clock FORD RANGER 2000 2.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2000, Model line: RANGER, Model: FORD RANGER 2000 2.GPages: 240, PDF Size: 2.07 MB

Page 152 of 240

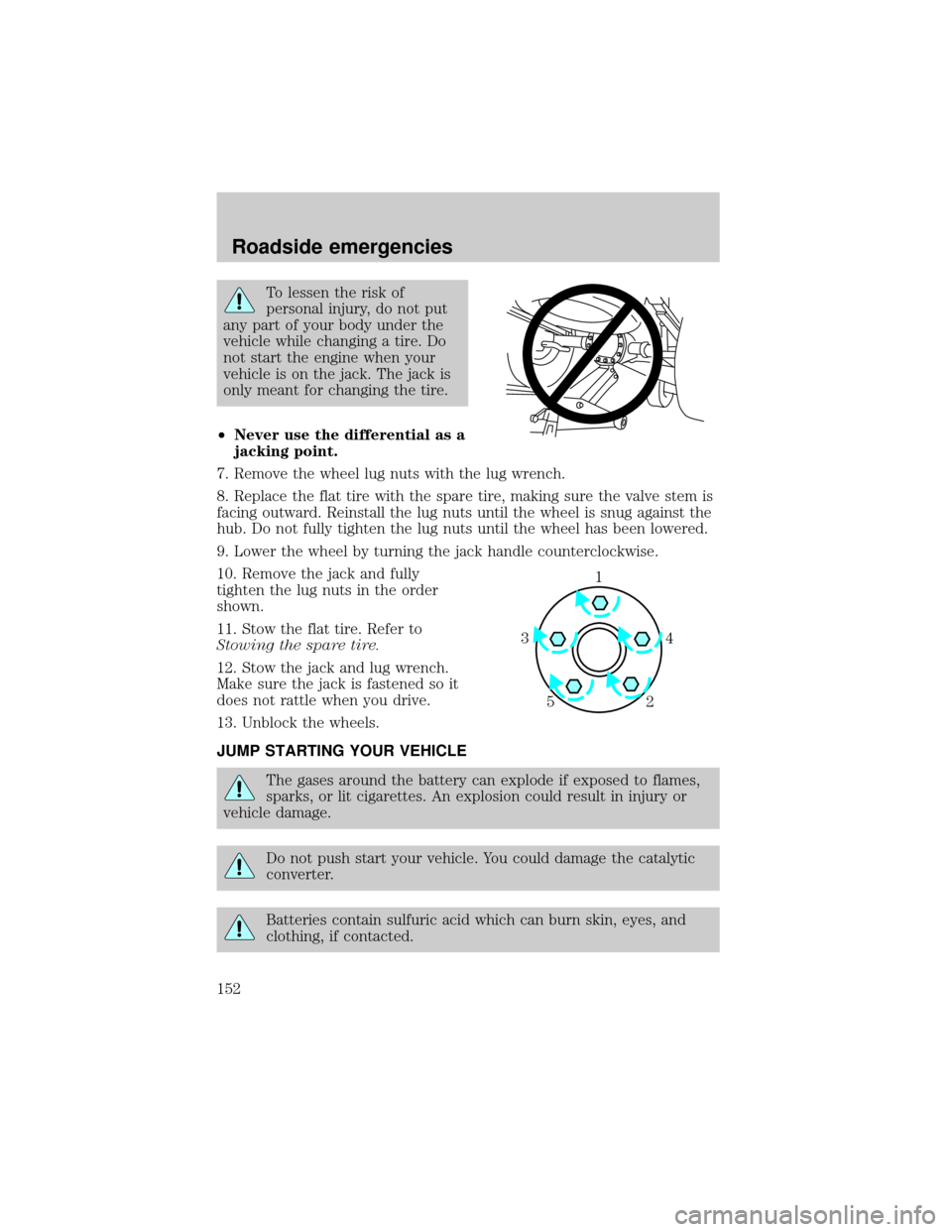

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

²Never use the differential as a

jacking point.

7. Remove the wheel lug nuts with the lug wrench.

8. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall the lug nuts until the wheel is snug against the

hub. Do not fully tighten the lug nuts until the wheel has been lowered.

9. Lower the wheel by turning the jack handle counterclockwise.

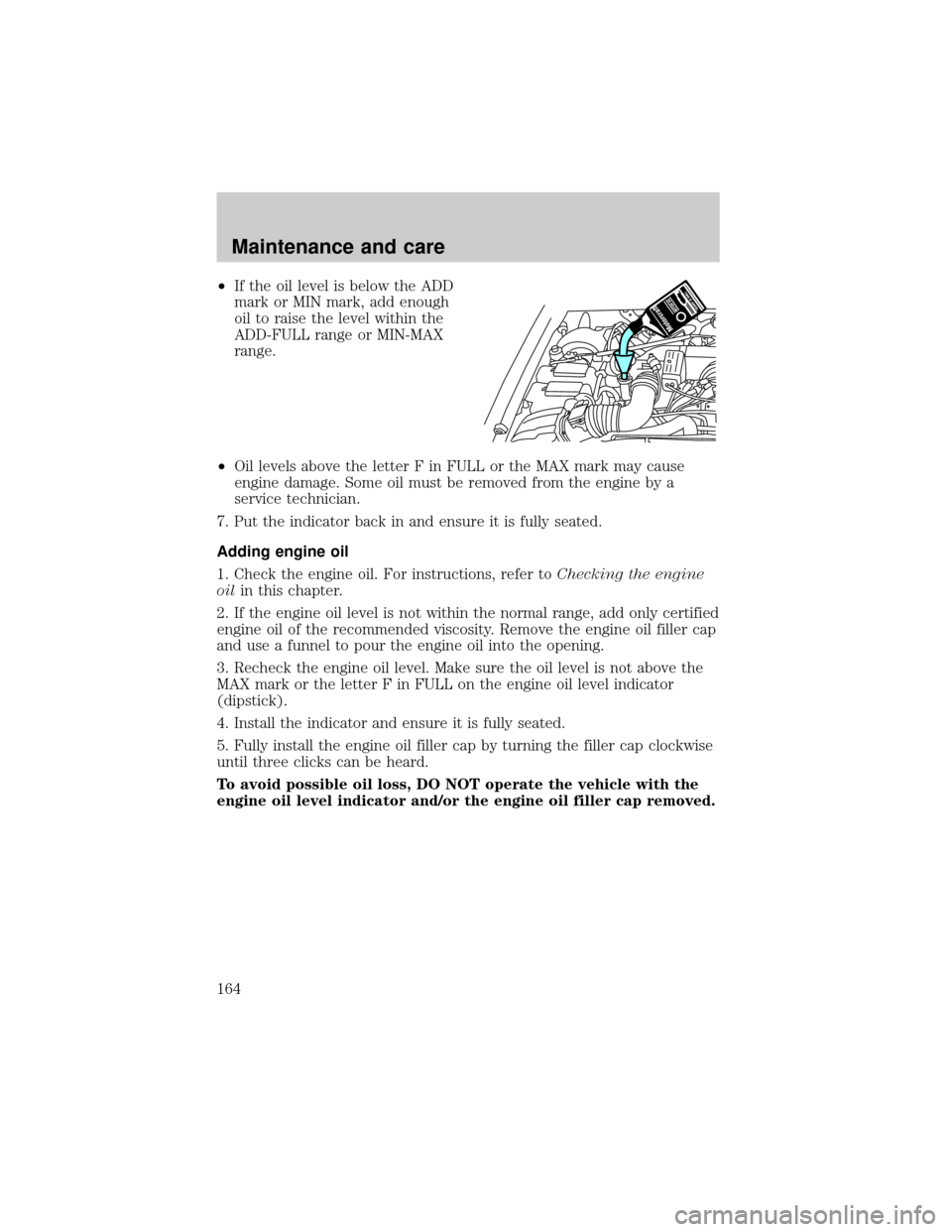

10. Remove the jack and fully

tighten the lug nuts in the order

shown.

11. Stow the flat tire. Refer to

Stowing the spare tire.

12. Stow the jack and lug wrench.

Make sure the jack is fastened so it

does not rattle when you drive.

13. Unblock the wheels.

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Do not push start your vehicle. You could damage the catalytic

converter.

Batteries contain sulfuric acid which can burn skin, eyes, and

clothing, if contacted.

1

4 3

2 5

Roadside emergencies

152

Page 164 of 240

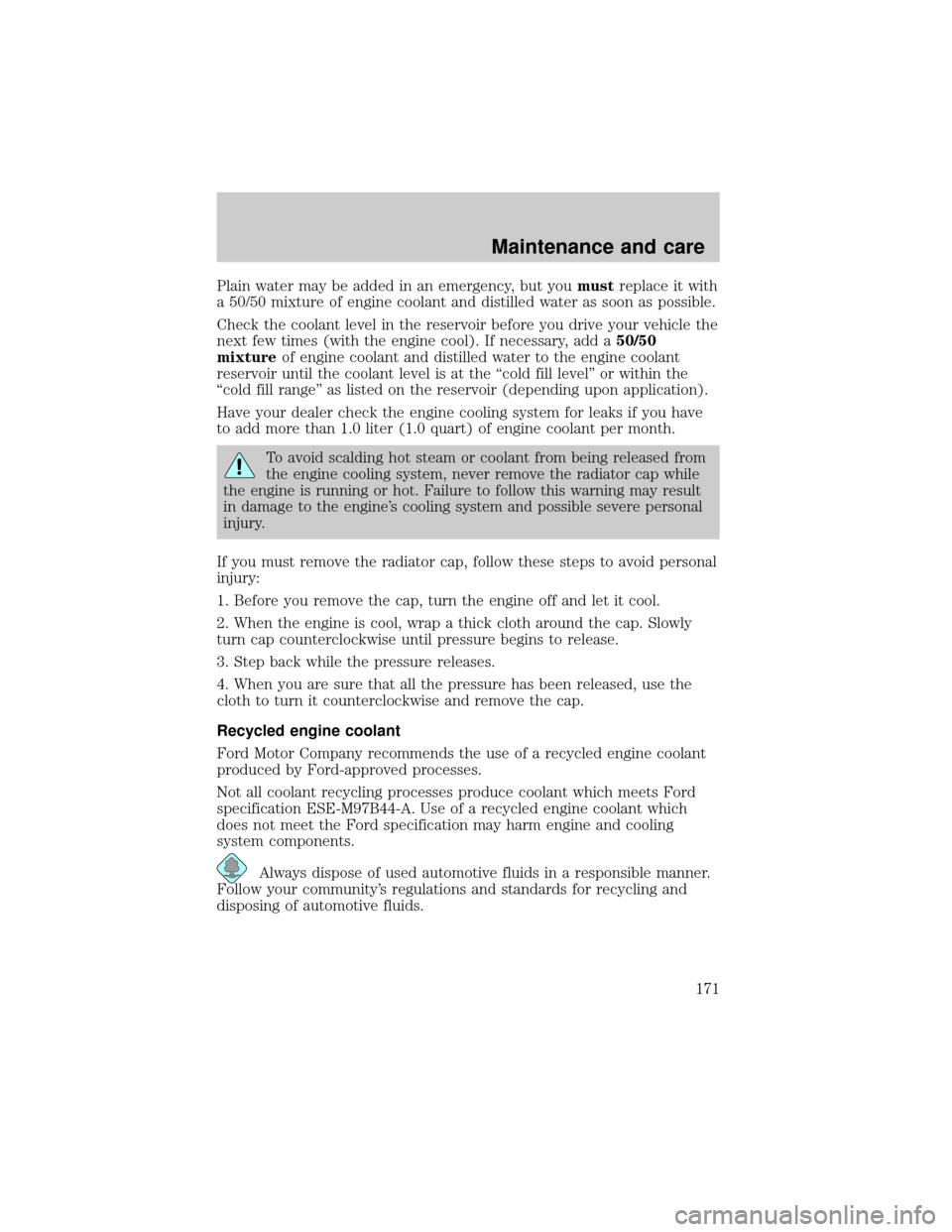

²If the oil level is below the ADD

mark or MIN mark, add enough

oil to raise the level within the

ADD-FULL range or MIN-MAX

range.

²Oil levels above the letter F in FULL or the MAX mark may cause

engine damage. Some oil must be removed from the engine by a

service technician.

7. Put the indicator back in and ensure it is fully seated.

Adding engine oil

1. Check the engine oil. For instructions, refer toChecking the engine

oilin this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

MAX mark or the letter F in FULL on the engine oil level indicator

(dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

until three clicks can be heard.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level indicator and/or the engine oil filler cap removed.

Maintenance and care

164

Page 171 of 240

Plain water may be added in an emergency, but youmustreplace it with

a 50/50 mixture of engine coolant and distilled water as soon as possible.

Check the coolant level in the reservoir before you drive your vehicle the

next few times (with the engine cool). If necessary, add a50/50

mixtureof engine coolant and distilled water to the engine coolant

reservoir until the coolant level is at the ªcold fill levelº or within the

ªcold fill rangeº as listed on the reservoir (depending upon application).

Have your dealer check the engine cooling system for leaks if you have

to add more than 1.0 liter (1.0 quart) of engine coolant per month.

To avoid scalding hot steam or coolant from being released from

the engine cooling system, never remove the radiator cap while

the engine is running or hot. Failure to follow this warning may result

in damage to the engine's cooling system and possible severe personal

injury.

If you must remove the radiator cap, follow these steps to avoid personal

injury:

1. Before you remove the cap, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the cap. Slowly

turn cap counterclockwise until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been released, use the

cloth to turn it counterclockwise and remove the cap.

Recycled engine coolant

Ford Motor Company recommends the use of a recycled engine coolant

produced by Ford-approved processes.

Not all coolant recycling processes produce coolant which meets Ford

specification ESE-M97B44-A. Use of a recycled engine coolant which

does not meet the Ford specification may harm engine and cooling

system components.

Always dispose of used automotive fluids in a responsible manner.

Follow your community's regulations and standards for recycling and

disposing of automotive fluids.

Maintenance and care

171

Page 180 of 240

²If you do not allow the engine to relearn its idle trim, the idle

quality of your vehicle may be adversely affected until the idle

trim is eventually relearned.

If the battery has been disconnected or a new battery has been installed,

the clock and the preset radio stations must be reset once the battery is

reconnected.

²Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

WINDSHIELD WIPER BLADES

Check the wiper blades at least twice a year or when they seem less

effective. Substances such as tree sap and some hot wax treatments used

by commercial car washes reduce the effectiveness of wiper blades.

Checking the wiper blades

If the wiper blades do not wipe properly, clean both the windshield and

wiper blades using undiluted windshield wiper solution or a mild

detergent. Rinse thoroughly with clean water. To avoid damaging the

blades, do not use fuel, kerosene, paint thinner or other solvents.

LEAD

RETURN

RECYCLE

Maintenance and care

180

Page 188 of 240

Ethanol is more chemically active than gasoline. It corrodes some metals

and causes some plastic and rubber components to swell, break down or

become brittle and crack, especially when mixed with gasoline. Special

materials and procedures have been developed for flexible fuel vehicles

and the dispensers used by ethanol fuel providers.

Flexible fuel components and standard unleaded gasoline fuel

components are not interchangeable. If your vehicle is not

serviced in accordance with flexible fuel vehicles procedures, damage

may occur and your warranty may be invalidated.

When refueling always shut the engine off and never allow

sparks or open flames near the filler neck. Never smoke while

refueling. Fuel vapor is extremely hazardous under certain conditions.

Care should be taken to avoid inhaling excess fumes.

The flow of fuel through a fuel pump nozzle can produce static

electricity, which can cause a fire if fuel is pumped into an

ungrounded fuel container.

Use the following guidelines to avoid static build-up when filling an

ungrounded fuel container:

²Place approved fuel container on the ground.

²DO NOT fill a fuel container while it is in the vehicle.

²Keep the fuel pump nozzle in contact with the fuel container while

filling.

²DO NOT use a device that would hold the fuel pump handle in the fill

position.

Fuel Filler Cap

Your fuel tank filler cap has an indexed design with a 1/8 turn on/off

feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise 1/8 of a turn until it

stops.

Maintenance and care

188

Page 189 of 240

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/8 of a turn until it stops.

If the ªService Engine Soon/Check Engineº indicator comes on and stays

on when you start the engine, the fuel filler cap may not be properly

installed. Turn off the engine, remove the fuel filler cap, align the cap

properly and reinstall it.

If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The customer warranty may

be void for any damage to the fuel tank or fuel system if the

correct genuine Ford or Motorcraft fuel filler cap is not used.

The fuel system may be under pressure. If the fuel filler cap is

venting vapor or if you hear a hissing sound, wait until it stops

before completely removing the fuel filler cap. Otherwise, fuel may

spray out and injure you or others.

If you do not use the proper fuel filler cap, excessive pressure or

vacuum in the fuel tank may damage the fuel system or cause

the fuel system to work improperly in a collision, which may result in

possible personal injury.

Choosing the right fuel

Use only UNLEADED FUEL. The use of leaded fuel is prohibited by law

and could damage your vehicle.

If your vehicle is a flexible fuel vehicle (FFV), use only UNLEADED

FUEL and ETHANOL (E85). The use of leaded fuel is prohibited by law

and could damage your vehicle.

Do not use fuel containing methanol. It can damage critical fuel system

components.

Your vehicle was not designed to use fuel or fuel additives with metallic

compounds, including manganese-based compounds containing MMT.

Repairs to correct the effects of using a fuel for which your vehicle was

not designed may not be covered by your warranty.

Maintenance and care

189

Page 198 of 240

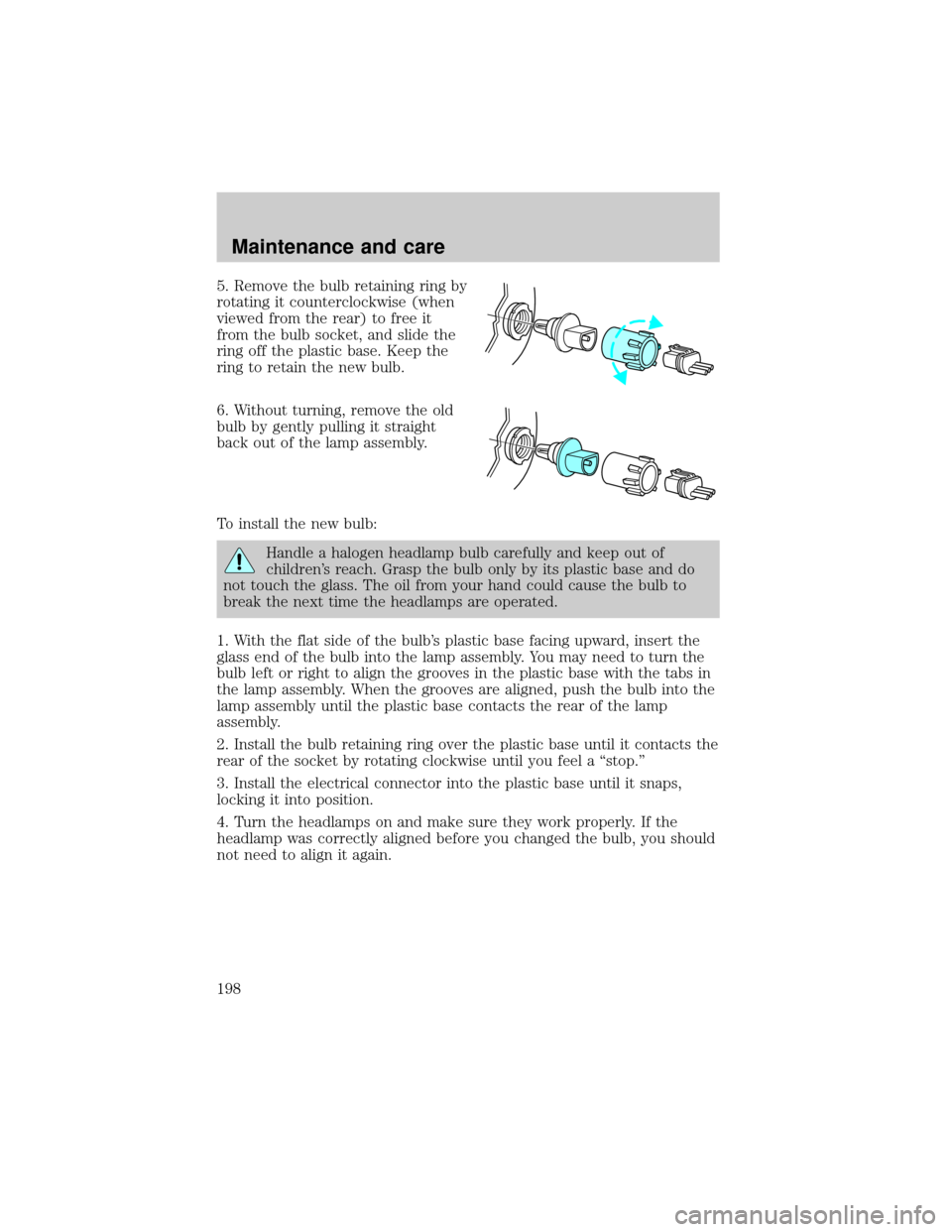

5. Remove the bulb retaining ring by

rotating it counterclockwise (when

viewed from the rear) to free it

from the bulb socket, and slide the

ring off the plastic base. Keep the

ring to retain the new bulb.

6. Without turning, remove the old

bulb by gently pulling it straight

back out of the lamp assembly.

To install the new bulb:

Handle a halogen headlamp bulb carefully and keep out of

children's reach. Grasp the bulb only by its plastic base and do

not touch the glass. The oil from your hand could cause the bulb to

break the next time the headlamps are operated.

1. With the flat side of the bulb's plastic base facing upward, insert the

glass end of the bulb into the lamp assembly. You may need to turn the

bulb left or right to align the grooves in the plastic base with the tabs in

the lamp assembly. When the grooves are aligned, push the bulb into the

lamp assembly until the plastic base contacts the rear of the lamp

assembly.

2. Install the bulb retaining ring over the plastic base until it contacts the

rear of the socket by rotating clockwise until you feel a ªstop.º

3. Install the electrical connector into the plastic base until it snaps,

locking it into position.

4. Turn the headlamps on and make sure they work properly. If the

headlamp was correctly aligned before you changed the bulb, you should

not need to align it again.

Maintenance and care

198

Page 199 of 240

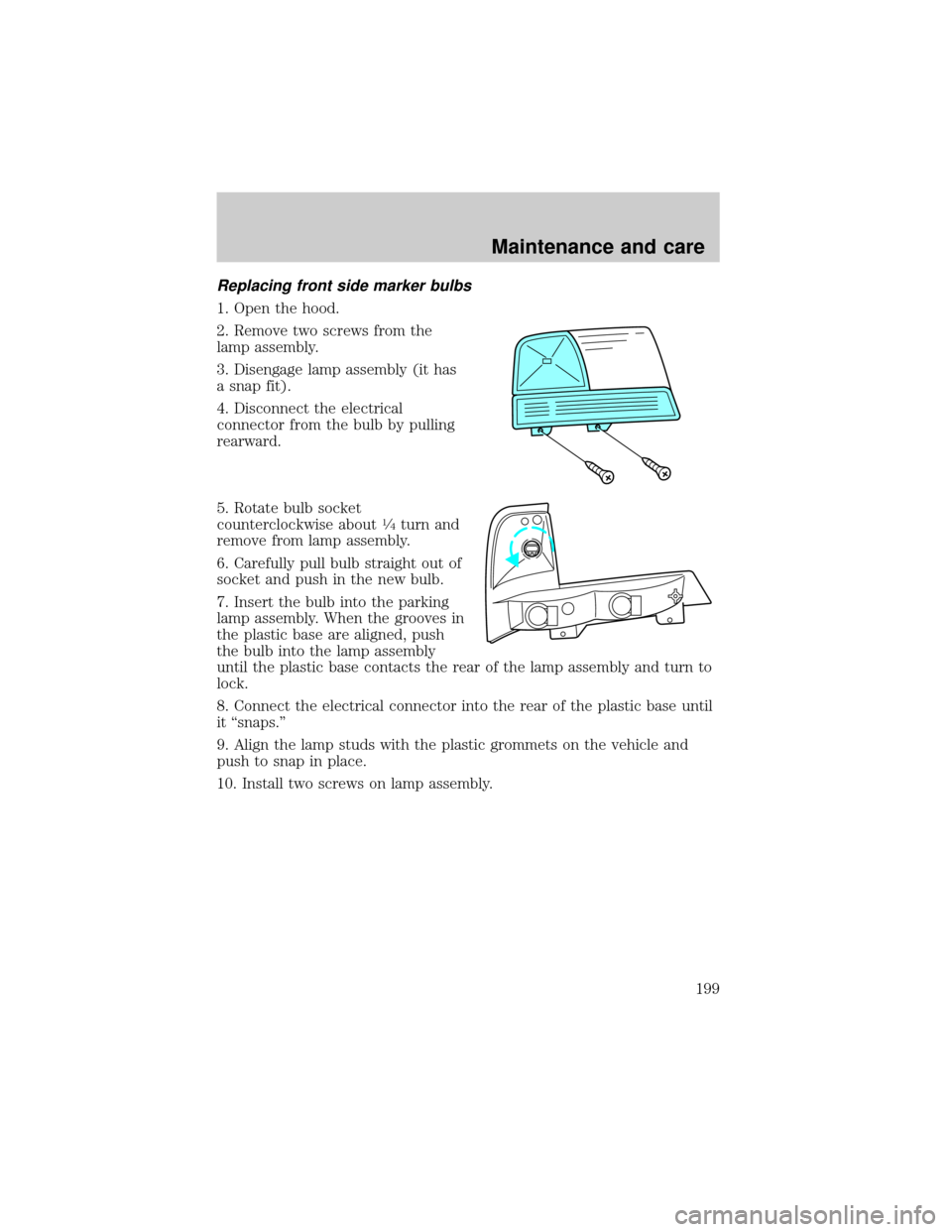

Replacing front side marker bulbs

1. Open the hood.

2. Remove two screws from the

lamp assembly.

3. Disengage lamp assembly (it has

a snap fit).

4. Disconnect the electrical

connector from the bulb by pulling

rearward.

5. Rotate bulb socket

counterclockwise about

1¤4turn and

remove from lamp assembly.

6. Carefully pull bulb straight out of

socket and push in the new bulb.

7. Insert the bulb into the parking

lamp assembly. When the grooves in

the plastic base are aligned, push

the bulb into the lamp assembly

until the plastic base contacts the rear of the lamp assembly and turn to

lock.

8. Connect the electrical connector into the rear of the plastic base until

it ªsnaps.º

9. Align the lamp studs with the plastic grommets on the vehicle and

push to snap in place.

10. Install two screws on lamp assembly.

Maintenance and care

199

Page 200 of 240

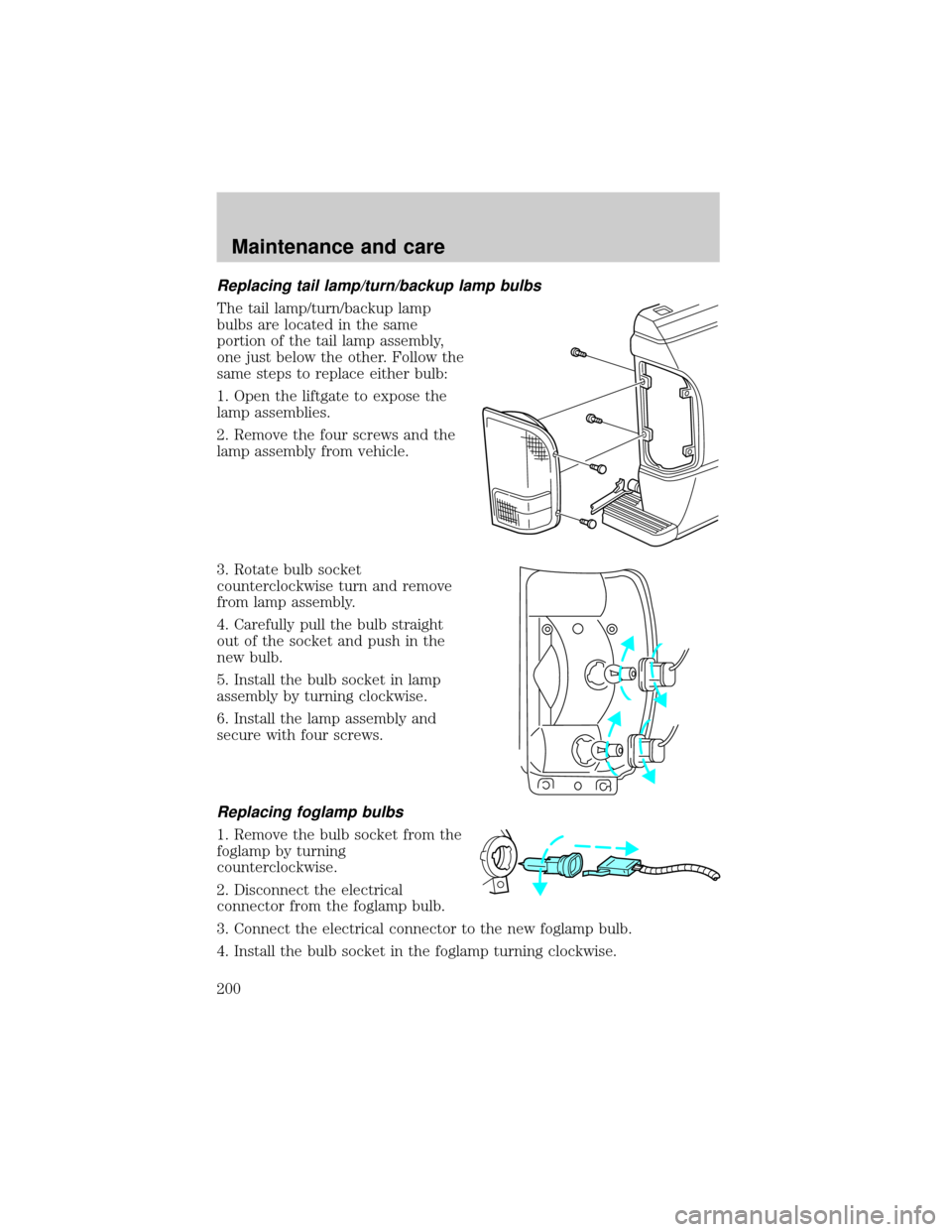

Replacing tail lamp/turn/backup lamp bulbs

The tail lamp/turn/backup lamp

bulbs are located in the same

portion of the tail lamp assembly,

one just below the other. Follow the

same steps to replace either bulb:

1. Open the liftgate to expose the

lamp assemblies.

2. Remove the four screws and the

lamp assembly from vehicle.

3. Rotate bulb socket

counterclockwise turn and remove

from lamp assembly.

4. Carefully pull the bulb straight

out of the socket and push in the

new bulb.

5. Install the bulb socket in lamp

assembly by turning clockwise.

6. Install the lamp assembly and

secure with four screws.

Replacing foglamp bulbs

1. Remove the bulb socket from the

foglamp by turning

counterclockwise.

2. Disconnect the electrical

connector from the foglamp bulb.

3. Connect the electrical connector to the new foglamp bulb.

4. Install the bulb socket in the foglamp turning clockwise.

Maintenance and care

200

Page 201 of 240

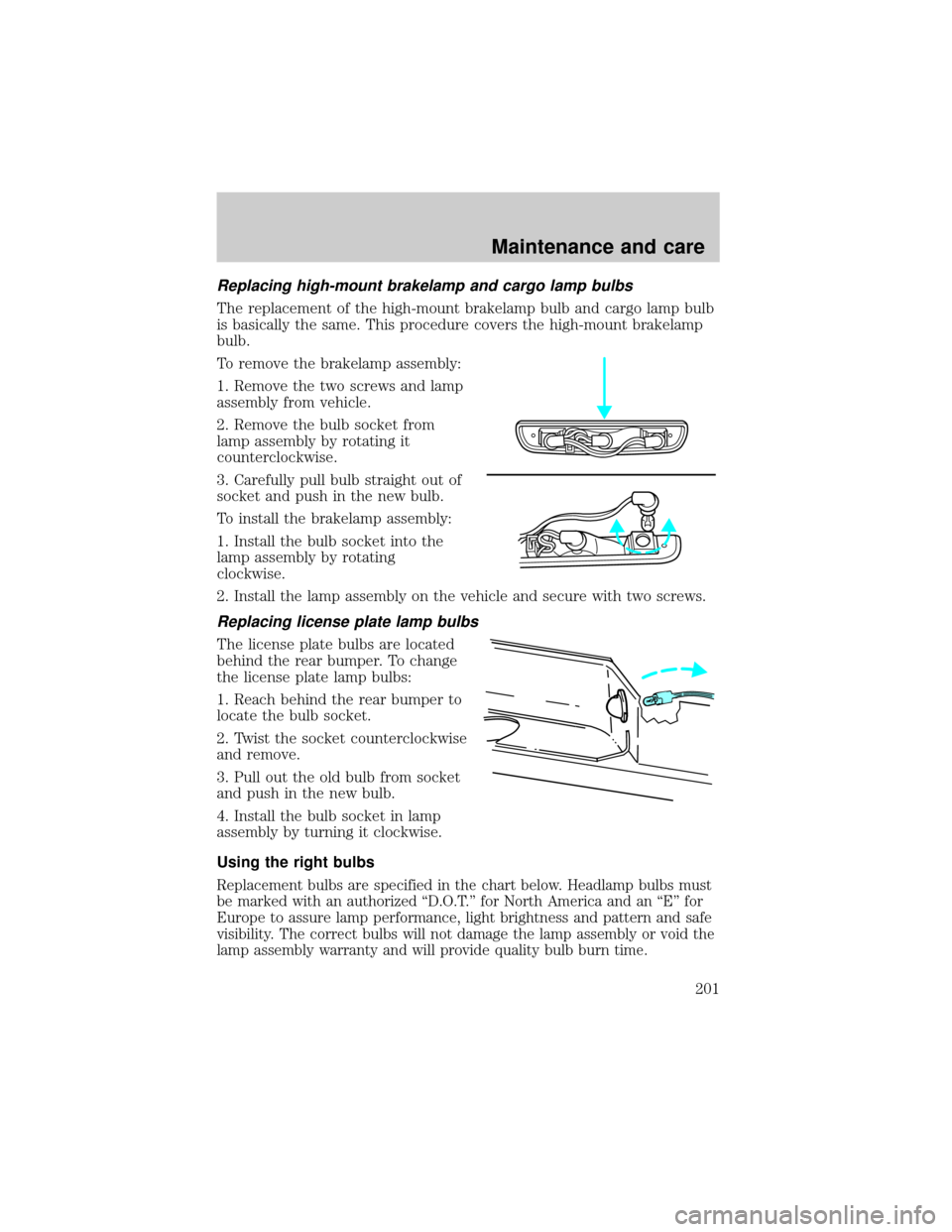

Replacing high-mount brakelamp and cargo lamp bulbs

The replacement of the high-mount brakelamp bulb and cargo lamp bulb

is basically the same. This procedure covers the high-mount brakelamp

bulb.

To remove the brakelamp assembly:

1. Remove the two screws and lamp

assembly from vehicle.

2. Remove the bulb socket from

lamp assembly by rotating it

counterclockwise.

3. Carefully pull bulb straight out of

socket and push in the new bulb.

To install the brakelamp assembly:

1. Install the bulb socket into the

lamp assembly by rotating

clockwise.

2. Install the lamp assembly on the vehicle and secure with two screws.

Replacing license plate lamp bulbs

The license plate bulbs are located

behind the rear bumper. To change

the license plate lamp bulbs:

1. Reach behind the rear bumper to

locate the bulb socket.

2. Twist the socket counterclockwise

and remove.

3. Pull out the old bulb from socket

and push in the new bulb.

4. Install the bulb socket in lamp

assembly by turning it clockwise.

Using the right bulbs

Replacement bulbs are specified in the chart below. Headlamp bulbs must

be marked with an authorized ªD.O.T.º for North America and an ªEº for

Europe to assure lamp performance, light brightness and pattern and safe

visibility. The correct bulbs will not damage the lamp assembly or void the

lamp assembly warranty and will provide quality bulb burn time.

Maintenance and care

201