fuel reserve FORD SIERRA 1983 1.G Body Electrical System Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1983, Model line: SIERRA, Model: FORD SIERRA 1983 1.GPages: 25, PDF Size: 1.7 MB

Page 2 of 25

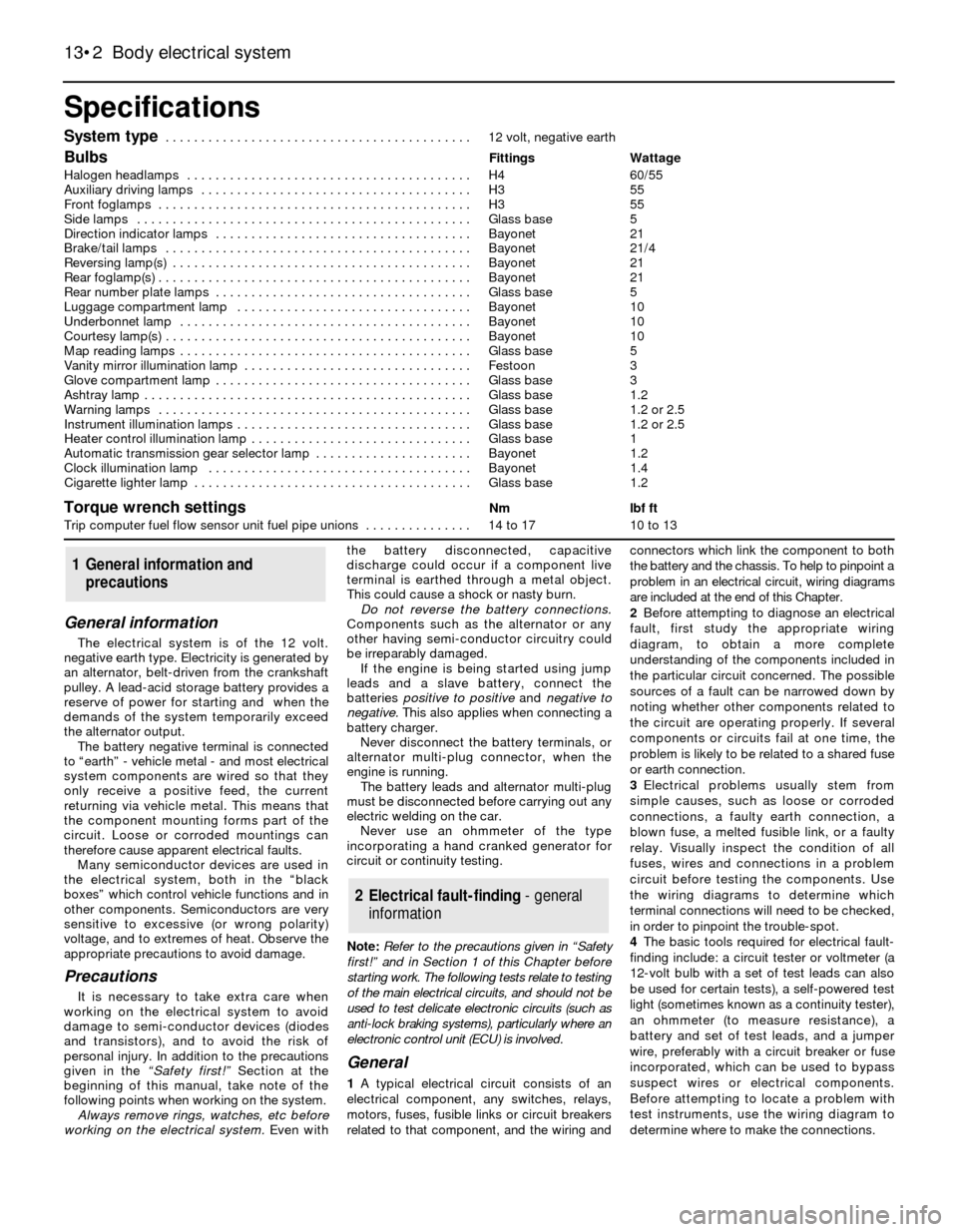

System type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 volt, negative earth

BulbsFittingsWattage

Halogen headlamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H460/55

Auxiliary driving lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H355

Front foglamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H355

Side lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Glass base5

Direction indicator lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bayonet21

Brake/tail lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bayonet21/4

Reversing lamp(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bayonet21

Rear foglamp(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bayonet21

Rear number plate lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Glass base5

Luggage compartment lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bayonet10

Underbonnet lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bayonet10

Courtesy lamp(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bayonet10

Map reading lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Glass base5

Vanity mirror illumination lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Festoon3

Glove compartment lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Glass base3

Ashtray lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Glass base1.2

Warning lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Glass base1.2 or 2.5

Instrument illumination lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Glass base1.2 or 2.5

Heater control illumination lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Glass base1

Automatic transmission gear selector lamp . . . . . . . . . . . . . . . . . . . . . .Bayonet1.2

Clock illumination lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bayonet1.4

Cigarette lighter lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Glass base1.2

Torque wrench settingsNmlbf ft

Trip computer fuel flow sensor unit fuel pipe unions . . . . . . . . . . . . . . .14 to 1710 to 13

General information

The electrical system is of the 12 volt.

negative earth type. Electricity is generated by

an alternator, belt-driven from the crankshaft

pulley. A lead-acid storage battery provides a

reserve of power for starting and when the

demands of the system temporarily exceed

the alternator output.

The battery negative terminal is connected

to “earth” - vehicle metal - and most electrical

system components are wired so that they

only receive a positive feed, the current

returning via vehicle metal. This means that

the component mounting forms part of the

circuit. Loose or corroded mountings can

therefore cause apparent electrical faults.

Many semiconductor devices are used in

the electrical system, both in the “black

boxes” which control vehicle functions and in

other components. Semiconductors are very

sensitive to excessive (or wrong polarity)

voltage, and to extremes of heat. Observe the

appropriate precautions to avoid damage.

Precautions

It is necessary to take extra care when

working on the electrical system to avoid

damage to semi-conductor devices (diodes

and transistors), and to avoid the risk of

personal injury. In addition to the precautions

given in the

“Safety first!” Section at the

beginning of this manual, take note of the

following points when working on the system.

Always remove rings, watches, etc before

working on the electrical system. Even withthe battery disconnected, capacitive

discharge could occur if a component live

terminal is earthed through a metal object.

This could cause a shock or nasty burn.

Do not reverse the battery connections.

Components such as the alternator or any

other having semi-conductor circuitry could

be irreparably damaged.

If the engine is being started using jump

leads and a slave battery, connect the

batteries positive to positive and negative to

negative. This also applies when connecting a

battery charger.

Never disconnect the battery terminals, or

alternator multi-plug connector, when the

engine is running.

The battery leads and alternator multi-plug

must be disconnected before carrying out any

electric welding on the car.

Never use an ohmmeter of the type

incorporating a hand cranked generator for

circuit or continuity testing.

Note:Refer to the precautions given in “Safety

first!” and in Section 1 of this Chapter before

starting work. The following tests relate to testing

of the main electrical circuits, and should not be

used to test delicate electronic circuits (such as

anti-lock braking systems), particularly where an

electronic control unit (ECU) is involved.General

1A typical electrical circuit consists of an

electrical component, any switches, relays,

motors, fuses, fusible links or circuit breakers

related to that component, and the wiring andconnectors which link the component to both

the battery and the chassis. To help to pinpoint a

problem in an electrical circuit, wiring diagrams

are included at the end of this Chapter.

2Before attempting to diagnose an electrical

fault, first study the appropriate wiring

diagram, to obtain a more complete

understanding of the components included in

the particular circuit concerned. The possible

sources of a fault can be narrowed down by

noting whether other components related to

the circuit are operating properly. If several

components or circuits fail at one time, the

problem is likely to be related to a shared fuse

or earth connection.

3Electrical problems usually stem from

simple causes, such as loose or corroded

connections, a faulty earth connection, a

blown fuse, a melted fusible link, or a faulty

relay. Visually inspect the condition of all

fuses, wires and connections in a problem

circuit before testing the components. Use

the wiring diagrams to determine which

terminal connections will need to be checked,

in order to pinpoint the trouble-spot.

4The basic tools required for electrical fault-

finding include: a circuit tester or voltmeter (a

12-volt bulb with a set of test leads can also

be used for certain tests), a self-powered test

light (sometimes known as a continuity tester),

an ohmmeter (to measure resistance), a

battery and set of test leads, and a jumper

wire, preferably with a circuit breaker or fuse

incorporated, which can be used to bypass

suspect wires or electrical components.

Before attempting to locate a problem with

test instruments, use the wiring diagram to

determine where to make the connections.

2Electrical fault-finding - general

information

1General information and

precautions

13•2Body electrical system

Specifications