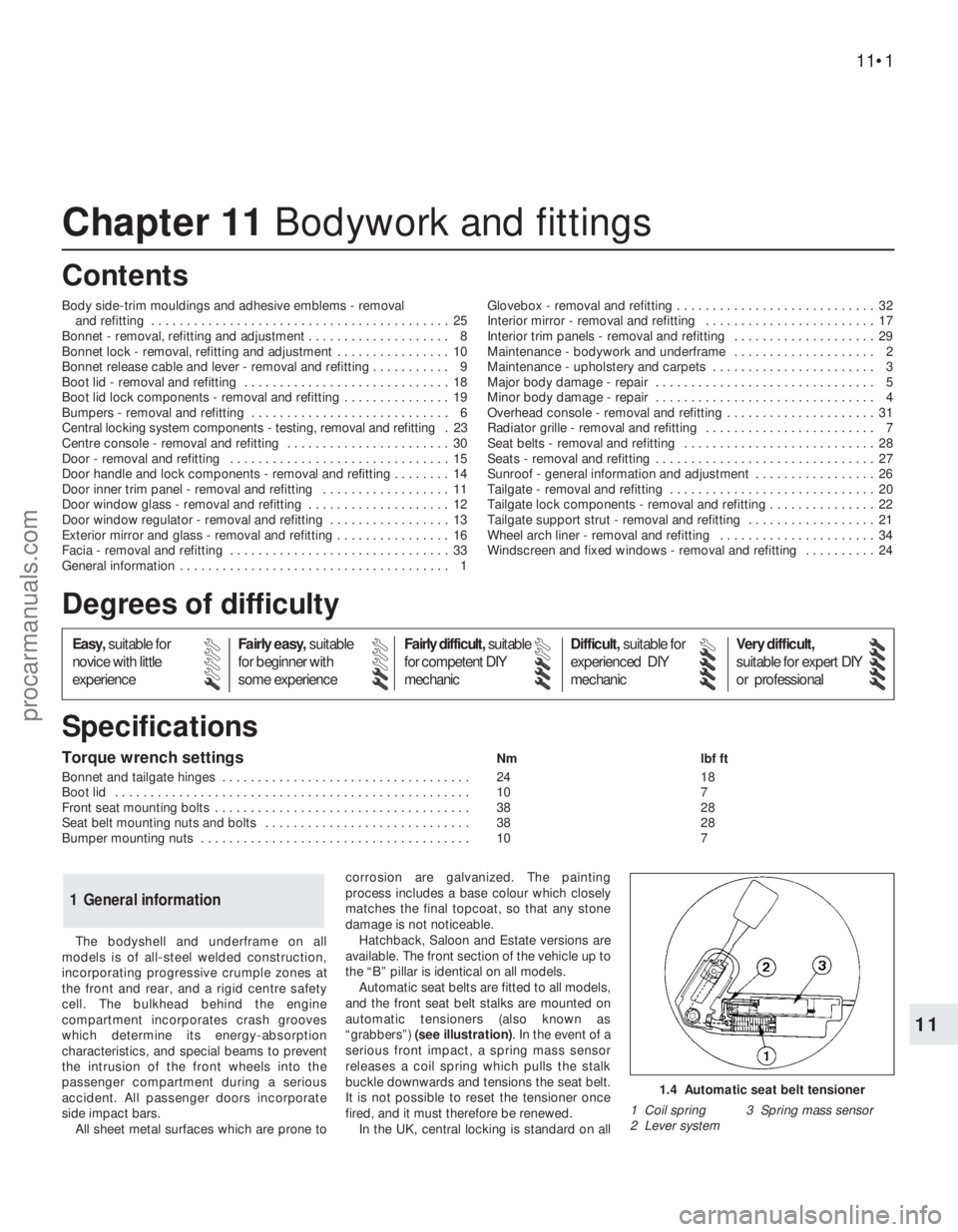

6Unscrew and remove the steering gear

mounting bolts. The bolts are located on top

of the steering gear, and are difficult to reach.

Ideally, the special U-shaped Ford spanner

should be used, but it is just possible to reach

them with a normal spanner (see illustration).

7Withdraw the steering gear through the

wheel arch.

Refitting

8If the steering gear is being replaced with a

new one, the new unit will be supplied

together with union nuts already fitted. The

new nuts must only be used with new feed

and return lines - otherwise, they must be

removed and discarded. If the original lines

and union nuts are being used, the Teflon

rings on the union nuts must be renewed. To

do this, the rings must be expanded

individually onto a fitting adaptor (see

illustration), then located in the grooves of

the union nuts.

9Locate the steering gear on the subframe,

and insert the two mounting bolts. Tighten the

bolts to the specified torque (see illustration).

Note that, if the special Ford tool is being

used, the bottom of the tool must be turned

anti-clockwise in order to tighten the

mounting bolts.10Remove the covers from the apertures on

the steering gear, then reconnect the fluid

lines and tighten the union nuts to the

specified torque. Refit the clamps and tighten

the bolts.

11Refit the track rod end balljoints to the

steering knuckles, and tighten the nuts to the

specified torque. Check that the split pin

holes are aligned; if necessary, turn the nuts

to the nearest alignment, making sure that the

torque wrench setting is still within the

specified range. Insert new split pins, and

bend them back to secure.

12Refit the rear engine mounting to the

transmission and underbody, and tighten the

bolts to the specified torque.

13Refit the front wheels, and lower the

vehicle to the ground.

14Refit the steering column flexible coupling

with reference to Section 29.

15Bleed the power steering hydraulic

system as described in Section 33.

16Have the front wheel alignment checked,

and if necessary adjusted, at the earliest

opportunity (refer to Section 36).Removal

1Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

2Working inside the vehicle, unscrew the

clamp plate bolt securing the steering column

shaft to the flexible coupling. Swivel the clamp

plate around, and disengage it from the

flexible coupling stub.

3Apply the handbrake, then jack up the front

of the vehicle and support it on axle stands.

Remove both wheels.

4On manual transmission models,

disconnect the gearchange linkage and

support rods from the transmission, as

described in Chapter 7, Part A.

5Remove the exhaust downpipe complete,

as described in Chapter 4.

6Remove the cover from under the radiator

by unscrewing the screws and releasing the

clips.

31 Power steering gear

(left-hand-drive models with

ABS) - removal and refitting

30 Power steering gear (all except

left-hand-drive models with

ABS) - removal and refitting

29 Steering column flexible

coupling - removal and refitting

10•20 Suspension and steering systems

30.6 U-shaped Ford spanner for

unscrewing the steering gear mounting

bolts

30.8 Using an adaptor to fit the Teflon

rings to the union nuts

1 Adaptor 2 Teflon ring 3 Union nut

4 Groove location for the Teflon ring

30.9 Tightening the steering gear

mounting bolts using the U-shaped

spanner (arrowed)

procarmanuals.com

Page 178 of 279

Chapter 11 Bodywork and fittings

Body side-trim mouldings and adhesive emblems - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Bonnet - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . 8

Bonnet lock - removal, refitting and adjustment . . . . . . . . . . . . . . . . 10

Bonnet release cable and lever - removal and refitting . . . . . . . . . . . 9

Boot lid - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Boot lid lock components - removal and refitting . . . . . . . . . . . . . . . 19

Bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Central locking system components - testing, removal and refitting . 23

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 30

Door - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Door handle and lock components - removal and refitting . . . . . . . . 14

Door inner trim panel - removal and refitting . . . . . . . . . . . . . . . . . . 11

Door window glass - removal and refitting . . . . . . . . . . . . . . . . . . . . 12

Door window regulator - removal and refitting . . . . . . . . . . . . . . . . . 13

Exterior mirror and glass - removal and refitting . . . . . . . . . . . . . . . . 16

Facia - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1Glovebox - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Interior mirror - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 17

Interior trim panels - removal and refitting . . . . . . . . . . . . . . . . . . . . 29

Maintenance - bodywork and underframe . . . . . . . . . . . . . . . . . . . . 2

Maintenance - upholstery and carpets . . . . . . . . . . . . . . . . . . . . . . . 3

Major body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Minor body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Overhead console - removal and refitting . . . . . . . . . . . . . . . . . . . . . 31

Radiator grille - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 7

Seat belts - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Seats - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Sunroof - general information and adjustment . . . . . . . . . . . . . . . . . 26

Tailgate - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Tailgate lock components - removal and refitting . . . . . . . . . . . . . . . 22

Tailgate support strut - removal and refitting . . . . . . . . . . . . . . . . . . 21

Wheel arch liner - removal and refitting . . . . . . . . . . . . . . . . . . . . . . 34

Windscreen and fixed windows - removal and refitting . . . . . . . . . . 24

Torque wrench settingsNm lbf ft

Bonnet and tailgate hinges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 18

Boot lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

Front seat mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 28

Seat belt mounting nuts and bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 28

Bumper mounting nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

11•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,suitable

for competent DIY

mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

Specifications Contents

11

The bodyshell and underframe on all

models is of all-steel welded construction,

incorporating progressive crumple zones at

the front and rear, and a rigid centre safety

cell. The bulkhead behind the engine

compartment incorporates crash grooves

which determine its energy-absorption

characteristics, and special beams to prevent

the intrusion of the front wheels into the

passenger compartment during a serious

accident. All passenger doors incorporate

side impact bars.

All sheet metal surfaces which are prone tocorrosion are galvanized. The painting

process includes a base colour which closely

matches the final topcoat, so that any stone

damage is not noticeable.

Hatchback, Saloon and Estate versions are

available. The front section of the vehicle up to

the “B” pillar is identical on all models.

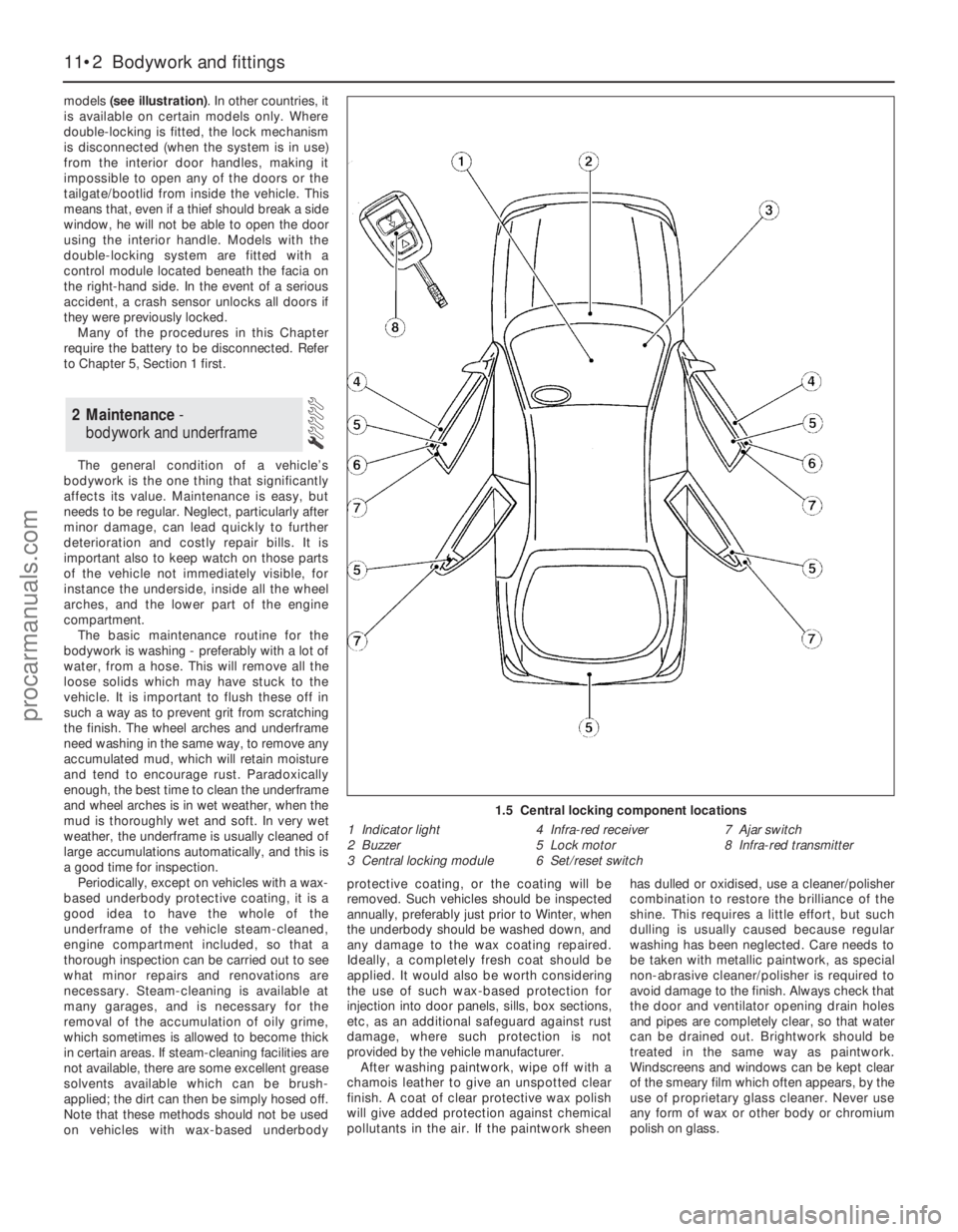

Automatic seat belts are fitted to all models,

and the front seat belt stalks are mounted on

automatic tensioners (also known as

“grabbers”) (see illustration). In the event of a

serious front impact, a spring mass sensor

releases a coil spring which pulls the stalk

buckle downwards and tensions the seat belt.

It is not possible to reset the tensioner once

fired, and it must therefore be renewed.

In the UK, central locking is standard on all

1 General information

1.4 Automatic seat belt tensioner

1 Coil spring 3 Spring mass sensor

2 Lever system

procarmanuals.com

Page 179 of 279

models (see illustration). In other countries, it

is available on certain models only. Where

double-locking is fitted, the lock mechanism

is disconnected (when the system is in use)

from the interior door handles, making it

impossible to open any of the doors or the

tailgate/bootlid from inside the vehicle. This

means that, even if a thief should break a side

window, he will not be able to open the door

using the interior handle. Models with the

double-locking system are fitted with a

control module located beneath the facia on

the right-hand side. In the event of a serious

accident, a crash sensor unlocks all doors if

they were previously locked.

Many of the procedures in this Chapter

require the battery to be disconnected. Refer

to Chapter 5, Section 1 first.

The general condition of a vehicle’s

bodywork is the one thing that significantly

affects its value. Maintenance is easy, but

needs to be regular. Neglect, particularly after

minor damage, can lead quickly to further

deterioration and costly repair bills. It is

important also to keep watch on those parts

of the vehicle not immediately visible, for

instance the underside, inside all the wheel

arches, and the lower part of the engine

compartment.

The basic maintenance routine for the

bodywork is washing - preferably with a lot of

water, from a hose. This will remove all the

loose solids which may have stuck to the

vehicle. It is important to flush these off in

such a way as to prevent grit from scratching

the finish. The wheel arches and underframe

need washing in the same way, to remove any

accumulated mud, which will retain moisture

and tend to encourage rust. Paradoxically

enough, the best time to clean the underframe

and wheel arches is in wet weather, when the

mud is thoroughly wet and soft. In very wet

weather, the underframe is usually cleaned of

large accumulations automatically, and this is

a good time for inspection.

Periodically, except on vehicles with a wax-

based underbody protective coating, it is a

good idea to have the whole of the

underframe of the vehicle steam-cleaned,

engine compartment included, so that a

thorough inspection can be carried out to see

what minor repairs and renovations are

necessary. Steam-cleaning is available at

many garages, and is necessary for the

removal of the accumulation of oily grime,

which sometimes is allowed to become thick

in certain areas. If steam-cleaning facilities are

not available, there are some excellent grease

solvents available which can be brush-

applied; the dirt can then be simply hosed off.

Note that these methods should not be used

on vehicles with wax-based underbodyprotective coating, or the coating will be

removed. Such vehicles should be inspected

annually, preferably just prior to Winter, when

the underbody should be washed down, and

any damage to the wax coating repaired.

Ideally, a completely fresh coat should be

applied. It would also be worth considering

the use of such wax-based protection for

injection into door panels, sills, box sections,

etc, as an additional safeguard against rust

damage, where such protection is not

provided by the vehicle manufacturer.

After washing paintwork, wipe off with a

chamois leather to give an unspotted clear

finish. A coat of clear protective wax polish

will give added protection against chemical

pollutants in the air. If the paintwork sheenhas dulled or oxidised, use a cleaner/polisher

combination to restore the brilliance of the

shine. This requires a little effort, but such

dulling is usually caused because regular

washing has been neglected. Care needs to

be taken with metallic paintwork, as special

non-abrasive cleaner/polisher is required to

avoid damage to the finish. Always check that

the door and ventilator opening drain holes

and pipes are completely clear, so that water

can be drained out. Brightwork should be

treated in the same way as paintwork.

Windscreens and windows can be kept clear

of the smeary film which often appears, by the

use of proprietary glass cleaner. Never use

any form of wax or other body or chromium

polish on glass.

2 Maintenance -

bodywork and underframe

11•2 Bodywork and fittings

1.5 Central locking component locations

1 Indicator light

2 Buzzer

3 Central locking module4 Infra-red receiver

5 Lock motor

6 Set/reset switch7 Ajar switch

8 Infra-red transmitter

procarmanuals.com

Page 191 of 279

door, then drive the hinge pins down through

the hinges using a small drift (see

illustrations).

6Carefully withdraw the door from the

hinges.

Refitting

7Refitting is a reversal of the removal

procedure, but check that the door lock

passes over the striker centrally. If necessary,

re-position the striker.

Removal

1Where electric mirrors are fitted, disconnect

the battery negative (earth) lead (Chapter 5,

Section 1).

2Prise off the cap, unscrew the screw, and

remove the quarter bezel from the front of the

window opening.

3On manual mirrors, detach the adjustment

lever.

4On electric mirrors, disconnect the wiring

multi-plug (see illustration).

5On both types of mirror, use a Torx key to

unscrew the mirror mounting screws, then

withdraw the mirror from the outside of the

door (see illustrations). Recover the gasket.

Refitting

6Refitting is a reversal of the removal

procedure.

Removal

1Using a length of strong thin cord or fishing

line, break the adhesive bond between the

base of the mirror and the glass. Have an

assistant support and remove the mirror as it

is released.

2If the original mirror is to be refitted,

thoroughly clean its base with methylated

spirit and a lint-free cloth. Allow a period of

one minute for the spirit to evaporate. Clean

the windscreen black patch in a similar

manner.

Refitting

3During the installation of the mirror, it is

important that the mirror base, windscreen

black patch and the adhesive patch are not

touched or contaminated in any way,

otherwise poor adhesion will result.

4Prior to fitting the mirror, the vehicle should

have been at an ambient temperature of at

least 20ºC.

5With the contact surfaces thoroughly

cleaned, remove the protective tape from one

side of the adhesive patch, and press it firmly

into contact with the mirror base.

6If fitting the mirror to a new windscreen, the

protective tape must also be removed from

the windscreen black patch.

7Using a hairdryer or a hot air gun, warm themirror base and the adhesive patch for about

30 seconds to a temperature of 50 to 70ºC.

Peel back the protective tape from the other

side of the adhesive patch on the mirror base.

Align the mirror base and the windscreen

patch, and press the mirror firmly into

position. Hold the base of the mirror firmly

against the windscreen for a minimum period

of two minutes, to ensure full adhesion.

8Wait at least thirty minutes before adjusting

the mirror position.

Removal

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1), and open the boot lid.

2Where applicable, pull off the trim covering,

and release the wiring on the hinge arm.

3Where fitted, remove the trim from inside

the boot lid.

4Disconnect the wiring at the connectors

visible through the boot lid inner skin aperture.

5Attach a length of strong cord to the end of

the wires in the aperture, to act as an aid to

guiding the wiring through the lid when it is

refitted.

6Release the cable guide rubber grommet,

and withdraw the wiring loom through it. Untie

the cord, and leave it in the boot lid.

7Mark the position of the hinge arms with a

pencil.

8Place rags beneath each corner of the boot

lid, to prevent damage to the paintwork.

9With the help of an assistant, unscrew the

mounting bolts and lift the boot lid from the

car.

Refitting

10Refitting is a reversal of the removal

procedure. Check that the boot lid is correctly

aligned with the surrounding bodywork, with

an equal clearance around its edge.

Adjustment is made by loosening the hinge

bolts, and moving the boot lid within the

elongated mounting holes. Check that the

lock enters the striker centrally when the boot

lid is closed.

18 Boot lid - removal and refitting

17 Interior mirror -

removal and refitting

16 Exterior mirror and glass-

removal and refitting

11•14 Bodywork and fittings

15.5A . . . then drive out the hinge pins . . .15.5B . . . and remove them16.4 Disconnecting the wiring multi-plug

from an electric exterior mirror

16.5A Unscrew the screws . . .16.5B . . . and withdraw the mirror

procarmanuals.com

Page 192 of 279

Removal

Lock barrel

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2With the boot lid open, remove the luggage

space trim from the right-hand rear corner.

3Remove the screws, and prise out the rear

light trim cover from the guides.

4Release the door-ajar sensor from the clip

near the lock.

5Slide the outer cable from the lock bracket.

Raise the inner cable until it is aligned with the

slot in the barrel lever, and disconnect it.

6Pull out the lock locating spring clip.

7Detach the cable mounting bracket from

the barrel, and remove the barrel.

Lock

8Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

9With the boot lid open, prise out the clips

and remove the trim from inside the boot lid.

10Release the door-ajar sensor from the clip

near the lock.

11Using a Torx key, unscrew the lock

mounting screws, and withdraw the lock for

access to the cables.

12Disconnect both the inner and outer

cables from the lock bracket.13Prise open the plastic lip, and remove the

central locking control rod.

14Withdraw the lock assembly.

Refitting

Lock barrel and lock

15Refitting is a reversal of the removal

procedure.

Removal

Hatchback

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1). Open the tailgate.

2The tailgate may be unbolted from the

hinges and the hinges left in position, or the

hinges may be detached from the roof panel

by unscrewing the mounting nuts. In the latter

case, carefully pull down the rear edge of the

headlining for access to the nuts. Take care

not to damage the headlining.

3Remove the parcel shelf left-hand support

bracket as follows. Fold the rear seat

forwards, and disconnect the left-hand seat

pull cable from the bracket and clips.

Unscrew the screws and remove the bracket.

4Pull up the rear seat side bolster, then

carefully remove the side trim from the left-

hand side of the luggage area. On low-series

models, the bolster is retained with a screw.5Separate the tailgate wiring loom multi-

plugs, located on the left-hand side of the

luggage compartment, on top of the wheel

arch.

6Unclip and remove the upper trim panel

from the inside of the tailgate. Also remove

the rear shelf cord plastic post (see

illustrations).

7Prise out the rubber grommet from the top

of the tailgate aperture, and pull the wiring

loom out through the hole in the body (see

illustration).

8Disconnect the rear window washer tube

from the jet.

9Prise out the rubber grommet from the

right-hand side of the tailgate aperture, and

pull out the washer tube.

10Have an assistant support the tailgate in

its open position.

11Using a small screwdriver, prise off the

clips securing the struts to the tailgate. Pull

the sockets from the ball-studs, and move the

struts downwards.

12If the headlining has been pulled back,

unscrew and remove the hinge nuts from the

roof panel. Otherwise, unscrew the bolts

securing the tailgate to the hinges (see

illustration).

13Withdraw the tailgate from the body

aperture, taking care not to damage the

paintwork.

Estate

14Disconnect the battery negative (earth)

lead (Chapter 5, Section 1).

15The tailgate may be unbolted from the

hinges and the hinges left in position, or the

hinges may be detached from the rear roof

panel by unscrewing the mounting nuts. In the

latter case, carefully pull down the rear edge

of the headlining for access to the nuts. Take

care not to damage the headlining.

16Unscrew the retaining screws, then unclip

the “D” pillar trim panels from both sides (see

illustration).

17Unclip and remove the upper trim panel

from inside the tailgate.

18Carefully remove the side trim from the

left-hand side of the luggage area, and

separate the tailgate wiring loom multi-plugs

in the rear light cluster housing.

20 Tailgate -

removal and refitting

19 Boot lid lock components-

removal and refitting

Bodywork and fittings 11•15

11

20.12 Unscrewing the bolts securing the

tailgate to the hinges20.16 “D” pillar trim panel retaining

screws (arrowed) - Estate models

20.6A Unclipping the upper trim panel

from the tailgate20.6B Shelf cord post removal20.7 Removing the wiring loom rubber

grommet

procarmanuals.com