sensor FORD SIERRA 1986 1.G Engine Electrical Systems Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1986, Model line: SIERRA, Model: FORD SIERRA 1986 1.GPages: 24, PDF Size: 0.93 MB

Page 2 of 24

Ignition timingLeaded petrolUnleaded petrol

(at idle with vacuum pipe disconnected)(4-star, 97 RON)(Premium, 95 RON)

Early “Economy” models (800 rpm - vacuum pipe connected) . . . . . . .16º BTDC12º BTDC

1.3 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12º BTDC8º BTDC*

1.6 litre models with VV carburettor . . . . . . . . . . . . . . . . . . . . . . . . . . . .12º BTDC8º BTDC*

1.6 litre models with 2V carburettor . . . . . . . . . . . . . . . . . . . . . . . . . . . .10º BTDC6º BTDC†

1.8 litre SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10º BTDC6º BTDC†

1.8 litre CVH models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ESC Hybrid controlled, no adjustment possible

2.0 litre carburettor models up to 1985 . . . . . . . . . . . . . . . . . . . . . . . . .8º BTDC4º BTDC*

2.0 litre carburettor models from 1985 (except P100) . . . . . . . . . . . . . .10º BTDC6º BTDC†

P100 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6º BTDC2º BTDC†

2.0 litre fuel injection models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12º BTDC8º BTDC†

*Fill with leaded petrol (4-star, 97 RON) every 4th tankful

†Not all vehicles are suitable for continuous operation on unleaded petrol.

Spark plugs

Make and type:

All models except 1.8 CVH, CVH (R6A), 2.0 DOHC and P100 . . . . . . . .Champion RF7YCC or RF7YC

1.8 CVH engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RC7YCC or RC7YC

P100 model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RF7YC or F7YC

1.6 and 1.8 CVH (R6A type) and 2.0 DOHC . . . . . . . . . . . . . . . . . . . . . .Champion RC7YCC

Electrode gap:

Champion F7YCC or RC7YCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.8 mm (0.032 in)

Champion RF7YC, F7YC or RC7YC . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.7 mm (0.028 in)

Note: The electrode gap above is the figure quoted by Champion for use with their recommended spark plugs. If plugs of any other type are fitted,

refer to their manufacturer’s gap recommendations.

HT leads

All SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion LS-09 or LS-10 boxed set

1.8 CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion LS-10 boxed set

1.6 and 1.8 CVH (R6A type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion LS-30 boxed set

2.0 DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion LS-29 boxed set

Maximum resistance per lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 000 ohms

Alternator

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bosch, Lucas, Motorola, or Mitsubishi

Regulated output voltage at 4000 rpm (3 to 7 amp load) . . . . . . . . . . . .13.7 to 14.6 volts

Minimum brush length:

All alternator types except Motorola . . . . . . . . . . . . . . . . . . . . . . . . . .5.0 mm (0.20 in)

Motorola type alternators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.0 mm (0.16 in)

Starter motor

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Pre-engaged; Bosch, Cajavec, Lucas, or Nippondenso

Minimum brush length:

All except Bosch long frame 1.1 kW and JF, and Nippondenso . . . .8.0 mm (0.32 in)

Bosch long frame 1.1 kW and JF, Nippondenso starter motors . . . .10.0 mm (0.40 in)

Battery charge condition:

Poor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12.5 volts

Normal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12.6 volts

Good . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12.7 volts

Torque wrench settingsNmlbf ft

Spark plugs:

SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2815 to 21

CVH models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 to 3313 to 24

DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 to 2111 to 15

Crankshaft speed/position sensor clamp bolt (ESC Hybrid system) . . .4 to 73 to 5

Crankshaft speed/position sensor screw (DOHC) . . . . . . . . . . . . . . . . .3 to 52 to 4

Camshaft sprocket bolt (CVH models) . . . . . . . . . . . . . . . . . . . . . . . . . .95 to 11570 to 85

Air charge temperature sensor (CVH-R6A and DOHC) . . . . . . . . . . . . .20 to 2515 to 18

Engine coolant temperature sensor (CVH-R6A and DOHC) . . . . . . . . . .20 to 2515 to 18

Fuel temperature sensor (DOHC injection) . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Alternator adjustment bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2815 to 20

Alternator mounting bolts:

With coloured patch on threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41 to 5130 to 38

Without coloured patch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

5•2Engine electrical systems

Page 3 of 24

General information

The electrical system is of the 12 volt

negative earth type, and consists of a 12 volt

battery, alternator with integral voltage

regulator, starter motor and related electrical

accessories, components and wiring. The

battery is of the low maintenance or

maintenance-free “sealed for life” type and is

charged by an alternator which is belt-driven

from the crankshaft pulley. The starter motor

is of the pre-engaged type, incorporating an

integral solenoid. On starting the solenoid

moves the drive pinion into engagement with

the flywheel ring gear before the starter motor

is energised. Once the engine has started, a

one-way clutch prevents the motor armature

being driven by the engine until the pinion

disengages from the flywheel.

The ignition system is responsible for

igniting the air/fuel mixture in each cylinder at

the correct moment in relation to engine

speed and load. A number of different ignition

systems are fitted to models within the

Sierra/P100 range, ranging from a basic

breakerless electronic system to a fully

integrated engine management system

controlling ignition and fuel injection systems.

The ignition system is based on feeding low

tension voltage from the battery to the coil

where it is converted to high tension voltage.

The high tension voltage is powerful enough

to jump the spark plug gap in the cylinders

many times a second under high compression

pressures, providing that the system is in

good condition. The low tension (or primary)

circuit consists of the battery, the lead to the

ignition switch, the lead from the ignition

switch to the low tension coil windings

(terminal + /15) and also to the supply terminal

on the electronic module, and the lead from

the low tension coil windings (terminal -/1) to

the control terminal on the electronic module.

The high tension (or secondary) circuit

consists of the high tension coil windings, the

HT (high tension) lead from the coil to the

distributor cap, the rotor arm, the HT leads to

the spark plugs, and the spark plugs.

The system functions in the following

manner. Current flowing through the low

tension coil windings produces a magnetic

field around the high tension windings. As the

engine rotates, a sensor produces an

electrical impulse which is amplified in the

electronic module and used to switch off the

low tension circuit.

The subsequent collapse of the magnetic

field over the high tension windings produces

high tension voltage which is then fed to the

relevant spark plug via the distributor cap and

rotor arm. The low tension circuit is

automatically switched on again by the

electronic module, to allow the magnetic field

to build up again before the firing of the next

spark plug. The ignition is advanced and

retarded automatically to ensure that thespark occurs at the correct instant in relation

to the engine speed and load.

To improve driveability during warm-up

conditions and to reduce exhaust emission

levels, a vacuum-operated,

temperature-sensitive spark control system is

fitted to certain vehicles.Inductive discharge system

This is the least sophisticated system fitted

to the Sierra/P100 range, and comprises a

breakerless distributor and an electronic

switching/amplifier module in addition to the

coil and spark plugs.

The electrical impulse which is required to

switch off the low tension circuit is generated

by a magnetic trigger coil in the distributor. A

trigger wheel rotates within a magnetic stator,

the magnetic field being provided by a

permanent magnet. The magnetic field across

the two poles (stator arm and trigger wheel) is

dependent on the air gap between the two

poles. When the air gap is at its minimum, the

trigger wheel arm is directly opposite the

stator arm, and this is the trigger point. As the

magnetic flux between the stator arm and

trigger wheel varies, a voltage is induced in

the trigger coil mounted below the trigger

wheel, and this voltage is sensed and then

amplified by the electronic module and used

to switch off the low tension circuit. There is

one trigger wheel arm and one stator arm for

each cylinder (4).

The ignition advance is a function of the

distributor and is controlled both mechanically

and by a vacuum operated system. The

mechanical governor mechanism consists of

two weights which move out from the

distributor shaft as the engine speed rises due

to centrifugal force. As they move outwards,

they rotate the trigger wheel relative to the

distributor shaft and so advance the spark.

The weights are held in position by two light

springs and it is the tension of the springs

which is largely responsible for correct spark

advancement.

The vacuum control consists of a

diaphragm, one side of which is connected

via a small bore hose to the carburettor or

inlet manifold and the other side to the

distributor. Depression in the inlet manifold

and/or carburettor, which varies with engine

speed and throttle position, causes the

diaphragm to move, so moving the baseplate

and advancing or retarding the spark. A fine

degree of control is achieved by a spring in

the diaphragm assembly.

ESC (Electronic Spark Control) system

This system is only fitted to early

“Economy” models, and comprises a “Hall

effect” distributor, and an ESC module, in

addition to the coil and spark plugs.

The electrical impulse which is required to

switch off the low tension circuit is generated

by a sensor in the distributor. A trigger vane

rotates in the gap between a permanent

magnet and the sensor. The trigger vane has

four cut-outs, one for each cylinder. When

one of the trigger vane cut-outs is in line with

the sensor, magnetic flux can pass betweenthe magnet and the sensor. When a trigger

vane segment is in line with the sensor, the

magnetic flux is diverted through the trigger

vane away from the sensor. The sensor

senses the change in magnetic flux and sends

an impulse to the ESC module, which

switches off the low tension circuit.

The ignition advance is a function of the

ESC module and is controlled by vacuum. The

module is connected to the inlet manifold by a

vacuum pipe, and a transducer in the module

translates the vacuum signal into electrical

voltage. From the vacuum signal, the ESC

module determines engine load, and engine

speed is determined from the interval

between impulses supplied by the distributor

sensor. The module has a range of spark

advance settings stored in its memory, and a

suitable setting is selected for the relevant

engine speed and load. The degree of

advance can thus be constantly varied to suit

the prevailing engine speed and load

conditions.

ESC II (Electronic Spark Control II)

system

1.8 and 2.0 litre SOHC carburettor models

This system is a development of the ESC

system described previously in this Section,

but it enables more accurate control of engine

operation due to the inclusion of additional

monitoring features and control outputs.

Vehicles fitted with the ESC II system have an

electric inlet manifold heater which warms the

air/fuel mixture when the engine is cold, thus

reducing the amount of fuel enrichment

required, lowering fuel consumption and

improving driveability when the engine is cold.

The heater is operated by the ESC II module

receiving information on the engine temperature

from an engine coolant temperature sensor

mounted in the inlet manifold.

On 2.0 litre SOHC models, the ESC II

module operates a carburettor stepper motor

to control the engine idle speed. Using

information on engine speed, load,

temperature and throttle position (supplied by

a switch on the carburettor), the module

operates the stepper motor to maintain a

constant idle speed. On models equipped

with automatic transmission and/or air

conditioning, additional inputs are supplied to

the module to allow it to operate the stepper

motor to compensate for the additional engine

load imposed by the automatic

transmission/air conditioning. The ESC II

module also operates a “power hold” relay

which allows the stepper motor to function

briefly after the ignition has been switched off

in order to perform an anti-run-on and

manifold ventilation cycle.

2.0 litre DOHC carburettor models

A development of the ESC II system is used

to control the operation of the engine. The

module receives information from a

crankshaft speed/position sensor (similar to

that described for the ESC Hybrid system),

except that the sensor is activated by a

toothed disc on the rear of the crankshaft,

inside the cylinder block), and an engine

coolant temperature sensor.

1General information and

precautions

Engine electrical systems 5•3

5

Page 4 of 24

The ignition advance is a function of the

ESC II module, and is controlled by vacuum.

The module is connected to the carburettor

by a vacuum pipe, and a transducer in the

module translates the vacuum signal into an

electrical voltage. From the vacuum signal,

the module determines engine load; engine

speed and temperature are determined from

the crankshaft speed/position sensor and the

engine coolant temperature sensor. The

module has a range of spark advance settings

stored in its memory, and a suitable setting is

selected for the relevant engine speed, load

and temperature. The degree of advance can

thus be constantly varied to suit the prevailing

engine speed and load conditions.

ESC Hybrid (Electronic Spark Control

Hybrid) system

This system is fitted to 1.8 CVH models,

and comprises various sensors and an ESC

Hybrid module, in addition to the coil and

spark plugs. The distributor serves purely to

distribute the HT voltage to the spark plugs

and consists simply of a rotor arm mounted

directly on the end of the camshaft, and a

distributor cap.

The electrical impulse which is required to

switch off the low tension circuit is generated

by a crankshaft speed/position sensor which

is activated by a toothed wheel on the

crankshaft. The toothed wheel has 35 equally

spaced teeth with a gap in the 36th position.

The gap is used by the sensor to determine

the crankshaft position relative to TDC (top

dead centre) of No 1 piston.

Engine load information is supplied to the

ESC Hybrid module by a vacuum transducer

within the module which is connected to the

inlet manifold by a vacuum pipe. Additional

inputs are supplied by an inlet

manifold-mounted engine coolant temperature

sensor, and an air charge temperature sensor

mounted in the base of the air cleaner. The

module selects the optimum ignition advance

setting based on the information received from

the various sensors. The degree of advance

can thus be constantly varied to suit the

prevailing engine conditions.

In addition to the ignition circuit, the module

also controls an electric choke heater, and a

solenoid valve which in turn controls a throttle

damper on the carburettor. The electric choke

heater is operated by the module using

information supplied by the engine coolant

temperature sensor. The heater is used to

slow down the rate at which the choke comes

off, thereby improving driveability and overall

fuel consumption when the engine is cold. The

solenoid valve controls the vacuum supply to

the carburettor throttle damper. The throttle

damper prevents sudden closing of the throttle

during deceleration, thus maintaining

combustion of the air/fuel mixture which

reduces harmful exhaust gas emissions.

Note that there is no provision for

adjustment of ignition timing with the ESC

Hybrid system.

EEC IV (Electronic Engine Control IV)

system

2.0 litre SOHC fuel injection models

This system controls both the ignition and

fuel injection systems. The EEC IV module

receives information from a “Hall effect”

distributor sensor (similar to that described

previously in this Section for the ESC system),

an engine coolant temperature sensor

mounted in the inlet manifold, a throttle

position sensor, and an air flow meter.

Additionally, on models equipped with

automatic transmission and/or air

conditioning, additional inputs are supplied to

the module to allow it to raise the idle speed

to compensate for the additional engine load

imposed by the automatic transmission/air

conditioning. The module provides outputs to

control the fuel pump, fuel injectors, idle

speed, and ignition circuit. Using the inputs

from the various sensors, the EEC IV module

computes the optimum ignition advance, and

fuel injector pulse duration to suit the

prevailing engine conditions. This system

gives very accurate control of the engine

under all conditions, improving fuel

consumption and driveability, and reducing

exhaust gas emissions. A “limited operation

strategy” (LOS) means that the vehicle is still

driveable, albeit at reduced power and

efficiency, in the event of a failure in the

module or its sensors.

2.0 litre DOHC fuel injection models

A development of the EEC IV system is

used to control both the ignition and fuel

injection systems. The module receives

information from a crankshaft speed/position

sensor (similar to that described for the ESC

Hybrid system), except that the sensor is

activated by a toothed disc on the rear of the

crankshaft, inside the cylinder block), a

throttle position sensor, an engine coolant

temperature sensor, a fuel temperature

sensor, an air charge temperature sensor, a

manifold absolute pressure (MAP) sensor, and

a vehicle speed sensor (mounted on the

gearbox). Additionally, on models with a

catalytic converter, an additional input is

supplied to the EEC IV module from an

exhaust gas oxygen (HEGO) sensor. On

models with automatic transmission,

additional sensors are fitted to the

transmission, to inform the EEC IV module

when the transmission is in neutral, and when

the kickdown is being operated.

The module provides outputs to control the

fuel pump, fuel injectors, idle speed, ignition

system and automatic transmission.

Additionally, on models with air conditioning,

the EEC IV module disengages the air

conditioning compressor clutch when starting

the engine, and when the engine is suddenly

accelerated. On models fitted with a catalytic

converter, the EEC IV module also controls

the carbon canister-purge solenoid valve.

Using the inputs from the various sensors,

the EEC IV module computes the optimum

ignition advance, and fuel injector pulse

duration to suit the prevailing engine

conditions. A “limited operation strategy” (LOS)means that the vehicle is still driveable, albeit at

reduced power and efficiency, in the event of a

failure in the module or one of its sensors.

1.6 litre and 1.8 litre (R6A type) CVH models

A development of the EEC IV system is

used to control both the ignition and fuel

injection systems. A fully electronic

Distributorless Ignition System (DIS) is fitted,

replacing the mechanical distribution of high

tension voltage (by a rotating distributor) with

“static” solid-state electronic components.

The system selects the most appropriate

ignition advance setting for the prevailing

engine operating conditions from a three-

dimensional map of values stored in the EEC

IV control module memory. The module

selects the appropriate advance value

according to information supplied on engine

load, speed, and operating temperature from

various sensors.

The EEC IV module receives information

from a crankshaft speed/position sensor

(similar to that described for the ESC Hybrid

system), except that on 1.6 litre engines, the

sensor is activated by a toothed disc on the

flywheel), a throttle position sensor, an engine

coolant temperature sensor, an air charge

temperature sensor, a manifold absolute

pressure (MAP) sensor, a vehicle speed

sensor (mounted on the gearbox), and an

exhaust gas oxygen sensor.

The module provides outputs to control the

fuel pump, fuel injector, throttle valve control

motor, pulse-air control solenoid, carbon

canister purge solenoid (where applicable),

and the ignition system.

Using the inputs from the various sensors,

the EEC IV module computes the optimum

ignition advance and fuel injector pulse dura-

tion to suit the prevailing engine conditions. A

“limited operation strategy” (LOS) means that

the vehicle will still be driveable, albeit at

reduced power and efficiency, in the event of

a failure in the module or one of its sensors.

Precautions

General

It is necessary to take extra care when

working on the electrical system to avoid

damage to semi-conductor devices (diodes

and transistors), and to avoid the risk of

personal injury. In addition to the precautions

given in the “Safety first!” Section at the

beginning of this manual, take note of the

following points when working on the system.

Always remove rings, watches, etc before

working on the electrical system. Even with

the battery disconnected, capacitive

discharge could occur if a component live

terminal is earthed through a metal object.

This could cause a shock or nasty burn.

Do not reverse the battery connections.

Components such as the alternator or any

other having semi-conductor circuitry could

be irreparably damaged.

If the engine is being started using jump

leads and a slave battery, connect the

batteries positive to positive and negative to

negative. This also applies when connecting a

battery charger.

5•4Engine electrical systems

Page 16 of 24

sprocket bolt. Note that there is no need to

remove the timing belt or the sprockets.

Note: During production the engine ignition

timing is accurately set using a microwave

process, and sealant is applied to the

distributor clamp bolt. Removal of the

distributor should be avoided except where

excessive bearing wear has occurred due to

high mileage or during major engine overhaul.

A timing light will be required to check the

ignition timing after refitting the distributor.

All models except early

“Economy”

Removal

1Disconnect the battery negative lead.

2If necessary, identify each HT lead for

position, so that the leads can be refitted to

their correct cylinders, then disconnect the

leads from the spark plugs by pulling on the

connectors, not the leads.

3Where applicable, unclip the screening can

from the top of the distributor and disconnect

the earth strap. On fuel injection models,

disconnect the crankcase ventilation hose

from the air inlet hose, then disconnect the air

inlet hose from the inlet manifold and the

airflow meter for improved access.4Prise away the spring clips with a

screwdriver, or remove the two securing

screws, as applicable, and lift off the

distributor cap.

5Disconnect the HT lead from the coil by

pulling on the connector, not the lead, then

slide the HT lead holder from the clip on the

camshaft cover, and withdraw the distributor

cap.

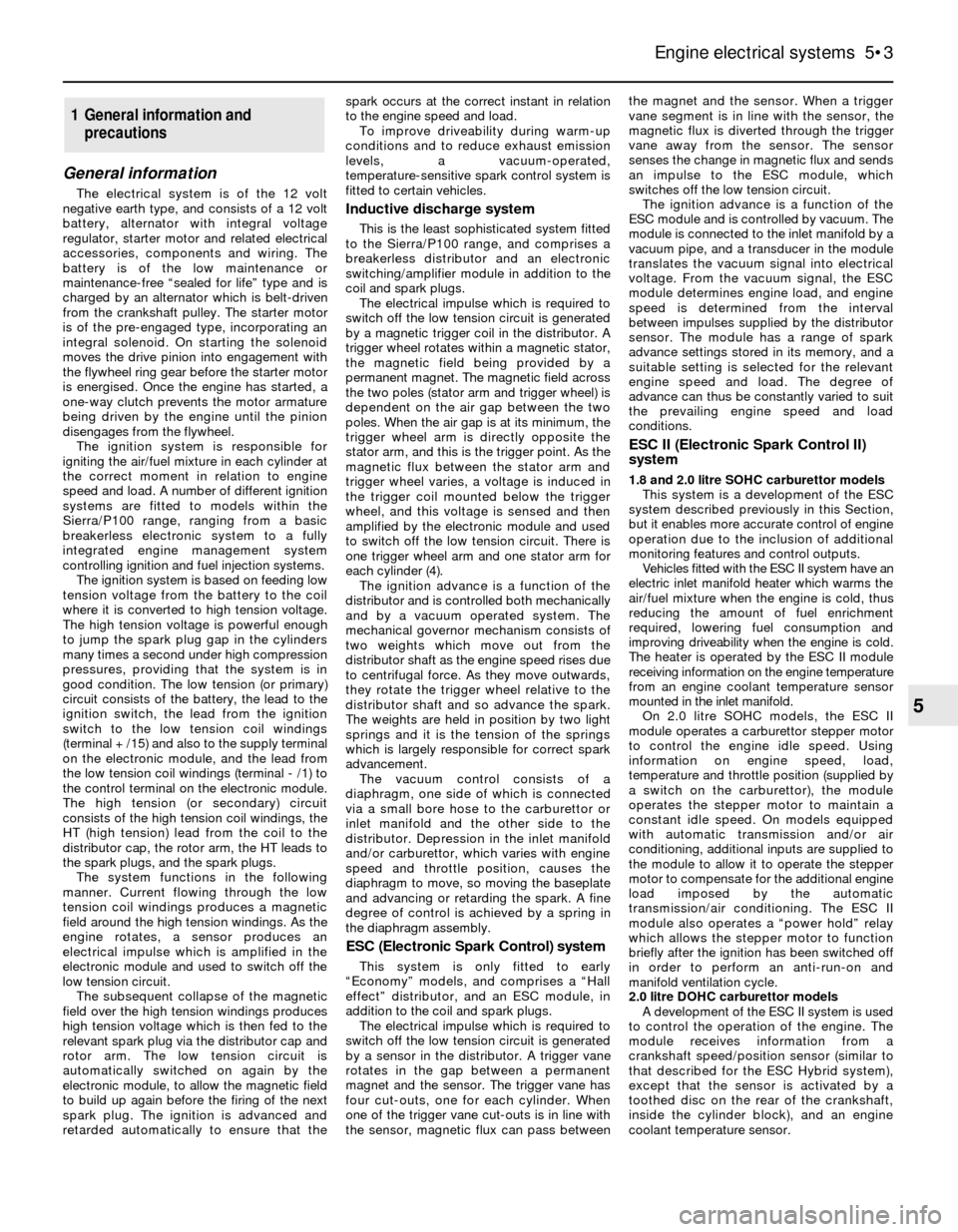

6Where applicable, disconnect the vacuum

pipe from the vacuum advance unit on the

side of the distributor (see illustration).

7Using a suitable socket or spanner on the

crankshaft pulley bolt, turn the crankshaft to

bring No 1 cylinder to the firing point. If the

distributor cap is secured by clips, make sure

that the clips stay clear of the distributormoving parts. No 1 cylinder is at the firing

point when:

a)The relevant timing marks are in

alignment.

b)The tip of the rotor arm is pointing to the

position occupied by the No 1 cylinder HT

lead terminal in the distributor cap. Note

that the position of No 1 HT lead terminal

is identified by a pip or a number “1”

c)On Lucas distributors, the cut-out in the

trigger vane is aligned with the sensor

(see illustration)

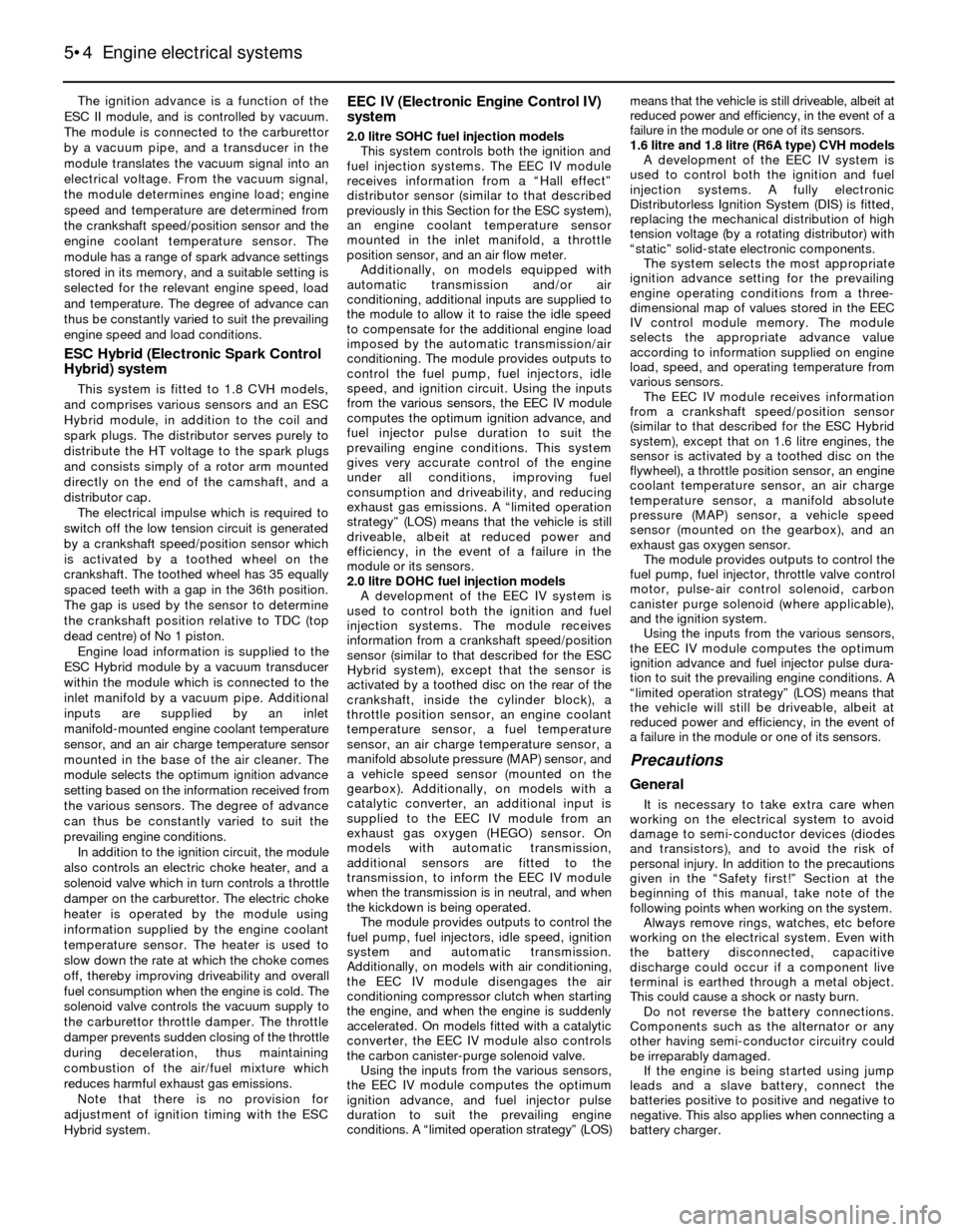

d)On Bosch distributors, the tip of the rotor

arm is aligned with the scribed line on the

distributor body (where applicable,

remove rotor arm and dust cover, then

refit rotor arm to check alignment with

scribed line) (see illustration)

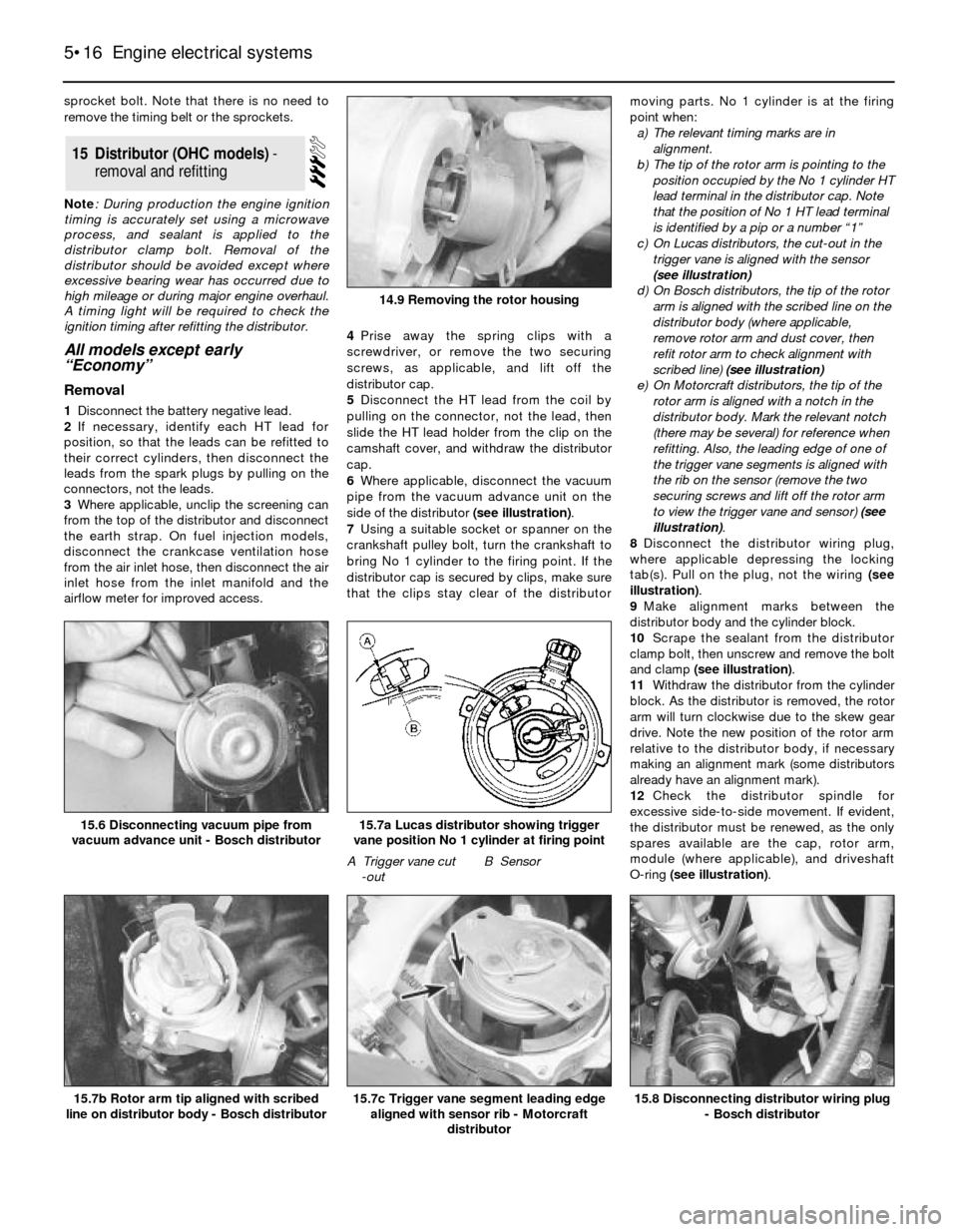

e)On Motorcraft distributors, the tip of the

rotor arm is aligned with a notch in the

distributor body. Mark the relevant notch

(there may be several) for reference when

refitting. Also, the leading edge of one of

the trigger vane segments is aligned with

the rib on the sensor (remove the two

securing screws and lift off the rotor arm

to view the trigger vane and sensor) (see

illustration).

8Disconnect the distributor wiring plug,

where applicable depressing the locking

tab(s). Pull on the plug, not the wiring (see

illustration).

9Make alignment marks between the

distributor body and the cylinder block.

10Scrape the sealant from the distributor

clamp bolt, then unscrew and remove the bolt

and clamp (see illustration).

11Withdraw the distributor from the cylinder

block. As the distributor is removed, the rotor

arm will turn clockwise due to the skew gear

drive. Note the new position of the rotor arm

relative to the distributor body, if necessary

making an alignment mark (some distributors

already have an alignment mark).

12Check the distributor spindle for

excessive side-to-side movement. If evident,

the distributor must be renewed, as the only

spares available are the cap, rotor arm,

module (where applicable), and driveshaft

O-ring (see illustration).

15Distributor (OHC models) -

removal and refitting

5•16Engine electrical systems

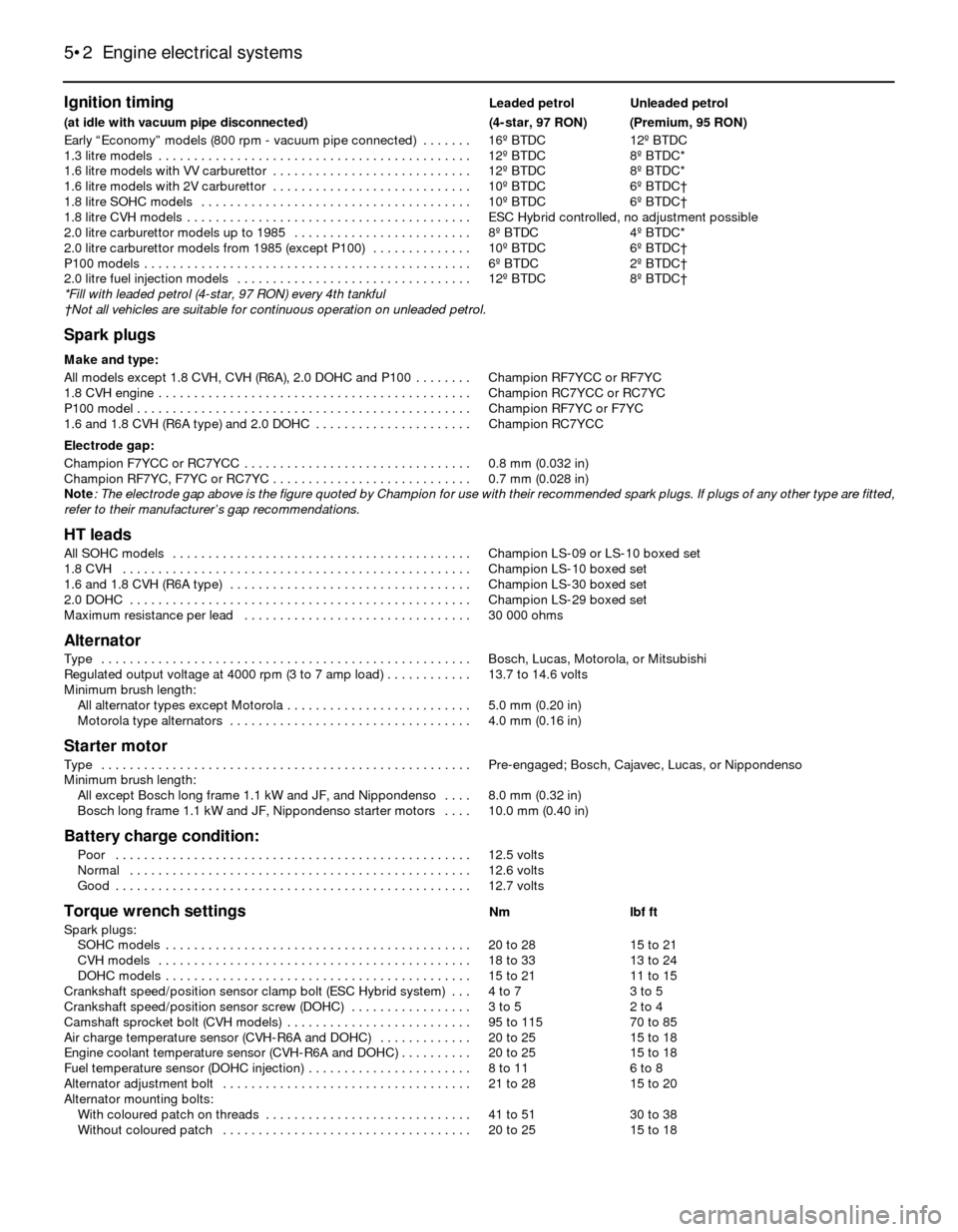

14.9 Removing the rotor housing

15.7a Lucas distributor showing trigger

vane position No 1 cylinder at firing point

A Trigger vane cut

-outB Sensor

15.8 Disconnecting distributor wiring plug

- Bosch distributor15.7c Trigger vane segment leading edge

aligned with sensor rib - Motorcraft

distributor15.7b Rotor arm tip aligned with scribed

line on distributor body - Bosch distributor

15.6 Disconnecting vacuum pipe from

vacuum advance unit - Bosch distributor

Page 20 of 24

EEC IV modules

Ignition module

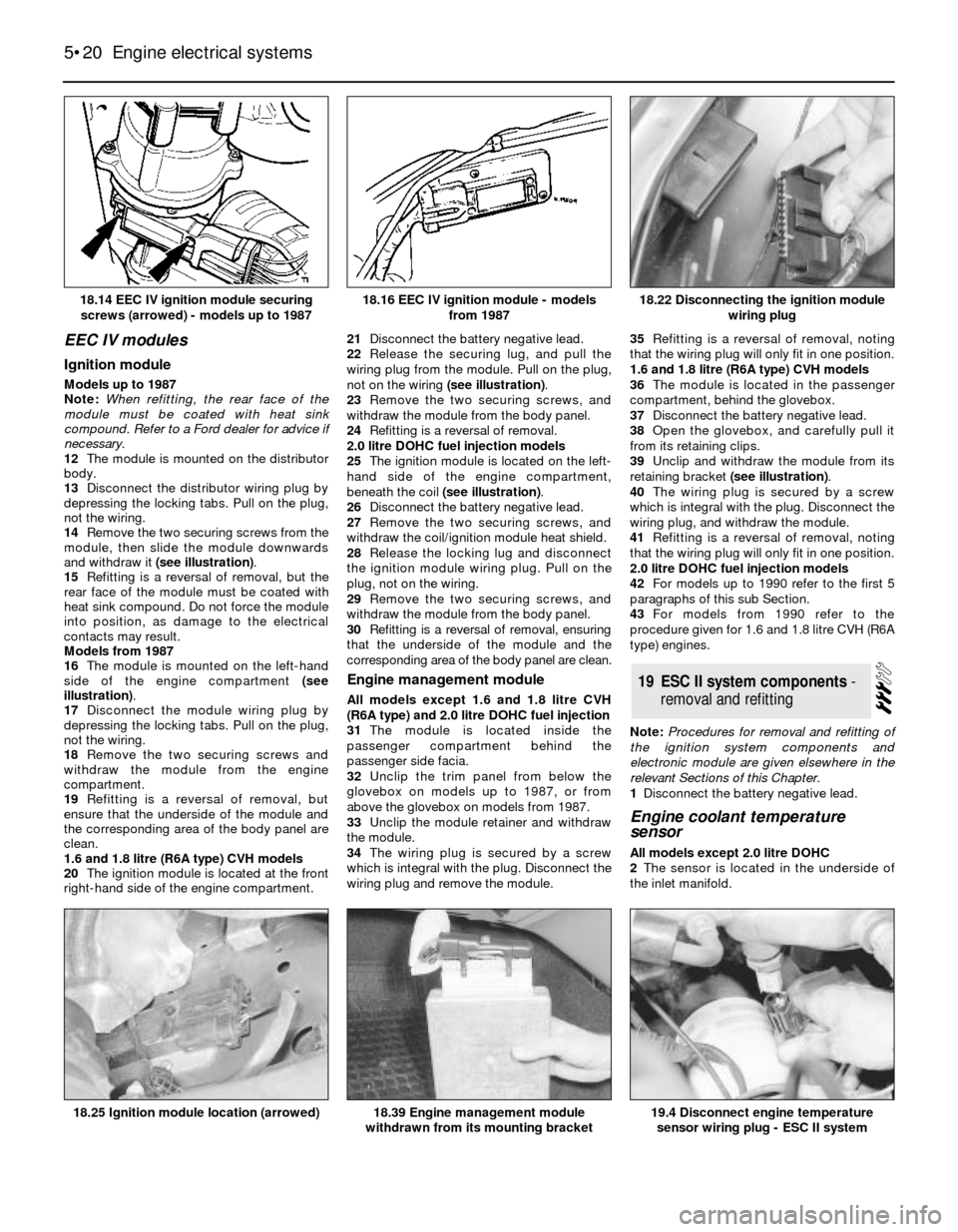

Models up to 1987

Note: When refitting, the rear face of the

module must be coated with heat sink

compound. Refer to a Ford dealer for advice if

necessary.

12The module is mounted on the distributor

body.

13Disconnect the distributor wiring plug by

depressing the locking tabs. Pull on the plug,

not the wiring.

14Remove the two securing screws from the

module, then slide the module downwards

and withdraw it (see illustration).

15Refitting is a reversal of removal, but the

rear face of the module must be coated with

heat sink compound. Do not force the module

into position, as damage to the electrical

contacts may result.

Models from 1987

16The module is mounted on the left-hand

side of the engine compartment (see

illustration).

17Disconnect the module wiring plug by

depressing the locking tabs. Pull on the plug,

not the wiring.

18Remove the two securing screws and

withdraw the module from the engine

compartment.

19Refitting is a reversal of removal, but

ensure that the underside of the module and

the corresponding area of the body panel are

clean.

1.6 and 1.8 litre (R6A type) CVH models

20The ignition module is located at the front

right-hand side of the engine compartment. 21Disconnect the battery negative lead.

22Release the securing lug, and pull the

wiring plug from the module. Pull on the plug,

not on the wiring (see illustration).

23Remove the two securing screws, and

withdraw the module from the body panel.

24Refitting is a reversal of removal.

2.0 litre DOHC fuel injection models

25The ignition module is located on the left-

hand side of the engine compartment,

beneath the coil (see illustration).

26Disconnect the battery negative lead.

27Remove the two securing screws, and

withdraw the coil/ignition module heat shield.

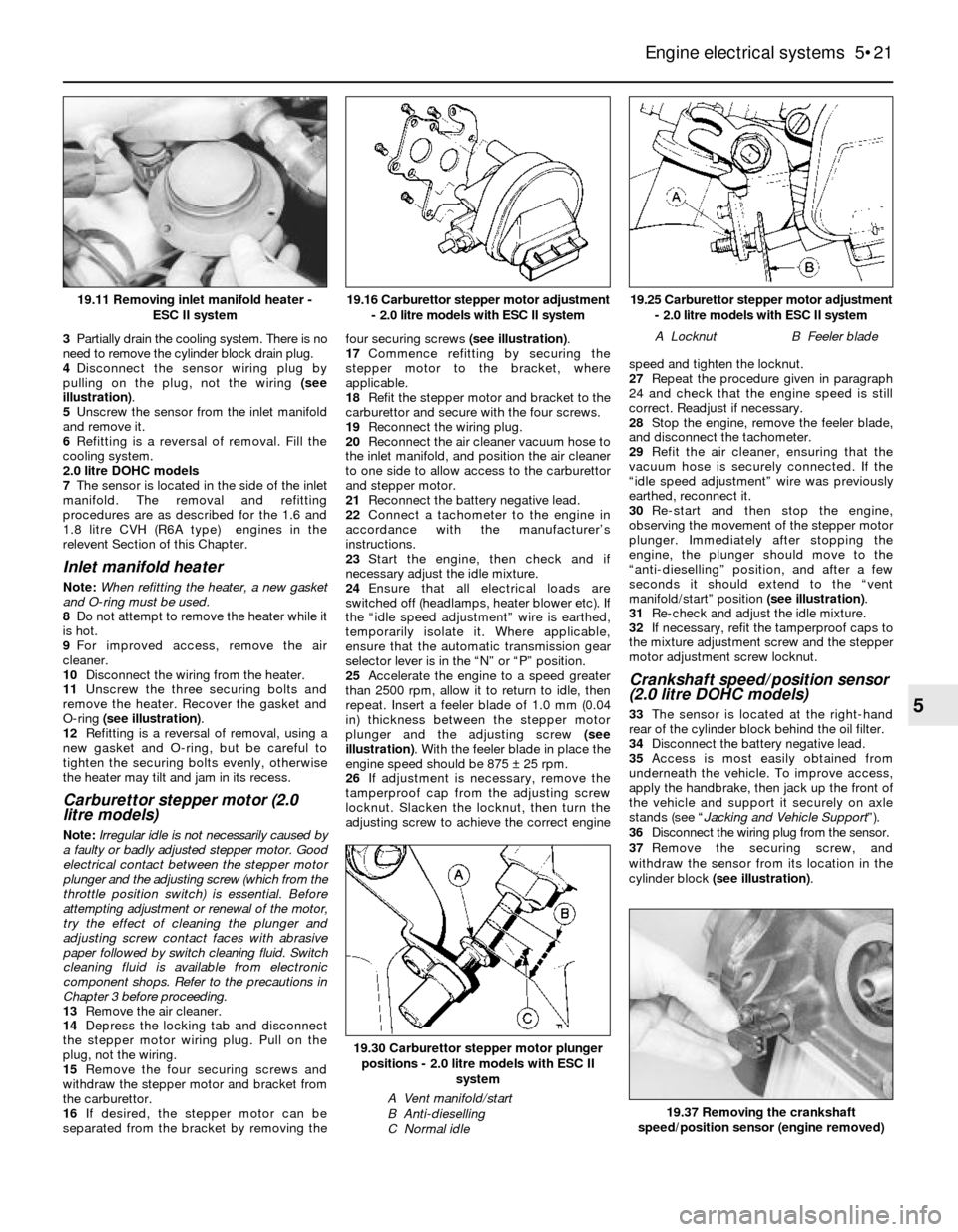

28Release the locking lug and disconnect

the ignition module wiring plug. Pull on the

plug, not on the wiring.

29Remove the two securing screws, and

withdraw the module from the body panel.

30Refitting is a reversal of removal, ensuring

that the underside of the module and the

corresponding area of the body panel are clean.

Engine management module

All models except 1.6 and 1.8 litre CVH

(R6A type) and 2.0 litre DOHC fuel injection

31The module is located inside the

passenger compartment behind the

passenger side facia.

32Unclip the trim panel from below the

glovebox on models up to 1987, or from

above the glovebox on models from 1987.

33Unclip the module retainer and withdraw

the module.

34The wiring plug is secured by a screw

which is integral with the plug. Disconnect the

wiring plug and remove the module.35Refitting is a reversal of removal, noting

that the wiring plug will only fit in one position.

1.6 and 1.8 litre (R6A type) CVH models

36The module is located in the passenger

compartment, behind the glovebox.

37Disconnect the battery negative lead.

38Open the glovebox, and carefully pull it

from its retaining clips.

39Unclip and withdraw the module from its

retaining bracket (see illustration).

40The wiring plug is secured by a screw

which is integral with the plug. Disconnect the

wiring plug, and withdraw the module.

41Refitting is a reversal of removal, noting

that the wiring plug will only fit in one position.

2.0 litre DOHC fuel injection models

42For models up to 1990 refer to the first 5

paragraphs of this sub Section.

43For models from 1990 refer to the

procedure given for 1.6 and 1.8 litre CVH (R6A

type) engines.

Note: Procedures for removal and refitting of

the ignition system components and

electronic module are given elsewhere in the

relevant Sections of this Chapter.

1Disconnect the battery negative lead.

Engine coolant temperature

sensor

All models except 2.0 litre DOHC

2The sensor is located in the underside of

the inlet manifold.

19ESC II system components -

removal and refitting

5•20Engine electrical systems

18.14 EEC IV ignition module securing

screws (arrowed) - models up to 198718.22 Disconnecting the ignition module

wiring plug

19.4 Disconnect engine temperature

sensor wiring plug - ESC II system18.39 Engine management module

withdrawn from its mounting bracket18.25 Ignition module location (arrowed)

18.16 EEC IV ignition module - models

from 1987

Page 21 of 24

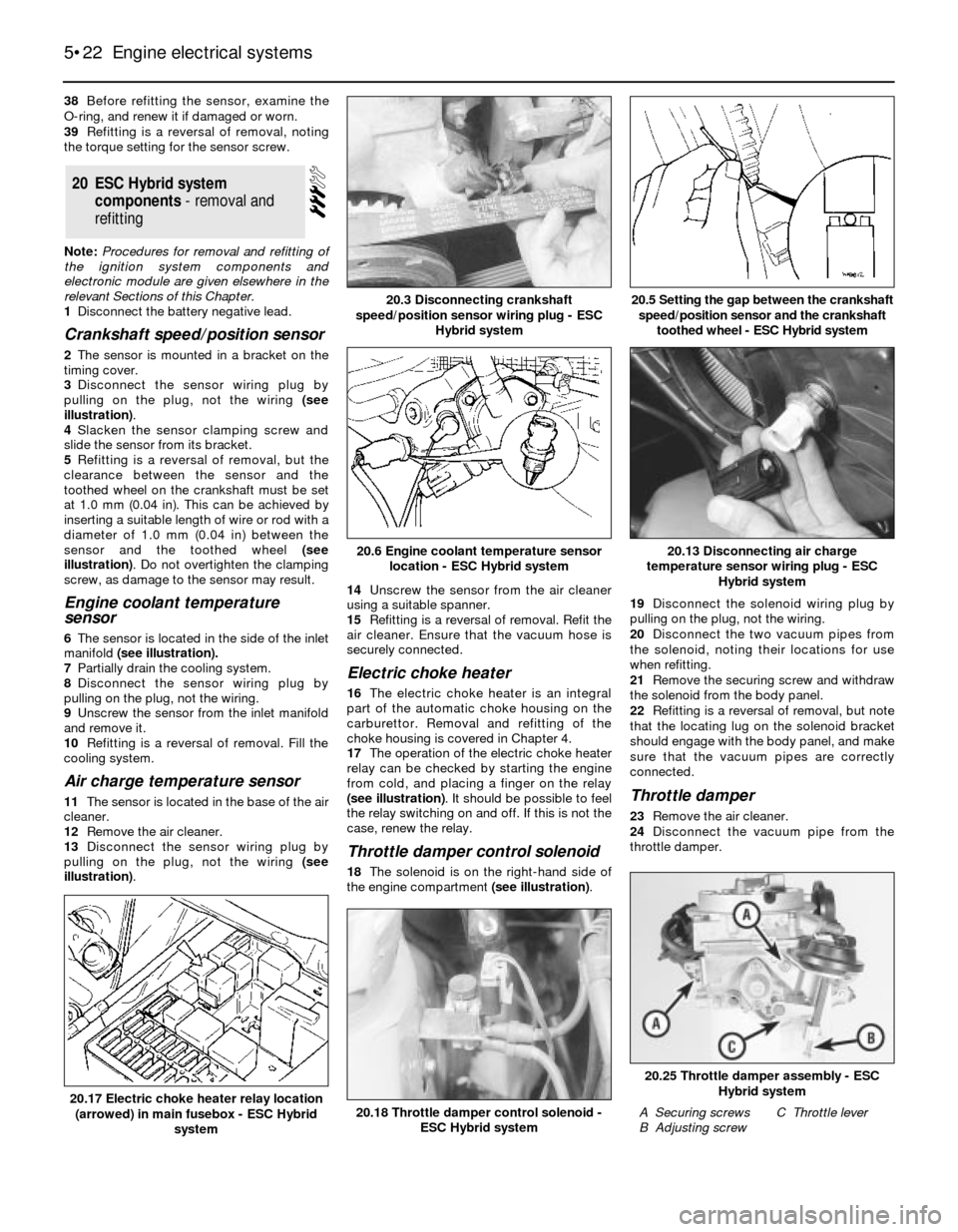

3Partially drain the cooling system. There is no

need to remove the cylinder block drain plug.

4Disconnect the sensor wiring plug by

pulling on the plug, not the wiring (see

illustration).

5Unscrew the sensor from the inlet manifold

and remove it.

6Refitting is a reversal of removal. Fill the

cooling system.

2.0 litre DOHC models

7The sensor is located in the side of the inlet

manifold. The removal and refitting

procedures are as described for the 1.6 and

1.8 litre CVH (R6A type) engines in the

relevent Section of this Chapter.

Inlet manifold heater

Note: When refitting the heater, a new gasket

and O-ring must be used.

8Do not attempt to remove the heater while it

is hot.

9For improved access, remove the air

cleaner.

10Disconnect the wiring from the heater.

11Unscrew the three securing bolts and

remove the heater. Recover the gasket and

O-ring (see illustration).

12Refitting is a reversal of removal, using a

new gasket and O-ring, but be careful to

tighten the securing bolts evenly, otherwise

the heater may tilt and jam in its recess.

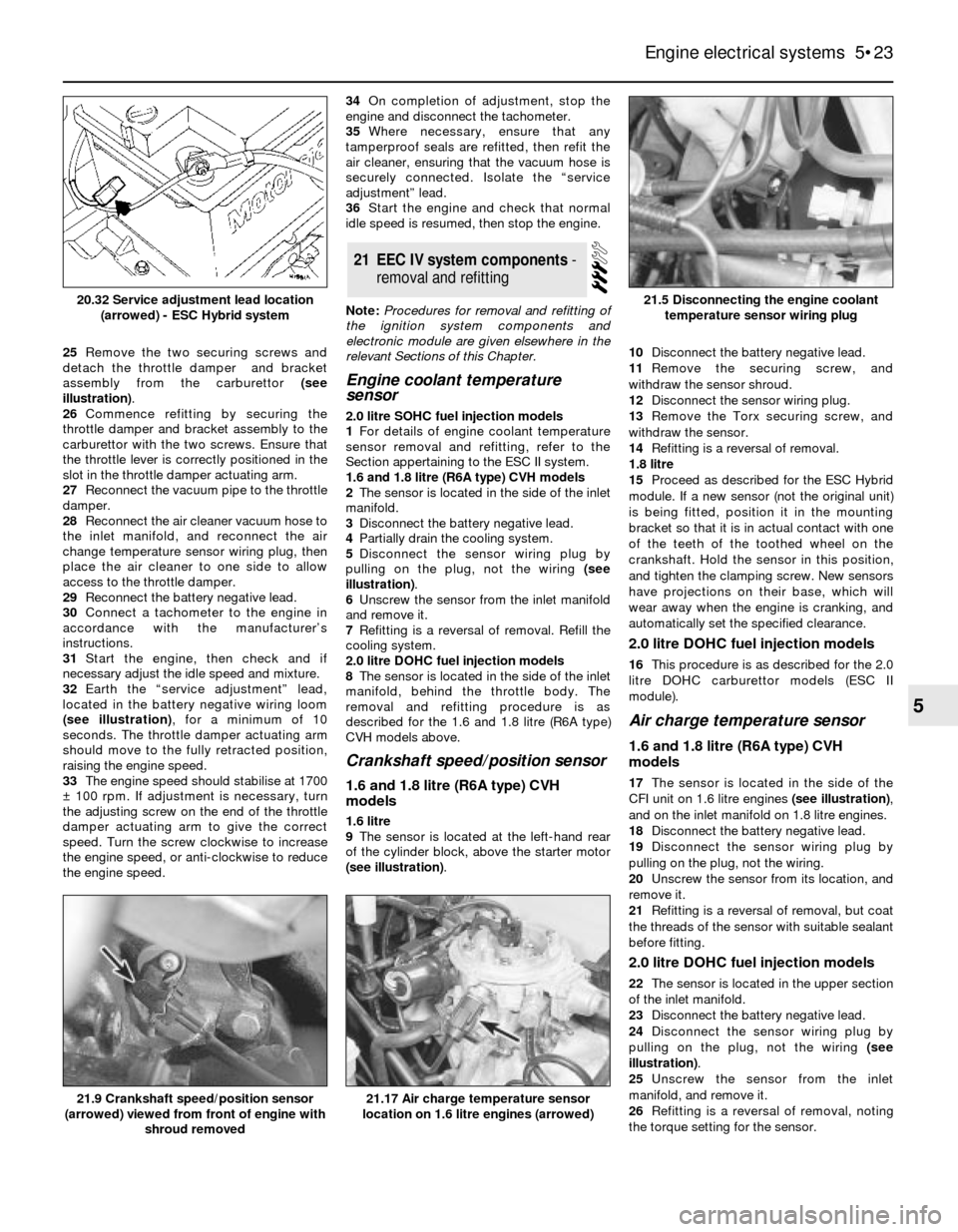

Carburettor stepper motor (2.0

litre models)

Note: Irregular idle is not necessarily caused by

a faulty or badly adjusted stepper motor. Good

electrical contact between the stepper motor

plunger and the adjusting screw (which from the

throttle position switch) is essential. Before

attempting adjustment or renewal of the motor,

try the effect of cleaning the plunger and

adjusting screw contact faces with abrasive

paper followed by switch cleaning fluid. Switch

cleaning fluid is available from electronic

component shops. Refer to the precautions in

Chapter 3 before proceeding.

13Remove the air cleaner.

14Depress the locking tab and disconnect

the stepper motor wiring plug. Pull on the

plug, not the wiring.

15Remove the four securing screws and

withdraw the stepper motor and bracket from

the carburettor.

16If desired, the stepper motor can be

separated from the bracket by removing thefour securing screws (see illustration).

17Commence refitting by securing the

stepper motor to the bracket, where

applicable.

18Refit the stepper motor and bracket to the

carburettor and secure with the four screws.

19Reconnect the wiring plug.

20Reconnect the air cleaner vacuum hose to

the inlet manifold, and position the air cleaner

to one side to allow access to the carburettor

and stepper motor.

21Reconnect the battery negative lead.

22Connect a tachometer to the engine in

accordance with the manufacturer’s

instructions.

23Start the engine, then check and if

necessary adjust the idle mixture.

24Ensure that all electrical loads are

switched off (headlamps, heater blower etc). If

the “idle speed adjustment” wire is earthed,

temporarily isolate it. Where applicable,

ensure that the automatic transmission gear

selector lever is in the “N” or “P” position.

25Accelerate the engine to a speed greater

than 2500 rpm, allow it to return to idle, then

repeat. Insert a feeler blade of 1.0 mm (0.04

in) thickness between the stepper motor

plunger and the adjusting screw (see

illustration). With the feeler blade in place the

engine speed should be 875 ±25 rpm.

26If adjustment is necessary, remove the

tamperproof cap from the adjusting screw

locknut. Slacken the locknut, then turn the

adjusting screw to achieve the correct enginespeed and tighten the locknut.

27Repeat the procedure given in paragraph

24 and check that the engine speed is still

correct. Readjust if necessary.

28Stop the engine, remove the feeler blade,

and disconnect the tachometer.

29Refit the air cleaner, ensuring that the

vacuum hose is securely connected. If the

“idle speed adjustment” wire was previously

earthed, reconnect it.

30Re-start and then stop the engine,

observing the movement of the stepper motor

plunger. Immediately after stopping the

engine, the plunger should move to the

“anti-dieselling” position, and after a few

seconds it should extend to the “vent

manifold/start” position (see illustration).

31Re-check and adjust the idle mixture.

32If necessary, refit the tamperproof caps to

the mixture adjustment screw and the stepper

motor adjustment screw locknut.

Crankshaft speed/position sensor

(2.0 litre DOHC models)

33The sensor is located at the right-hand

rear of the cylinder block behind the oil filter.

34Disconnect the battery negative lead.

35Access is most easily obtained from

underneath the vehicle. To improve access,

apply the handbrake, then jack up the front of

the vehicle and support it securely on axle

stands (see “Jacking and Vehicle Support”).

36Disconnect the wiring plug from the sensor.

37Remove the securing screw, and

withdraw the sensor from its location in the

cylinder block (see illustration).

Engine electrical systems 5•21

5

19.25 Carburettor stepper motor adjustment

- 2.0 litre models with ESC II system

A LocknutB Feeler blade

19.37 Removing the crankshaft

speed/position sensor (engine removed)

19.30 Carburettor stepper motor plunger

positions - 2.0 litre models with ESC II

system

A Vent manifold/start

B Anti-dieselling

C Normal idle

19.16 Carburettor stepper motor adjustment

- 2.0 litre models with ESC II system19.11 Removing inlet manifold heater -

ESC II system

Page 22 of 24

38Before refitting the sensor, examine the

O-ring, and renew it if damaged or worn.

39Refitting is a reversal of removal, noting

the torque setting for the sensor screw.

Note: Procedures for removal and refitting of

the ignition system components and

electronic module are given elsewhere in the

relevant Sections of this Chapter.

1Disconnect the battery negative lead.

Crankshaft speed/position sensor

2The sensor is mounted in a bracket on the

timing cover.

3Disconnect the sensor wiring plug by

pulling on the plug, not the wiring (see

illustration).

4Slacken the sensor clamping screw and

slide the sensor from its bracket.

5Refitting is a reversal of removal, but the

clearance between the sensor and the

toothed wheel on the crankshaft must be set

at 1.0 mm (0.04 in). This can be achieved by

inserting a suitable length of wire or rod with a

diameter of 1.0 mm (0.04 in) between the

sensor and the toothed wheel (see

illustration). Do not overtighten the clamping

screw, as damage to the sensor may result.

Engine coolant temperature

sensor

6The sensor is located in the side of the inlet

manifold(see illustration).

7Partially drain the cooling system.

8Disconnect the sensor wiring plug by

pulling on the plug, not the wiring.

9Unscrew the sensor from the inlet manifold

and remove it.

10Refitting is a reversal of removal. Fill the

cooling system.

Air charge temperature sensor

11The sensor is located in the base of the air

cleaner.

12Remove the air cleaner.

13Disconnect the sensor wiring plug by

pulling on the plug, not the wiring (see

illustration).14Unscrew the sensor from the air cleaner

using a suitable spanner.

15Refitting is a reversal of removal. Refit the

air cleaner. Ensure that the vacuum hose is

securely connected.

Electric choke heater

16The electric choke heater is an integral

part of the automatic choke housing on the

carburettor. Removal and refitting of the

choke housing is covered in Chapter 4.

17The operation of the electric choke heater

relay can be checked by starting the engine

from cold, and placing a finger on the relay

(see illustration). It should be possible to feel

the relay switching on and off. If this is not the

case, renew the relay.

Throttle damper control solenoid

18The solenoid is on the right-hand side of

the engine compartment (see illustration). 19Disconnect the solenoid wiring plug by

pulling on the plug, not the wiring.

20Disconnect the two vacuum pipes from

the solenoid, noting their locations for use

when refitting.

21Remove the securing screw and withdraw

the solenoid from the body panel.

22Refitting is a reversal of removal, but note

that the locating lug on the solenoid bracket

should engage with the body panel, and make

sure that the vacuum pipes are correctly

connected.

Throttle damper

23Remove the air cleaner.

24Disconnect the vacuum pipe from the

throttle damper.

20ESC Hybrid system

components - removal and

refitting

5•22Engine electrical systems

20.3 Disconnecting crankshaft

speed/position sensor wiring plug - ESC

Hybrid system

20.6 Engine coolant temperature sensor

location - ESC Hybrid system

20.25 Throttle damper assembly - ESC

Hybrid system

A Securing screws

B Adjusting screwC Throttle lever20.18 Throttle damper control solenoid -

ESC Hybrid system20.17 Electric choke heater relay location

(arrowed) in main fusebox - ESC Hybrid

system

20.13 Disconnecting air charge

temperature sensor wiring plug - ESC

Hybrid system

20.5 Setting the gap between the crankshaft

speed/position sensor and the crankshaft

toothed wheel - ESC Hybrid system

Page 23 of 24

25Remove the two securing screws and

detach the throttle damper and bracket

assembly from the carburettor (see

illustration).

26Commence refitting by securing the

throttle damper and bracket assembly to the

carburettor with the two screws. Ensure that

the throttle lever is correctly positioned in the

slot in the throttle damper actuating arm.

27Reconnect the vacuum pipe to the throttle

damper.

28Reconnect the air cleaner vacuum hose to

the inlet manifold, and reconnect the air

change temperature sensor wiring plug, then

place the air cleaner to one side to allow

access to the throttle damper.

29Reconnect the battery negative lead.

30Connect a tachometer to the engine in

accordance with the manufacturer’s

instructions.

31Start the engine, then check and if

necessary adjust the idle speed and mixture.

32Earth the “service adjustment” lead,

located in the battery negative wiring loom

(see illustration), for a minimum of 10

seconds. The throttle damper actuating arm

should move to the fully retracted position,

raising the engine speed.

33The engine speed should stabilise at 1700

±100 rpm. If adjustment is necessary, turn

the adjusting screw on the end of the throttle

damper actuating arm to give the correct

speed. Turn the screw clockwise to increase

the engine speed, or anti-clockwise to reduce

the engine speed.34On completion of adjustment, stop the

engine and disconnect the tachometer.

35Where necessary, ensure that any

tamperproof seals are refitted, then refit the

air cleaner, ensuring that the vacuum hose is

securely connected. Isolate the “service

adjustment” lead.

36Start the engine and check that normal

idle speed is resumed, then stop the engine.

Note:Procedures for removal and refitting of

the ignition system components and

electronic module are given elsewhere in the

relevant Sections of this Chapter.

Engine coolant temperature

sensor

2.0 litre SOHC fuel injection models

1For details of engine coolant temperature

sensor removal and refitting, refer to the

Section appertaining to the ESC II system.

1.6 and 1.8 litre (R6A type) CVH models

2The sensor is located in the side of the inlet

manifold.

3Disconnect the battery negative lead.

4Partially drain the cooling system.

5Disconnect the sensor wiring plug by

pulling on the plug, not the wiring (see

illustration).

6Unscrew the sensor from the inlet manifold

and remove it.

7Refitting is a reversal of removal. Refill the

cooling system.

2.0 litre DOHC fuel injection models

8The sensor is located in the side of the inlet

manifold, behind the throttle body. The

removal and refitting procedure is as

described for the 1.6 and 1.8 litre (R6A type)

CVH models above.

Crankshaft speed/position sensor

1.6 and 1.8 litre (R6A type) CVH

models

1.6 litre

9The sensor is located at the left-hand rear

of the cylinder block, above the starter motor

(see illustration).10Disconnect the battery negative lead.

11Remove the securing screw, and

withdraw the sensor shroud.

12Disconnect the sensor wiring plug.

13Remove the Torx securing screw, and

withdraw the sensor.

14Refitting is a reversal of removal.

1.8 litre

15Proceed as described for the ESC Hybrid

module. If a new sensor (not the original unit)

is being fitted, position it in the mounting

bracket so that it is in actual contact with one

of the teeth of the toothed wheel on the

crankshaft. Hold the sensor in this position,

and tighten the clamping screw. New sensors

have projections on their base, which will

wear away when the engine is cranking, and

automatically set the specified clearance.

2.0 litre DOHC fuel injection models

16This procedure is as described for the 2.0

litre DOHC carburettor models (ESC II

module).

Air charge temperature sensor

1.6 and 1.8 litre (R6A type) CVH

models

17The sensor is located in the side of the

CFI unit on 1.6 litre engines (see illustration),

and on the inlet manifold on 1.8 litre engines.

18Disconnect the battery negative lead.

19Disconnect the sensor wiring plug by

pulling on the plug, not the wiring.

20Unscrew the sensor from its location, and

remove it.

21Refitting is a reversal of removal, but coat

the threads of the sensor with suitable sealant

before fitting.

2.0 litre DOHC fuel injection models

22The sensor is located in the upper section

of the inlet manifold.

23Disconnect the battery negative lead.

24Disconnect the sensor wiring plug by

pulling on the plug, not the wiring (see

illustration).

25Unscrew the sensor from the inlet

manifold, and remove it.

26Refitting is a reversal of removal, noting

the torque setting for the sensor.

21EEC IV system components -

removaland refitting

Engine electrical systems 5•23

5

21.9 Crankshaft speed/position sensor

(arrowed) viewed from front of engine with

shroud removed21.17 Air charge temperature sensor

location on 1.6 litre engines (arrowed)

21.5 Disconnecting the engine coolant

temperature sensor wiring plug20.32 Service adjustment lead location

(arrowed) - ESC Hybrid system

Page 24 of 24

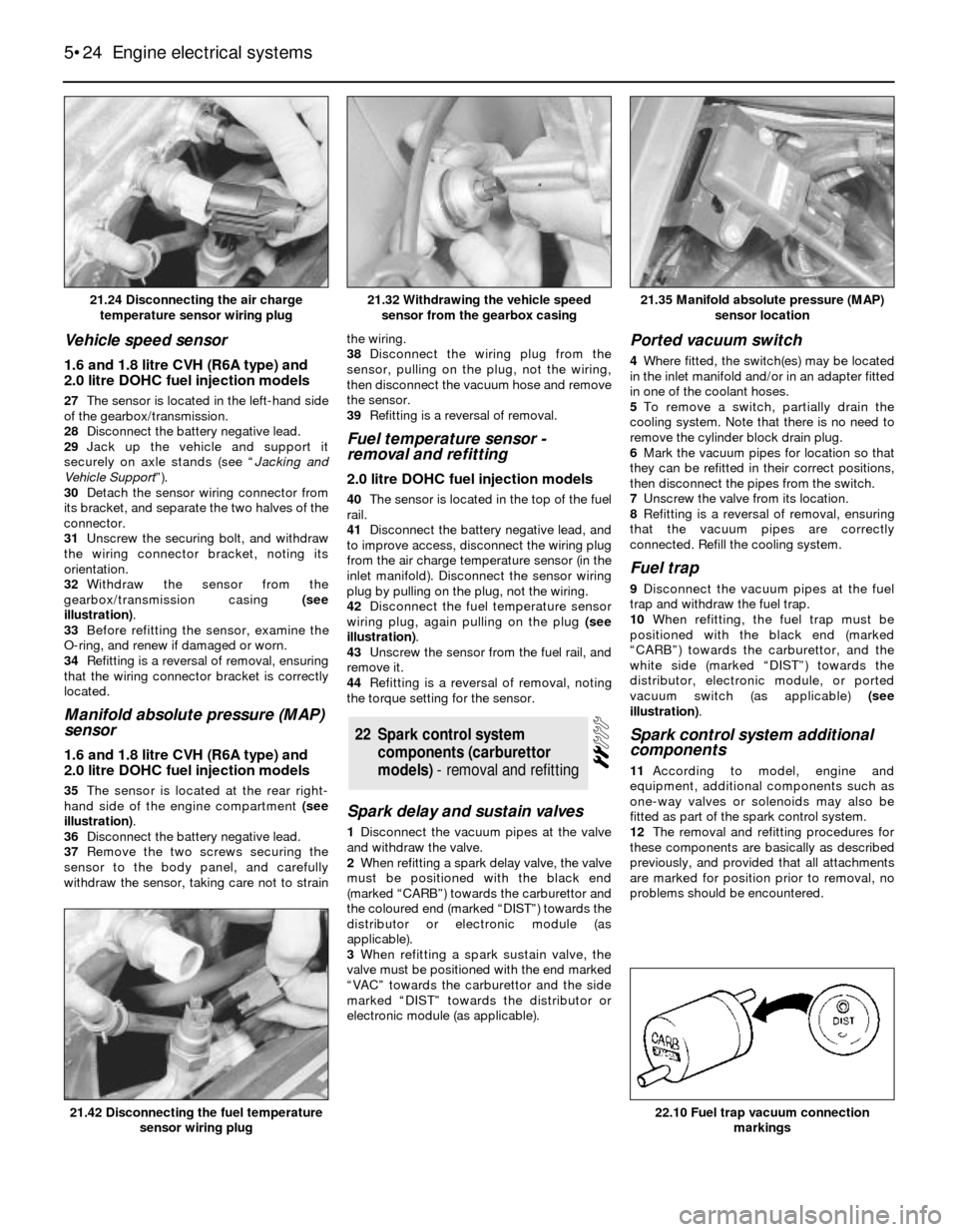

Vehicle speed sensor

1.6 and 1.8 litre CVH (R6A type) and

2.0 litre DOHC fuel injection models

27The sensor is located in the left-hand side

of the gearbox/transmission.

28Disconnect the battery negative lead.

29Jack up the vehicle and support it

securely on axle stands (see “Jacking and

Vehicle Support”).

30Detach the sensor wiring connector from

its bracket, and separate the two halves of the

connector.

31Unscrew the securing bolt, and withdraw

the wiring connector bracket, noting its

orientation.

32Withdraw the sensor from the

gearbox/transmission casing (see

illustration).

33Before refitting the sensor, examine the

O-ring, and renew if damaged or worn.

34Refitting is a reversal of removal, ensuring

that the wiring connector bracket is correctly

located.

Manifold absolute pressure (MAP)

sensor

1.6 and 1.8 litre CVH (R6A type) and

2.0 litre DOHC fuel injection models

35The sensor is located at the rear right-

hand side of the engine compartment (see

illustration).

36Disconnect the battery negative lead.

37Remove the two screws securing the

sensor to the body panel, and carefully

withdraw the sensor, taking care not to strainthe wiring.

38Disconnect the wiring plug from the

sensor, pulling on the plug, not the wiring,

then disconnect the vacuum hose and remove

the sensor.

39Refitting is a reversal of removal.

Fuel temperature sensor -

removal and refitting

2.0 litre DOHC fuel injection models

40The sensor is located in the top of the fuel

rail.

41Disconnect the battery negative lead, and

to improve access, disconnect the wiring plug

from the air charge temperature sensor (in the

inlet manifold). Disconnect the sensor wiring

plug by pulling on the plug, not the wiring.

42Disconnect the fuel temperature sensor

wiring plug, again pulling on the plug (see

illustration).

43Unscrew the sensor from the fuel rail, and

remove it.

44Refitting is a reversal of removal, noting

the torque setting for the sensor.

Spark delay and sustain valves

1Disconnect the vacuum pipes at the valve

and withdraw the valve.

2When refitting a spark delay valve, the valve

must be positioned with the black end

(marked “CARB”) towards the carburettor and

the coloured end (marked “DIST”) towards the

distributor or electronic module (as

applicable).

3When refitting a spark sustain valve, the

valve must be positioned with the end marked

“VAC” towards the carburettor and the side

marked “DIST” towards the distributor or

electronic module (as applicable).

Ported vacuum switch

4Where fitted, the switch(es) may be located

in the inlet manifold and/or in an adapter fitted

in one of the coolant hoses.

5To remove a switch, partially drain the

cooling system. Note that there is no need to

remove the cylinder block drain plug.

6Mark the vacuum pipes for location so that

they can be refitted in their correct positions,

then disconnect the pipes from the switch.

7Unscrew the valve from its location.

8Refitting is a reversal of removal, ensuring

that the vacuum pipes are correctly

connected. Refill the cooling system.

Fuel trap

9Disconnect the vacuum pipes at the fuel

trap and withdraw the fuel trap.

10When refitting, the fuel trap must be

positioned with the black end (marked

“CARB”) towards the carburettor, and the

white side (marked “DIST”) towards the

distributor, electronic module, or ported

vacuum switch (as applicable) (see

illustration).

Spark control system additional

components

11According to model, engine and

equipment, additional components such as

one-way valves or solenoids may also be

fitted as part of the spark control system.

12The removal and refitting procedures for

these components are basically as described

previously, and provided that all attachments

are marked for position prior to removal, no

problems should be encountered.

22Spark control system

components (carburettor

models) - removal and refitting

5•24Engine electrical systems

21.24 Disconnecting the air charge

temperature sensor wiring plug21.35 Manifold absolute pressure (MAP)

sensor location

22.10 Fuel trap vacuum connection

markings21.42 Disconnecting the fuel temperature

sensor wiring plug

21.32 Withdrawing the vehicle speed

sensor from the gearbox casing