radiator FORD SIERRA 1983 1.G Bodywork And Fittings Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1983, Model line: SIERRA, Model: FORD SIERRA 1983 1.GPages: 22, PDF Size: 1.2 MB

Page 1 of 22

Torque wrench settingsNm lbf ft

Front seat belt stalk-to-seat bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 to 28 18 to 22

Seat belt anchor bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 to 41 22 to 30

Seat belt inertia reel securing bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 to 41 22 to 30

Seat mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 32 18 to 24

Cab safety grille securing bolts (P100 models) . . . . . . . . . . . . . . . . . . . 20 to 27 15 to 20

Rear bump stop securing nuts (P100 models) . . . . . . . . . . . . . . . . . . . . 8 to 11 6 to 8

Cargo area-to-chassis bolts (P100 models) . . . . . . . . . . . . . . . . . . . . . . 40 to 50 29 to 37

Tailboard hinge securing screws (P100 models) . . . . . . . . . . . . . . . . . . 20 to 25 15 to 18

Chapter 12

Bodywork and fittings

Bonnet - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Bonnet lock - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Bonnet lock release cable - removal and refitting . . . . . . . . . . . . . . . .7

Boot lid (Saloon models) - removal and refitting . . . . . . . . . . . . . . . . .9

Boot lid lock (Saloon models) - removal and refitting . . . . . . . . . . . . .10

Bumper - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Bumper trim moulding - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Cab air vent panel (P100 models) - removal and refitting . . . . . . . . .35

Cab interior trim panels (P100 models) - removal and refitting . . . . .42

Cargo area (P100 models) - removal and refitting . . . . . . . . . . . . . . .23

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .44

Door - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Door check arm - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .22

Door exterior handle - removal and refitting . . . . . . . . . . . . . . . . . . . .19

Door inner trim panel - removal and refitting . . . . . . . . . . . . . . . . . . .17

Door interior handle - removal and refitting . . . . . . . . . . . . . . . . . . . .18

Door lock - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Door lock barrel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .20

Door mirror - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Door window - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .27

Door window regulator - removal and refitting . . . . . . . . . . . . . . . . . .28

Exterior rear pillar trim panel (Saloon models) - removal and refitting .34

Facia panels - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .43

Front seat air cushion assembly - removal and refitting . . . . . . . . . .49

Fuel filler flap - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .37

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1Headlining - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Inner gutter weatherstrip (Saloon, Hatchback and Estate models)-

removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Interior pillar trim panels - removal and refitting . . . . . . . . . . . . . . . . .41

Interior trim panels - general information . . . . . . . . . . . . . . . . . . . . . .40

Maintenance - bodywork, underside and fittings . . . . . . . . . . . . . . . . .2

Maintenance - upholstery and carpets . . . . . . . . . . . . . . . . . . . . . . . . .3

Major body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Minor body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Overhead console - removal and refitting . . . . . . . . . . . . . . . . . . . . .45

Opening rear quarter window - removal and refitting . . . . . . . . . . . . .26

Radiator grille panel - removal and refitting . . . . . . . . . . . . . . . . . . . .32

Rear seat catch - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .48

Seats - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Seat belts - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Sunroof - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . .39

Tailboard (P100 models) - removal and refitting . . . . . . . . . . . . . . . .24

Tailgate/boot lid/fuel filler flap release cable - removal and refitting .14

Tailgate/boot lid spoiler - removal and refitting . . . . . . . . . . . . . . . . .15

Tailgate (Hatchback and Estate models) - removal and refitting . . . .11

Tailgate lock (Hatchback and Estate models) - removal and refitting . .12

Tailgate strut (Hatchback and Estate models) - removal and refitting .13

Wheel arch liners - removal and refitting . . . . . . . . . . . . . . . . . . . . . .36

Windscreen cowl panel - removal and refitting . . . . . . . . . . . . . . . . .33

Windscreen, rear window and fixed rear quarter windows - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

12•1

Specifications Contents

12

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Page 4 of 22

compatible with the type of plastic used. At one

time the use of a universal paint was not

possible owing to the complex range of plastics

encountered in body component applications.

Standard paints, generally speaking, will not

bond to plastic or rubber satisfactorily.

However, it is now possible to obtain a plastic

body parts finishing kit which consists of a pre-

primer treatment, a primer and coloured top

coat. Full instructions are normally supplied with

a kit, but basically the method of use is to first

apply the pre-primer to the component

concerned and allow it to dry for up to 30

minutes. Then the primer is applied and left to

dry for about an hour before finally applying the

special coloured top coat. The result is a

correctly coloured component where the paint

will flex with the plastic or rubber, a property

that standard paint does not normally possess.

Where serious damage has occurred or large

areas need renewal due to neglect, it means

certainly that completely new sections or panels

will need welding in and this is best left to

professionals. If the damage is due to impact, it

will also be necessary to completely check the

alignment of the bodyshell structure. Due to the

principle of construction, the strength and shape

of the whole car can be affected by damage to

one part. In such instances the services of a

Ford agent with specialist checking jigs are

essential. If a body is left misaligned, it is first of

all dangerous as the car will not handle properly,

and secondly uneven stresses will be imposed

on the steering, engine and transmission,

causing abnormal wear or complete failure. Tyre

wear may also be excessive.

Removal

1Support the bonnet in its open position,

and place protective covers (old rags or

cardboard) beneath the corners of the bonnet,

and over the front wings to prevent damage to

the paintwork.

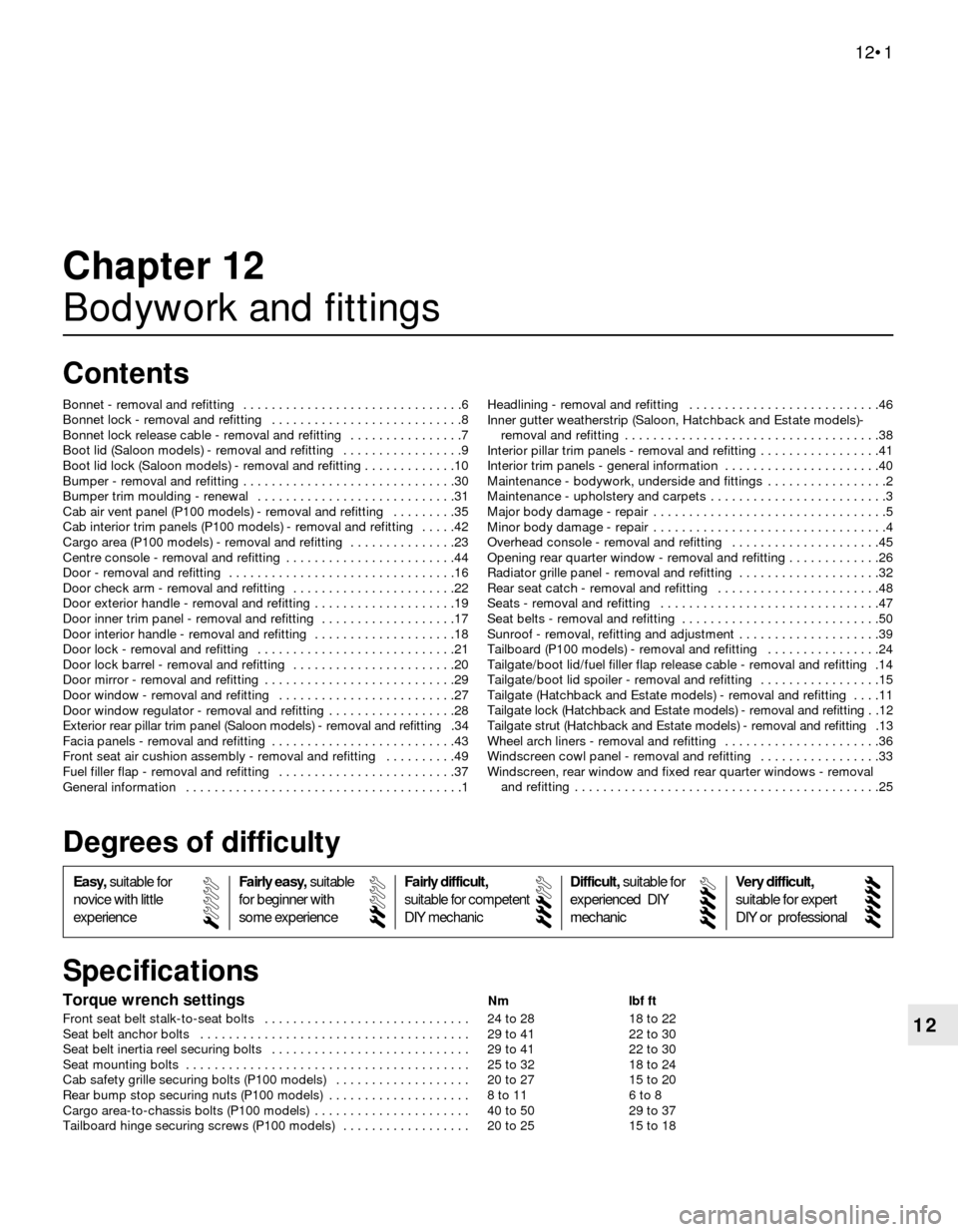

2Remove the screw and disconnect the earth

strap from the rear left-hand edge of the bonnet

(see illustration). Where applicable, disconnect

the wiring from the underbonnet lamp.

3Mark the location of the hinges on the sides

of the bonnet with a soft pencil or masking

tape, then loosen the four hinge bolts.

4With the help of an assistant, remove the

bolts and lift the bonnet from the vehicle (see

illustration).

5If required, the underbonnet insulation can

be removed by prising out the two-piece

plastic securing clips.

Refitting

6Refitting is a reversal of removal, bearing in

mind the following points.7Adjust the hinges to their original marked

positions before tightening the bolts.

8On completion, check that the bonnet is

central within its aperture and aligned with the

surrounding bodywork. Re-adjust the hinges

to give satisfactory alignment if necessary.

9Check that the bonnet lock striker engages

fully in the lock, and if necessary adjust the

position of the lock striker and/or the height of

the bonnet rubber bump stops (see

illustration).

Removal

1Working inside the vehicle, remove the

three retaining screws, and withdraw the

lower steering column shroud.

2Remove the retaining screw, and withdraw

the release cable bracket from the steering

column.

3Working in the engine compartment, pull

the cable sheath end fitting from its bracket,

and release the cable end fitting from the lock

lever (see illustration).

4Release the cable from the clips in the

engine compartment.

5Pull the cable through the bulkhead into the

passenger compartment, taking care not to

lose the bulkhead grommet.

Refitting

6Refitting is a reversal of removal, but ensure

that the grommet is correctly located in thebulkhead, and that the cable is free from

sharp bends and kinks. There should be a

small amount of free play at the lock end of

the cable if necessary re-route the cable to

achieve this condition.

7Note that should the release cable snap

while the bonnet is shut, the bonnet may be

opened as follows.

8Apply the handbrake, jack up the front of

the vehicle and support on axle stands (see

“

Jacking and Vehicle Support”).

9Using an inspection lamp or torch, look up

between the radiator and the radiator grille

panel and locate the circular hole below the

bonnet lock (see illustration).

10Insert a screwdriver through the hole so

that it passes to the right of the lock striker.

Twist or lever the lock sliding plate to the right

until the striker is released. The bonnet can

now be opened.

7Bonnet lock release cable -

removal and refitting

6Bonnet - removal and refitting

5Major body damage - repair

12•4Bodywork and fittings

6.2 Remove the screw and disconnect the

bonnet earth cable

6.9 Adjustable bonnet rubber bump stop

7.9 Access hole (arrowed) below bonnet

lock7.3 Bonnet lock release cable end fittings -

models up to 1987

6.4 Lifting the bonnet from the vehicle

Page 5 of 22

Models up to 1987

1Working in the engine compartment,

disconnect the cable from the bonnet lock by

pulling the cable sheath end fitting from its

bracket, then releasing the end fitting from the

lock lever.

2Remove the three securing screws and

withdraw the lock from the front panel.

3Refitting is a reversal of removal.

Models from 1987

4Remove the radiator grille panel.

5Disconnect the cable from the bonnet lock

by pulling the cable sheath end fitting from its

bracket, then releasing the end fitting from the

lock lever.

6Detach the bracing strut from the lock by

removing the screw, then remove the two

securing screws and withdraw the lock from

the front panel.

7Refitting is a reversal of removal.

Removal

1Open the boot lid, and place protective

covers (old rags or cardboard) beneath the

corners of the lid, and over the rear wings to

prevent damage to the paintwork.

2Where applicable, disconnect the wiring

from the lock solenoid and “boot lid ajar”

sensor, after disconnecting the battery

negative lead.

3Release the wiring loom grommets, taking

care not to lose them, then tie string to the

wiring loom(s), and pull the loom(s) through

the boot lid. Leave the string(s) in position in

the boot lid to aid refitting of the loom(s).

4Mark the location of the hinges on the

underside of the lid using a soft pencil or

masking type, then loosen the four hinge bolts.5With the help of an assistant, remove the

bolts and lift the boot lid from the vehicle.

Refitting

6Refitting is a reversal of removal, bearing in

mind the following points.

7Adjust the hinges to their original marked

positions before tightening the bolts.

8On completion, check that the boot lid is

central within its aperture and aligned with the

surrounding bodywork. Re-adjust the hinges

to give satisfactory alignment if necessary.

9Check that the lock striker engages fully in

the lock, and if necessary adjust the position

of the lock striker.

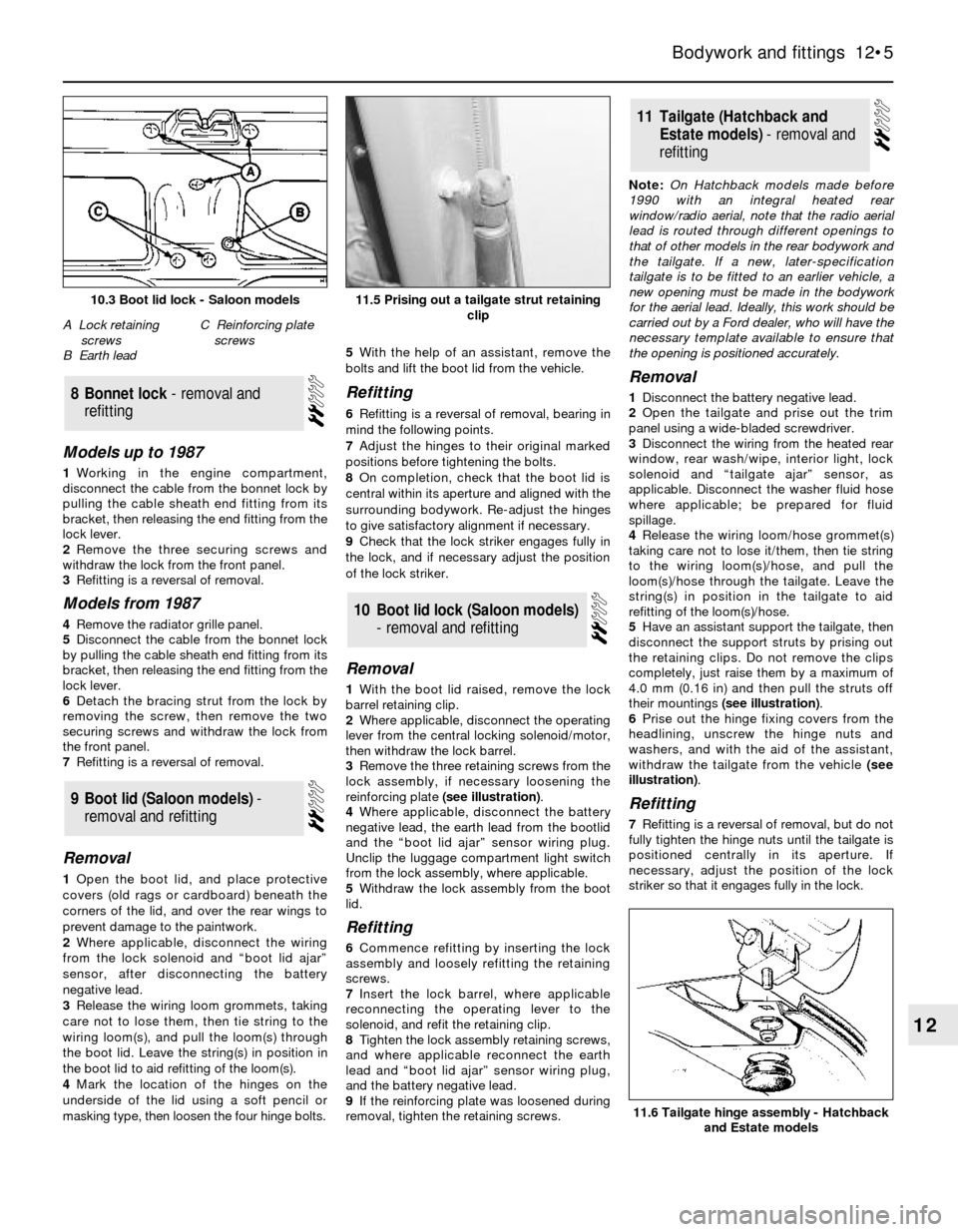

Removal

1With the boot lid raised, remove the lock

barrel retaining clip.

2Where applicable, disconnect the operating

lever from the central locking solenoid/motor,

then withdraw the lock barrel.

3Remove the three retaining screws from the

lock assembly, if necessary loosening the

reinforcing plate (see illustration).

4Where applicable, disconnect the battery

negative lead, the earth lead from the bootlid

and the “boot lid ajar” sensor wiring plug.

Unclip the luggage compartment light switch

from the lock assembly, where applicable.

5Withdraw the lock assembly from the boot

lid.

Refitting

6Commence refitting by inserting the lock

assembly and loosely refitting the retaining

screws.

7Insert the lock barrel, where applicable

reconnecting the operating lever to the

solenoid, and refit the retaining clip.

8Tighten the lock assembly retaining screws,

and where applicable reconnect the earth

lead and “boot lid ajar” sensor wiring plug,

and the battery negative lead.

9If the reinforcing plate was loosened during

removal, tighten the retaining screws.Note: On Hatchback models made before

1990 with an integral heated rear

window/radio aerial, note that the radio aerial

lead is routed through different openings to

that of other models in the rear bodywork and

the tailgate. If a new, later-specification

tailgate is to be fitted to an earlier vehicle, a

new opening must be made in the bodywork

for the aerial lead. Ideally, this work should be

carried out by a Ford dealer, who will have the

necessary template available to ensure that

the opening is positioned accurately.

Removal

1Disconnect the battery negative lead.

2Open the tailgate and prise out the trim

panel using a wide-bladed screwdriver.

3Disconnect the wiring from the heated rear

window, rear wash/wipe, interior light, lock

solenoid and “tailgate ajar” sensor, as

applicable. Disconnect the washer fluid hose

where applicable; be prepared for fluid

spillage.

4Release the wiring loom/hose grommet(s)

taking care not to lose it/them, then tie string

to the wiring loom(s)/hose, and pull the

loom(s)/hose through the tailgate. Leave the

string(s) in position in the tailgate to aid

refitting of the loom(s)/hose.

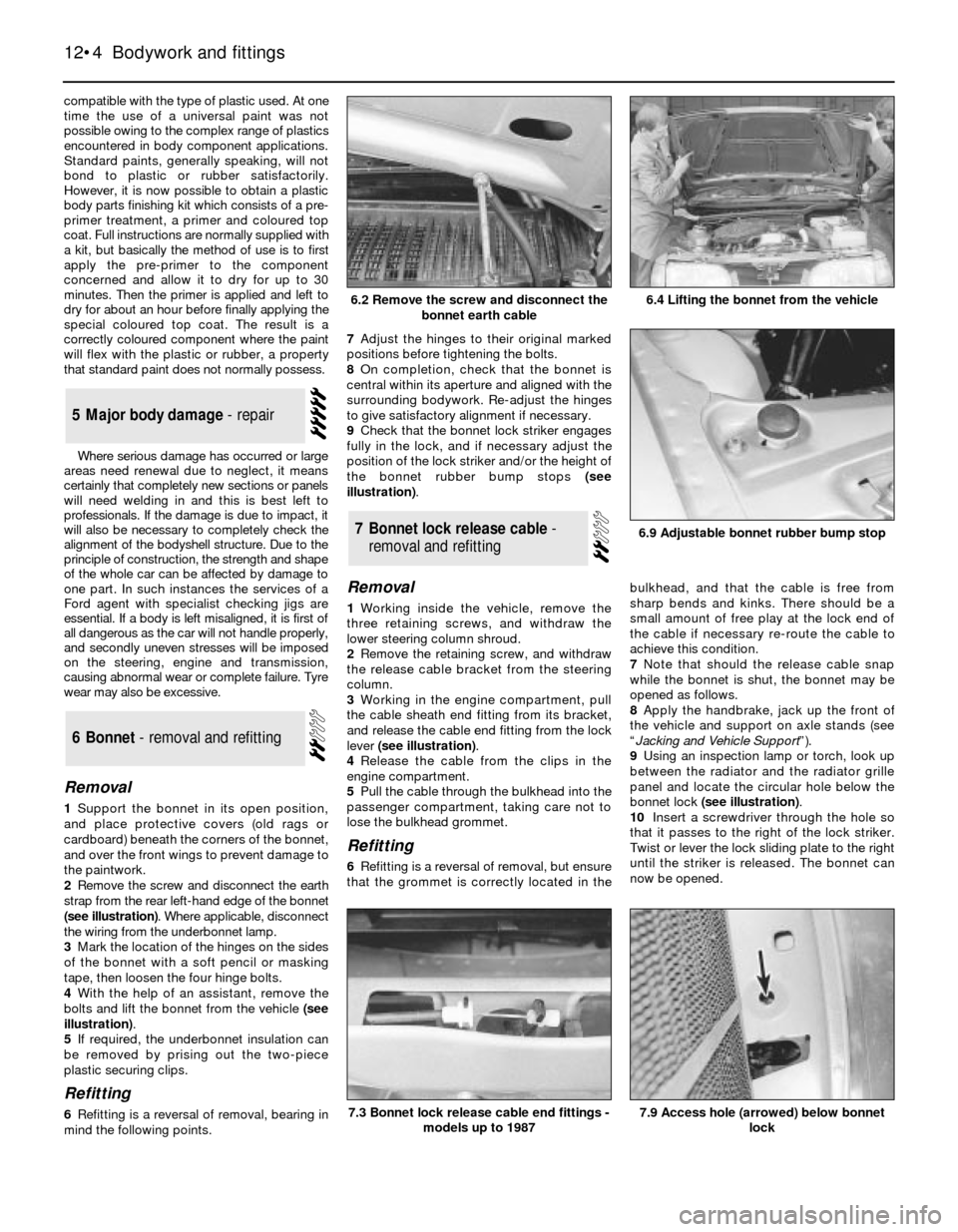

5Have an assistant support the tailgate, then

disconnect the support struts by prising out

the retaining clips. Do not remove the clips

completely, just raise them by a maximum of

4.0 mm (0.16 in) and then pull the struts off

their mountings (see illustration).

6Prise out the hinge fixing covers from the

headlining, unscrew the hinge nuts and

washers, and with the aid of the assistant,

withdraw the tailgate from the vehicle (see

illustration).

Refitting

7Refitting is a reversal of removal, but do not

fully tighten the hinge nuts until the tailgate is

positioned centrally in its aperture. If

necessary, adjust the position of the lock

striker so that it engages fully in the lock.

11Tailgate (Hatchback and

Estate models) - removal and

refitting

10Boot lid lock (Saloon models)

- removal and refitting

9Boot lid (Saloon models) -

removal and refitting

8Bonnet lock - removal and

refitting

Bodywork and fittings 12•5

12

11.6 Tailgate hinge assembly - Hatchback

and Estate models

11.5 Prising out a tailgate strut retaining

clip10.3 Boot lid lock - Saloon models

A Lock retaining

screws

B Earth leadC Reinforcing plate

screws

Page 13 of 22

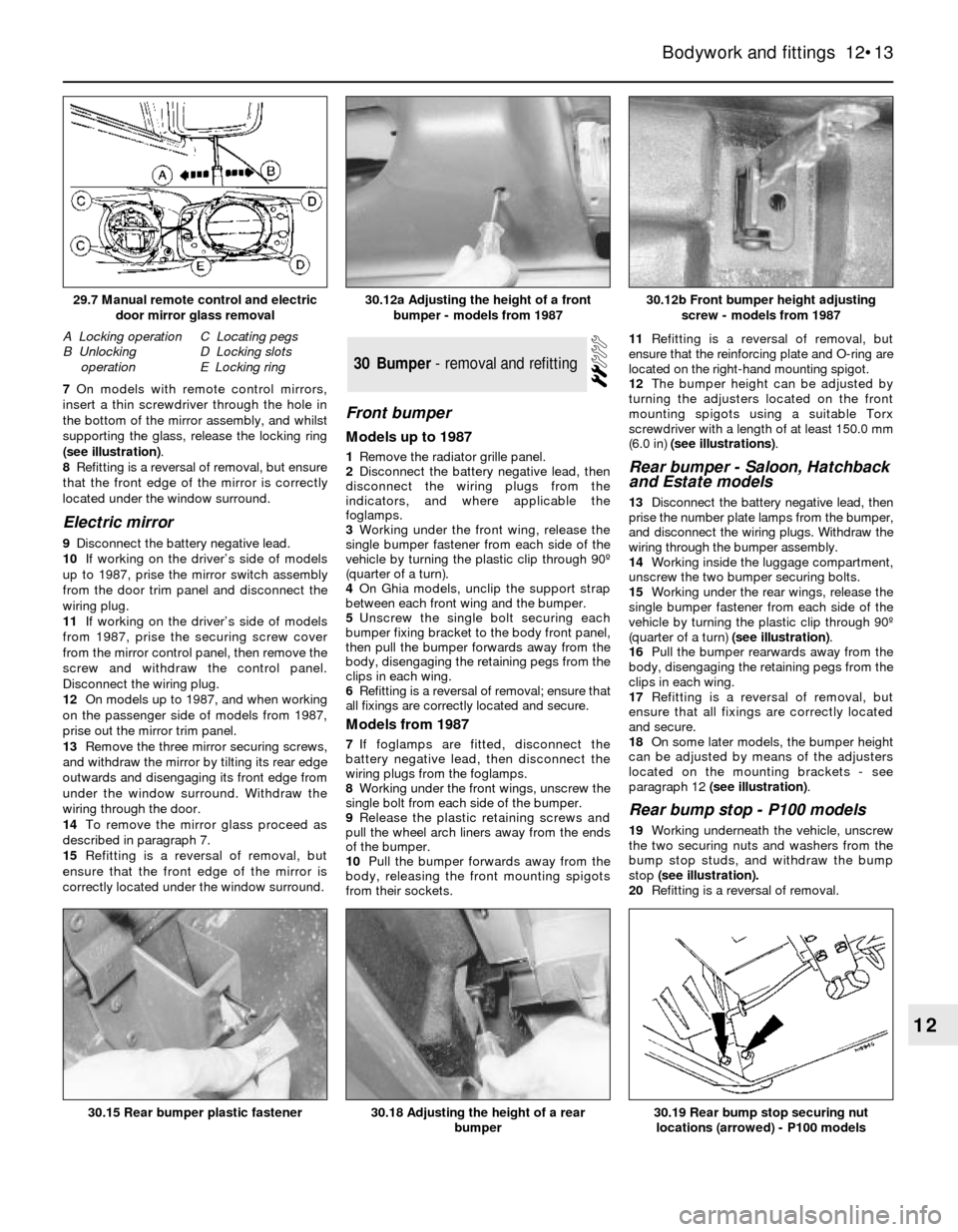

7On models with remote control mirrors,

insert a thin screwdriver through the hole in

the bottom of the mirror assembly, and whilst

supporting the glass, release the locking ring

(see illustration).

8Refitting is a reversal of removal, but ensure

that the front edge of the mirror is correctly

located under the window surround.

Electric mirror

9Disconnect the battery negative lead.

10If working on the driver’s side of models

up to 1987, prise the mirror switch assembly

from the door trim panel and disconnect the

wiring plug.

11If working on the driver’s side of models

from 1987, prise the securing screw cover

from the mirror control panel, then remove the

screw and withdraw the control panel.

Disconnect the wiring plug.

12On models up to 1987, and when working

on the passenger side of models from 1987,

prise out the mirror trim panel.

13Remove the three mirror securing screws,

and withdraw the mirror by tilting its rear edge

outwards and disengaging its front edge from

under the window surround. Withdraw the

wiring through the door.

14To remove the mirror glass proceed as

described in paragraph 7.

15Refitting is a reversal of removal, but

ensure that the front edge of the mirror is

correctly located under the window surround.

Front bumper

Models up to 1987

1Remove the radiator grille panel.

2Disconnect the battery negative lead, then

disconnect the wiring plugs from the

indicators, and where applicable the

foglamps.

3Working under the front wing, release the

single bumper fastener from each side of the

vehicle by turning the plastic clip through 90º

(quarter of a turn).

4On Ghia models, unclip the support strap

between each front wing and the bumper.

5Unscrew the single bolt securing each

bumper fixing bracket to the body front panel,

then pull the bumper forwards away from the

body, disengaging the retaining pegs from the

clips in each wing.

6Refitting is a reversal of removal; ensure that

all fixings are correctly located and secure.

Models from 1987

7If foglamps are fitted, disconnect the

battery negative lead, then disconnect the

wiring plugs from the foglamps.

8Working under the front wings, unscrew the

single bolt from each side of the bumper.

9Release the plastic retaining screws and

pull the wheel arch liners away from the ends

of the bumper.

10Pull the bumper forwards away from the

body, releasing the front mounting spigots

from their sockets.11Refitting is a reversal of removal, but

ensure that the reinforcing plate and O-ring are

located on the right-hand mounting spigot.

12The bumper height can be adjusted by

turning the adjusters located on the front

mounting spigots using a suitable Torx

screwdriver with a length of at least 150.0 mm

(6.0 in) (see illustrations).

Rear bumper - Saloon, Hatchback

and Estate models

13Disconnect the battery negative lead, then

prise the number plate lamps from the bumper,

and disconnect the wiring plugs. Withdraw the

wiring through the bumper assembly.

14Working inside the luggage compartment,

unscrew the two bumper securing bolts.

15Working under the rear wings, release the

single bumper fastener from each side of the

vehicle by turning the plastic clip through 90º

(quarter of a turn) (see illustration).

16Pull the bumper rearwards away from the

body, disengaging the retaining pegs from the

clips in each wing.

17Refitting is a reversal of removal, but

ensure that all fixings are correctly located

and secure.

18On some later models, the bumper height

can be adjusted by means of the adjusters

located on the mounting brackets - see

paragraph 12 (see illustration).

Rear bump stop - P100 models

19Working underneath the vehicle, unscrew

the two securing nuts and washers from the

bump stop studs, and withdraw the bump

stop (see illustration).

20Refitting is a reversal of removal.

30Bumper - removal and refitting

Bodywork and fittings 12•13

12

30.15 Rear bumper plastic fastener30.19 Rear bump stop securing nut

locations (arrowed) - P100 models30.18 Adjusting the height of a rear

bumper

30.12b Front bumper height adjusting

screw - models from 198730.12a Adjusting the height of a front

bumper - models from 198729.7 Manual remote control and electric

door mirror glass removal

A Locking operation

B Unlocking

operationC Locating pegs

D Locking slots

E Locking ring

Page 14 of 22

New bumpers are supplied without the trim

moulding fitted. Special primer and adhesive

tape are specified by the manufacturer to

retain the moulding: it is suggested that a

Ford dealer is consulted for further details.

A damaged moulding can be removed by

prising it from the bumper using a screwdriver.

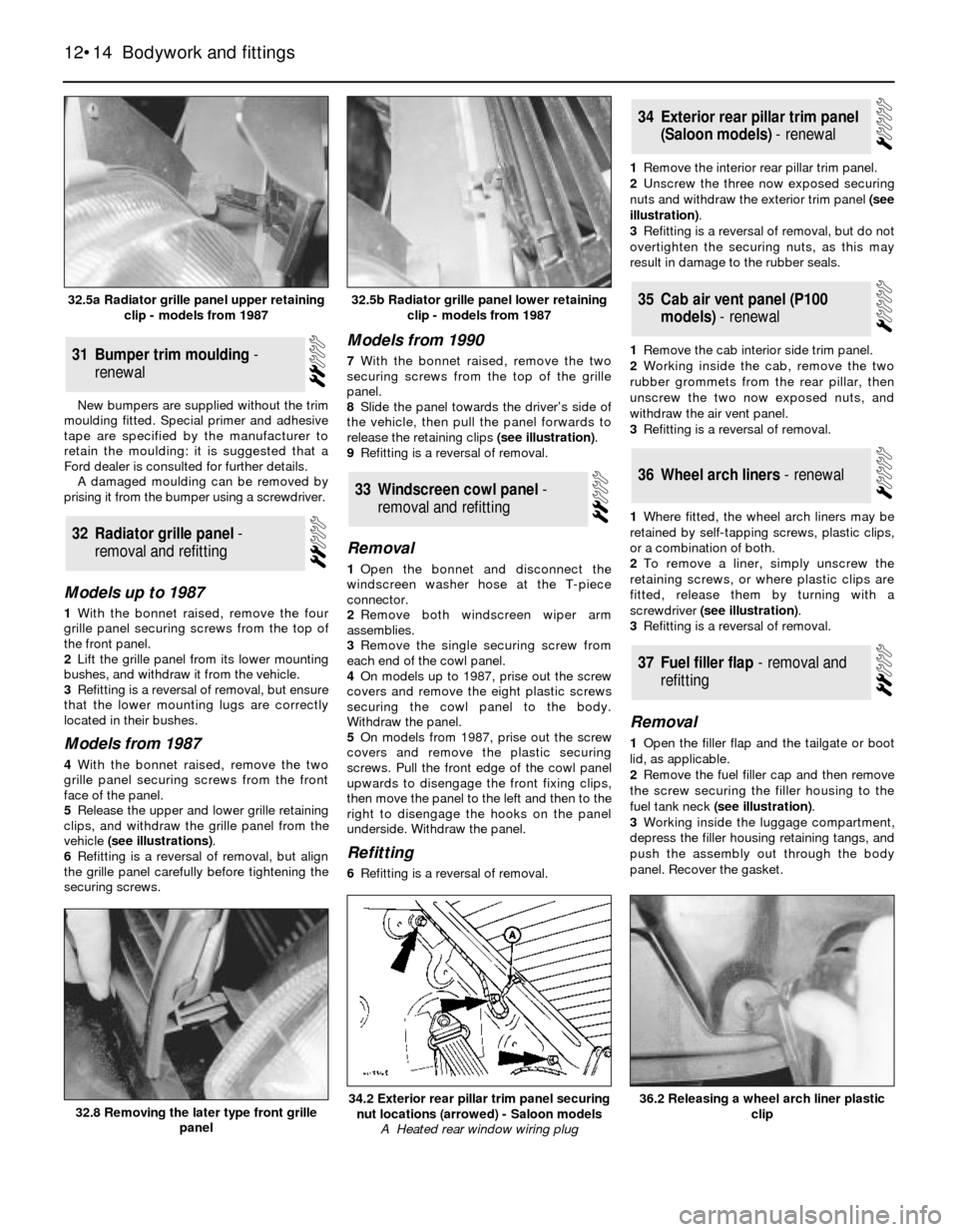

Models up to 1987

1With the bonnet raised, remove the four

grille panel securing screws from the top of

the front panel.

2Lift the grille panel from its lower mounting

bushes, and withdraw it from the vehicle.

3Refitting is a reversal of removal, but ensure

that the lower mounting lugs are correctly

located in their bushes.

Models from 1987

4With the bonnet raised, remove the two

grille panel securing screws from the front

face of the panel.

5Release the upper and lower grille retaining

clips, and withdraw the grille panel from the

vehicle (see illustrations).

6Refitting is a reversal of removal, but align

the grille panel carefully before tightening the

securing screws.

Models from 1990

7With the bonnet raised, remove the two

securing screws from the top of the grille

panel.

8Slide the panel towards the driver’s side of

the vehicle, then pull the panel forwards to

release the retaining clips (see illustration).

9Refitting is a reversal of removal.

Removal

1Open the bonnet and disconnect the

windscreen washer hose at the T-piece

connector.

2Remove both windscreen wiper arm

assemblies.

3Remove the single securing screw from

each end of the cowl panel.

4On models up to 1987, prise out the screw

covers and remove the eight plastic screws

securing the cowl panel to the body.

Withdraw the panel.

5On models from 1987, prise out the screw

covers and remove the plastic securing

screws. Pull the front edge of the cowl panel

upwards to disengage the front fixing clips,

then move the panel to the left and then to the

right to disengage the hooks on the panel

underside. Withdraw the panel.

Refitting

6Refitting is a reversal of removal.1Remove the interior rear pillar trim panel.

2Unscrew the three now exposed securing

nuts and withdraw the exterior trim panel (see

illustration).

3Refitting is a reversal of removal, but do not

overtighten the securing nuts, as this may

result in damage to the rubber seals.

1Remove the cab interior side trim panel.

2Working inside the cab, remove the two

rubber grommets from the rear pillar, then

unscrew the two now exposed nuts, and

withdraw the air vent panel.

3Refitting is a reversal of removal.

1Where fitted, the wheel arch liners may be

retained by self-tapping screws, plastic clips,

or a combination of both.

2To remove a liner, simply unscrew the

retaining screws, or where plastic clips are

fitted, release them by turning with a

screwdriver (see illustration).

3Refitting is a reversal of removal.

Removal

1Open the filler flap and the tailgate or boot

lid, as applicable.

2Remove the fuel filler cap and then remove

the screw securing the filler housing to the

fuel tank neck (see illustration).

3Working inside the luggage compartment,

depress the filler housing retaining tangs, and

push the assembly out through the body

panel. Recover the gasket.

37Fuel filler flap - removal and

refitting

36Wheel arch liners - renewal

35Cab air vent panel (P100

models) - renewal

34Exterior rear pillar trim panel

(Saloon models) - renewal

33Windscreen cowl panel -

removal and refitting

32Radiator grille panel -

removal and refitting

31Bumper trim moulding -

renewal

12•14Bodywork and fittings

32.8 Removing the later type front grille

panel36.2 Releasing a wheel arch liner plastic

clip34.2 Exterior rear pillar trim panel securing

nut locations (arrowed) - Saloon models

A Heated rear window wiring plug

32.5b Radiator grille panel lower retaining

clip - models from 198732.5a Radiator grille panel upper retaining

clip - models from 1987