weight FORD SIERRA 1982 1.G DOHC Engine Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1982, Model line: SIERRA, Model: FORD SIERRA 1982 1.GPages: 18, PDF Size: 0.9 MB

Page 5 of 18

34Make a final check to ensure that all

relevant wires, pipes and hoses have been

disconnected to facilitate engine removal.

35Attach a suitable hoist to the engine lifting

brackets located at the front and rear of the

cylinder head, and carefully take the weight of

the engine.

36To improve clearance in the engine

compartment when lifting the engine, unbolt

the engine mounting brackets from the

cylinder block, and remove them (see

illustration).

37Detach the brake lines from the front

suspension crossmember (see illustration).

38Support the crossmember with a jack (do

not remove the jack from under the gearbox),

then loosen the bolts securing the

crossmember to the underbody. Remove the

bolts from one side (see illustration), and

carefully lower the crossmember sufficiently

to allow the sump to clear the steering rack

and crossmember when pulling the engine

forwards from the gearbox.

39Gently raise the engine, then pull it

forwards to disconnect it from the gearbox.

Ensure that the gearbox is adequately

supported, and take care not to strain the

gearbox input shaft. It may be necessary to

rock the engine a little to release it from the

gearbox.

40Once clear of the gearbox, lift the engine

from the vehicle, taking care not to damage

the components in the engine compartment

(see illustration).Note: Refer to the warning at the beginning of

Section 5 before proceeding. A suitable hoist

and lifting tackle will be required for this

operation.

1Proceed as described in paragraphs 1 to 21

of Section 5.

2Unscrew and remove the top engine-to-

transmission bolts which are accessible from

the engine compartment. Note the location of

the earth strap, vacuum pipe bracket, and

transmission dipstick tube bracket, as

applicable.

3Proceed as described in paragraphs 23 to 29

of Section 5.

4Where applicable, remove the bolt securing

the transmission fluid dipstick tube to the left-

hand side of the cylinder block.

5Working through the starter motor aperture,

unscrew the four torque converter-to-

driveplate nuts. It will be necessary to turn the

crankshaft, using a suitable spanner on the

crankshaft pulley bolt, in order to gain access

to each bolt in turn through the aperture.

6Support the transmission with a trolley jack,

using a block of wood between the jack and

the transmission to spread the load.

7Unscrew and remove the remaining engine-

to-transmission bolts, and remove the bolt

from the engine adapter plate. Recover any

shims fitted between the sump and the

transmission when removing the lower engine-

to-transmission bolts. Where applicable, pull

the blanking plug from the adapter plate.

8Proceed as described in paragraphs 34 to 38

of Section 5.

9Gently raise the engine, then pull the engine

forwards to disconnect it from the

transmission. Ensure that the torque converter

is held firmly in place in the transmission

housing, otherwise it could fall out, resulting in

fluid spillage and possible damage. It may be

necessary to rock the engine a little to release

it from the transmission.

10Once clear of the transmission, lift the

engine from the vehicle, taking care not to

damage the components in the engine

compartment.Note: Refer to the warning at the beginning of

Section 5 before proceeding. A suitable hoist

and lifting tackle will be required for this

operation.

Removal

1Proceed as described in paragraphs 1 to 21

of Section 5.

2Unscrew the securing bolt, and disconnect

the earth lead from the rear left-hand side of

the cylinder head.

3Unscrew the nuts securing the engine

mountings to the engine mounting brackets.

4Jack up the vehicle and support it securely

on axle stands (see “Jacking and Vehicle

Support”).

Ensure that there is enough working room

beneath the vehicle.

5To improve access, disconnect the exhaust

downpipe from the manifold, and remove the

exhaust system.

6Drain the engine oil into a suitable

container.

7On models fitted with a catalytic converter,

release the securing clips, and withdraw the

exhaust heat shield from under the vehicle for

access to the propeller shaft.

8Remove the propeller shaft.

9Where applicable, bend back the locktabs,

then unscrew the two bolts in each case

securing the two anti-roll bar U-clamps to the

vehicle underbody. Lower the anti-roll bar as

far as possible.

10Working inside the vehicle, place a

wooden block under the clutch pedal to raise

it fully against its stop, so holding the

automatic adjuster pawl clear of the toothed

quadrant.

11Disconnect the clutch cable from the

clutch release arm, and pass the cable

through the bellhousing.

12Support the gearbox with a trolley jack,

using a block of wood between the jack and

the gearbox to spread the load.

13Unscrew the four nuts securing the

gearbox crossmember to the vehicle

underbody. Unscrew the central bolt securing

7Engine/manual gearbox

assembly - removal and

separation6Engine - removal leaving

automatic transmission in

vehicle

DOHC engine 2B•5

2B

5.38 Removing a suspension crossmember

securing bolt

5.40 Lifting the engine from the vehicle

5.37 Removing a brake line securing clip

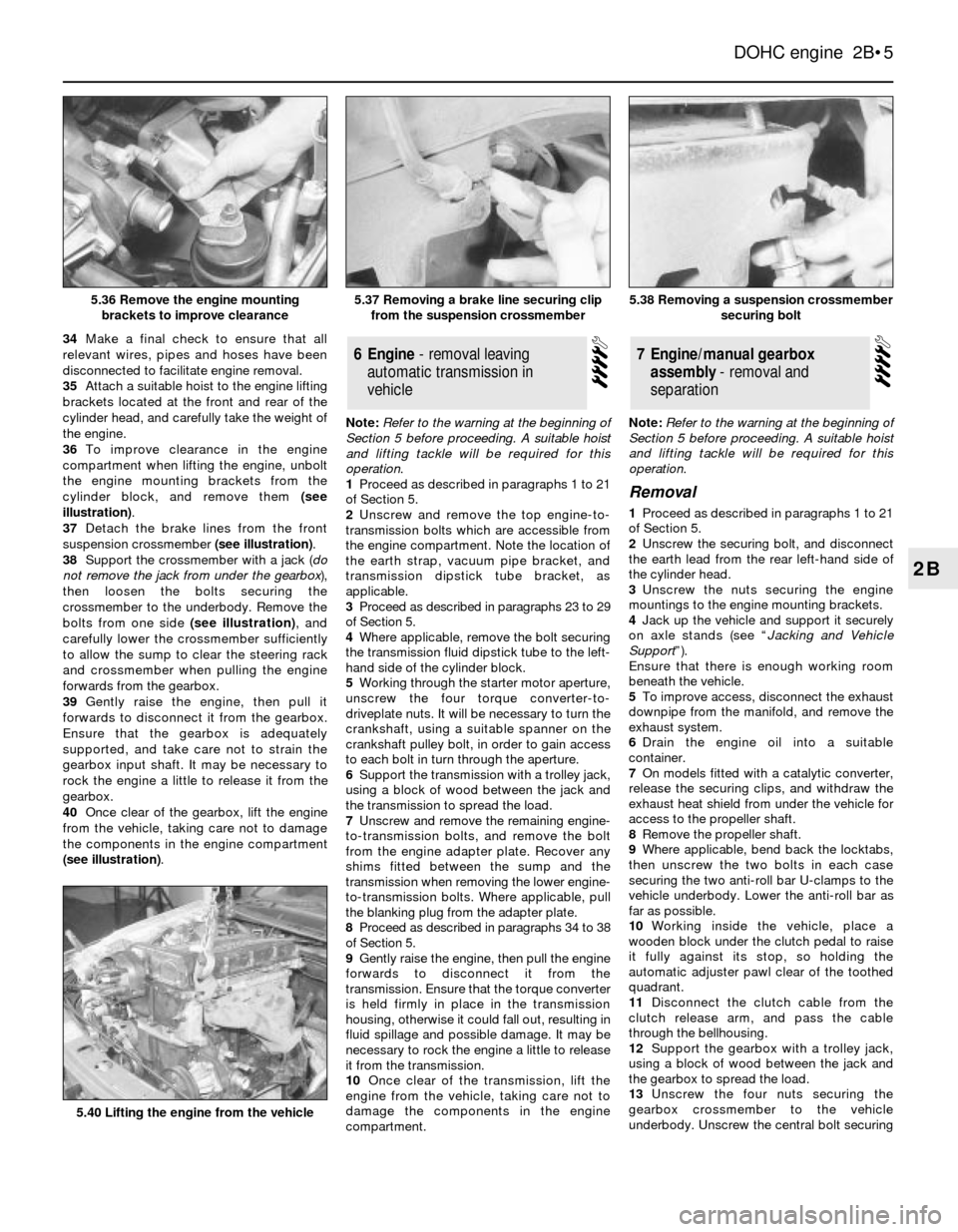

from the suspension crossmember5.36 Remove the engine mounting

brackets to improve clearance

Page 6 of 18

the crossmember to the gearbox, and remove

the crossmember. Note the position of the

earth strap, where applicable. Recover the

mounting cup, and where applicable the

exhaust mounting bracket and heat shield.

14Lower the gearbox slightly on the jack,

then remove the securing circlip, and

disconnect the speedometer drive cable from

the gearbox.

15Disconnect the wiring from the reversing

lamp switch. On models with fuel injection,

disconnect the wiring from the vehicle speed

sensor mounted in the side of the gearbox.

16Unscrew the two securing bolts, and

disconnect the gear linkage support bracket

from the gearbox.

17Using a suitable pin punch, drive out the

roll-pin securing the gearchange rod to the

gear linkage.

18Attach a suitable hoist to the engine lifting

brackets located at the front and rear of the

cylinder head, and carefully take the weight of

the engine. Arrange the lifting tackle so that

the engine/gearbox assembly will assume a

steep angle of approximately 40º to 45º as it is

being removed.

19To improve clearance in the engine

compartment when lifting the engine, unbolt

the engine mounting brackets from the

cylinder block, and remove them.

20Ensure that the steering wheel is

positioned in the straight-ahead position, then

remove the clamp bolt from the lower steering

column clamp, swivel the plate to one side,

and disconnect the lower steering column

from the lower flexible coupling.

21Detach the brake lines from the front

suspension crossmember.

22Support the crossmember with a jack (do

not remove the jack from under the gearbox),

then loosen the bolts securing the

crossmember to the underbody. Remove the

crossmember securing bolts, and carefully

lower the crossmember sufficiently to allow

the engine sump to clear the steering rack and

crossmember as the engine/gearbox

assembly is removed.

23Make a final check to ensure that all

relevant wires, pipes and hoses have been

disconnected to facilitate removal of the en-

gine/gearbox assembly.

24Raise the engine/gearbox, at the same

time lowering the trolley jack which is

supporting the gearbox.

25Place a suitable rod across the vehicle

underbody to support the gear linkage

support bracket whilst the gearbox is

removed.

26Tilt the engine/gearbox assembly using

the hoist and the trolley jack, until the

assembly can be lifted from the vehicle. Take

care not to damage surrounding components.

27If the vehicle is to be moved while the

engine/gearbox assembly is removed,

temporarily refit the suspension crossmember

and the anti-roll bar to the underbody, and

reconnect the steering column to the

intermediate shaft.Separation

28To separate the engine from the gearbox,

proceed as follows.

29Remove the starter motor.

30Support the engine and gearbox

horizontally on blocks of wood.

31Unscrew the engine-to-gearbox bolts,

noting the locations of the bolts, and the

positions of the earth strap and any wiring

clips attached to the bolts. Recover any shims

fitted between the sump and the gearbox

when removing the lower engine-to-gearbox

bolts.

32Unscrew the bolt from the engine adapter

plate.

33Pull the engine and gearbox apart, taking

care not to strain the gearbox input shaft. It

may be necessary to rock the units slightly to

separate them.

Note: Refer to the warning at the beginning of

Section 5 before proceeding. A suitable hoist

and lifting tackle will be required for this

operation. Any suspected faults in the

automatic transmission should be referred to a

Ford dealer or automatic transmission

specialist before removal of unit, as the

specialist fault diagnosis equipment is

designed to operate with the transmission in

the vehicle.

Removal

1Proceed as described in paragraphs 1 to 21

of Section 5.

2Unscrew the securing bolt, and disconnect

the earth lead from the rear left-hand side of

the cylinder head.

3Unscrew the nuts securing the engine

mountings to the engine mounting brackets.

4Jack up the vehicle and support it securely

on axle stands. (see “Jacking and Vehicle

Support”).

Ensure that there is enough working room

beneath the vehicle.

5To improve access, disconnect the exhaust

downpipe from the manifold, and remove the

exhaust system.

6Drain the engine oil into a suitable

container.

7On models fitted with a catalytic converter,

release the securing clips and withdraw the

exhaust heat shield from under the vehicle for

access to the propeller shaft.

8Remove the propeller shaft.

9Where applicable, bend back the locktabs,

then unscrew the two bolts in each case

securing the two anti-roll bar U-clamps to the

vehicle underbody. Lower the anti-roll bar as

far as possible.

10Support the transmission with a trolley

jack, using a block of wood between the jack

and the transmission to spread the load.

11Unscrew the four bolts securing thetransmission crossmember to the vehicle

underbody. Unscrew the central bolt securing

the crossmember to the transmission, and

remove the crossmember. Note the position

of the earth strap, where applicable. Recover

the mounting cup, and where applicable, the

exhaust mounting bracket and heat shield.

12Lower the transmission slightly on the

jack.

13Unscrew the unions and disconnect the

fluid cooler pipes from the transmission. Plug

the open ends of the pipes and the

transmission, to prevent dirt ingress and fluid

leakage. Where applicable, detach the fluid

cooler pipe bracket from the engine mounting

bracket, and move it to one side.

14Remove the two clips securing the

selector rod, and detach the selector rod from

the manual selector lever, and from the

selector lever on the transmission.

15Disconnect the wiring from the starter

inhibitor switch, kickdown solenoid, lock-up

clutch, reversing lamp switch, and where

applicable, the 3rd/4th gearchange solenoid.

16Remove the securing screw, and

disconnect the speedometer cable from the

transmission extension housing. Plug the

opening in the transmission to prevent dirt

ingress.

17Proceed as described in paragraphs 18 to

27 of Section 7, substituting transmission for

gearbox, and ignoring paragraph 25.

Separation

18To separate the engine from the

transmission, proceed as follows.

19Remove the starter motor.

20Support the engine and transmission

horizontally on blocks of wood.

21Working through the starter motor

aperture, unscrew the four torque converter-

to-driveplate nuts. It will be necessary to turn

the crankshaft using a suitable spanner on the

crankshaft pulley bolt in order to gain access

to each nut in turn through the aperture.

22Where applicable, remove the bolt

securing the transmission fluid dipstick tube

to the left-hand side of the cylinder block.

23Unscrew the engine-to-transmission

bolts, noting the locations of the bolts, and

the positions of the earth strap and any wiring

clips attached to the bolts. Recover any shims

fitted between the sump and the transmission

when removing the lower engine-to-

transmission bolts.

24Unscrew the bolt from the engine adapter

plate and, where applicable, pull the blanking

plug from the adapter plate.

25Pull the engine and the transmission

apart, ensuring that the torque converter is

held firmly in place in the transmission

housing, otherwise it could fall out, resulting in

fluid spillage and possible damage. It may be

necessary to rock the units slightly to

separate them.

8Engine/automatic

transmission assembly -

removal and separation

2B•6DOHC engine

Page 15 of 18

Inspection

3Examine the surfaces of the camshaft

journals and lobes and the contact surfaces of

the cam followers for wear. If wear is

excessive considerable noise would have

been noticed from the top of the engine when

running, and new camshafts and followers

must be fitted. It is unlikely that this level of

wear will occur unless a considerable mileage

has been covered. Note that the cam

followers cannot be dismantled for renewal of

individual components.

4Check the camshaft bearing surfaces in the

cylinder head and the bearing caps for wear. If

excessive wear is evident, the only course of

action available is to renew the cylinder head

and bearing caps.

5Check the cam follower bores in the

cylinder head for wear. If excessive wear is

evident, the cylinder head must be renewed.

6Check the cam follower oil grooves and the

oil ports in the cylinder head for obstructions.

Refitting

7Refit the cam followers and the camshafts

as described in paragraphs 27 to 55 of

Section 18.

8If the engine is in the vehicle, reverse the

operations given in paragraph 1.

Note: New flywheel/driveplate securing bolts

must be used on refitting.

1Refer to Chapter 2, PartA, noting the

following points.

2If the engine is in the car, refer to Chapter 6

when removing and refitting the clutch.

3There is no need to make alignment marks

between the flywheel/driveplate and the end

of the crankshaft, as the securing bolt holes

are offset, so the flywheel/driveplate can only

be fitted to the crankshaft in one position.

4The flywheel/driveplate securing bolts must

be renewed when refitting, and the new bolts

are supplied ready-coated with threadlocking

compound (see illustration).

5Check on the availability of new parts

before contemplating renewal of the ring gear.Note: A suitable puller will be required to

remove the crankshaft pulley. A new

crankshaft pulley bolt, and a new lower timing

chain cover gasket, must be used on refitting.

1The crankshaft front oil seal is located in the

lower timing chain cover.

2If the engine is in the car, carry out the

following operations:

a)Disconnect the battery negative lead.

b)To improve access, remove the radiator. It

will be difficult to remove the crankshaft

pulley with the radiator in place.

c)On fuel injection models, remove the air

inlet hose, plenum chamber, and air

cleaner lid as an assembly.

3Proceed as described in paragraphs 3 to 8

of Section 15.

4With the lower timing chain cover removed,

prise the old oil seal from the cover using a

screwdriver, and drive in the new seal using a

suitable metal tube. Make sure that the seal

lip faces into the engine. Take care not to

damage the timing chain cover.

5Refit the lower timing chain cover as

described in paragraphs 31 to 39 of Section

15.

6If the engine is in the vehicle, reverse the

operations given in paragraph 2.

Note: New flywheel/driveplate bolts must be

used on refitting.

1Remove the flywheel/driveplate and the

engine adapter plate.

2Extract the seal using an oil seal removal

tool if available. It may also be possible to

remove the oil seal by drilling the outer face

and using self-tapping screws and a pair of

grips.

3Clean the oil seal housing, then carefully

wind a thin layer of tape around the edge of

the crankshaft to protect the oil seal lip as the

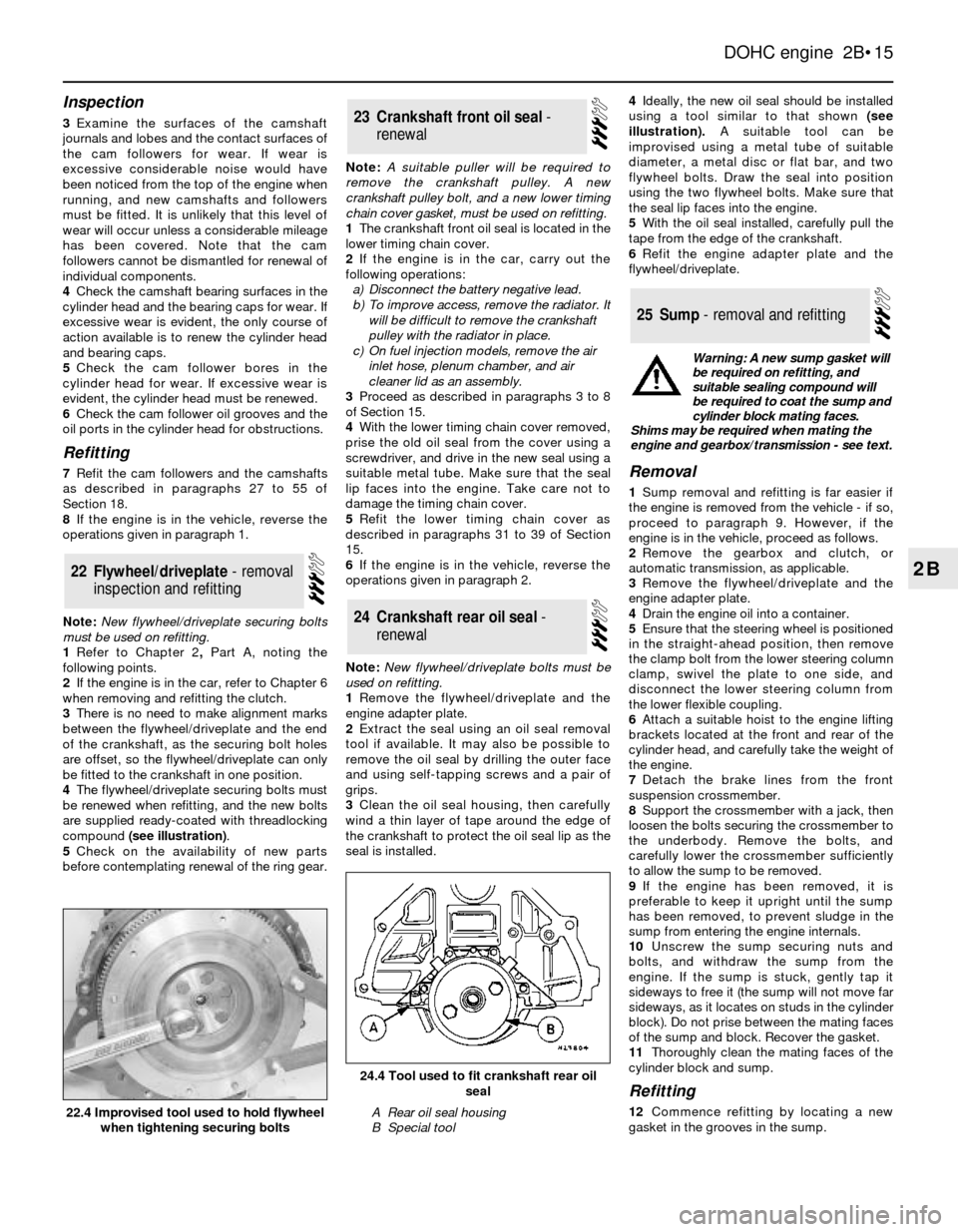

seal is installed.4Ideally, the new oil seal should be installed

using a tool similar to that shown (see

illustration).A suitable tool can be

improvised using a metal tube of suitable

diameter, a metal disc or flat bar, and two

flywheel bolts. Draw the seal into position

using the two flywheel bolts. Make sure that

the seal lip faces into the engine.

5With the oil seal installed, carefully pull the

tape from the edge of the crankshaft.

6Refit the engine adapter plate and the

flywheel/driveplate.Removal

1Sump removal and refitting is far easier if

the engine is removed from the vehicle - if so,

proceed to paragraph 9. However, if the

engine is in the vehicle, proceed as follows.

2Remove the gearbox and clutch, or

automatic transmission, as applicable.

3Remove the flywheel/driveplate and the

engine adapter plate.

4Drain the engine oil into a container.

5Ensure that the steering wheel is positioned

in the straight-ahead position, then remove

the clamp bolt from the lower steering column

clamp, swivel the plate to one side, and

disconnect the lower steering column from

the lower flexible coupling.

6Attach a suitable hoist to the engine lifting

brackets located at the front and rear of the

cylinder head, and carefully take the weight of

the engine.

7Detach the brake lines from the front

suspension crossmember.

8Support the crossmember with a jack, then

loosen the bolts securing the crossmember to

the underbody. Remove the bolts, and

carefully lower the crossmember sufficiently

to allow the sump to be removed.

9If the engine has been removed, it is

preferable to keep it upright until the sump

has been removed, to prevent sludge in the

sump from entering the engine internals.

10Unscrew the sump securing nuts and

bolts, and withdraw the sump from the

engine. If the sump is stuck, gently tap it

sideways to free it (the sump will not move far

sideways, as it locates on studs in the cylinder

block). Do not prise between the mating faces

of the sump and block. Recover the gasket.

11Thoroughly clean the mating faces of the

cylinder block and sump.

Refitting

12Commence refitting by locating a new

gasket in the grooves in the sump.

25Sump - removal and refitting

24Crankshaft rear oil seal -

renewal

23Crankshaft front oil seal -

renewal

22Flywheel/driveplate - removal

inspection and refitting

DOHC engine 2B•15

2B

24.4 Tool used to fit crankshaft rear oil

seal

A Rear oil seal housing

B Special tool22.4 Improvised tool used to hold flywheel

when tightening securing bolts

Warning: A new sump gasket will

be required on refitting, and

suitable sealing compound will

be required to coat the sump and

cylinder block mating faces.

Shims may be required when mating the

engine and gearbox/transmission - see text.

Page 18 of 18

6Before removing the crankshaft, check that

the endfloat is within the specified limits by

inserting a feeler blade between the centre

crankshaft web and one of the thrustwashers

(the thrustwashers are fitted to the crankcase,

not the bearing cap). This will indicate whether

or not new thrustwashers are required.

7Unscrew the bolts, and tap off the main

bearing caps complete with bearing shells.

8Lift the crankshaft from the cylinder block,

and remove the rear oil seal if it is still in place

on the crankshaft.

9Extract the bearing shells, and recover the

thrustwashers, keeping them identified for

location.

Refitting

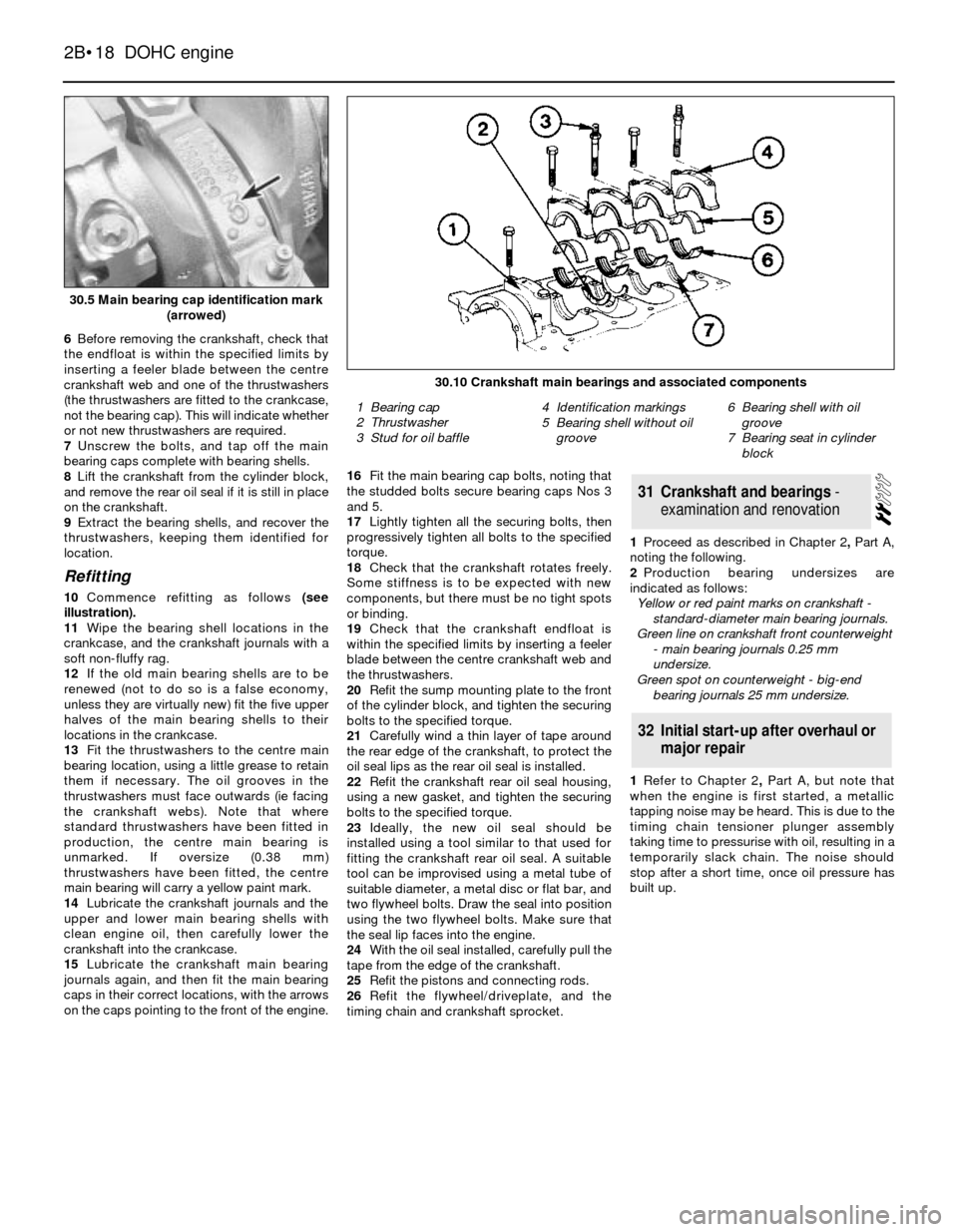

10Commence refitting as follows(see

illustration).

11Wipe the bearing shell locations in the

crankcase, and the crankshaft journals with a

soft non-fluffy rag.

12If the old main bearing shells are to be

renewed (not to do so is a false economy,

unless they are virtually new) fit the five upper

halves of the main bearing shells to their

locations in the crankcase.

13Fit the thrustwashers to the centre main

bearing location, using a little grease to retain

them if necessary. The oil grooves in the

thrustwashers must face outwards (ie facing

the crankshaft webs). Note that where

standard thrustwashers have been fitted in

production, the centre main bearing is

unmarked. If oversize (0.38 mm)

thrustwashers have been fitted, the centre

main bearing will carry a yellow paint mark.

14Lubricate the crankshaft journals and the

upper and lower main bearing shells with

clean engine oil, then carefully lower the

crankshaft into the crankcase.

15Lubricate the crankshaft main bearing

journals again, and then fit the main bearing

caps in their correct locations, with the arrows

on the caps pointing to the front of the engine.16Fit the main bearing cap bolts, noting that

the studded bolts secure bearing caps Nos 3

and 5.

17Lightly tighten all the securing bolts, then

progressively tighten all bolts to the specified

torque.

18Check that the crankshaft rotates freely.

Some stiffness is to be expected with new

components, but there must be no tight spots

or binding.

19Check that the crankshaft endfloat is

within the specified limits by inserting a feeler

blade between the centre crankshaft web and

the thrustwashers.

20Refit the sump mounting plate to the front

of the cylinder block, and tighten the securing

bolts to the specified torque.

21Carefully wind a thin layer of tape around

the rear edge of the crankshaft, to protect the

oil seal lips as the rear oil seal is installed.

22Refit the crankshaft rear oil seal housing,

using a new gasket, and tighten the securing

bolts to the specified torque.

23Ideally, the new oil seal should be

installed using a tool similar to that used for

fitting the crankshaft rear oil seal. A suitable

tool can be improvised using a metal tube of

suitable diameter, a metal disc or flat bar, and

two flywheel bolts. Draw the seal into position

using the two flywheel bolts. Make sure that

the seal lip faces into the engine.

24With the oil seal installed, carefully pull the

tape from the edge of the crankshaft.

25Refit the pistons and connecting rods.

26Refit the flywheel/driveplate, and the

timing chain and crankshaft sprocket.1Proceed as described in Chapter 2, PartA,

noting the following.

2Production bearing undersizes are

indicated as follows:

Yellow or red paint marks on crankshaft -

standard-diameter main bearing journals.

Green line on crankshaft front counterweight

- main bearing journals 0.25 mm

undersize.

Green spot on counterweight - big-end

bearing journals 25 mm undersize.

1Refer to Chapter 2, PartA, but note that

when the engine is first started, a metallic

tapping noise may be heard. This is due to the

timing chain tensioner plunger assembly

taking time to pressurise with oil, resulting in a

temporarily slack chain. The noise should

stop after a short time, once oil pressure has

built up.

32Initial start-up after overhaul or

major repair

31Crankshaft and bearings -

examination and renovation

2B•18DOHC engine

30.5 Main bearing cap identification mark

(arrowed)

30.10 Crankshaft main bearings and associated components

1 Bearing cap

2 Thrustwasher

3 Stud for oil baffle4 Identification markings

5 Bearing shell without oil

groove6 Bearing shell with oil

groove

7 Bearing seat in cylinder

block