fuel type FORD SIERRA 1991 2.G Introduction Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: SIERRA, Model: FORD SIERRA 1991 2.GPages: 18, PDF Size: 0.5 MB

Page 4 of 18

0•4

The Ford Sierra was first introduced in late 1982 with the option of

seven different engines and four different trim levels. This manual

covers the four cylinder in-line petrol engines, but other models in the

range are fitted with V6 or diesel engines.

The Sierra was introduced by Ford as the successor to the Cortina

and initially received a mixed reception as it was one of the first

vehicles to make use of the “aeroback” body style designed to reduce

the air drag coefficient to a minimum in the interests of fuel economy.

Mechanically the Sierra is similar to the Cortina with the exception of

all-round independent suspension.

Initially, 1.3, 1.6 and 2.0 litre SOHC carburettor engines were

available, with Hatchback and Estate body styles. In late 1984, a 1.8

litre SOHC engine became available and in 1985, a performance

orientated 2.0 litre SOHC fuel injection engine was introduced.Towards the end of 1986, the 1.3 litre engine was phased out. In order

to fill a gap in the range, a Saloon body style, designated the Sapphire,

was introduced in early 1987 and shortly afterwards, a 1.8 litre CVH

engine replaced the previously used 1.8 litre SOHC engine throughout

the model range.

A 1.6 litre CVH engine was introduced in September 1991 to replace

the 1.6 litre SOHC engine used previously, this engine being broadly

similar to the original 1.8 litre CVH engine which was in turn uprated in

March, 1992.

A 2.0 litre DOHC (Double OverHead Camshaft) engine was in-

troduced in August 1989 to replace the 2.0 litre SOHC engine.

In early 1988, a Sierra-based P100 pick-up model became available

to replace the previous Cortina-based design. The P100 consists of a

Sierra-type “cab” and front suspension, and a Ford Transit-type rear

suspension and 2.0 litre engine.

A wide range of standard and optional

equipment is available within the Sierra

range to suit most tastes, including an

anti-lock braking system.

For the home mechanic, the Sierra is a

straightforward vehicle to maintain and

repair since design features have been

incorporated to reduce the actual cost of

ownership to a minimum, and most of the

items requiring frequent attention are

easily accessible.

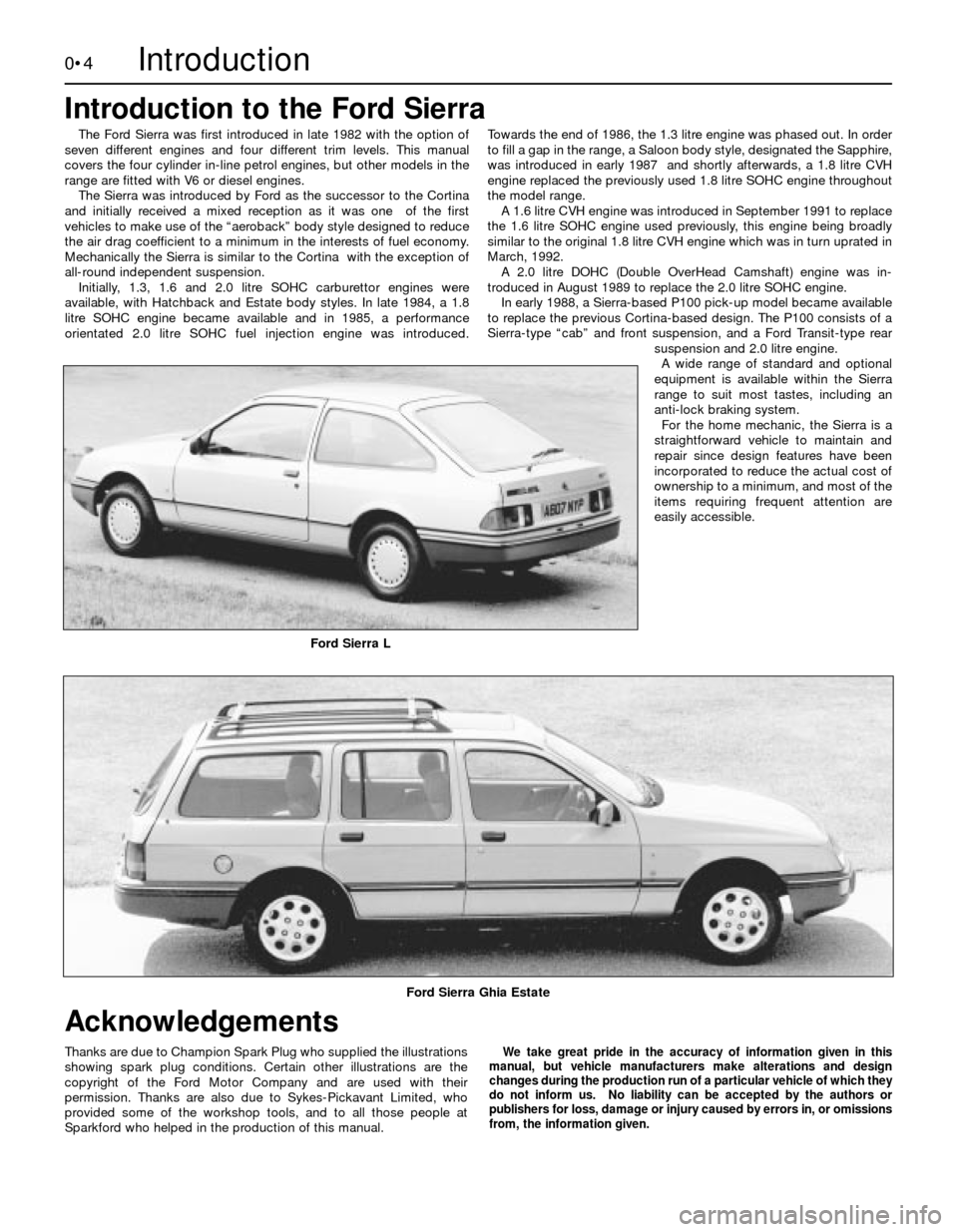

Ford Sierra L

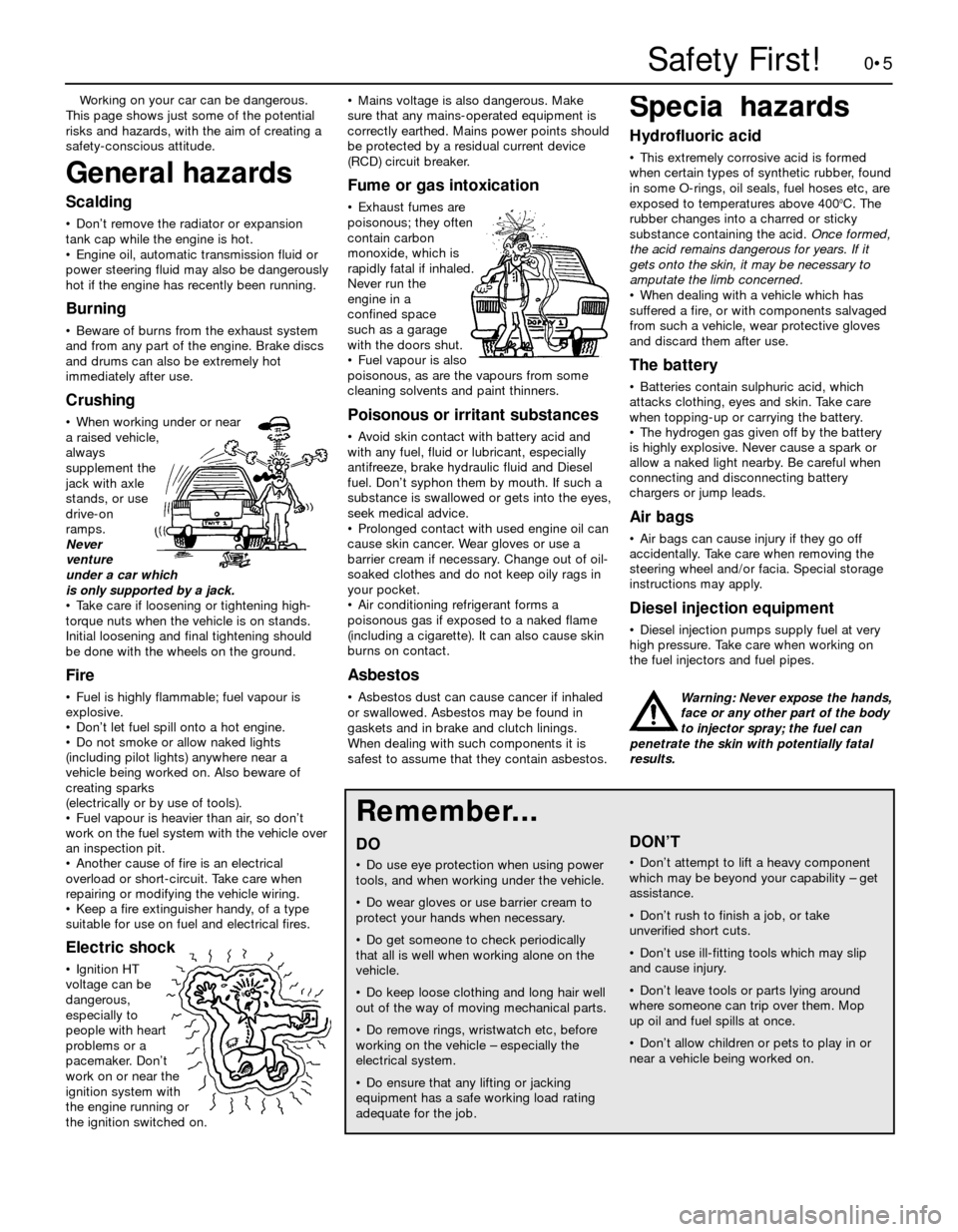

Ford Sierra Ghia Estate

Introduction

We take great pride in the accuracy of information given in this

manual, but vehicle manufacturers make alterations and design

changes during the production run of a particular vehicle of which they

do not inform us. No liability can be accepted by the authors or

publishers for loss, damage or injury caused by errors in, or omissions

from, the information given.Thanks are due to Champion Spark Plug who supplied the illustrations

showing spark plug conditions. Certain other illustrations are the

copyright of the Ford Motor Company and are used with their

permission. Thanks are also due to Sykes-Pickavant Limited, who

provided some of the workshop tools, and to all those people at

Sparkford who helped in the production of this manual.

Introduction to the Ford Sierra

Acknowledgements

Page 5 of 18

0•5Safety First!

Working on your car can be dangerous.

This page shows just some of the potential

risks and hazards, with the aim of creating a

safety-conscious attitude.

General hazards

Scalding

• Don’t remove the radiator or expansion

tank cap while the engine is hot.

• Engine oil, automatic transmission fluid or

power steering fluid may also be dangerously

hot if the engine has recently been running.

Burning

• Beware of burns from the exhaust system

and from any part of the engine. Brake discs

and drums can also be extremely hot

immediately after use.

Crushing

• When working under or near

a raised vehicle,

always

supplement the

jack with axle

stands, or use

drive-on

ramps.

Never

venture

under a car which

is only supported by a jack.

• Take care if loosening or tightening high-

torque nuts when the vehicle is on stands.

Initial loosening and final tightening should

be done with the wheels on the ground.

Fire

• Fuel is highly flammable; fuel vapour is

explosive.

• Don’t let fuel spill onto a hot engine.

• Do not smoke or allow naked lights

(including pilot lights) anywhere near a

vehicle being worked on. Also beware of

creating sparks

(electrically or by use of tools).

• Fuel vapour is heavier than air, so don’t

work on the fuel system with the vehicle over

an inspection pit.

• Another cause of fire is an electrical

overload or short-circuit. Take care when

repairing or modifying the vehicle wiring.

• Keep a fire extinguisher handy, of a type

suitable for use on fuel and electrical fires.

Electric shock

• Ignition HT

voltage can be

dangerous,

especially to

people with heart

problems or a

pacemaker. Don’t

work on or near the

ignition system with

the engine running or

the ignition switched on.• Mains voltage is also dangerous. Make

sure that any mains-operated equipment is

correctly earthed. Mains power points should

be protected by a residual current device

(RCD) circuit breaker.

Fume or gas intoxication

• Exhaust fumes are

poisonous; they often

contain carbon

monoxide, which is

rapidly fatal if inhaled.

Never run the

engine in a

confined space

such as a garage

with the doors shut.

• Fuel vapour is also

poisonous, as are the vapours from some

cleaning solvents and paint thinners.

Poisonous or irritant substances

• Avoid skin contact with battery acid and

with any fuel, fluid or lubricant, especially

antifreeze, brake hydraulic fluid and Diesel

fuel. Don’t syphon them by mouth. If such a

substance is swallowed or gets into the eyes,

seek medical advice.

• Prolonged contact with used engine oil can

cause skin cancer. Wear gloves or use a

barrier cream if necessary. Change out of oil-

soaked clothes and do not keep oily rags in

your pocket.

• Air conditioning refrigerant forms a

poisonous gas if exposed to a naked flame

(including a cigarette). It can also cause skin

burns on contact.

Asbestos

• Asbestos dust can cause cancer if inhaled

or swallowed. Asbestos may be found in

gaskets and in brake and clutch linings.

When dealing with such components it is

safest to assume that they contain asbestos.

Specia hazards

Hydrofluoric acid

• This extremely corrosive acid is formed

when certain types of synthetic rubber, found

in some O-rings, oil seals, fuel hoses etc, are

exposed to temperatures above 400

0C. The

rubber changes into a charred or sticky

substance containing the acid. Once formed,

the acid remains dangerous for years. If it

gets onto the skin, it may be necessary to

amputate the limb concerned.

• When dealing with a vehicle which has

suffered a fire, or with components salvaged

from such a vehicle, wear protective gloves

and discard them after use.

The battery

• Batteries contain sulphuric acid, which

attacks clothing, eyes and skin. Take care

when topping-up or carrying the battery.

• The hydrogen gas given off by the battery

is highly explosive. Never cause a spark or

allow a naked light nearby. Be careful when

connecting and disconnecting battery

chargers or jump leads.

Air bags

• Air bags can cause injury if they go off

accidentally. Take care when removing the

steering wheel and/or facia. Special storage

instructions may apply.

Diesel injection equipment

• Diesel injection pumps supply fuel at very

high pressure. Take care when working on

the fuel injectors and fuel pipes.

Warning: Never expose the hands,

face or any other part of the body

to injector spray; the fuel can

penetrate the skin with potentially fatal

results.

Remember...

DO

• Do use eye protection when using power

tools, and when working under the vehicle.

• Do wear gloves or use barrier cream to

protect your hands when necessary.

• Do get someone to check periodically

that all is well when working alone on the

vehicle.

• Do keep loose clothing and long hair well

out of the way of moving mechanical parts.

• Do remove rings, wristwatch etc, before

working on the vehicle – especially the

electrical system.

• Do ensure that any lifting or jacking

equipment has a safe working load rating

adequate for the job.

A few tips

DON’T

• Don’t attempt to lift a heavy component

which may be beyond your capability – get

assistance.

• Don’t rush to finish a job, or take

unverified short cuts.

• Don’t use ill-fitting tools which may slip

and cause injury.

• Don’t leave tools or parts lying around

where someone can trip over them. Mop

up oil and fuel spills at once.

• Don’t allow children or pets to play in or

near a vehicle being worked on.