check engine FORD SIERRA 1983 1.G Suspension And Steering Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1983, Model line: SIERRA, Model: FORD SIERRA 1983 1.GPages: 20, PDF Size: 0.94 MB

Page 5 of 20

7Working in the engine compartment,

unscrew the strut upper mounting nut, at the

same time supporting the strut from below.

Use a 6 mm Allen key inserted in the end of

the strut piston rod to prevent the rod from

turning as the upper mounting nut is

unscrewed (see illustration). On some

models, the upper mounting nut may be fitted

with a plastic cover. Note the upper mounting

cup under the nut.

8Withdraw the strut from under the wing of

the vehicle.

Overhaul

9To dismantle the strut, proceed as follows.

10Using spring compressors, compress the

coil spring. Do not attempt to compress the

spring without using purpose-made spring

compressors, as the spring is under

considerable tension, and personal injury may

occur if it is suddenly released (see

illustration).

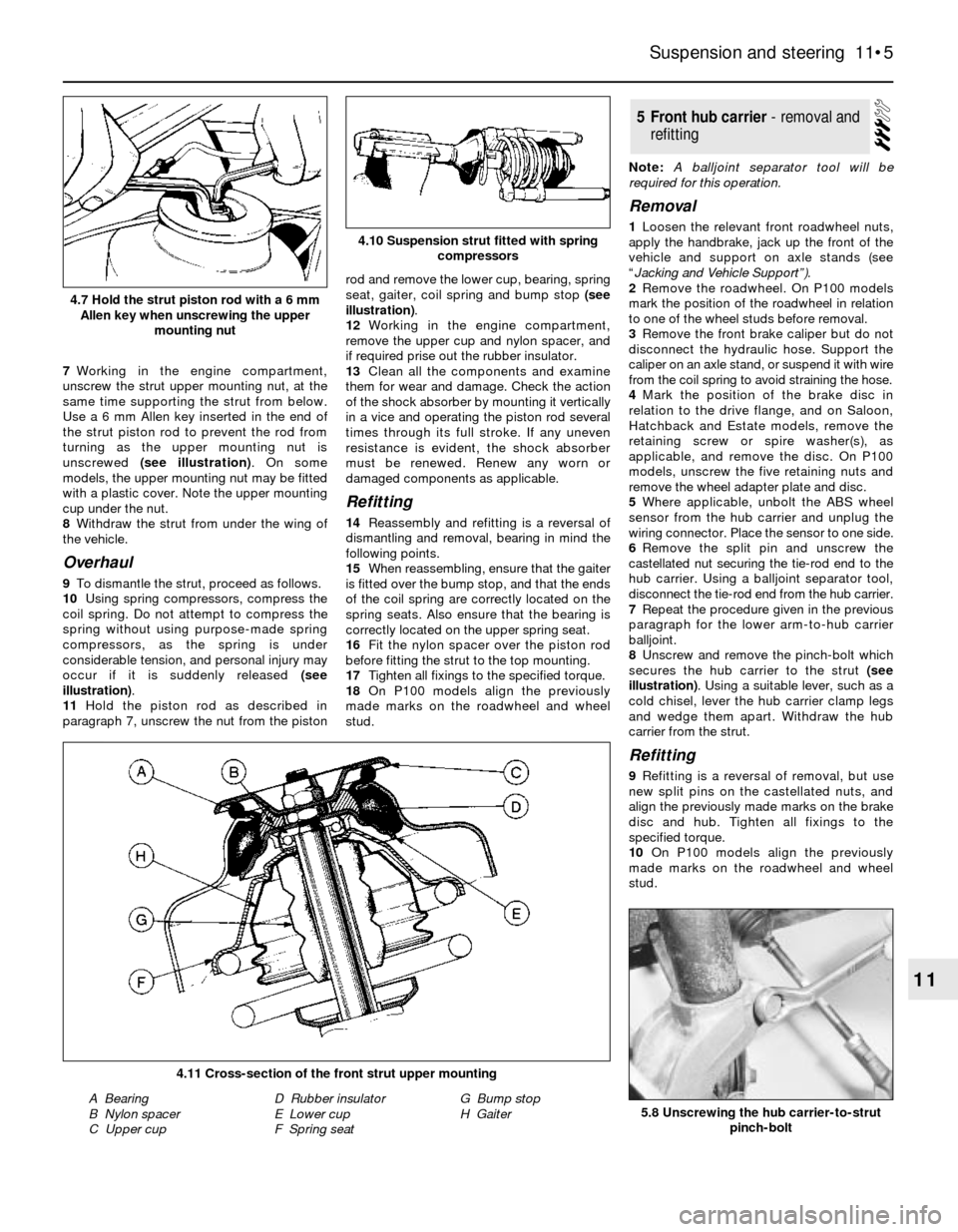

11Hold the piston rod as described in

paragraph 7, unscrew the nut from the pistonrod and remove the lower cup, bearing, spring

seat, gaiter, coil spring and bump stop (see

illustration).

12Working in the engine compartment,

remove the upper cup and nylon spacer, and

if required prise out the rubber insulator.

13Clean all the components and examine

them for wear and damage. Check the action

of the shock absorber by mounting it vertically

in a vice and operating the piston rod several

times through its full stroke. If any uneven

resistance is evident, the shock absorber

must be renewed. Renew any worn or

damaged components as applicable.

Refitting

14Reassembly and refitting is a reversal of

dismantling and removal, bearing in mind the

following points.

15When reassembling, ensure that the gaiter

is fitted over the bump stop, and that the ends

of the coil spring are correctly located on the

spring seats. Also ensure that the bearing is

correctly located on the upper spring seat.

16Fit the nylon spacer over the piston rod

before fitting the strut to the top mounting.

17Tighten all fixings to the specified torque.

18On P100 models align the previously

made marks on the roadwheel and wheel

stud.Note: A balljoint separator tool will be

required for this operation.

Removal

1Loosen the relevant front roadwheel nuts,

apply the handbrake, jack up the front of the

vehicle and support on axle stands (see

“Jacking and Vehicle Support”).

2Remove the roadwheel. On P100 models

mark the position of the roadwheel in relation

to one of the wheel studs before removal.

3Remove the front brake caliper but do not

disconnect the hydraulic hose. Support the

caliper on an axle stand, or suspend it with wire

from the coil spring to avoid straining the hose.

4Mark the position of the brake disc in

relation to the drive flange, and on Saloon,

Hatchback and Estate models, remove the

retaining screw or spire washer(s), as

applicable, and remove the disc. On P100

models, unscrew the five retaining nuts and

remove the wheel adapter plate and disc.

5Where applicable, unbolt the ABS wheel

sensor from the hub carrier and unplug the

wiring connector. Place the sensor to one side.

6Remove the split pin and unscrew the

castellated nut securing the tie-rod end to the

hub carrier. Using a balljoint separator tool,

disconnect the tie-rod end from the hub carrier.

7Repeat the procedure given in the previous

paragraph for the lower arm-to-hub carrier

balljoint.

8Unscrew and remove the pinch-bolt which

secures the hub carrier to the strut (see

illustration). Using a suitable lever, such as a

cold chisel, lever the hub carrier clamp legs

and wedge them apart. Withdraw the hub

carrier from the strut.

Refitting

9Refitting is a reversal of removal, but use

new split pins on the castellated nuts, and

align the previously made marks on the brake

disc and hub. Tighten all fixings to the

specified torque.

10On P100 models align the previously

made marks on the roadwheel and wheel

stud.

5Front hub carrier -removaland

refitting

Suspension and steering 11•5

11

5.8 Unscrewing the hub carrier-to-strut

pinch-bolt

4.11 Cross-section of the front strut upper mounting

A Bearing

B Nylon spacer

C Upper cupD Rubber insulator

E Lower cup

F Spring seatG Bump stop

H Gaiter

4.10 Suspension strut fitted with spring

compressors

4.7 Hold the strut piston rod with a 6 mm

Allen key when unscrewing the upper

mounting nut

Page 16 of 20

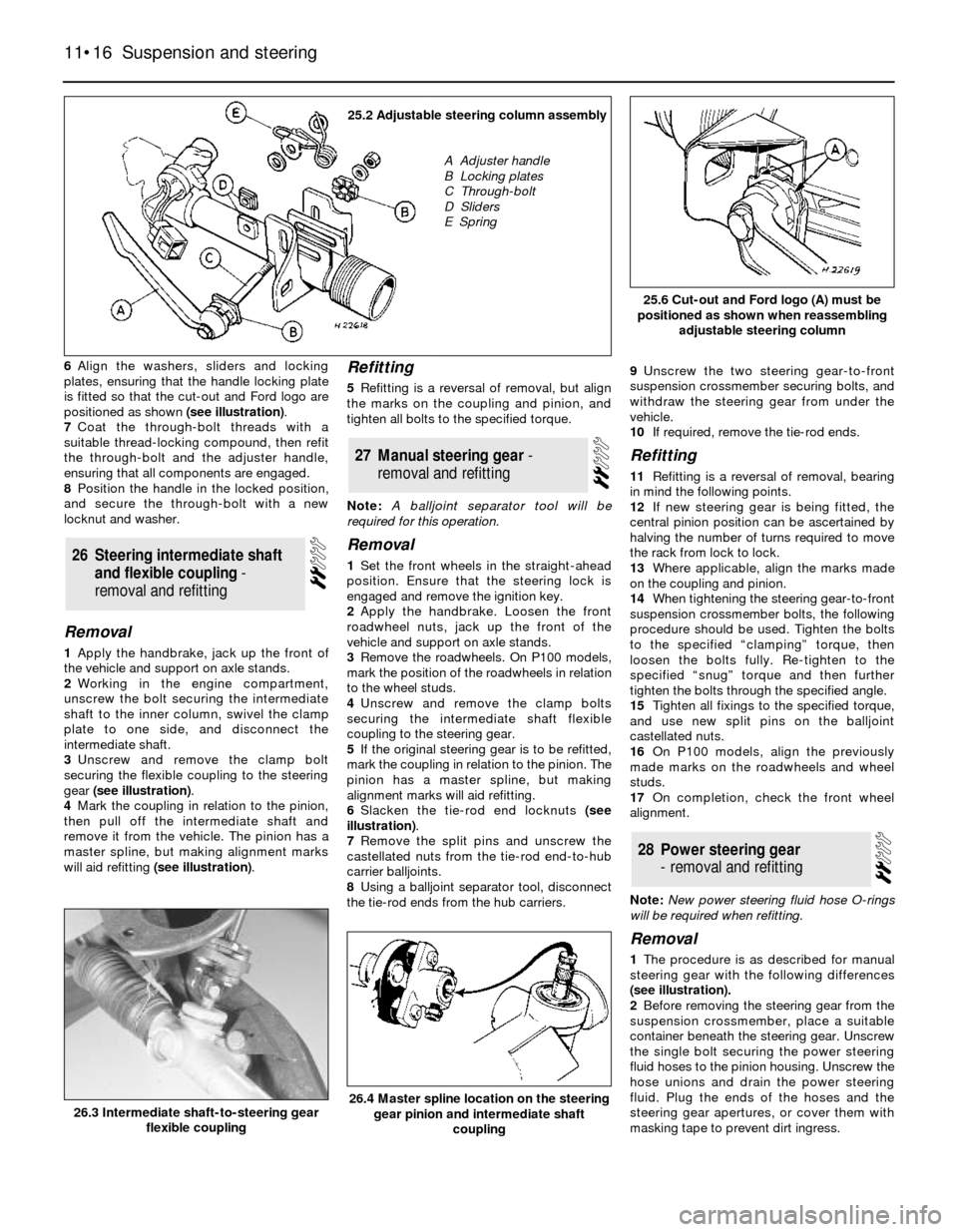

6Align the washers, sliders and locking

plates, ensuring that the handle locking plate

is fitted so that the cut-out and Ford logo are

positioned as shown (see illustration).

7Coat the through-bolt threads with a

suitable thread-locking compound, then refit

the through-bolt and the adjuster handle,

ensuring that all components are engaged.

8Position the handle in the locked position,

and secure the through-bolt with a new

locknut and washer.

Removal

1Apply the handbrake, jack up the front of

the vehicle and support on axle stands.

2Working in the engine compartment,

unscrew the bolt securing the intermediate

shaft to the inner column, swivel the clamp

plate to one side, and disconnect the

intermediate shaft.

3Unscrew and remove the clamp bolt

securing the flexible coupling to the steering

gear (see illustration).

4Mark the coupling in relation to the pinion,

then pull off the intermediate shaft and

remove it from the vehicle. The pinion has a

master spline, but making alignment marks

will aid refitting (see illustration).

Refitting

5Refitting is a reversal of removal, but align

the marks on the coupling and pinion, and

tighten all bolts to the specified torque.

Note: A balljoint separator tool will be

required for this operation.

Removal

1Set the front wheels in the straight-ahead

position. Ensure that the steering lock is

engaged and remove the ignition key.

2Apply the handbrake. Loosen the front

roadwheel nuts, jack up the front of the

vehicle and support on axle stands.

3Remove the roadwheels. On P100 models,

mark the position of the roadwheels in relation

to the wheel studs.

4Unscrew and remove the clamp bolts

securing the intermediate shaft flexible

coupling to the steering gear.

5If the original steering gear is to be refitted,

mark the coupling in relation to the pinion. The

pinion has a master spline, but making

alignment marks will aid refitting.

6Slacken the tie-rod end locknuts (see

illustration).

7Remove the split pins and unscrew the

castellated nuts from the tie-rod end-to-hub

carrier balljoints.

8Using a balljoint separator tool, disconnect

the tie-rod ends from the hub carriers.9Unscrew the two steering gear-to-front

suspension crossmember securing bolts, and

withdraw the steering gear from under the

vehicle.

10If required, remove the tie-rod ends.

Refitting

11Refitting is a reversal of removal, bearing

in mind the following points.

12If new steering gear is being fitted, the

central pinion position can be ascertained by

halving the number of turns required to move

the rack from lock to lock.

13Where applicable, align the marks made

on the coupling and pinion.

14When tightening the steering gear-to-front

suspension crossmember bolts, the following

procedure should be used. Tighten the bolts

to the specified “clamping” torque, then

loosen the bolts fully. Re-tighten to the

specified “snug” torque and then further

tighten the bolts through the specified angle.

15Tighten all fixings to the specified torque,

and use new split pins on the balljoint

castellated nuts.

16On P100 models, align the previously

made marks on the roadwheels and wheel

studs.

17On completion, check the front wheel

alignment.

Note: New power steering fluid hose O-rings

will be required when refitting.

Removal

1The procedure is as described for manual

steering gear with the following differences

(see illustration).

2Before removing the steering gear from the

suspension crossmember, place a suitable

container beneath the steering gear. Unscrew

the single bolt securing the power steering

fluid hoses to the pinion housing. Unscrew the

hose unions and drain the power steering

fluid. Plug the ends of the hoses and the

steering gear apertures, or cover them with

masking tape to prevent dirt ingress.

28Power steering gear

- removal and refitting

27Manual steering gear -

removaland refitting

26Steering intermediate shaft

and flexible coupling -

removal and refitting

11•16Suspension and steering

25.6 Cut-out and Ford logo (A) must be

positioned as shown when reassembling

adjustable steering column

26.4 Master spline location on the steering

gear pinion and intermediate shaft

coupling26.3 Intermediate shaft-to-steering gear

flexible coupling

25.2 Adjustable steering column assembly

A Adjuster handle

B Locking plates

C Through-bolt

D Sliders

E Spring

Page 18 of 20

Refitting

3When refitting the fluid hoses, use new

O-rings, and take care not to overtighten the

unions. Note that with the unions fully

tightened it is still possible to rotate and move

the hoses.

4On completion of refitting, bleed the power

steering fluid circuit (Section 34).

Note: New power steering fluid hose O-rings

will be required when refitting.

All engines except 1.8 litre (R6A)

CVH and 2.0 litre DOHC

1Place a suitable container under the power

steering pump, unscrew the fluid hose unions,

and drain the fluid. Ensure that fluid is not

allowed to spill onto the alternator.

2Remove the drivebelts and unbolt the

power steering pump pulley if necessary to

ease removal.

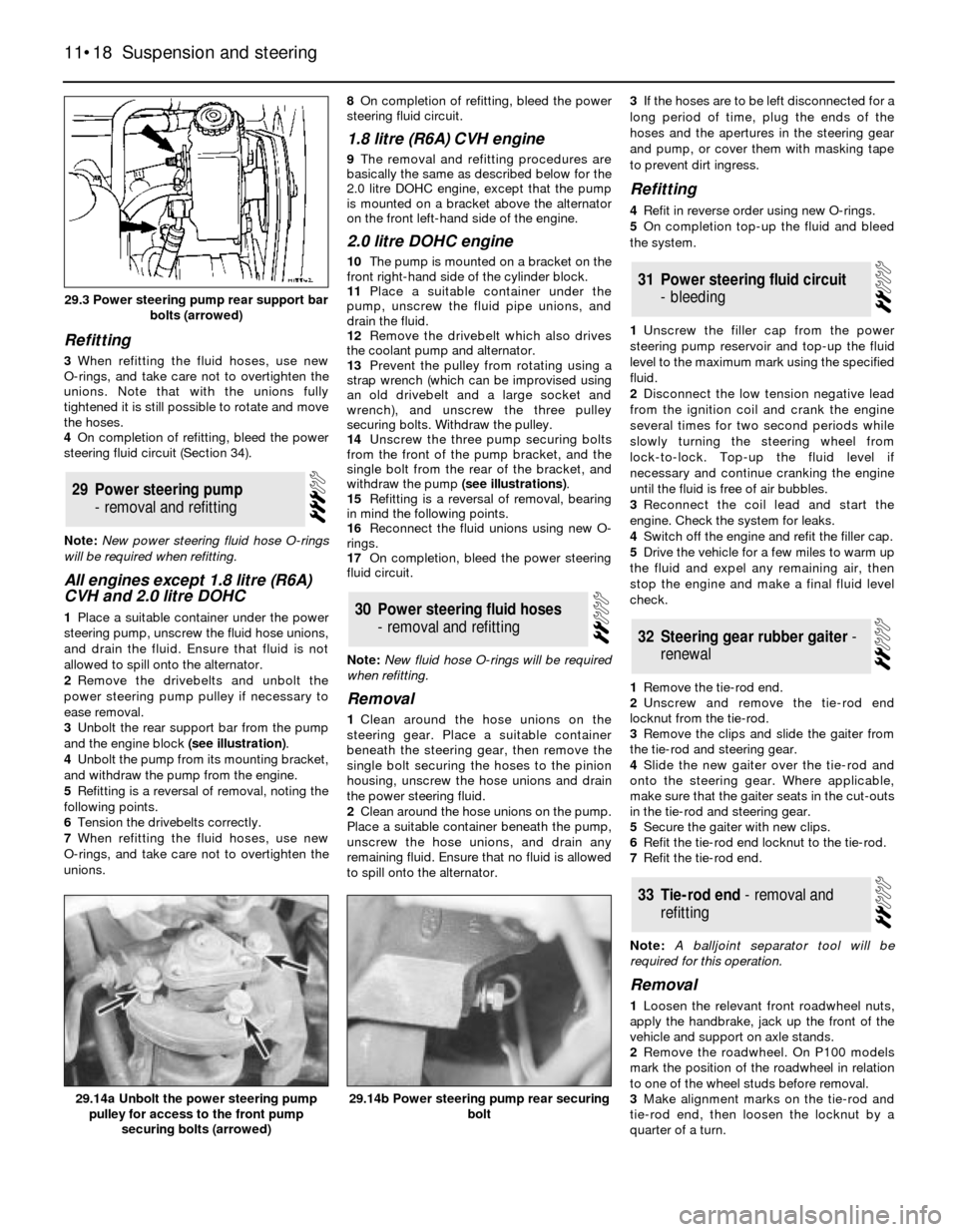

3Unbolt the rear support bar from the pump

and the engine block (see illustration).

4Unbolt the pump from its mounting bracket,

and withdraw the pump from the engine.

5Refitting is a reversal of removal, noting the

following points.

6Tension the drivebelts correctly.

7When refitting the fluid hoses, use new

O-rings, and take care not to overtighten the

unions. 8On completion of refitting, bleed the power

steering fluid circuit.

1.8 litre (R6A) CVH engine

9The removal and refitting procedures are

basically the same as described below for the

2.0 litre DOHC engine, except that the pump

is mounted on a bracket above the alternator

on the front left-hand side of the engine.

2.0 litre DOHC engine

10The pump is mounted on a bracket on the

front right-hand side of the cylinder block.

11Place a suitable container under the

pump, unscrew the fluid pipe unions, and

drain the fluid.

12Remove the drivebelt which also drives

the coolant pump and alternator.

13Prevent the pulley from rotating using a

strap wrench (which can be improvised using

an old drivebelt and a large socket and

wrench), and unscrew the three pulley

securing bolts. Withdraw the pulley.

14Unscrew the three pump securing bolts

from the front of the pump bracket, and the

single bolt from the rear of the bracket, and

withdraw the pump (see illustrations).

15Refitting is a reversal of removal, bearing

in mind the following points.

16Reconnect the fluid unions using new O-

rings.

17On completion, bleed the power steering

fluid circuit.

Note: New fluid hose O-rings will be required

when refitting.

Removal

1Clean around the hose unions on the

steering gear. Place a suitable container

beneath the steering gear, then remove the

single bolt securing the hoses to the pinion

housing, unscrew the hose unions and drain

the power steering fluid.

2Clean around the hose unions on the pump.

Place a suitable container beneath the pump,

unscrew the hose unions, and drain any

remaining fluid. Ensure that no fluid is allowed

to spill onto the alternator.3If the hoses are to be left disconnected for a

long period of time, plug the ends of the

hoses and the apertures in the steering gear

and pump, or cover them with masking tape

to prevent dirt ingress.

Refitting

4Refit in reverse order using new O-rings.

5On completion top-up the fluid and bleed

the system.

1Unscrew the filler cap from the power

steering pump reservoir and top-up the fluid

level to the maximum mark using the specified

fluid.

2Disconnect the low tension negative lead

from the ignition coil and crank the engine

several times for two second periods while

slowly turning the steering wheel from

lock-to-lock. Top-up the fluid level if

necessary and continue cranking the engine

until the fluid is free of air bubbles.

3Reconnect the coil lead and start the

engine. Check the system for leaks.

4Switch off the engine and refit the filler cap.

5Drive the vehicle for a few miles to warm up

the fluid and expel any remaining air, then

stop the engine and make a final fluid level

check.

1Remove the tie-rod end.

2Unscrew and remove the tie-rod end

locknut from the tie-rod.

3Remove the clips and slide the gaiter from

the tie-rod and steering gear.

4Slide the new gaiter over the tie-rod and

onto the steering gear. Where applicable,

make sure that the gaiter seats in the cut-outs

in the tie-rod and steering gear.

5Secure the gaiter with new clips.

6Refit the tie-rod end locknut to the tie-rod.

7Refit the tie-rod end.

Note: A balljoint separator tool will be

required for this operation.

Removal

1Loosen the relevant front roadwheel nuts,

apply the handbrake, jack up the front of the

vehicle and support on axle stands.

2Remove the roadwheel. On P100 models

mark the position of the roadwheel in relation

to one of the wheel studs before removal.

3Make alignment marks on the tie-rod and

tie-rod end, then loosen the locknut by a

quarter of a turn.

33Tie-rod end - removal and

refitting

32Steering gear rubber gaiter -

renewal

31Power steering fluid circuit

- bleeding

30Power steering fluid hoses

- removal and refitting

29Power steering pump

- removal and refitting

11•18Suspension and steering

29.3 Power steering pump rear support bar

bolts (arrowed)

29.14b Power steering pump rear securing

bolt29.14a Unbolt the power steering pump

pulley for access to the front pump

securing bolts (arrowed)