brake rotor FORD SIERRA 1987 2.G CVH Engines Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1987, Model line: SIERRA, Model: FORD SIERRA 1987 2.GPages: 24, PDF Size: 1.09 MB

Page 6 of 24

a)Removal of the cylinder head

b)Removal of the camshaft

c)Removal of the timing belt and sprockets

d)Removal of the engine mountings

e)Removal of the clutch and flywheel

f)Removal of the crankshaft oil seals

a)Removal of the sump

b)Removal of the oil pump

c)Removal of the pistons/connecting rods

d)Removal of the big-end bearings

e)Removal of the crankshaft main bearings

f)Removal of the crankshaft

Refer to Section 8, Chapter 2, Part A.

Note: A suitable hoist and lifting tackle will be

required for this operation.

1.8 litre (R2A type)

1Disconnect the battery negative lead.

2Remove the bonnet.

3Remove the air cleaner.

4Disconnect the cooling fan wiring plug, then

unscrew the retaining nuts and washers and

withdraw the fan shroud and cooling fan

assembly.

5Drain the cooling system.

6Disconnect the coolant hoses from the

coolant pump elbow, and detach the heater

hose from the clip on the front of the timing

cover.

7Disconnect the upper radiator hose and the

expansion tank hose from the thermostat

housing (see illustration).8Disconnect the heater hose from the

automatic choke.

9Disconnect the brake servo vacuum hose

from the inlet manifold (see illustration).

10Disconnect the throttle damper solenoid

vacuum pipes (noting their locations) from the

throttle damper and the carburettor “T”-piece

connector.

11Disconnect the engine management

module vacuum pipe from the inlet manifold.

12Disconnect the fuel hoses from the

carburettor and fuel pump, and plug the ends

of the hoses to minimise petrol spillage. Take

adequate fire precautions.

13Disconnect the throttle cable.

14Disconnect the HT leads from the coil and

spark plugs, unclip the leads from the

camshaft cover, and remove the distributor

cap, rotor arm and housing.

15Disconnect the wiring from the following

components:

Alternator

Starter motor

Oil pressure warning lamp switch

Temperature gauge sender

Engine coolant temperature sensor

Automatic choke

Cooling fan switch

Crankshaft speed/position sensor

Engine earth strap to battery tray16Unscrew and remove the top engine-to-

gearbox bolts which are accessible from the

engine compartment.

17Apply the handbrake (if not already done),

jack up the front of the vehicle and support on

axle stands (see “Jacking and Vehicle

Support”).

18Drain the engine oil into a container.

19Remove the starter motor.

20Remove the exhaust downpipe.

21Unscrew the two nuts securing the engine

mountings to the crossmember. Recover the

washers.

22Unscrew and remove the remaining

engine-to-gearbox bolts, noting the location

of the earth strap (see illustration), and

remove the two bolts from the engine adapter

plate (see illustration).

23Working inside the vehicle, place a

wooden block under the clutch pedal to raise

it fully against its stop which will hold the

automatic adjuster pawl clear of the toothed

quadrant.

24Disconnect the clutch cable from the

release arm, and pass the cable through the

bellhousing. Remove the clip securing the

clutch cable to the right-hand engine

mounting bracket. Note the cable routing for

use when refitting.

25Lower the vehicle to the ground, and

support the gearbox with a trolley jack using a

block of wood between the jack and the

gearbox to spread the load.

26Make a final check to ensure that all

relevant wires, pipes and hoses have been

disconnected to facilitate engine removal.

27Attach a suitable hoist to the engine lifting

brackets located at the front and rear of the

cylinder head, and carefully take the weight of

the engine. The engine should be supported

horizontally, ie do not allow it to tilt front to

rear.

28Raise the engine until the engine

mounting studs are clear of the crossmember,

then pull the engine forwards to disconnect it

from the gearbox. Ensure that the gearbox is

adequately supported, and take care not to

strain the gearbox input shaft. It may be

necessary to rock the engine a little to release

it from the gearbox.

8Engine - removal leaving

manual gearbox in vehicle

7Method of engine removal

6Major operations requiring

engine removal

5Major operations possible with

the engine in the vehicle

2C•6CVH engines

8.9 Disconnecting the brake servo vacuum

hose from the inlet manifold -

1.8 litre (R2A)

8.22b Remove the two bolts (arrowed) from

the engine adapter plate - 1.8 litre (R2A)8.22a Earth strap location under engine-to-

gearbox bolt - 1.8 litre (R2A)

8.7 Disconnect the upper radiator hose (1)

and the expansion tank hose (2) from the

thermostat housing - 1.8 litre (R2A)

Page 10 of 24

1.8 litre (R2A type)

Dismantling

1It is best to mount the engine on a

dismantling stand, but if this is not available,

stand the engine on a strong bench at a

comfortable working height. Failing this, it will

have to stripped down on the floor.

2Cleanliness is most important, and if the

engine is dirty, it should be cleaned with

paraffin while keeping it in an upright position.

3Avoid working with the engine directly on a

concrete floor, as grit presents a real source

of trouble.

4As parts are removed, clean them in a

paraffin bath. However, do not immerse parts

with internal oilways in paraffin as it is difficult

to remove, usually requiring a high pressure

hose. Clean oilways with nylon pipe cleaners.

5It is advisable to have suitable containers

available to hold small items according to

their use, as this will help when reassembling

the engine and also prevent possible losses.

6Always obtain a complete set of new

gaskets for use during engine reassembly, but

retain the old gaskets with a view to using

them as a pattern to make a replacement if a

new one is not available.

7Where possible, refit securing nuts, bolts

and washers to their locations after removing

the relevant components. This will help to

protect the threads and will also prevent

possible losses.

8Retain unserviceable components in order

to compare them with the new components

supplied.

9A suitable Torx socket will be required to

remove the oil pump cover securing screws.

10Before dismantling the main engine

components, the following externally mounted

ancillary components can be removed:

Inlet manifold and carburettor

Exhaust manifold

Fuel pump and operating pushrod

Alternator

Spark plugs

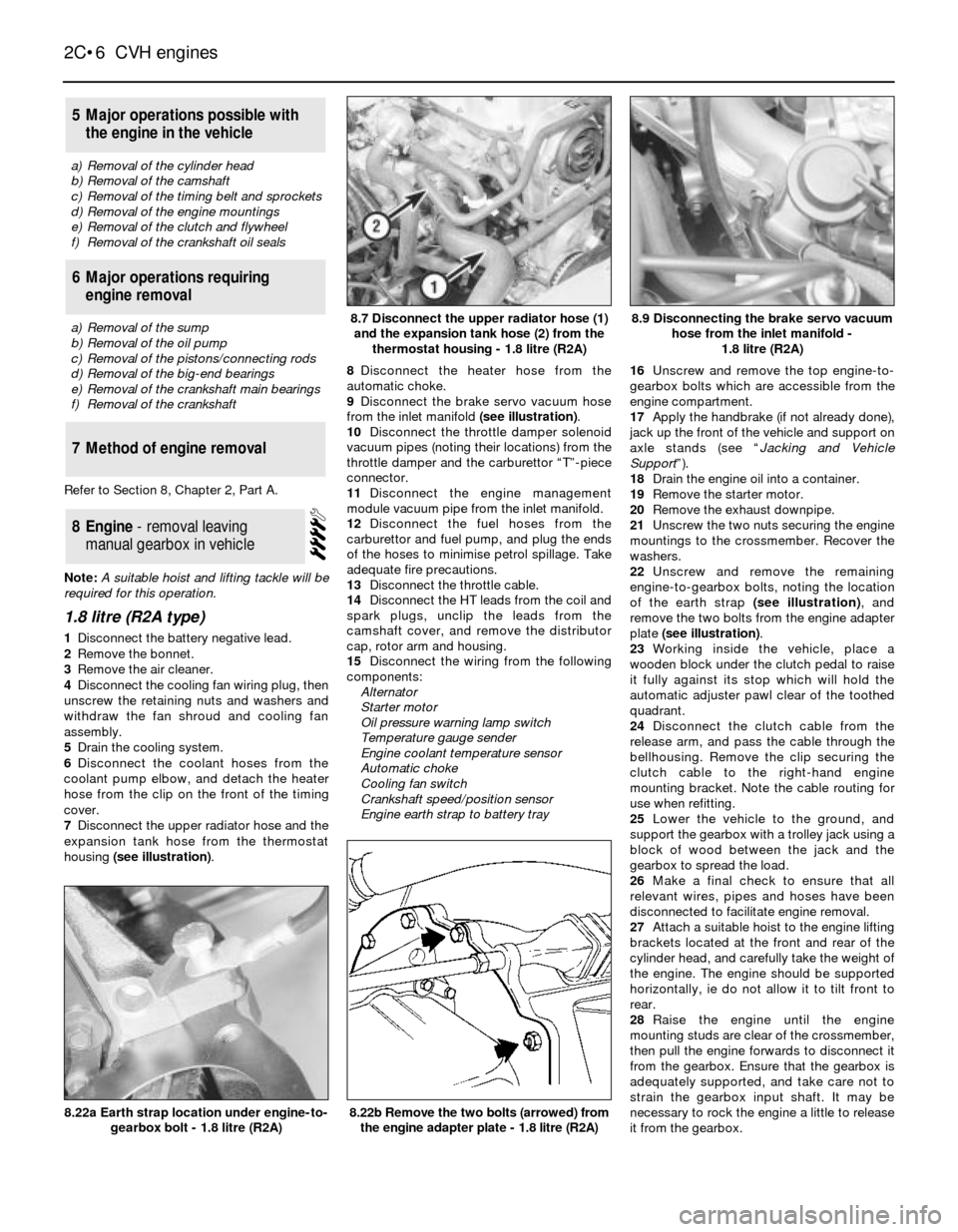

Oil pressure warning lamp switch (see

illustration)

Oil filter

Dipstick

Engine mounting brackets

Clutch

Alternator mounting bracket

Crankshaft speed/position sensor

Engine lifting brackets

Examination and renovation

11Refer to Section 18 in Chapter 2, PartA.

Reassembly

12To ensure maximum life with minimum

trouble from a rebuilt engine, not only must

everything be correctly assembled, but it mustalso be spotlessly clean. All oilways must be

clear, and locking washers and spring

washers must be fitted where indicated. Oil all

bearings and other working surfaces

thoroughly with engine oil during assembly.

13Before assembly begins, renew any bolts

or studs with damaged threads.

14Gather together a torque wrench, oil can,

clean rag, and a set of engine gaskets and oil

seals, together with a new oil filter.

15If they have been removed, new cylinder

head bolts, big-end bolts/nuts and new

flywheel bolts will be required.

16After reassembling the main engine

components, refer to paragraph 10 and refit

the ancillary components listed. Delicate

items such as the alternator may be left until

after the engine has been refitted.

1.6 and 1.8 litre (R6A type)

Dismantling

17Refer to paragraphs 1 to 9 inclusive.

18Before dismantling the main engine

components, the following ancillary

components can be removed:

Inlet manifold and CFI unit.

Exhaust manifold .

Alternator.

Spark plugs and HT leads.

Ignition coil and mounting bracket.

Oil pressure warning lamp switch.

Oil filter.

Dipstick and tube.

Engine mounting brackets.

Clutch.

Alternator mounting bracket.Crankshaft speed/position sensor.

Engine lifting brackets.

Crankcase ventilation hose.

Examination and renovation

19Refer to Section 18 in Chapter 2, PartA.

Reassembly

20Refer to paragraphs 12 to 16 but note that

new rocker arm nuts will be required, if they

have been removed.

Note: The belt tension should be checked

using Ford special tool No 21-113 after

refitting. A suitable puller may be required to

remove the sprockets. If the camshaft

sprocket is removed, a new retaining bolt

must be used on refitting, and suitable sealant

(Loctite 74 or 274, or Omnifit 30M blue) will be

required to coat the bolt threads.

1.8 litre (R2A type)

Removal

1If the engine is in the vehicle, carry out the

following operations:

a)Disconnect the battery negative lead

b)Remove the alternator drivebelt

c)Remove the distributor cap, rotor arm and

housing

d)Disconnect the wiring plug from the

crankshaft speed/position sensor

e)Unclip the coolant hoses from the timing

cover, and position them across the top

of the camshaft cover out of the way

f)If desired for improved access, remove

the fan shroud and cooling fan assembly,

although this is not essential

2Slacken the crankshaft pulley bolt. Prevent

the crankshaft from turning by engaging top

gear (manual gearbox only) and having an

assistant apply the brake pedal hard, or by

removing the starter motor and jamming the

ring gear teeth with a lever.

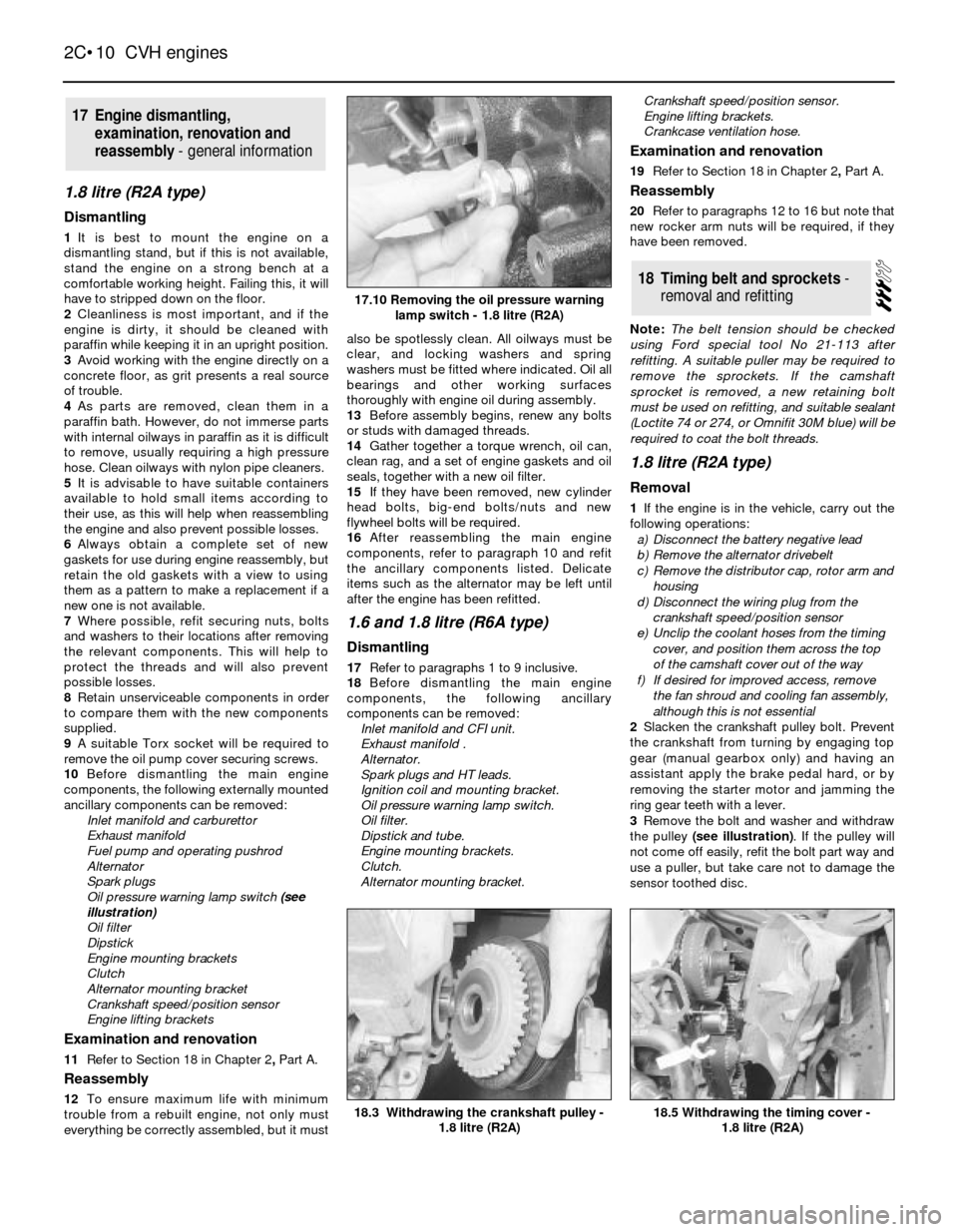

3Remove the bolt and washer and withdraw

the pulley (see illustration). If the pulley will

not come off easily, refit the bolt part way and

use a puller, but take care not to damage the

sensor toothed disc.

18Timing belt and sprockets -

removal and refitting

17Engine dismantling,

examination, renovation and

reassembly - general information

2C•10CVH engines

17.10 Removing the oil pressure warning

lamp switch - 1.8 litre (R2A)

18.5 Withdrawing the timing cover -

1.8 litre (R2A)18.3 Withdrawing the crankshaft pulley -

1.8 litre (R2A)