fuel additives FORD MONDEO 1993 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 33 of 279

evidence of leaks, severe corrosion, or

damage. Make sure that all brackets and

rubber mountings are in good condition, and

tight; if any of the mountings are to be

renewed, ensure that the replacements are of

the correct type (see illustration). Leakage at

any of the joints or in other parts of the system

will usually show up as a black sooty stain in

the vicinity of the leak. Note:Exhaust sealants

should not be used on any part of the exhaust

system upstream of the catalytic converter -

even if the sealant does not contain additives

harmful to the converter, pieces of it may

break off and foul the element, causing local

overheating.

3At the same time, inspect the underside of

the body for holes, corrosion, open seams,

etc. which may allow exhaust gases to enter

the passenger compartment. Seal all body

openings with silicone or body putty.

4Rattles and other noises can often be

traced to the exhaust system, especially the

rubber mountings. Try to move the system,

silencer(s) and catalytic converter. If any

components can touch the body or

suspension parts, secure the exhaust system

with new mountings.

5Check the running condition of the engine

by inspecting inside the end of the tailpipe;

the exhaust deposits here are an indication of

the engine’s state of tune. The inside of the

tailpipe should be dry, and should vary in

colour from dark grey to light grey/brown; if it

is black and sooty, or coated with white

deposits, the engine is in need of a thorough

fuel system inspection.

1With the vehicle raised and supported on

axle stands or over an inspection pit,

thoroughly inspect the underbody and wheel

arches for signs of damage and corrosion. In

particular, examine the bottom of the side

sills, and any concealed areas where mud can

collect. Where corrosion and rust is evident,press and tap firmly on the panel with a

screwdriver, and check for any serious

corrosion which would necessitate repairs. If

the panel is not seriously corroded, clean

away the rust, and apply a new coating of

underseal. Refer to Chapter 11 for more

details of body repairs.

2At the same time, inspect the PVC-coated

lower body panels for stone damage and

general condition.

3Inspect all of the fuel and brake lines on the

underbody for damage, rust, corrosion and

leakage. Also make sure that they are

correctly supported in their clips. Where

applicable, check the PVC coating on the

lines for damage.

Note:For detailed photographs of the brake

system, refer to Chapter 9.

1The work described in this Section should

be carried out at the specified intervals, or

whenever a defect is suspected in the braking

system. Any of the following symptoms could

indicate a potential brake system defect:

(a) The vehicle pulls to one side when the

brake pedal is depressed.

(b) The brakes make scraping or dragging

noises when applied.

(c) Brake pedal travel is excessive.

(d) The brake fluid requires repeated topping-

up.

2A brake pad wear warning light is fitted, and

it is illuminated when the thickness of the front

(or rear) disc brake pad linings reach the

minimum amount. However, a physical check

should be made to confirm the thickness of

the linings, as follows.

Disc brakes

3Jack up the front or rear of the vehicle, as

applicable, and support it on axle stands.

Where rear brake pads are fitted, also jack up

the rear of the vehicle and support on axle

stands.

4For better access to the brake calipers,

remove the wheels.

5Look through the inspection window in thecaliper, and check that the thickness of the

friction lining material on each of the pads is

not less than the recommended minimum

thickness given in the Specifications. Note:

Bear in mind that the lining material is normally

bonded to a metal backing plate.

6If it is difficult to determine the exact

thickness of the pad linings, or if you are at all

concerned about the condition of the pads,

then remove them from the calipers for further

inspection (refer to Chapter 9).

7Check the remaining brake caliper(s) in the

same way.

8If any one of the brake pads has worn down

to, or below, the specified limit, all fourpads

at that end of the car must be renewed as a

set (ie all the front pads or all the rear pads).

9Measure the thickness of the discs with a

micrometer, if available, to make sure that

they still have service life remaining. If any

disc is thinner than the specified minimum

thickness, renew it (refer to Chapter 9). In any

case, check the general condition of the

discs. Look for excessive scoring and

discolouration caused by overheating. If these

conditions exist, remove the relevant disc and

have it resurfaced or renewed (refer to

Chapter 9).

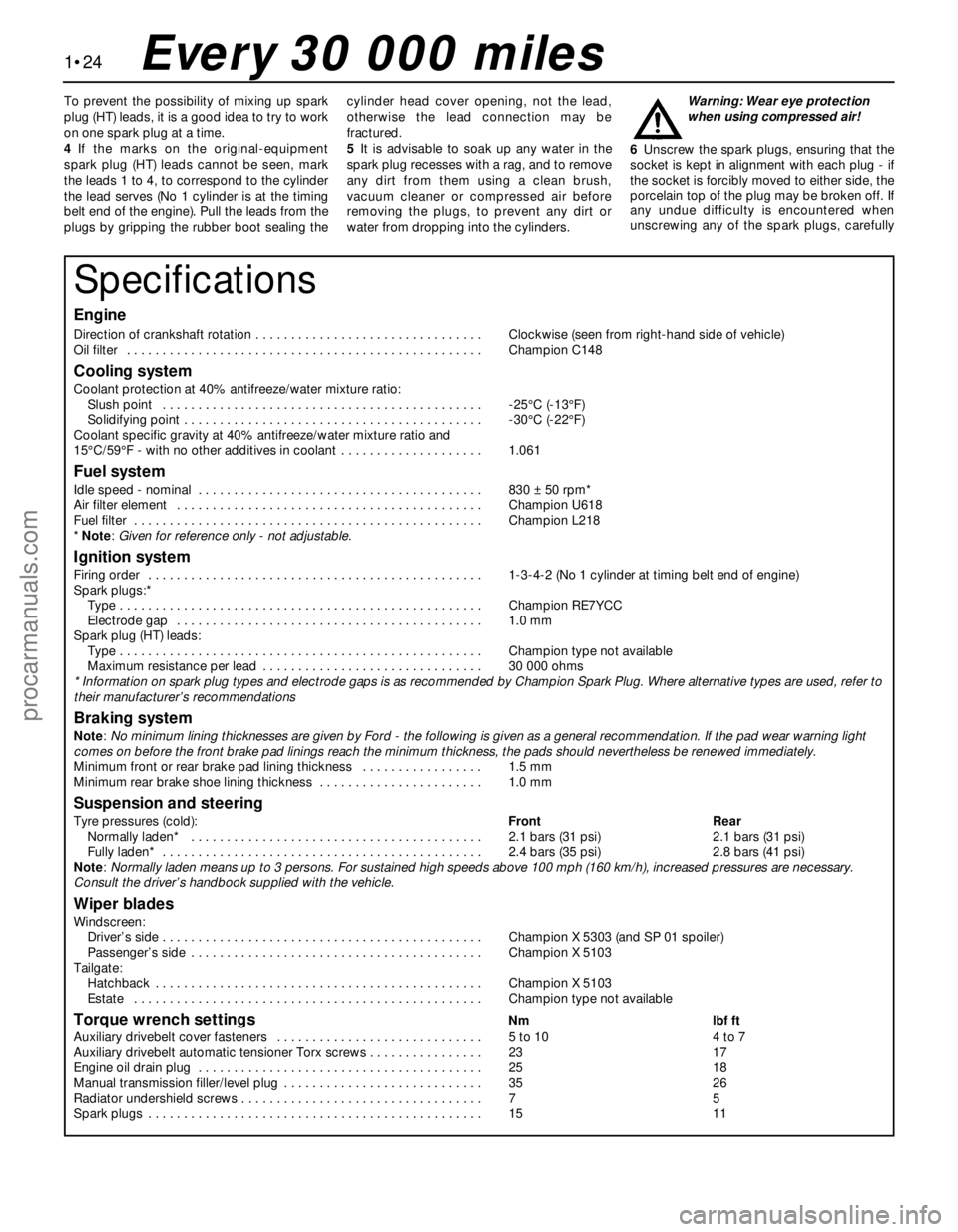

10Before refitting the wheels, check all

brake lines and hoses (refer to Chapter 9). In

particular, check the flexible hoses in the

vicinity of the calipers, where they are

subjected to most movement. Bend them

between the fingers (but do not actually bend

them double, or the casing may be damaged)

and check that this does not reveal

previously-hidden cracks, cuts or splits (see

illustration).

Rear drum brakes

11Chock the front wheels, then jack up the

rear of the vehicle and support on axle stands.

12For better access, remove the rear

wheels.

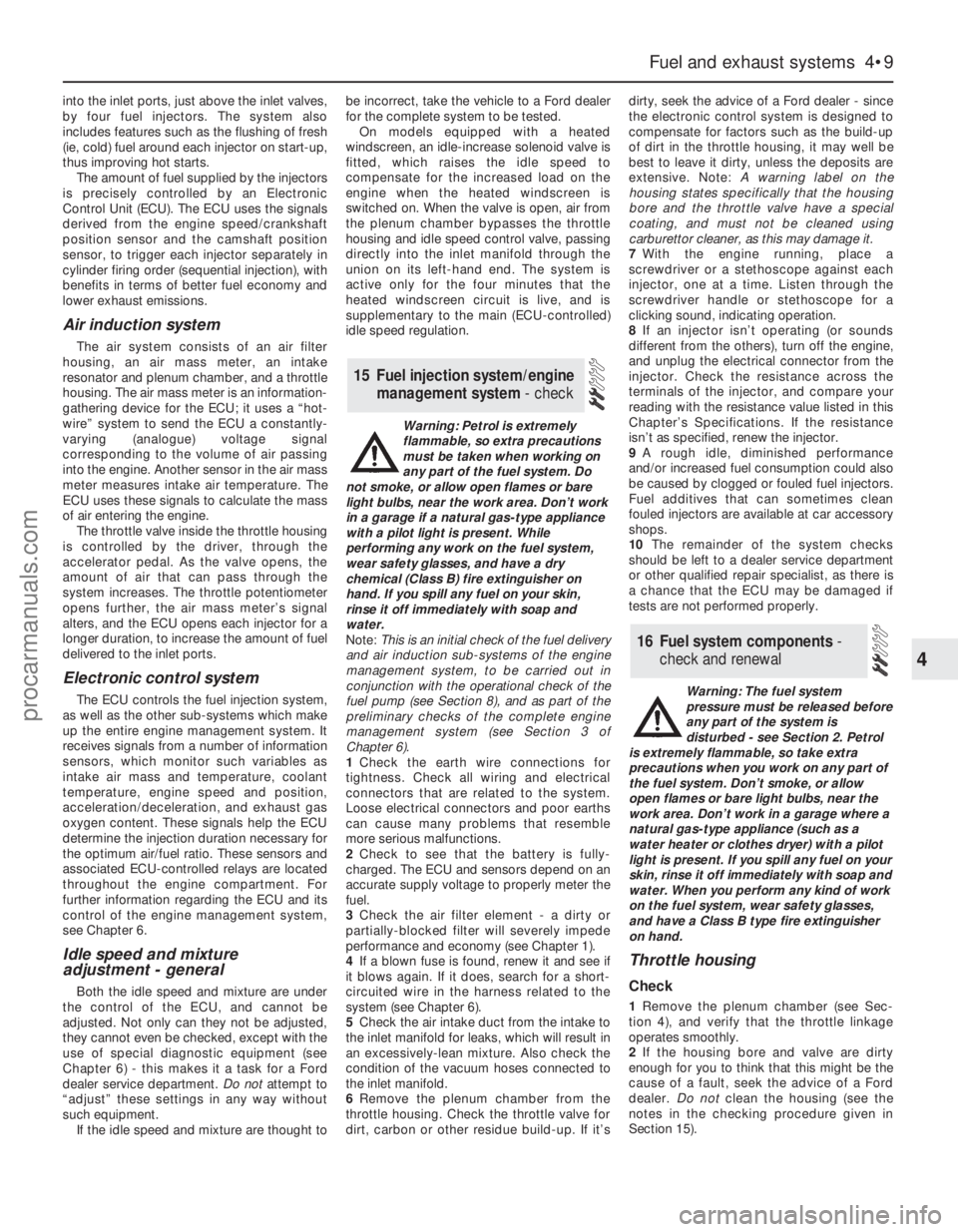

13To check the brake shoe lining thickness

without removing the brake drums, prise the

rubber plugs from the backplates, and use an

electric torch to inspect the linings of the

leading brake shoes (see illustration). Check

that the thickness of the lining material on the

23 Brake check

22 Underbody and fuel/brake

line check

1•19

121.2 If any of the exhaust system rubber

mountings are to be renewed, ensure that

the replacements are of the correct type -

their colour is a good guide. Those nearest

to the catalytic converter are more heat-

resistant than the others23.10 Checking the condition of a flexible

brake hose23.13 Prise the rubber plugs from the

backplates to inspect the leading brake

shoe linings

Every 000 miles

procarmanuals.com

Page 38 of 279

To prevent the possibility of mixing up spark

plug (HT) leads, it is a good idea to try to work

on one spark plug at a time.

4If the marks on the original-equipment

spark plug (HT) leads cannot be seen, mark

the leads 1 to 4, to correspond to the cylinder

the lead serves (No 1 cylinder is at the timing

belt end of the engine). Pull the leads from the

plugs by gripping the rubber boot sealing thecylinder head cover opening, not the lead,

otherwise the lead connection may be

fractured.

5It is advisable to soak up any water in the

spark plug recesses with a rag, and to remove

any dirt from them using a clean brush,

vacuum cleaner or compressed air before

removing the plugs, to prevent any dirt or

water from dropping into the cylinders. Warning: Wear eye protection

when using compressed air!

6Unscrew the spark plugs, ensuring that the

socket is kept in alignment with each plug - if

the socket is forcibly moved to either side, the

porcelain top of the plug may be broken off. If

any undue difficulty is encountered when

unscrewing any of the spark plugs, carefully

1•24Every 30 000 miles

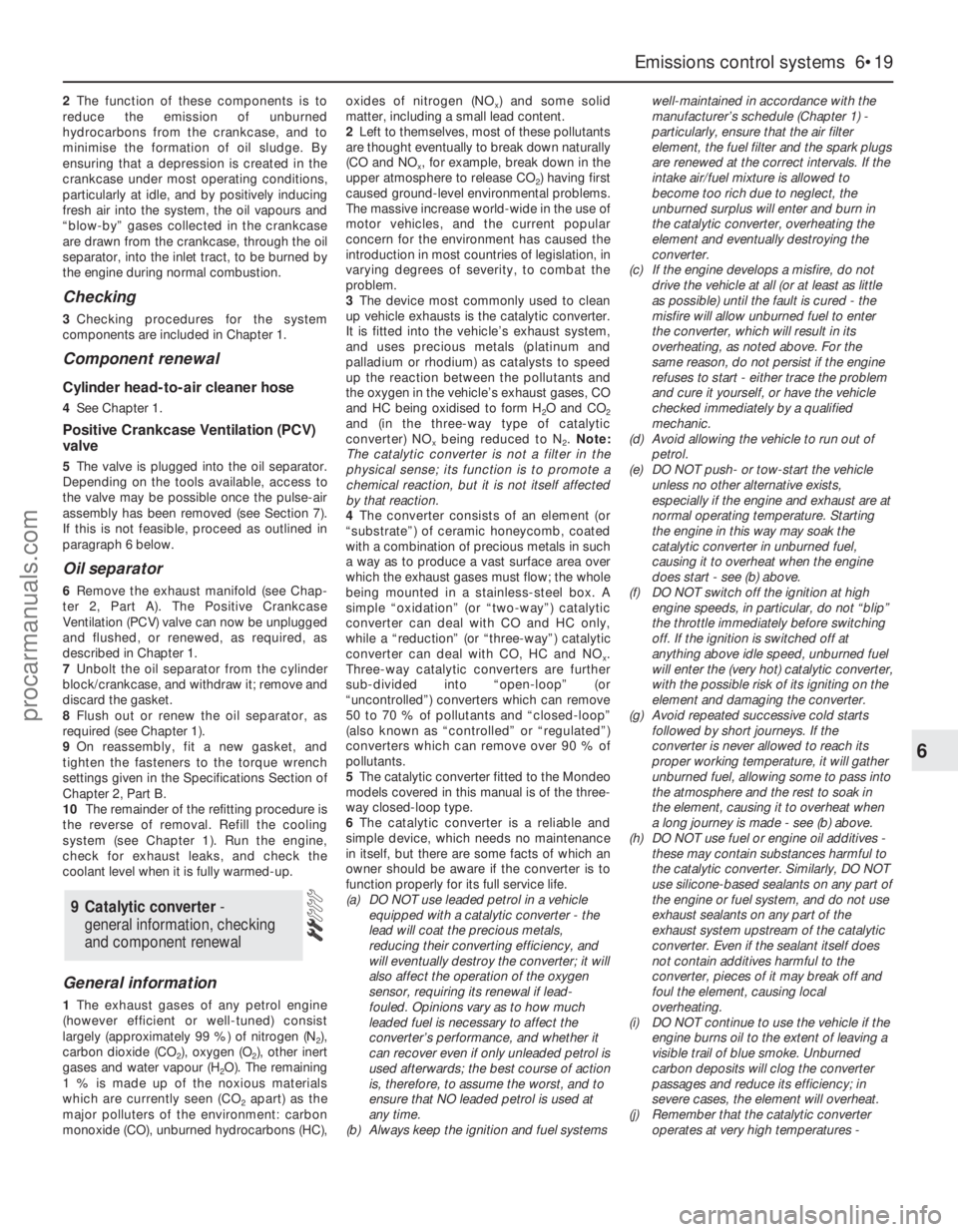

Specifications

Engine

Direction of crankshaft rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clockwise (seen from right-hand side of vehicle)

Oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C148

Cooling system

Coolant protection at 40% antifreeze/water mixture ratio:

Slush point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -25°C (-13°F)

Solidifying point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -30°C (-22°F)

Coolant specific gravity at 40% antifreeze/water mixture ratio and

15°C/59°F - with no other additives in coolant . . . . . . . . . . . . . . . . . . . . 1.061

Fuel system

Idle speed - nominal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 830 ± 50 rpm*

Air filter element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion U618

Fuel filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion L218

* Note: Given for reference only - not adjustable.

Ignition system

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-4-2 (No 1 cylinder at timing belt end of engine)

Spark plugs:*

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion RE7YCC

Electrode gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 mm

Spark plug (HT) leads:

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion type not available

Maximum resistance per lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 000 ohms

* Information on spark plug types and electrode gaps is as recommended by Champion Spark Plug. Where alternative types are used, refer to

their manufacturer’s recommendations

Braking system

Note: No minimum lining thicknesses are given by Ford - the following is given as a general recommendation. If the pad wear warning light

comes on before the front brake pad linings reach the minimum thickness, the pads should nevertheless be renewed immediately.

Minimum front or rear brake pad lining thickness . . . . . . . . . . . . . . . . . 1.5 mm

Minimum rear brake shoe lining thickness . . . . . . . . . . . . . . . . . . . . . . . 1.0 mm

Suspension and steering

Tyre pressures (cold):Front Rear

Normally laden* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 bars (31 psi) 2.1 bars (31 psi)

Fully laden* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.4 bars (35 psi) 2.8 bars (41 psi)

Note: Normally laden means up to 3 persons. For sustained high speeds above 100 mph (160 km/h), increased pressures are necessary.

Consult the driver’s handbook supplied with the vehicle.

Wiper blades

Windscreen:

Driver’s side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X 5303 (and SP 01 spoiler)

Passenger’s side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X 5103

Tailgate:

Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X 5103

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion type not available

Torque wrench settingsNm lbf ft

Auxiliary drivebelt cover fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 to 10 4 to 7

Auxiliary drivebelt automatic tensioner Torx screws . . . . . . . . . . . . . . . . 23 17

Engine oil drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 18

Manual transmission filler/level plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 26

Radiator undershield screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 5

Spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 11

procarmanuals.com

Page 107 of 279

into the inlet ports, just above the inlet valves,

by four fuel injectors. The system also

includes features such as the flushing of fresh

(ie, cold) fuel around each injector on start-up,

thus improving hot starts.

The amount of fuel supplied by the injectors

is precisely controlled by an Electronic

Control Unit (ECU). The ECU uses the signals

derived from the engine speed/crankshaft

position sensor and the camshaft position

sensor, to trigger each injector separately in

cylinder firing order (sequential injection), with

benefits in terms of better fuel economy and

lower exhaust emissions.

Air induction system

The air system consists of an air filter

housing, an air mass meter, an intake

resonator and plenum chamber, and a throttle

housing. The air mass meter is an information-

gathering device for the ECU; it uses a “hot-

wire” system to send the ECU a constantly-

varying (analogue) voltage signal

corresponding to the volume of air passing

into the engine. Another sensor in the air mass

meter measures intake air temperature. The

ECU uses these signals to calculate the mass

of air entering the engine.

The throttle valve inside the throttle housing

is controlled by the driver, through the

accelerator pedal. As the valve opens, the

amount of air that can pass through the

system increases. The throttle potentiometer

opens further, the air mass meter’s signal

alters, and the ECU opens each injector for a

longer duration, to increase the amount of fuel

delivered to the inlet ports.

Electronic control system

The ECU controls the fuel injection system,

as well as the other sub-systems which make

up the entire engine management system. It

receives signals from a number of information

sensors, which monitor such variables as

intake air mass and temperature, coolant

temperature, engine speed and position,

acceleration/deceleration, and exhaust gas

oxygen content. These signals help the ECU

determine the injection duration necessary for

the optimum air/fuel ratio. These sensors and

associated ECU-controlled relays are located

throughout the engine compartment. For

further information regarding the ECU and its

control of the engine management system,

see Chapter 6.

Idle speed and mixture

adjustment - general

Both the idle speed and mixture are under

the control of the ECU, and cannot be

adjusted. Not only can they not be adjusted,

they cannot even be checked, except with the

use of special diagnostic equipment (see

Chapter 6) - this makes it a task for a Ford

dealer service department. Do notattempt to

“adjust” these settings in any way without

such equipment.

If the idle speed and mixture are thought tobe incorrect, take the vehicle to a Ford dealer

for the complete system to be tested.

On models equipped with a heated

windscreen, an idle-increase solenoid valve is

fitted, which raises the idle speed to

compensate for the increased load on the

engine when the heated windscreen is

switched on. When the valve is open, air from

the plenum chamber bypasses the throttle

housing and idle speed control valve, passing

directly into the inlet manifold through the

union on its left-hand end. The system is

active only for the four minutes that the

heated windscreen circuit is live, and is

supplementary to the main (ECU-controlled)

idle speed regulation.

Warning: Petrol is extremely

flammable, so extra precautions

must be taken when working on

any part of the fuel system. Do

not smoke, or allow open flames or bare

light bulbs, near the work area. Don’t work

in a garage if a natural gas-type appliance

with a pilot light is present. While

performing any work on the fuel system,

wear safety glasses, and have a dry

chemical (Class B) fire extinguisher on

hand. If you spill any fuel on your skin,

rinse it off immediately with soap and

water.

Note: This is an initial check of the fuel delivery

and air induction sub-systems of the engine

management system, to be carried out in

conjunction with the operational check of the

fuel pump (see Section 8), and as part of the

preliminary checks of the complete engine

management system (see Section 3 of

Chapter 6).

1Check the earth wire connections for

tightness. Check all wiring and electrical

connectors that are related to the system.

Loose electrical connectors and poor earths

can cause many problems that resemble

more serious malfunctions.

2Check to see that the battery is fully-

charged. The ECU and sensors depend on an

accurate supply voltage to properly meter the

fuel.

3Check the air filter element - a dirty or

partially-blocked filter will severely impede

performance and economy (see Chapter 1).

4If a blown fuse is found, renew it and see if

it blows again. If it does, search for a short-

circuited wire in the harness related to the

system (see Chapter 6).

5Check the air intake duct from the intake to

the inlet manifold for leaks, which will result in

an excessively-lean mixture. Also check the

condition of the vacuum hoses connected to

the inlet manifold.

6Remove the plenum chamber from the

throttle housing. Check the throttle valve for

dirt, carbon or other residue build-up. If it’sdirty, seek the advice of a Ford dealer - since

the electronic control system is designed to

compensate for factors such as the build-up

of dirt in the throttle housing, it may well be

best to leave it dirty, unless the deposits are

extensive. Note: A warning label on the

housing states specifically that the housing

bore and the throttle valve have a special

coating, and must not be cleaned using

carburettor cleaner, as this may damage it.

7With the engine running, place a

screwdriver or a stethoscope against each

injector, one at a time. Listen through the

screwdriver handle or stethoscope for a

clicking sound, indicating operation.

8If an injector isn’t operating (or sounds

different from the others), turn off the engine,

and unplug the electrical connector from the

injector. Check the resistance across the

terminals of the injector, and compare your

reading with the resistance value listed in this

Chapter’s Specifications. If the resistance

isn’t as specified, renew the injector.

9A rough idle, diminished performance

and/or increased fuel consumption could also

be caused by clogged or fouled fuel injectors.

Fuel additives that can sometimes clean

fouled injectors are available at car accessory

shops.

10The remainder of the system checks

should be left to a dealer service department

or other qualified repair specialist, as there is

a chance that the ECU may be damaged if

tests are not performed properly.

Warning: The fuel system

pressure must be released before

any part of the system is

disturbed - see Section 2. Petrol

is extremely flammable, so take extra

precautions when you work on any part of

the fuel system. Don’t smoke, or allow

open flames or bare light bulbs, near the

work area. Don’t work in a garage where a

natural gas-type appliance (such as a

water heater or clothes dryer) with a pilot

light is present. If you spill any fuel on your

skin, rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses,

and have a Class B type fire extinguisher

on hand.

Throttle housing

Check

1Remove the plenum chamber (see Sec-

tion 4), and verify that the throttle linkage

operates smoothly.

2If the housing bore and valve are dirty

enough for you to think that this might be the

cause of a fault, seek the advice of a Ford

dealer. Do notclean the housing (see the

notes in the checking procedure given in

Section 15).

16 Fuel system components-

check and renewal

15 Fuel injection system/engine

management system - check

Fuel and exhaust systems 4•9

4

procarmanuals.com

Page 153 of 279

2The function of these components is to

reduce the emission of unburned

hydrocarbons from the crankcase, and to

minimise the formation of oil sludge. By

ensuring that a depression is created in the

crankcase under most operating conditions,

particularly at idle, and by positively inducing

fresh air into the system, the oil vapours and

“blow-by” gases collected in the crankcase

are drawn from the crankcase, through the oil

separator, into the inlet tract, to be burned by

the engine during normal combustion.

Checking

3Checking procedures for the system

components are included in Chapter 1.

Component renewal

Cylinder head-to-air cleaner hose

4See Chapter 1.

Positive Crankcase Ventilation (PCV)

valve

5The valve is plugged into the oil separator.

Depending on the tools available, access to

the valve may be possible once the pulse-air

assembly has been removed (see Section 7).

If this is not feasible, proceed as outlined in

paragraph 6 below.

Oil separator

6Remove the exhaust manifold (see Chap-

ter 2, Part A). The Positive Crankcase

Ventilation (PCV) valve can now be unplugged

and flushed, or renewed, as required, as

described in Chapter 1.

7Unbolt the oil separator from the cylinder

block/crankcase, and withdraw it; remove and

discard the gasket.

8Flush out or renew the oil separator, as

required (see Chapter 1).

9On reassembly, fit a new gasket, and

tighten the fasteners to the torque wrench

settings given in the Specifications Section of

Chapter 2, Part B.

10The remainder of the refitting procedure is

the reverse of removal. Refill the cooling

system (see Chapter 1). Run the engine,

check for exhaust leaks, and check the

coolant level when it is fully warmed-up.

General information

1The exhaust gases of any petrol engine

(however efficient or well-tuned) consist

largely (approximately 99 %) of nitrogen (N

2),

carbon dioxide (CO

2), oxygen (O2), other inert

gases and water vapour (H

2O). The remaining

1 % is made up of the noxious materials

which are currently seen (CO

2apart) as the

major polluters of the environment: carbon

monoxide (CO), unburned hydrocarbons (HC),oxides of nitrogen (NO

x) and some solid

matter, including a small lead content.

2Left to themselves, most of these pollutants

are thought eventually to break down naturally

(CO and NO

x, for example, break down in the

upper atmosphere to release CO

2) having first

caused ground-level environmental problems.

The massive increase world-wide in the use of

motor vehicles, and the current popular

concern for the environment has caused the

introduction in most countries of legislation, in

varying degrees of severity, to combat the

problem.

3The device most commonly used to clean

up vehicle exhausts is the catalytic converter.

It is fitted into the vehicle’s exhaust system,

and uses precious metals (platinum and

palladium or rhodium) as catalysts to speed

up the reaction between the pollutants and

the oxygen in the vehicle’s exhaust gases, CO

and HC being oxidised to form H

2O and CO2and (in the three-way type of catalytic

converter) NO

xbeing reduced to N2. Note:

The catalytic converter is not a filter in the

physical sense; its function is to promote a

chemical reaction, but it is not itself affected

by that reaction.

4The converter consists of an element (or

“substrate”) of ceramic honeycomb, coated

with a combination of precious metals in such

a way as to produce a vast surface area over

which the exhaust gases must flow; the whole

being mounted in a stainless-steel box. A

simple “oxidation” (or “two-way”) catalytic

converter can deal with CO and HC only,

while a “reduction” (or “three-way”) catalytic

converter can deal with CO, HC and NO

x.

Three-way catalytic converters are further

sub-divided into “open-loop” (or

“uncontrolled”) converters which can remove

50 to 70 % of pollutants and “closed-loop”

(also known as “controlled” or “regulated”)

converters which can remove over 90 % of

pollutants.

5The catalytic converter fitted to the Mondeo

models covered in this manual is of the three-

way closed-loop type.

6The catalytic converter is a reliable and

simple device, which needs no maintenance

in itself, but there are some facts of which an

owner should be aware if the converter is to

function properly for its full service life.

(a) DO NOT use leaded petrol in a vehicle

equipped with a catalytic converter - the

lead will coat the precious metals,

reducing their converting efficiency, and

will eventually destroy the converter; it will

also affect the operation of the oxygen

sensor, requiring its renewal if lead-

fouled. Opinions vary as to how much

leaded fuel is necessary to affect the

converter’s performance, and whether it

can recover even if only unleaded petrol is

used afterwards; the best course of action

is, therefore, to assume the worst, and to

ensure that NO leaded petrol is used at

any time.

(b) Always keep the ignition and fuel systemswell-maintained in accordance with the

manufacturer’s schedule (Chapter 1) -

particularly, ensure that the air filter

element, the fuel filter and the spark plugs

are renewed at the correct intervals. If the

intake air/fuel mixture is allowed to

become too rich due to neglect, the

unburned surplus will enter and burn in

the catalytic converter, overheating the

element and eventually destroying the

converter.

(c) If the engine develops a misfire, do not

drive the vehicle at all (or at least as little

as possible) until the fault is cured - the

misfire will allow unburned fuel to enter

the converter, which will result in its

overheating, as noted above. For the

same reason, do not persist if the engine

refuses to start - either trace the problem

and cure it yourself, or have the vehicle

checked immediately by a qualified

mechanic.

(d) Avoid allowing the vehicle to run out of

petrol.

(e) DO NOT push- or tow-start the vehicle

unless no other alternative exists,

especially if the engine and exhaust are at

normal operating temperature. Starting

the engine in this way may soak the

catalytic converter in unburned fuel,

causing it to overheat when the engine

does start - see (b) above.

(f) DO NOT switch off the ignition at high

engine speeds, in particular, do not “blip”

the throttle immediately before switching

off. If the ignition is switched off at

anything above idle speed, unburned fuel

will enter the (very hot) catalytic converter,

with the possible risk of its igniting on the

element and damaging the converter.

(g) Avoid repeated successive cold starts

followed by short journeys. If the

converter is never allowed to reach its

proper working temperature, it will gather

unburned fuel, allowing some to pass into

the atmosphere and the rest to soak in

the element, causing it to overheat when

a long journey is made - see (b) above.

(h) DO NOT use fuel or engine oil additives -

these may contain substances harmful to

the catalytic converter. Similarly, DO NOT

use silicone-based sealants on any part of

the engine or fuel system, and do not use

exhaust sealants on any part of the

exhaust system upstream of the catalytic

converter. Even if the sealant itself does

not contain additives harmful to the

converter, pieces of it may break off and

foul the element, causing local

overheating.

(i) DO NOT continue to use the vehicle if the

engine burns oil to the extent of leaving a

visible trail of blue smoke. Unburned

carbon deposits will clog the converter

passages and reduce its efficiency; in

severe cases, the element will overheat.

(j) Remember that the catalytic converter

operates at very high temperatures -

9 Catalytic converter -

general information, checking

and component renewal

Emissions control systems 6•19

6

procarmanuals.com