fuse box location FORD SIERRA 1986 1.G Engine Electrical Systems Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1986, Model line: SIERRA, Model: FORD SIERRA 1986 1.GPages: 24, PDF Size: 0.93 MB

Page 22 of 24

38Before refitting the sensor, examine the

O-ring, and renew it if damaged or worn.

39Refitting is a reversal of removal, noting

the torque setting for the sensor screw.

Note: Procedures for removal and refitting of

the ignition system components and

electronic module are given elsewhere in the

relevant Sections of this Chapter.

1Disconnect the battery negative lead.

Crankshaft speed/position sensor

2The sensor is mounted in a bracket on the

timing cover.

3Disconnect the sensor wiring plug by

pulling on the plug, not the wiring (see

illustration).

4Slacken the sensor clamping screw and

slide the sensor from its bracket.

5Refitting is a reversal of removal, but the

clearance between the sensor and the

toothed wheel on the crankshaft must be set

at 1.0 mm (0.04 in). This can be achieved by

inserting a suitable length of wire or rod with a

diameter of 1.0 mm (0.04 in) between the

sensor and the toothed wheel (see

illustration). Do not overtighten the clamping

screw, as damage to the sensor may result.

Engine coolant temperature

sensor

6The sensor is located in the side of the inlet

manifold(see illustration).

7Partially drain the cooling system.

8Disconnect the sensor wiring plug by

pulling on the plug, not the wiring.

9Unscrew the sensor from the inlet manifold

and remove it.

10Refitting is a reversal of removal. Fill the

cooling system.

Air charge temperature sensor

11The sensor is located in the base of the air

cleaner.

12Remove the air cleaner.

13Disconnect the sensor wiring plug by

pulling on the plug, not the wiring (see

illustration).14Unscrew the sensor from the air cleaner

using a suitable spanner.

15Refitting is a reversal of removal. Refit the

air cleaner. Ensure that the vacuum hose is

securely connected.

Electric choke heater

16The electric choke heater is an integral

part of the automatic choke housing on the

carburettor. Removal and refitting of the

choke housing is covered in Chapter 4.

17The operation of the electric choke heater

relay can be checked by starting the engine

from cold, and placing a finger on the relay

(see illustration). It should be possible to feel

the relay switching on and off. If this is not the

case, renew the relay.

Throttle damper control solenoid

18The solenoid is on the right-hand side of

the engine compartment (see illustration). 19Disconnect the solenoid wiring plug by

pulling on the plug, not the wiring.

20Disconnect the two vacuum pipes from

the solenoid, noting their locations for use

when refitting.

21Remove the securing screw and withdraw

the solenoid from the body panel.

22Refitting is a reversal of removal, but note

that the locating lug on the solenoid bracket

should engage with the body panel, and make

sure that the vacuum pipes are correctly

connected.

Throttle damper

23Remove the air cleaner.

24Disconnect the vacuum pipe from the

throttle damper.

20ESC Hybrid system

components - removal and

refitting

5•22Engine electrical systems

20.3 Disconnecting crankshaft

speed/position sensor wiring plug - ESC

Hybrid system

20.6 Engine coolant temperature sensor

location - ESC Hybrid system

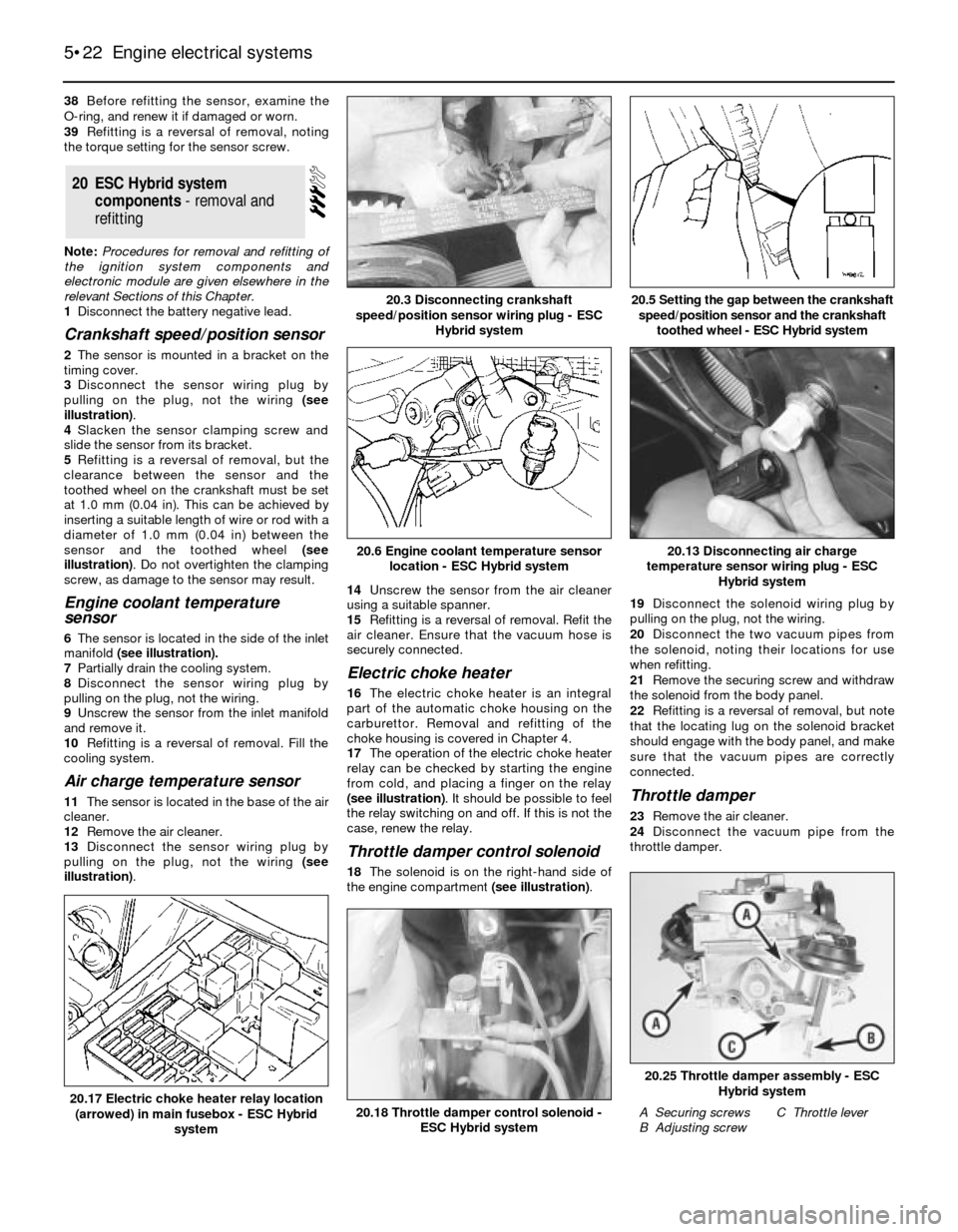

20.25 Throttle damper assembly - ESC

Hybrid system

A Securing screws

B Adjusting screwC Throttle lever20.18 Throttle damper control solenoid -

ESC Hybrid system20.17 Electric choke heater relay location

(arrowed) in main fusebox - ESC Hybrid

system

20.13 Disconnecting air charge

temperature sensor wiring plug - ESC

Hybrid system

20.5 Setting the gap between the crankshaft

speed/position sensor and the crankshaft

toothed wheel - ESC Hybrid system