oil type FORD SIERRA 1986 1.G Suspension And Steering Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1986, Model line: SIERRA, Model: FORD SIERRA 1986 1.GPages: 20, PDF Size: 0.94 MB

Page 1 of 20

Front suspension

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Independent by MacPherson struts with coil springs and integral

telescopic shock absorbers. Anti-roll bar fitted to all models

Rear suspension

Type:

Saloon, Hatchback and Estate models . . . . . . . . . . . . . . . . . . . . . . . Independent by semi-trailing arms and coil springs with telescopic

shock absorbers mounted behind coil springs on Saloon and

Hatchback models but concentric with coil springs on Estate models.

Self-levelling rear shock absorbers on certain Estate models. Anti-roll

bar fitted to certain models

P100 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Live beam axle with leaf springs and telescopic shock absorbers

Steering

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rack-and-pinion steering gear linked to collapsible steering column by

flexible coupling and universal joint. Power steering available on

certain models

Front wheel alignment*

Production toe-setting:

Saloon, Hatchback and Estate models . . . . . . . . . . . . . . . . . . . . . . . 2.0 mm (0.08 in) ± 1.0 mm (0.04 in) toe-in

P100 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 mm (0.08 in) ± 2.0 mm (0.08 in) toe-in

Service tolerance before adjustment is required . . . . . . . . . . . . . . . . . . 0.5 mm (0.02 in) toe-out to 4.5 mm (0.18 in) toe-in

*Toe-setting figures are quoted for vehicle at kerb weight with 3.0 litres (0.66 gallons) of fuel in tank

Chapter 11

Suspension and steering

Front anti-roll bar - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .7

Front anti-roll bar-to-lower arm compliance bushes - renewal . . . . . .8

Front hub carrier - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .5

Front suspension crossmember - removal and refitting . . . . . . . . . . . .2

Front suspension lower arm - removal, overhaul and refitting . . . . . . .3

Front suspension lower arm inner pivot bush - renewal . . . . . . . . . . .9

Front suspension strut - removal, overhaul and refitting . . . . . . . . . . .4

Front wheel - alignment checking and adjusting . . . . . . . . . . . . . . . .34

Front wheel bearings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Manual steering gear - removal and refitting . . . . . . . . . . . . . . . . . . .27

Power steering fluid circuit - bleeding . . . . . . . . . . . . . . . . . . . . . . . .31

Power steering fluid hoses - removal and refitting . . . . . . . . . . . . . . .30

Power steering gear - removal and refitting . . . . . . . . . . . . . . . . . . . .28

Power steering pump - removal and refitting . . . . . . . . . . . . . . . . . . .29

Rear anti-roll bar (Saloon, Hatchback and Estate models) - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Rear coil spring (Saloon, Hatchback and Estate models) - removal and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Rear shock absorber - removal and refitting . . . . . . . . . . . . . . . . . . .12

Rear suspension and axle assembly (P100 models) - removal and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18Rear suspension and final drive unit assembly (Saloon, Hatchback and

Estate models) - removal and refitting . . . . . . . . . . . . . . . . . . . . . .10

Rear suspension/final drive unit rear mounting (Saloon Hatchback and

Estate models) - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Rear suspension front mounting (Saloon, Hatchback and Estate

models) - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Rear suspension leaf spring (P100 models) - removal and refitting . .19

Rear suspension leaf spring bush (P100 models) - renewal . . . . . . .21

Rear suspension leaf spring shackle (P100 models) - removal and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Rear suspension lower arm (Saloon, Hatchback and Estate models) -

removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Rear wheel bearings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Steering column adjuster - dismantling and reassembly . . . . . . . . . .25

Steering column - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .24

Steering gear rubber gaiter - renewal . . . . . . . . . . . . . . . . . . . . . . . . .32

Steering intermediate shaft and flexible coupling - removal and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Steering wheel - centralising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Steering wheel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .22

Tie-rod end - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .33

11•1

Specifications Contents

11

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Page 3 of 20

Torque wrench settings (continued)Nmlbf ft

P100 models:

Shock absorber-to-chassis crossmember bolt . . . . . . . . . . . . . . . . . . .60 to 7044 to 52

Leaf spring-to-front bracket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157 to 196116 to 145

Leaf spring-to-spring shackle bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157 to 196116 to 145

Spring shackle-to-underbody bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80 to 8559 to 63

Axle-to-leaf spring U-bolt nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39 to 5829 to 43

Manual steering

Steering gear-to-crossmember bolts:

Stage 1 (“clamping” torque) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4533

Loosen fully, then Stage 2 (“snug” torque) . . . . . . . . . . . . . . . . . . . . .1511

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten through a further 90º

Steering column adjuster through-bolt . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Tie-rod end locknut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57 to 6842 to 50

Tie-rod end-to-hub carrier nut* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 3215 to 24

Tie-rod-to-steering rack balljoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72 to 8853 to 65

Steering wheel nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 to 5533 to 41

Intermediate shaft-to-inner column clamp bolt . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Flexible coupling-to-steering gear clamp nut . . . . . . . . . . . . . . . . . . . . .24 to 2617 to 19

Column mounting pinch-bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 to 5533 to 41

Pinion retaining nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 to 10052 to 74

Slipper plug† . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 to 53 to 4

*Tighten nut to specified torque and then tighten to next available split pin hole

†Tighten nut to specified torque and then loosen off 60º to 70º

Power steering (where different to manual steering)

Tie-rod to steering rack balljoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 to 7752 to 57

Flexible coupling-to-steering gear clamp bolt . . . . . . . . . . . . . . . . . . . .16 to 2012 to 15

Intermediate shaft-to-inner column clamp bolt . . . . . . . . . . . . . . . . . . .16 to 2012 to 15

Pinion locknut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37 to 4727 to 35

Slipper plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 to 42 to 3

Pump rear support bar nut and bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . .41 to 5130 to 38

Pump mounting bracket-to-engine bolts . . . . . . . . . . . . . . . . . . . . . . . .52 to 6438 to 47

Pump pulley bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 to 127 to 9

Fluid hose-to-pinion housing bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2615 to 19

Fluid pressure hose-to-pump union . . . . . . . . . . . . . . . . . . . . . . . . . . . .26 to 3119 to 23

Fluid return hose-to-pump union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 to 2012 to 15

The front suspension is of independent

MacPherson strut type incorporating coil

springs and integral telescopic shock

absorbers. The lower end of each strut is

attached to a hub carrier, which carries the

wheel hub and bearings, and the brake

assembly. The lower end of each hub carrier

is attached to a suspension lower arm by a

sealed balljoint. The inboard ends of the lower

arms are attached to the front suspension

crossmember and the lower arms thus

provide lateral location for the strut

assemblies. The upper end of each strut is

bolted to a suspension turret on the vehicle

body. An anti-roll bar is mounted to the rear of

the lower arms, and resists the roll tendency

of the front suspension.

On Saloon, Hatchback and Estate models,

the rear suspension is also of independent

type, incorporating semi-trailing arms, coil

springs and telescopic shock absorbers. The

semi-trailing arms are attached to the

suspension crossmember at their forward

ends, and to the hub carriers at the rear. Thecoil springs are located between the

semi-trailing arms and the vehicle underbody.

On Saloon and Hatchback models, the shock

absorbers are mounted behind the coil

springs, but on Estate models they are

concentric with the coil springs. On some

Estate models the shock absorbers are of the

self-levelling type. The suspension

crossmember is attached to the vehicle

underbody, and to the final drive unit. Certain

models are fitted with an anti-roll bar which is

mounted to the rear of the final drive unit, and

is attached to the semi-trailing arms by

connecting links.

The rear suspension on P100 models

consists of a beam axle located and

supported by a leaf spring on each side, and

utilizing telescopic shock absorbers to control

vertical movement. The hub and brake

assemblies are attached directly to each side

of the axle. The axle is bolted to the leaf

springs using U-bolts and counterplates, and

the shock absorbers are attached to the

counterplates at their lower ends and the

vehicle underbody at their upper ends.

The steering gear is of the conventional

rack and pinion type located ahead of the

front wheels. Movement of the steering wheelis transmitted to the steering gear by means

of a shaft containing a universal joint. The

front hub carriers are connected to the

steering gear by tie-rods, each having an inner

and outer balljoint. Power-assisted steering is

available on some models, assistance being

provided hydraulically by an engine-driven

pump.

Removal

1Remove the steering gear.

2Support the engine with a jack and

interposed block of wood under the sump.

3Unscrew and remove the engine mounting

nuts from the top of the mountings in the

engine bay (see illustration).

4Raise the engine slightly with the jack, and

ensure that it is safely supported, and just

clear of the engine mounting rubbers.

5Unscrew and remove the nuts, washers and

pivot bolts securing the lower arms to the

crossmember, and pull the arms from the

crossmember. Note that the pivot bolt heads

face to the rear of the vehicle.

2Front suspension crossmember

-removalandrefitting

1General information

Suspension and steering 11•3

11

Page 6 of 20

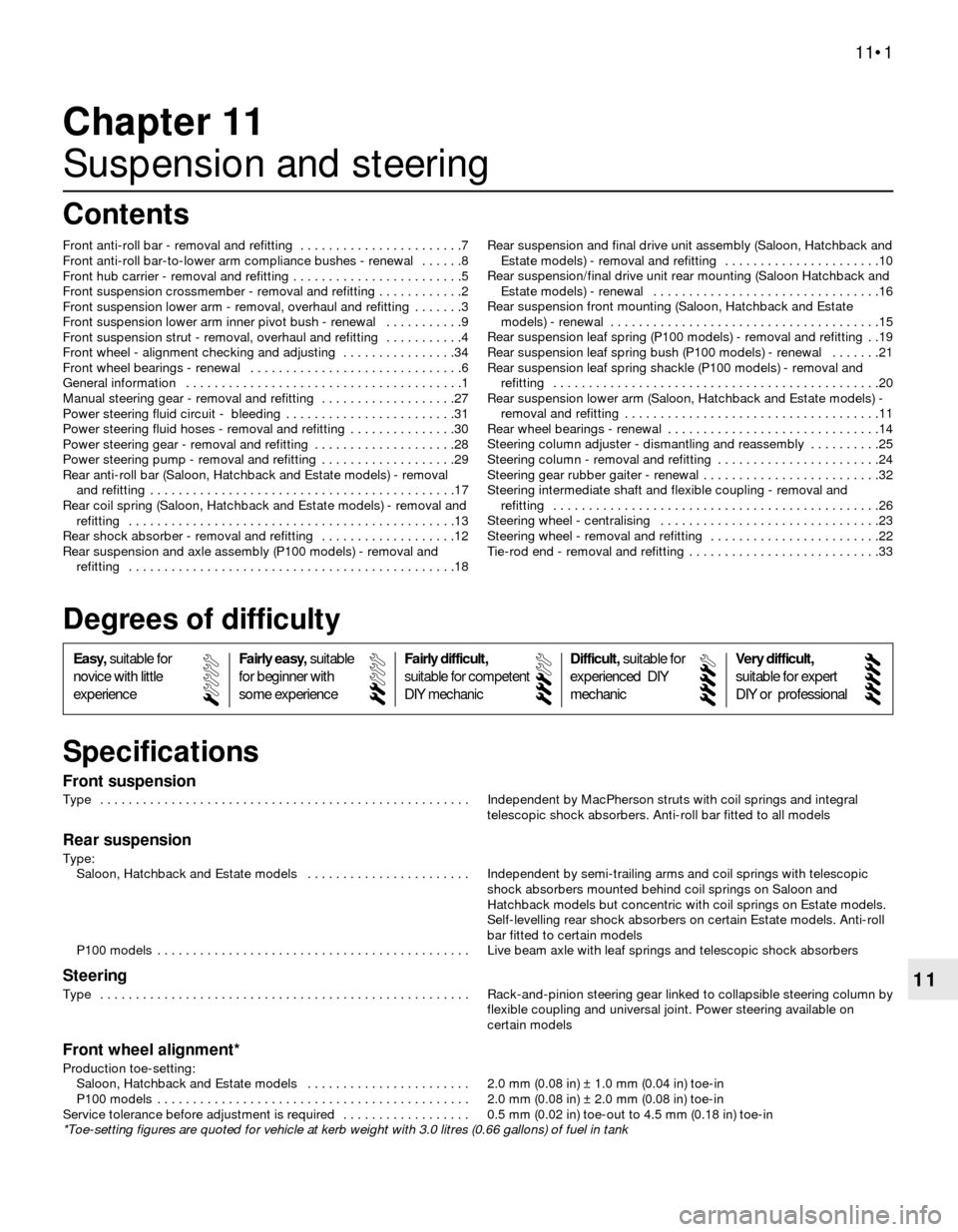

1Remove the hub carrier.

2Reverse the roadwheel nuts and screw

them fully onto the studs to protect the

threads, then mount the hub carrier assembly

in a vice as shown (see illustration).

3Prise the dust cap from the rear of the hub

carrier, and unscrew the hub nut with a

suitable socket. Note that on all models

manufactured before late December 1982,

both left and right-hand nuts have a

right-hand thread, but as from this date,

left-hand thread assemblies were

progressively fitted to the right-hand hub

carrier. The modified right-hand hub can be

identified by the letter “R” stamped on its

outer face, or by the colour of the hub nut

nylon insert, blue indicates a normal

right-hand thread, and yellow indicates a

left-hand thread.

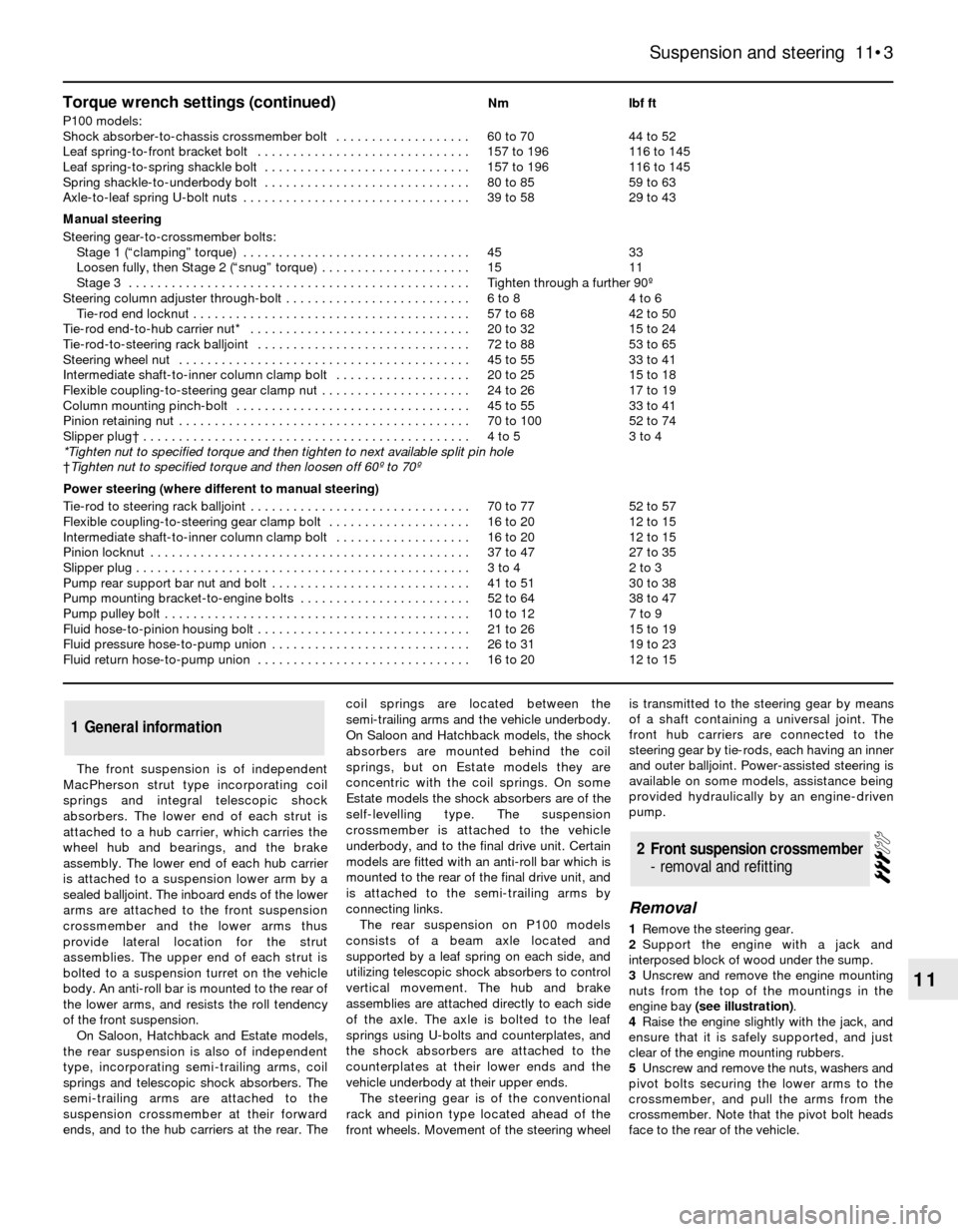

4Remove the splined washer, and tap the

hub carrier from the drive flange. Recover the

bearing inner race and rollers from the inner

end of the hub carrier (see illustration).

5Prise the oil seal from the outer end of the

hub carrier and remove the remaining bearing

inner race and rollers.

6Using a soft metal drift, drive the bearing

outer races from the hub carrier, taking care

not to damage the inner surface of the carrier.

7Clean the hub carrier and drive flange with

paraffin, wipe dry and examine for damage

and wear. Note that the components are

machined to very close tolerances, and the

bearings are supplied in matched pairs,

therefore scrupulous cleanliness must be

observed.

8Using a metal tube of suitable diameter,

drive the new bearing outer races fully into the

hub carrier. Ensure that the races are seated

correctly.

9Pack the inner bearing races and rollers

with high-melting-point lithium-based grease,

and locate the outer bearing assembly in the

hub camber.

10Fill the cavities between the sealing lips of

the oil seal with grease, then drive it fully into

the hub carrier using a block of wood or a

metal tube of suitable diameter. Note that onearly models the oil seal has a rubber casing,

and this early type of seal should be replaced

with the later type which has a metal casing.

The oil seal should be renewed regardless of

type, and a new seal of the correct type is

normally supplied with the new wheel bearings.

11With the drive flange mounted in a vice, as

during dismantling, tap the hub carrier onto

the drive flange.

12Fit the inner bearing assembly, tapping it

into place with a metal tube of suitable

diameter if necessary, and fit the splined

washer. Note that the bearings are self-setting

on assembly, and no subsequent adjustment

is required.

13Refit the hub nut and tighten it to the

specified torque.

14Tap the dust cap into position in the hub

carrier.

15Remove the assembly from the vice,

remove the roadwheel nuts, and refit the hub

carrier.

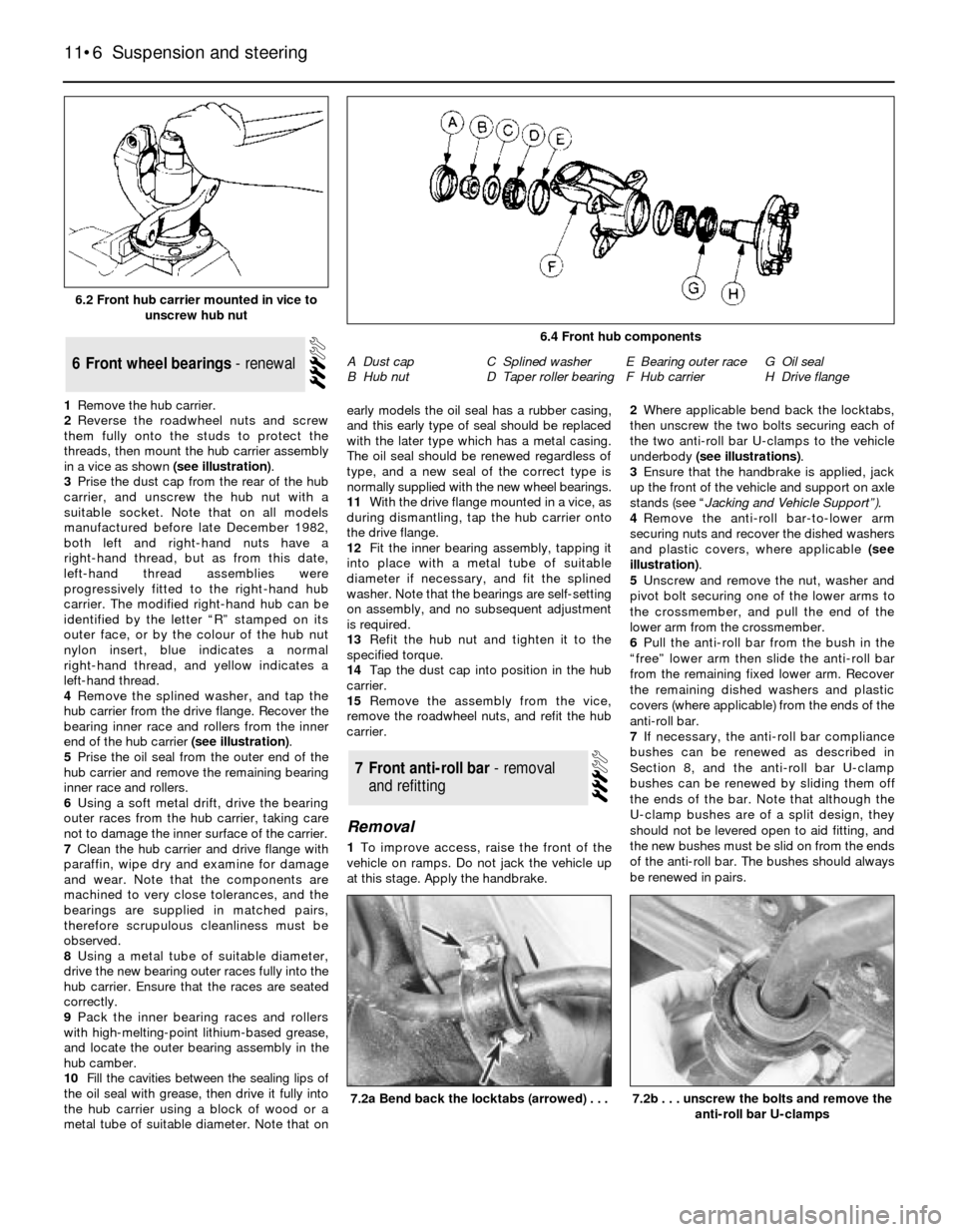

Removal

1To improve access, raise the front of the

vehicle on ramps. Do not jack the vehicle up

at this stage. Apply the handbrake.2Where applicable bend back the locktabs,

then unscrew the two bolts securing each of

the two anti-roll bar U-clamps to the vehicle

underbody (see illustrations).

3Ensure that the handbrake is applied, jack

up the front of the vehicle and support on axle

stands (see “Jacking and Vehicle Support”).

4Remove the anti-roll bar-to-lower arm

securing nuts and recover the dished washers

and plastic covers, where applicable (see

illustration).

5Unscrew and remove the nut, washer and

pivot bolt securing one of the lower arms to

the crossmember, and pull the end of the

lower arm from the crossmember.

6Pull the anti-roll bar from the bush in the

“free” lower arm then slide the anti-roll bar

from the remaining fixed lower arm. Recover

the remaining dished washers and plastic

covers (where applicable) from the ends of the

anti-roll bar.

7If necessary, the anti-roll bar compliance

bushes can be renewed as described in

Section 8, and the anti-roll bar U-clamp

bushes can be renewed by sliding them off

the ends of the bar. Note that although the

U-clamp bushes are of a split design, they

should not be levered open to aid fitting, and

the new bushes must be slid on from the ends

of the anti-roll bar. The bushes should always

be renewed in pairs.

7Front anti-roll bar - removal

and refitting

6Front wheel bearings - renewal

11•6Suspension and steering

6.2 Front hub carrier mounted in vice to

unscrew hub nut

7.2b . . . unscrew the bolts and remove the

anti-roll bar U-clamps7.2a Bend back the locktabs (arrowed) . . .

6.4 Front hub components

A Dust cap

B Hub nutC Splined washer

D Taper roller bearingE Bearing outer race

F Hub carrierG Oil seal

H Drive flange

Page 10 of 20

3With an assistant supporting the shock

absorber from below, unscrew and remove

the upper mounting bolt and nut. Withdraw

the shock absorber from under the vehicle.

4Refitting is a reversal of removal. Tighten

the mounting bolts securely.

Estate models

Note: On models fitted with heavy duty

Nivomat shock absorbers, follow the

procedure given in Section 13, as the shock

absorber and coil spring are an integrated unit.

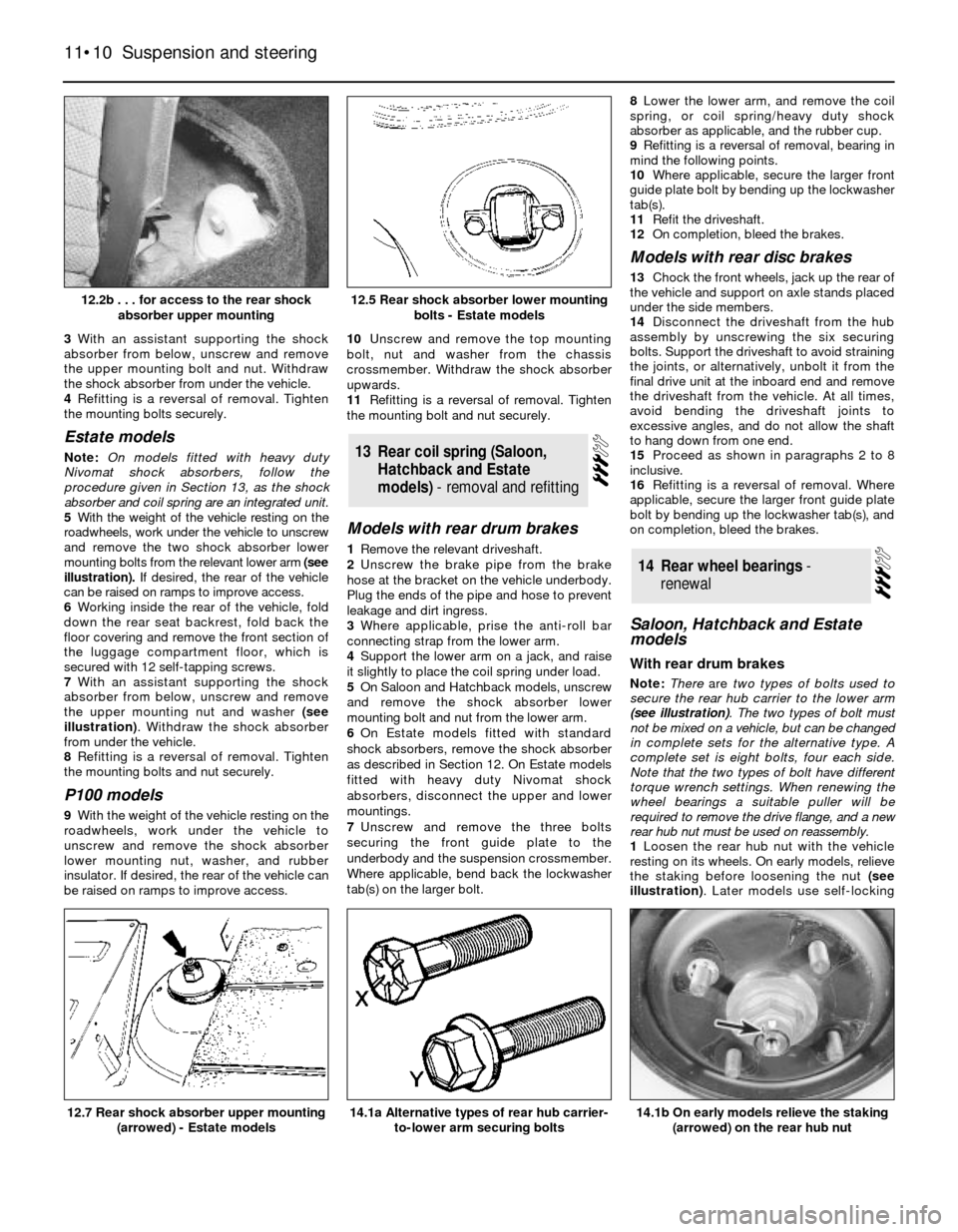

5With the weight of the vehicle resting on the

roadwheels, work under the vehicle to unscrew

and remove the two shock absorber lower

mounting bolts from the relevant lower arm(see

illustration).If desired, the rear of the vehicle

can be raised on ramps to improve access.

6Working inside the rear of the vehicle, fold

down the rear seat backrest, fold back the

floor covering and remove the front section of

the luggage compartment floor, which is

secured with 12 self-tapping screws.

7With an assistant supporting the shock

absorber from below, unscrew and remove

the upper mounting nut and washer (see

illustration). Withdraw the shock absorber

from under the vehicle.

8Refitting is a reversal of removal. Tighten

the mounting bolts and nut securely.

P100 models

9With the weight of the vehicle resting on the

roadwheels, work under the vehicle to

unscrew and remove the shock absorber

lower mounting nut, washer, and rubber

insulator. If desired, the rear of the vehicle can

be raised on ramps to improve access.10Unscrew and remove the top mounting

bolt, nut and washer from the chassis

crossmember. Withdraw the shock absorber

upwards.

11Refitting is a reversal of removal. Tighten

the mounting bolt and nut securely.

Models with rear drum brakes

1Remove the relevant driveshaft.

2Unscrew the brake pipe from the brake

hose at the bracket on the vehicle underbody.

Plug the ends of the pipe and hose to prevent

leakage and dirt ingress.

3Where applicable, prise the anti-roll bar

connecting strap from the lower arm.

4Support the lower arm on a jack, and raise

it slightly to place the coil spring under load.

5On Saloon and Hatchback models, unscrew

and remove the shock absorber lower

mounting bolt and nut from the lower arm.

6On Estate models fitted with standard

shock absorbers, remove the shock absorber

as described in Section 12. On Estate models

fitted with heavy duty Nivomat shock

absorbers, disconnect the upper and lower

mountings.

7Unscrew and remove the three bolts

securing the front guide plate to the

underbody and the suspension crossmember.

Where applicable, bend back the lockwasher

tab(s) on the larger bolt.8Lower the lower arm, and remove the coil

spring, or coil spring/heavy duty shock

absorber as applicable, and the rubber cup.

9Refitting is a reversal of removal, bearing in

mind the following points.

10Where applicable, secure the larger front

guide plate bolt by bending up the lockwasher

tab(s).

11Refit the driveshaft.

12On completion, bleed the brakes.

Models with rear disc brakes

13Chock the front wheels, jack up the rear of

the vehicle and support on axle stands placed

under the side members.

14Disconnect the driveshaft from the hub

assembly by unscrewing the six securing

bolts. Support the driveshaft to avoid straining

the joints, or alternatively, unbolt it from the

final drive unit at the inboard end and remove

the driveshaft from the vehicle. At all times,

avoid bending the driveshaft joints to

excessive angles, and do not allow the shaft

to hang down from one end.

15Proceed as shown in paragraphs 2 to 8

inclusive.

16Refitting is a reversal of removal. Where

applicable, secure the larger front guide plate

bolt by bending up the lockwasher tab(s), and

on completion, bleed the brakes.

Saloon, Hatchback and Estate

models

With rear drum brakes

Note: There are two types of bolts used to

secure the rear hub carrier to the lower arm

(see illustration). The two types of bolt must

not be mixed on a vehicle, but can be changed

in complete sets for the alternative type. A

complete set is eight bolts, four each side.

Note that the two types of bolt have different

torque wrench settings. When renewing the

wheel bearings a suitable puller will be

required to remove the drive flange, and a new

rear hub nut must be used on reassembly.

1Loosen the rear hub nut with the vehicle

resting on its wheels. On early models, relieve

the staking before loosening the nut (see

illustration). Later models use self-locking

14Rear wheel bearings -

renewal

13Rear coil spring (Saloon,

Hatchback and Estate

models) - removal and refitting

11•10Suspension and steering

12.5 Rear shock absorber lower mounting

bolts - Estate models

14.1a Alternative types of rear hub carrier-

to-lower arm securing bolts12.7 Rear shock absorber upper mounting

(arrowed) - Estate models

12.2b . . . for access to the rear shock

absorber upper mounting

14.1b On early models relieve the staking

(arrowed) on the rear hub nut

Page 11 of 20

nuts, and it is important to note that where

this type of nut is fitted, the left-hand nut has

a left-hand thread, ie. it is undone in a

clockwise direction. Before loosening the nut,

ensure that the handbrake is applied, and

chock the relevant rear wheel. A suitable

extension bar will be required, as the nut is

extremely tight.

2Loosen the rear roadwheel nuts on the side

concerned, chock the front wheels, and jack

up the rear of the vehicle and support on axle

stands (see “Jacking and Vehicle Support”).

Remove the rear roadwheel.

3Remove the brake drum retaining spire

washer(s) from the wheel stud(s) and remove

the brake drum. Ensure that the handbrake is

released before removing the brake drum,

otherwise the drum will be held in place by the

clamping action of the brake shoes.

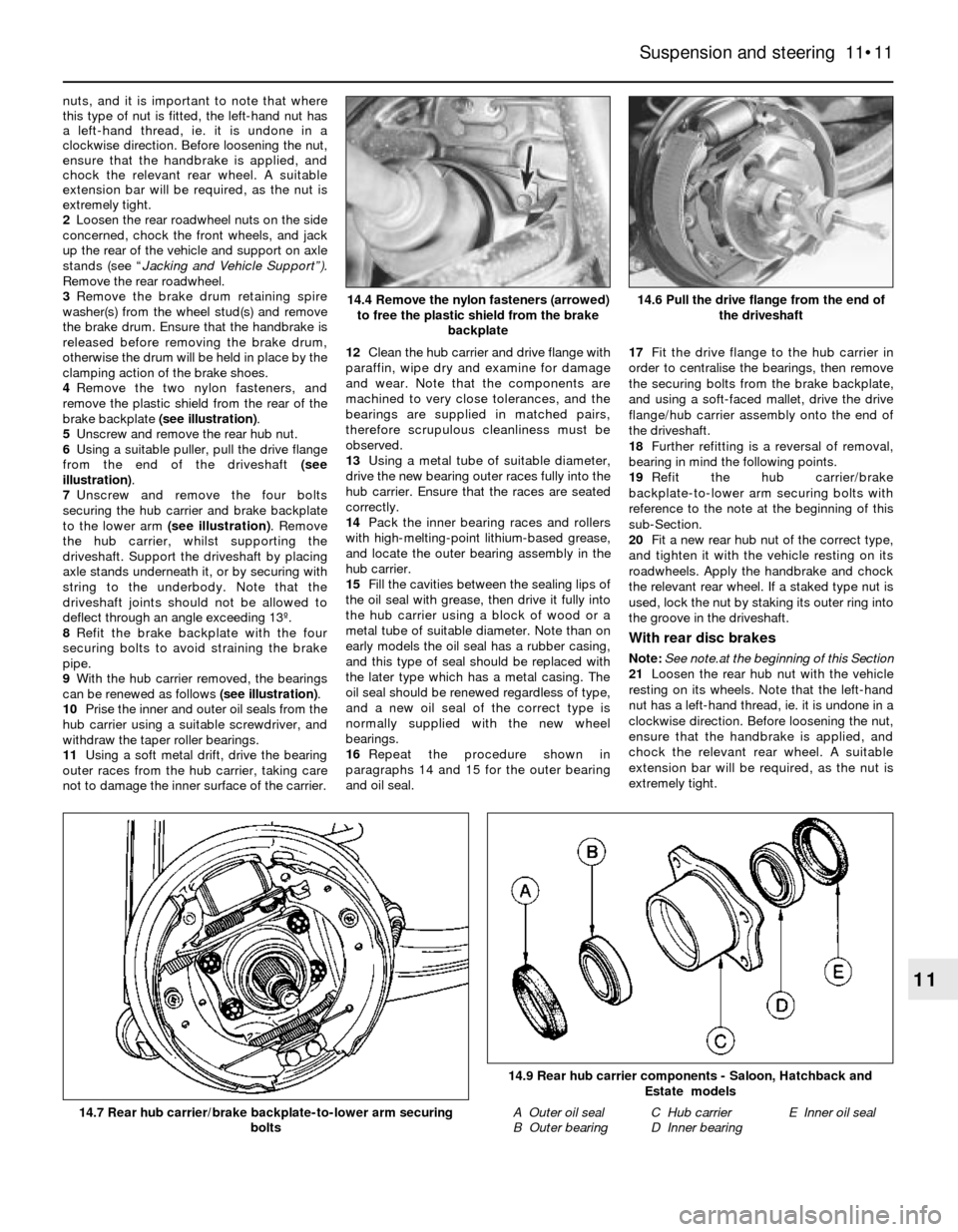

4Remove the two nylon fasteners, and

remove the plastic shield from the rear of the

brake backplate (see illustration).

5Unscrew and remove the rear hub nut.

6Using a suitable puller, pull the drive flange

from the end of the driveshaft (see

illustration).

7Unscrew and remove the four bolts

securing the hub carrier and brake backplate

to the lower arm (see illustration). Remove

the hub carrier, whilst supporting the

driveshaft. Support the driveshaft by placing

axle stands underneath it, or by securing with

string to the underbody. Note that the

driveshaft joints should not be allowed to

deflect through an angle exceeding 13º.

8Refit the brake backplate with the four

securing bolts to avoid straining the brake

pipe.

9With the hub carrier removed, the bearings

can be renewed as follows (see illustration).

10Prise the inner and outer oil seals from the

hub carrier using a suitable screwdriver, and

withdraw the taper roller bearings.

11Using a soft metal drift, drive the bearing

outer races from the hub carrier, taking care

not to damage the inner surface of the carrier.12Clean the hub carrier and drive flange with

paraffin, wipe dry and examine for damage

and wear. Note that the components are

machined to very close tolerances, and the

bearings are supplied in matched pairs,

therefore scrupulous cleanliness must be

observed.

13Using a metal tube of suitable diameter,

drive the new bearing outer races fully into the

hub carrier. Ensure that the races are seated

correctly.

14Pack the inner bearing races and rollers

with high-melting-point lithium-based grease,

and locate the outer bearing assembly in the

hub carrier.

15Fill the cavities between the sealing lips of

the oil seal with grease, then drive it fully into

the hub carrier using a block of wood or a

metal tube of suitable diameter. Note than on

early models the oil seal has a rubber casing,

and this type of seal should be replaced with

the later type which has a metal casing. The

oil seal should be renewed regardless of type,

and a new oil seal of the correct type is

normally supplied with the new wheel

bearings.

16Repeat the procedure shown in

paragraphs 14 and 15 for the outer bearing

and oil seal.17Fit the drive flange to the hub carrier in

order to centralise the bearings, then remove

the securing bolts from the brake backplate,

and using a soft-faced mallet, drive the drive

flange/hub carrier assembly onto the end of

the driveshaft.

18Further refitting is a reversal of removal,

bearing in mind the following points.

19Refit the hub carrier/brake

backplate-to-lower arm securing bolts with

reference to the note at the beginning of this

sub-Section.

20Fit a new rear hub nut of the correct type,

and tighten it with the vehicle resting on its

roadwheels. Apply the handbrake and chock

the relevant rear wheel. If a staked type nut is

used, lock the nut by staking its outer ring into

the groove in the driveshaft.

With rear disc brakes

Note: See note.at the beginning of this Section

21Loosen the rear hub nut with the vehicle

resting on its wheels. Note that the left-hand

nut has a left-hand thread, ie. it is undone in a

clockwise direction. Before loosening the nut,

ensure that the handbrake is applied, and

chock the relevant rear wheel. A suitable

extension bar will be required, as the nut is

extremely tight.

Suspension and steering 11•11

11

14.6 Pull the drive flange from the end of

the driveshaft

14.9 Rear hub carrier components - Saloon, Hatchback and

Estate models

A Outer oil seal

B Outer bearingC Hub carrier

D Inner bearingE Inner oil seal14.7 Rear hub carrier/brake backplate-to-lower arm securing

bolts

14.4 Remove the nylon fasteners (arrowed)

to free the plastic shield from the brake

backplate

Page 12 of 20

22Loosen the rear roadwheel nuts on the

side concerned, chock the front wheels, and

jack up the rear of the vehicle and support on

axle stands. Remove the roadwheel and

release the handbrake.

23Unbolt the brake caliper carrier bracket

and support the caliper on an axle stand,

taking care not to strain the flexible hose.

24Mark the position of the brake disc in

relation to the drive flange, remove the

retaining spire washer(s), and remove the disc.

25Unscrew and remove the rear hub nut,

and using a puller, pull off the drive flange.

26Unscrew the four bolts securing the hub

carrier and splash shield to the lower arm.

Remove the hub carrier and splash shield,

whilst supporting the driveshaft. Support the

driveshaft by placing axle stands underneath

it, or by securing with string to the underbody.

Avoid bending the driveshaft joints to

excessive angles, and do not allow the shaft

to hang down from one end.

27With the hub carrier removed, the

bearings can be renewed as described in

paragraphs 10 to 16 of this Section.

28Fit the drive flange to the hub carrier in

order to centralise the bearings, then using a

soft-faced mallet, drive the drive flange/hub

carrier assembly onto the end of the stub axle.

Do not forget to fit the splash shield.

29Further refitting is a reversal of removal,

bearing in mind the following points.

30Refit the hub carrier/splash

shield-to-lower arm securing bolts with

reference to the note at the beginning of this

sub-Section.

31When refitting the brake disc, align the

previously made marks on disc and drive

flange.

32Fit a new rear hub nut of the correct type,

and tighten it with the vehicle resting on its

roadwheels. Apply the handbrake and chock

the relevant rear wheel.

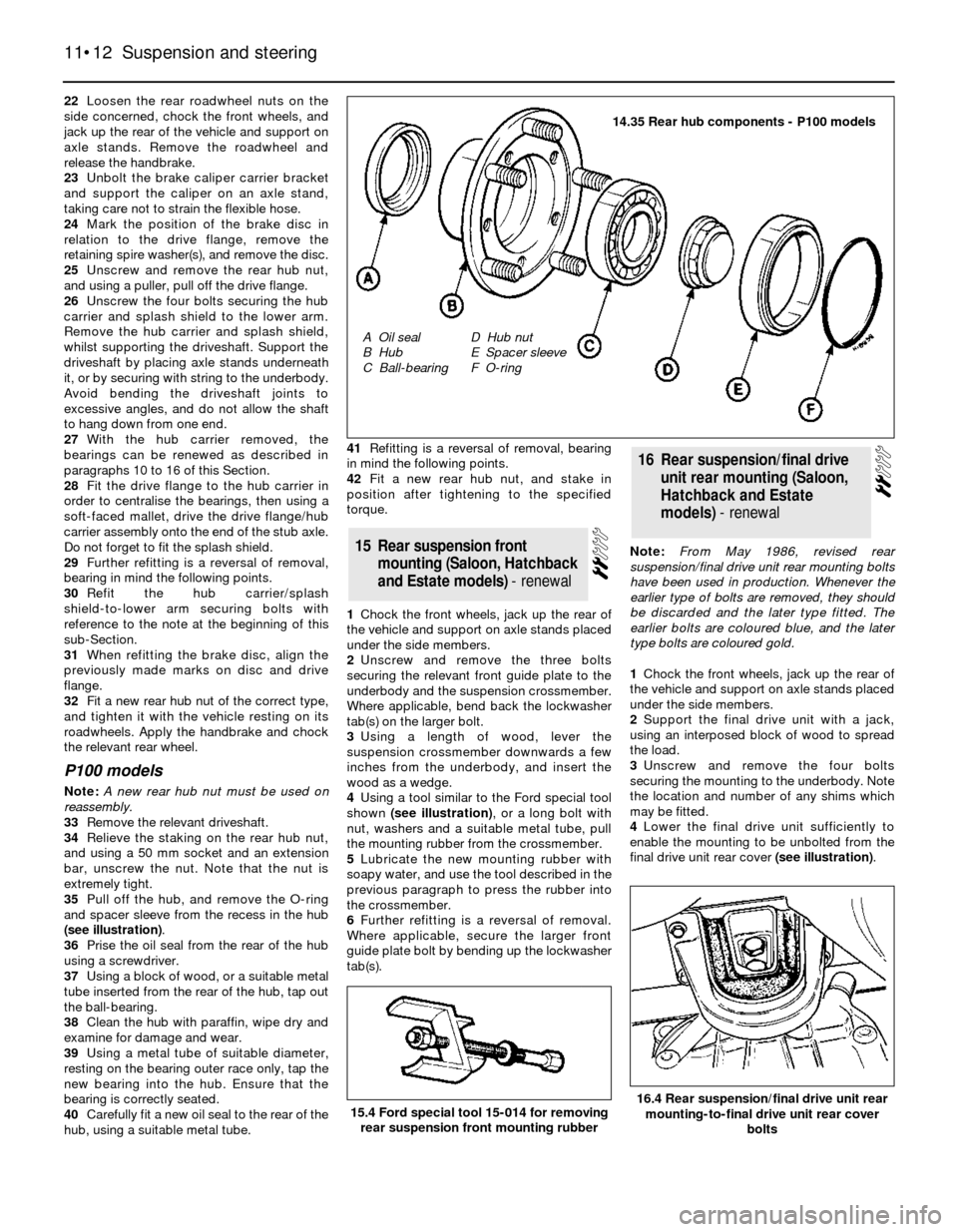

P100 models

Note: A new rear hub nut must be used on

reassembly.

33Remove the relevant driveshaft.

34Relieve the staking on the rear hub nut,

and using a 50 mm socket and an extension

bar, unscrew the nut. Note that the nut is

extremely tight.

35Pull off the hub, and remove the O-ring

and spacer sleeve from the recess in the hub

(see illustration).

36Prise the oil seal from the rear of the hub

using a screwdriver.

37Using a block of wood, or a suitable metal

tube inserted from the rear of the hub, tap out

the ball-bearing.

38Clean the hub with paraffin, wipe dry and

examine for damage and wear.

39Using a metal tube of suitable diameter,

resting on the bearing outer race only, tap the

new bearing into the hub. Ensure that the

bearing is correctly seated.

40Carefully fit a new oil seal to the rear of the

hub, using a suitable metal tube.41Refitting is a reversal of removal, bearing

in mind the following points.

42Fit a new rear hub nut, and stake in

position after tightening to the specified

torque.

1Chock the front wheels, jack up the rear of

the vehicle and support on axle stands placed

under the side members.

2Unscrew and remove the three bolts

securing the relevant front guide plate to the

underbody and the suspension crossmember.

Where applicable, bend back the lockwasher

tab(s) on the larger bolt.

3Using a length of wood, lever the

suspension crossmember downwards a few

inches from the underbody, and insert the

wood as a wedge.

4Using a tool similar to the Ford special tool

shown (see illustration), or a long bolt with

nut, washers and a suitable metal tube, pull

the mounting rubber from the crossmember.

5Lubricate the new mounting rubber with

soapy water, and use the tool described in the

previous paragraph to press the rubber into

the crossmember.

6Further refitting is a reversal of removal.

Where applicable, secure the larger front

guide plate bolt by bending up the lockwasher

tab(s).Note: From May 1986, revised rear

suspension/final drive unit rear mounting bolts

have been used in production. Whenever the

earlier type of bolts are removed, they should

be discarded and the later type fitted. The

earlier bolts are coloured blue, and the later

type bolts are coloured gold.

1Chock the front wheels, jack up the rear of

the vehicle and support on axle stands placed

under the side members.

2Support the final drive unit with a jack,

using an interposed block of wood to spread

the load.

3Unscrew and remove the four bolts

securing the mounting to the underbody. Note

the location and number of any shims which

may be fitted.

4Lower the final drive unit sufficiently to

enable the mounting to be unbolted from the

final drive unit rear cover (see illustration).

16Rear suspension/final drive

unit rear mounting (Saloon,

Hatchback and Estate

models) - renewal

15Rear suspension front

mounting (Saloon, Hatchback

and Estate models) - renewal

11•12Suspension and steering

15.4 Ford special tool 15-014 for removing

rear suspension front mounting rubber

14.35 Rear hub components - P100 models

A Oil seal

B Hub

C Ball-bearingD Hub nut

E Spacer sleeve

F O-ring

16.4 Rear suspension/final drive unit rear

mounting-to-final drive unit rear cover

bolts