brake FORD MUSTANG 1998 4.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1998, Model line: MUSTANG, Model: FORD MUSTANG 1998 4.GPages: 192, PDF Size: 1.67 MB

Page 55 of 192

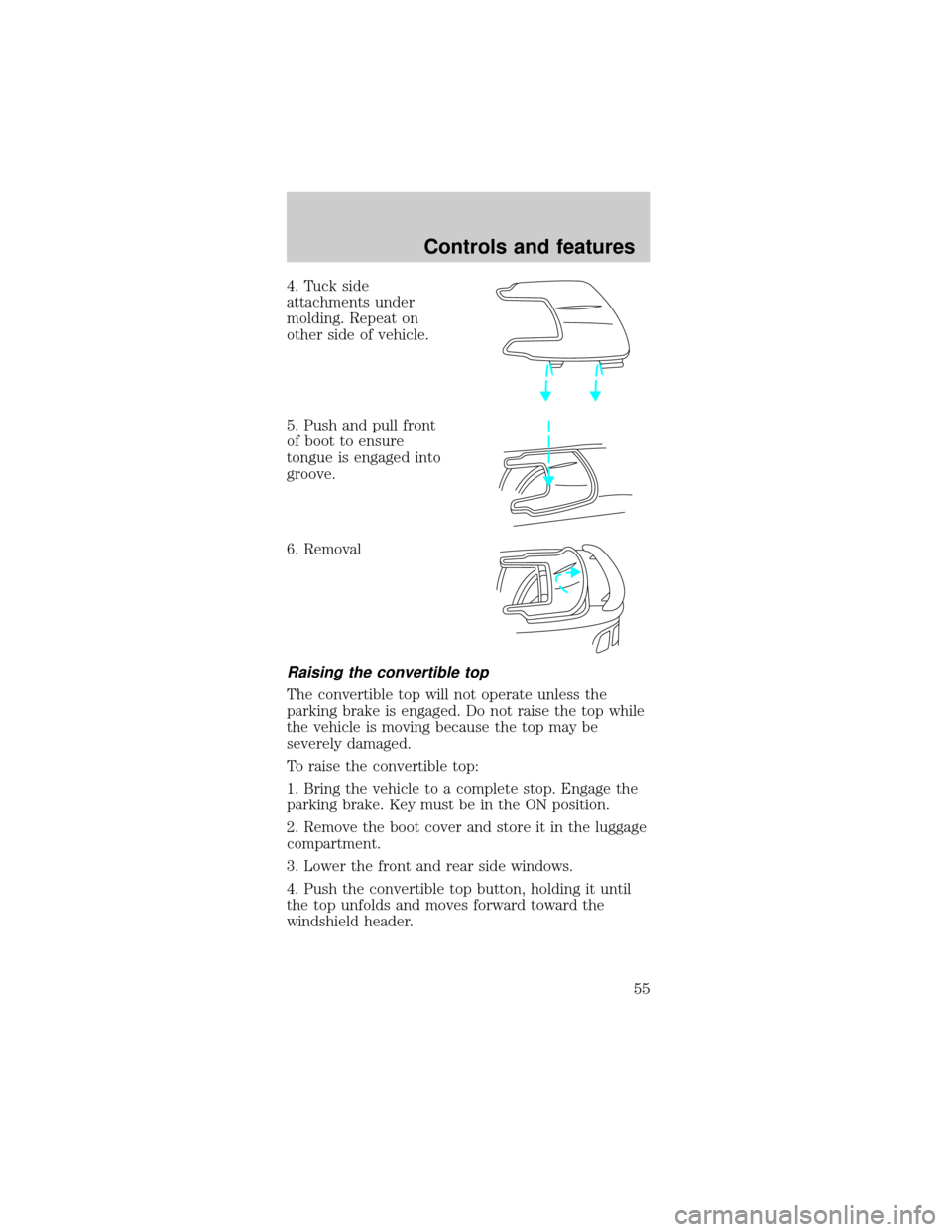

4. Tuck side

attachments under

molding. Repeat on

other side of vehicle.

5. Push and pull front

of boot to ensure

tongue is engaged into

groove.

6. Removal

Raising the convertible top

The convertible top will not operate unless the

parking brake is engaged. Do not raise the top while

the vehicle is moving because the top may be

severely damaged.

To raise the convertible top:

1. Bring the vehicle to a complete stop. Engage the

parking brake. Key must be in the ON position.

2. Remove the boot cover and store it in the luggage

compartment.

3. Lower the front and rear side windows.

4. Push the convertible top button, holding it until

the top unfolds and moves forward toward the

windshield header.

Controls and features

55

Page 56 of 192

5. Open both top clamps before the top meets the

windshield header

6. Continue to use the top motor to raise the top

until it has reached the fully closed position flush to

the header.

7. The two pins under the forward edge of the top

should seat themselves in the matching holes in the

header.

8. To fasten both clamps securely, push the clamp

handles into the header on the top until they are

flush with the header. Pulling down on the header at

the center grip while closing the latches may assist

in fastening the clamps.

9. Raise the front and rear side windows.

10. Disengage the parking brake.

REMOTE ENTRY SYSTEM

The remote entry system allows you to:

²lock or unlock all vehicle doors without a key.

²open the trunk.

²activate the panic alarm.

²confirms that the vehicle is locked with a short

ªbeepº from the horn.

The remote entry features only operate with the

ignition in the OFF position.

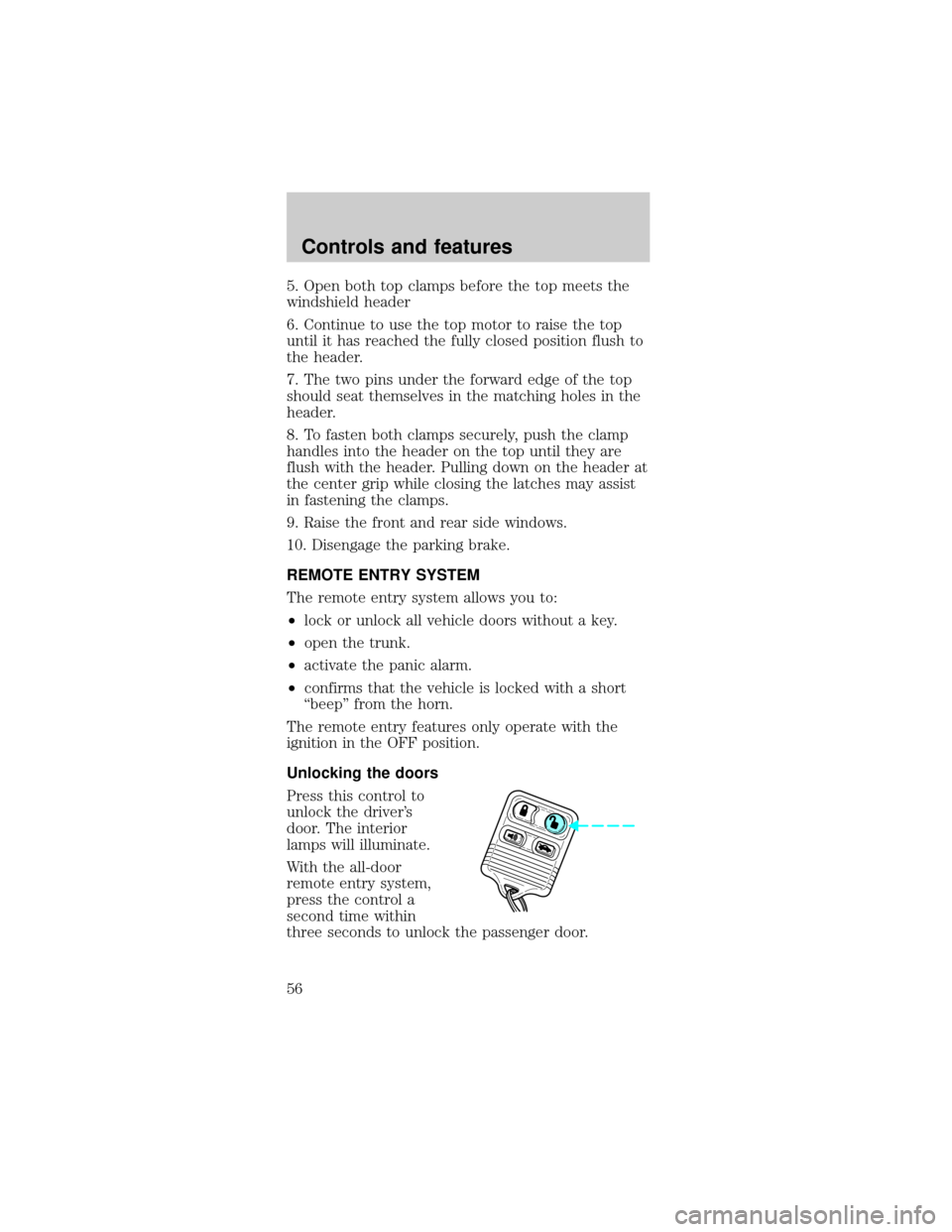

Unlocking the doors

Press this control to

unlock the driver's

door. The interior

lamps will illuminate.

With the all-door

remote entry system,

press the control a

second time within

three seconds to unlock the passenger door.

Controls and features

56

Page 68 of 192

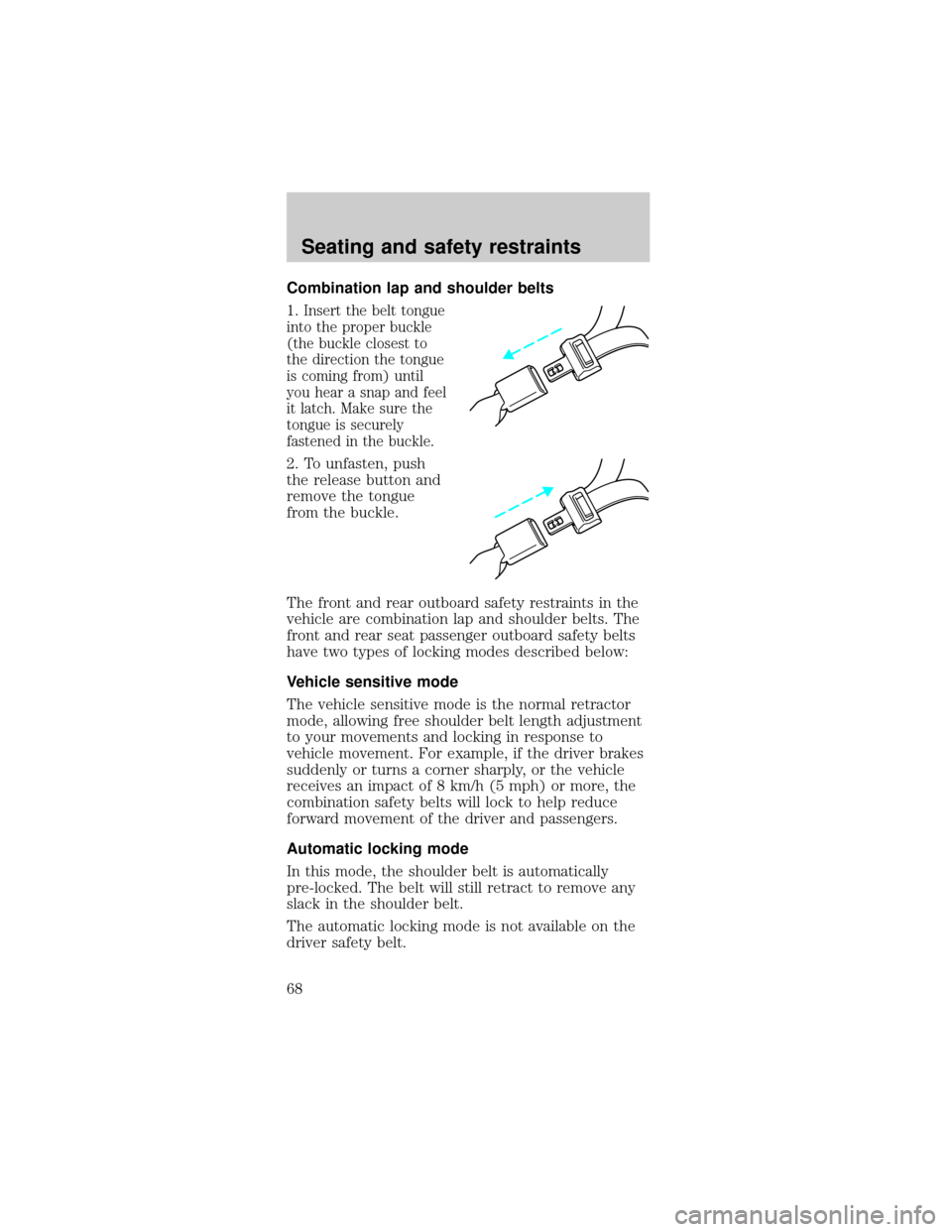

Combination lap and shoulder belts

1.

Insert the belt tongue

into the proper buckle

(the buckle closest to

the direction the tongue

is coming from) until

you hear a snap and feel

it latch. Make sure the

tongue is securely

fastened in the buckle.

2. To unfasten, push

the release button and

remove the tongue

from the buckle.

The front and rear outboard safety restraints in the

vehicle are combination lap and shoulder belts. The

front and rear seat passenger outboard safety belts

have two types of locking modes described below:

Vehicle sensitive mode

The vehicle sensitive mode is the normal retractor

mode, allowing free shoulder belt length adjustment

to your movements and locking in response to

vehicle movement. For example, if the driver brakes

suddenly or turns a corner sharply, or the vehicle

receives an impact of 8 km/h (5 mph) or more, the

combination safety belts will lock to help reduce

forward movement of the driver and passengers.

Automatic locking mode

In this mode, the shoulder belt is automatically

pre-locked. The belt will still retract to remove any

slack in the shoulder belt.

The automatic locking mode is not available on the

driver safety belt.

Seating and safety restraints

68

Page 84 of 192

Important safety precautions

A computer system controls the engine's idle

revolutions per minute (RPM). When the engine

starts, the idle RPM runs faster to warm the engine.

If the engine idle speed does not slow down

automatically, have the vehicle checked. Do not

allow the vehicle to idle for more than ten minutes

at high engine RPM.

Before starting the vehicle:

1. Make sure all vehicle occupants have buckled

their safety belts. For more information on safety

belts and their proper usage, refer to theSeating

and safety restraintschapter.

2. Make sure the headlamps and vehicle accessories

are off.

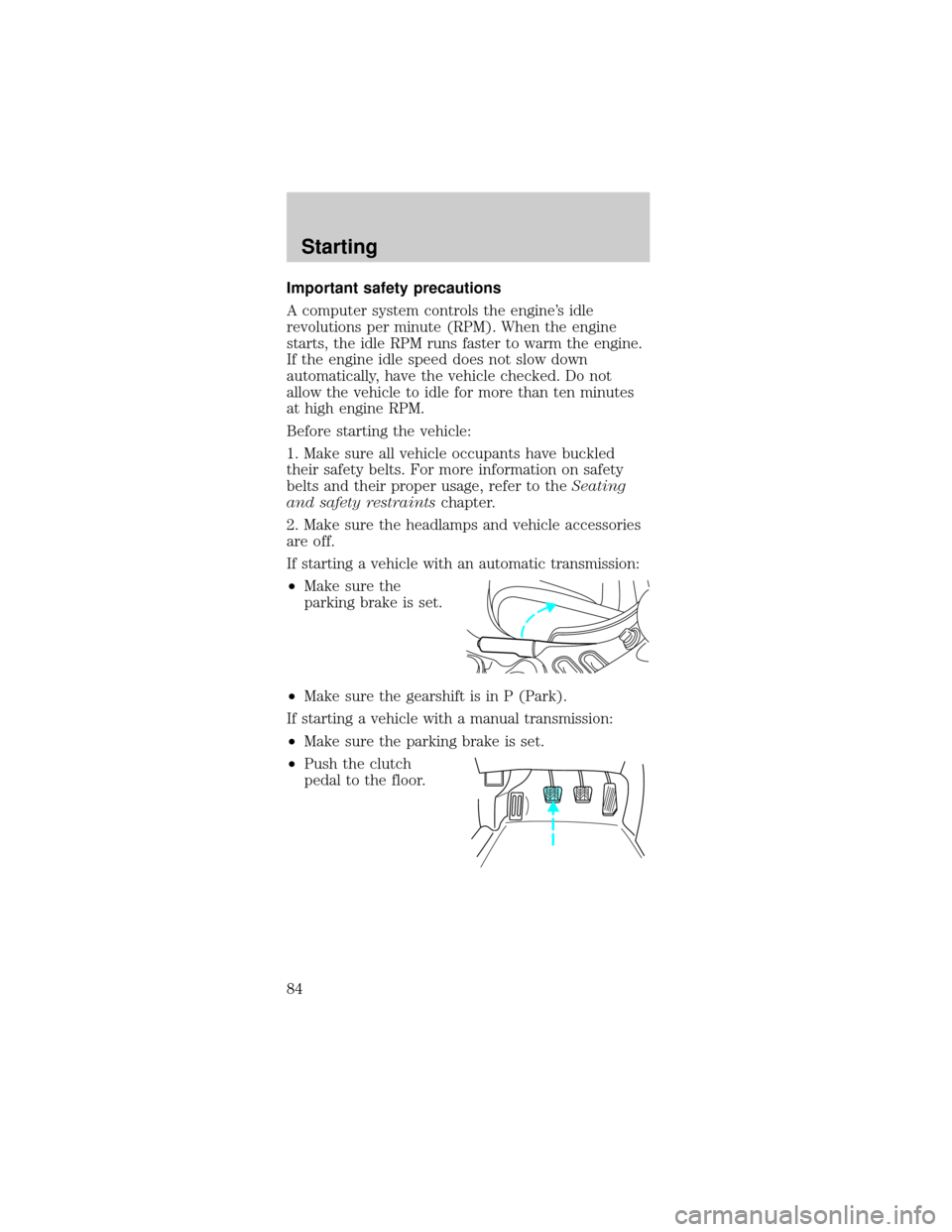

If starting a vehicle with an automatic transmission:

²Make sure the

parking brake is set.

²Make sure the gearshift is in P (Park).

If starting a vehicle with a manual transmission:

²Make sure the parking brake is set.

²Push the clutch

pedal to the floor.

Starting

84

Page 85 of 192

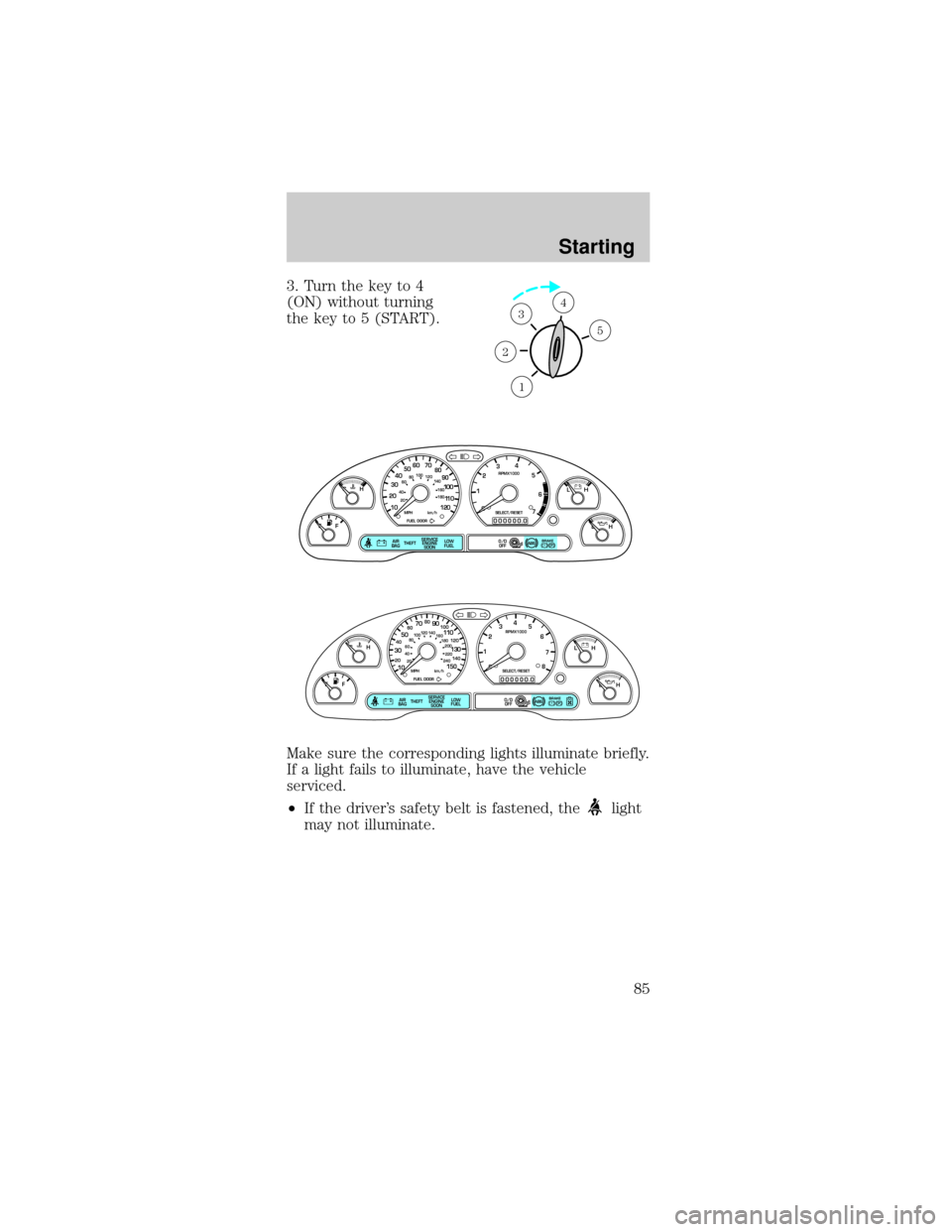

3. Turn the key to 4

(ON) without turning

the key to 5 (START).

Make sure the corresponding lights illuminate briefly.

If a light fails to illuminate, have the vehicle

serviced.

²If the driver's safety belt is fastened, the

light

may not illuminate.

1

2

34

5

P! BRAKE

L

0

00000 00

C

E

FH

LH

10 203020 406080100

120

140

160

180

405060 70

80

90

100

11 0

1204

5

6

7 3

2

1

H

THEFT

RPMX1000

FUEL DOORSELECT/RESET

LOW

FUELO/D

OFF AIR

BAGSERVICE

ENGINE

SOON

MPH km/h

ABS

.

P! BRAKE

L

0

00000 00

C

E

FH

LH

102040608020 40608010 012 0 14 0

160

180

200

220

240

100

120

140

305070 90

110

13 0

1504

5

6

7

8 3

2

1

H

THEFT

RPMX1000

FUEL DOORSELECT/RESET

LOW

FUELO/D

OFF AIR

BAGSERVICE

ENGINE

SOON

MPH km/h

ABS

.

Starting

85

Page 86 of 192

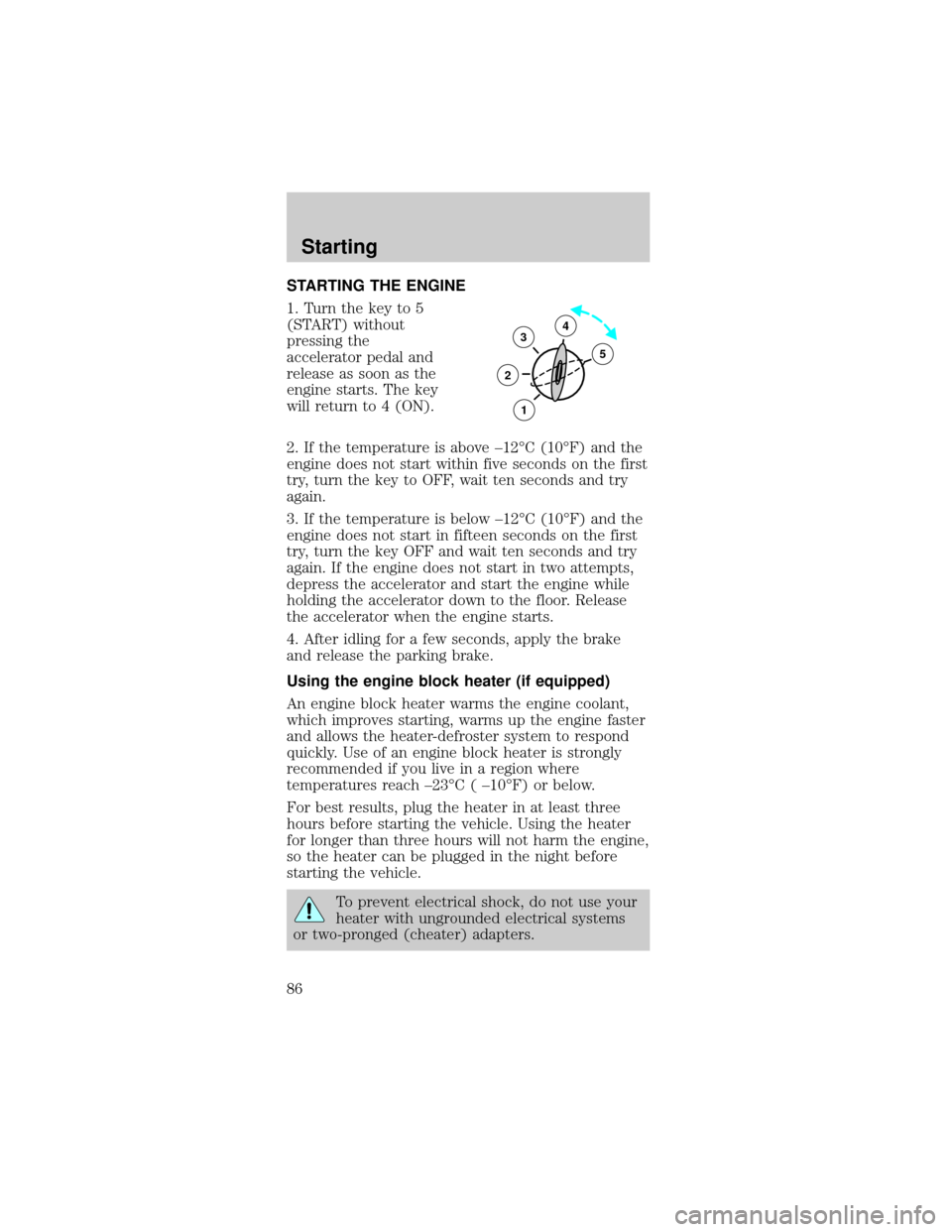

STARTING THE ENGINE

1. Turn the key to 5

(START) without

pressing the

accelerator pedal and

release as soon as the

engine starts. The key

will return to 4 (ON).

2. If the temperature is above ±12ÉC (10ÉF) and the

engine does not start within five seconds on the first

try, turn the key to OFF, wait ten seconds and try

again.

3. If the temperature is below ±12ÉC (10ÉF) and the

engine does not start in fifteen seconds on the first

try, turn the key OFF and wait ten seconds and try

again. If the engine does not start in two attempts,

depress the accelerator and start the engine while

holding the accelerator down to the floor. Release

the accelerator when the engine starts.

4. After idling for a few seconds, apply the brake

and release the parking brake.

Using the engine block heater (if equipped)

An engine block heater warms the engine coolant,

which improves starting, warms up the engine faster

and allows the heater-defroster system to respond

quickly. Use of an engine block heater is strongly

recommended if you live in a region where

temperatures reach ±23ÉC ( ±10ÉF) or below.

For best results, plug the heater in at least three

hours before starting the vehicle. Using the heater

for longer than three hours will not harm the engine,

so the heater can be plugged in the night before

starting the vehicle.

To prevent electrical shock, do not use your

heater with ungrounded electrical systems

or two-pronged (cheater) adapters.

3

2

1

5

4

Starting

86

Page 88 of 192

BRAKES

Your service brakes are self-adjusting. Refer to the

scheduled maintenance guide for scheduled

maintenance.

Occasional brake noise is normal and often does not

indicate a performance concern with the vehicle's

brake system. In normal operation, automotive brake

systems may emit occasional or intermittent squeal

or groan noises when the brakes are applied. Such

noises are usually heard during the first few brake

applications in the morning; however, they may be

heard at any time while braking and can be

aggravated by environmental conditions such as

cold, heat, moisture, road dust, salt or mud. If a

ªmetal-to-metal,º ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking,

the brake linings may be worn-out and should be

inspected by a qualified service technician.

Anti-lock brake system (ABS) (if equipped)

On vehicles equipped with an anti-lock braking

system (ABS), a noise from the hydraulic pump

motor and pulsation in the pedal may be observed

during ABS braking events. Pedal pulsation coupled

with noise while braking under panic conditions or

on loose gravel, bumps, wet or snowy roads is

normal and indicates proper functioning of the

vehicle's anti-lock brake system. The ABS performs a

self-check at 17 km/h (10 mph) after you start the

engine and begin to drive away. A brief mechanical

noise may be heard during this test. This is normal.

If a malfunction is found, the ABS warning light will

come on. If the vehicle has continuous vibration or

shudder in the steering wheel while braking, the

vehicle should be inspected by a qualified service

technician.

Driving

88

Page 89 of 192

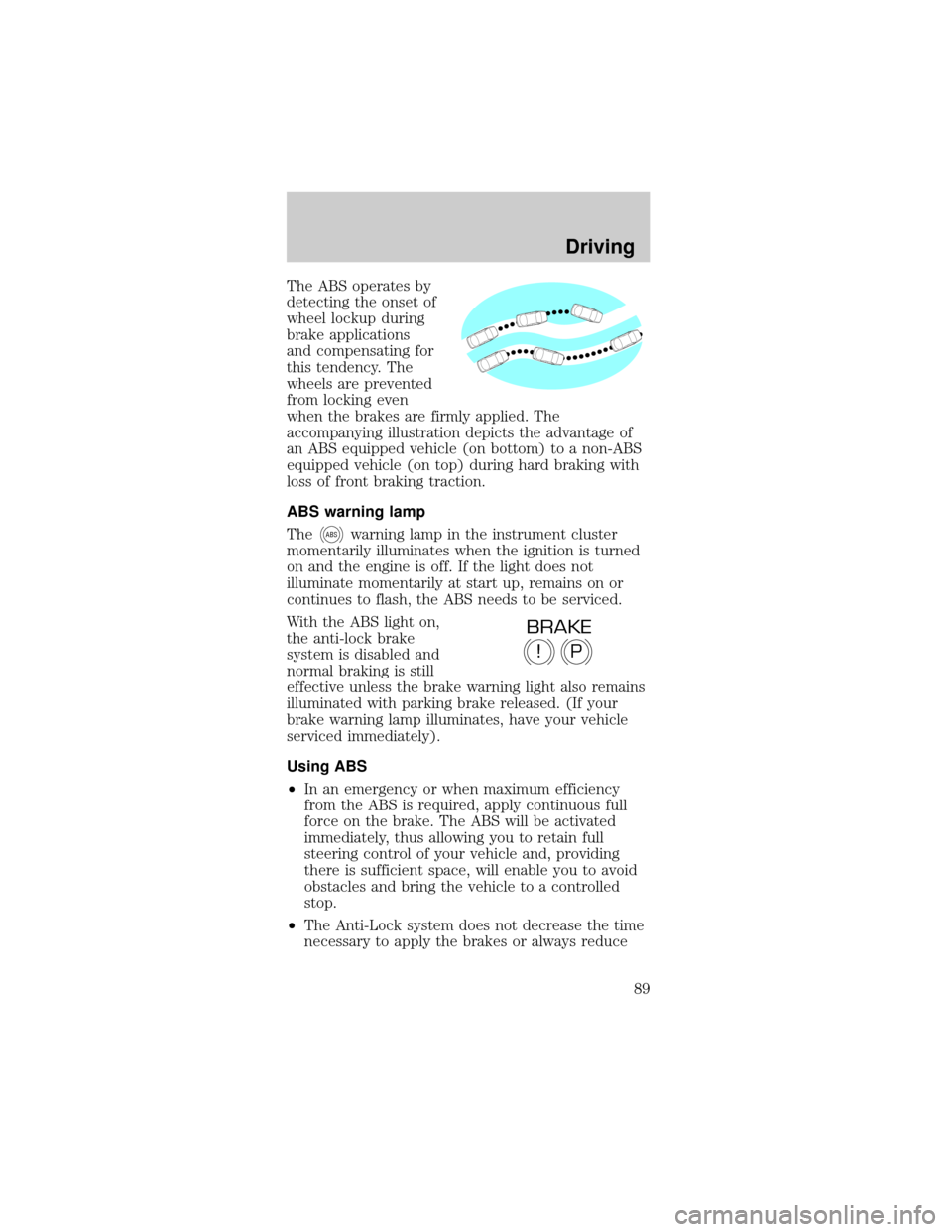

The ABS operates by

detecting the onset of

wheel lockup during

brake applications

and compensating for

this tendency. The

wheels are prevented

from locking even

when the brakes are firmly applied. The

accompanying illustration depicts the advantage of

an ABS equipped vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with

loss of front braking traction.

ABS warning lamp

The

ABSwarning lamp in the instrument cluster

momentarily illuminates when the ignition is turned

on and the engine is off. If the light does not

illuminate momentarily at start up, remains on or

continues to flash, the ABS needs to be serviced.

With the ABS light on,

the anti-lock brake

system is disabled and

normal braking is still

effective unless the brake warning light also remains

illuminated with parking brake released. (If your

brake warning lamp illuminates, have your vehicle

serviced immediately).

Using ABS

²In an emergency or when maximum efficiency

from the ABS is required, apply continuous full

force on the brake. The ABS will be activated

immediately, thus allowing you to retain full

steering control of your vehicle and, providing

there is sufficient space, will enable you to avoid

obstacles and bring the vehicle to a controlled

stop.

²The Anti-Lock system does not decrease the time

necessary to apply the brakes or always reduce

P!

BRAKE

Driving

89

Page 90 of 192

stopping distance. Always leave enough room

between your vehicle and the vehicle in front of

you to stop.

²We recommend that you familiarize yourself with

this braking technique. However, avoid taking any

unnecessary risks.

Hydraulic brake booster system (Hydroboost)

The Hydroboost system receives fluid pressure from

the power steering pump to provide power assist

during braking.

The sound of the pump operating may be heard by

the driver, but this is a normal characteristic of the

system.

For Hydroboost-equipped vehicles operating under

normal conditions, the noise of the fluid flowing

through the booster may be heard whenever the

brake is applied. This condition is normal. Vehicle

service is not required.

If braking performance or pedal response becomes

very poor, even when the pedal is strongly

depressed, it may indicate the presence of air in the

hydraulic system or leakage of fluid. Stop the vehicle

safely as soon as possible and seek service

immediately.

Parking brake

Apply the parking

brake whenever the

vehicle is parked. To

set the parking brake,

apply the brake pedal

and pull the handle up

as far as possible.

The BRAKE warning

lamp in the instrument

cluster illuminates and

remains illuminated

(when the ignition is turned ON) until the parking

brake is released.

P!

BRAKE

Driving

90

Page 91 of 192

The parking brake is not recommended to stop a

moving vehicle. However, if the normal brakes fail,

the parking brake can be used to stop your vehicle

in an emergency. Since the parking brake applies

only the rear brakes, the vehicle's stopping distance

will increase greatly and the handling of your vehicle

will be adversely affected.

Always set the parking brake fully and make

sure that the gearshift is securely latched in

P (Park) (automatic transmission) or in 1 (First)

(manual transmission).

Your brake handle may

need to be pulled up

slightly to release

pressure before

pushing in the button.

Push the button on the

end of the parking

brake and push the handle down as far as possible

to release the brake. Driving with the parking brake

on will cause the brakes to wear out quickly and

reduce fuel economy.

TRACTION CONTROLY(IF EQUIPPED)

Your vehicle may be equipped with the optional

Traction Controlysystem. This system helps you

maintain the stability and steerability of your

vehicle. It is especially useful on slippery and/or hilly

road surfaces. The system operates by detecting and

controlling wheel spin. The system borrows many of

the electronic and mechanical elements already

present in the anti-lock braking system (ABS).

Wheel-speed sensors allow excess rear wheel spin to

be detected by the Traction Controlyportion of the

ABS computer. Any excessive wheel spin is

controlled by automatically applying and releasing

the rear brakes in conjunction with engine torque

reductions. Engine torque reduction is realized via

Driving

91