width FORD SIERRA 1992 2.G CVH Engines Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 24, PDF Size: 1.09 MB

Page 3 of 24

Torque wrench settingsNmlbf ft

Main bearing cap bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90 to 10066 to 74

Connecting rod (big-end bearing cap) bolts . . . . . . . . . . . . . . . . . . . . . .30 to 3622 to 27

Crankshaft pulley bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 to 11574 to 85

Camshaft sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54 to 5940 to 44

Flywheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82 to 9261 to 68

Oil pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Oil pump cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 126 to 9

Sump bolts (in two stages) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 to 84 to 6

Rocker arm nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 to 2918 to 21

Cylinder head bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 4015 to 30

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 to 6030 to 44

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle-tighten a further 90º

Stage 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle-tighten a further 90º

Camshaft cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Timing cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 117 to 8

Timing belt tensioner bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 to 2012 to 15

Oil pick-up tube/strainer-to-oil pump bolts . . . . . . . . . . . . . . . . . . . . . .8 to 126 to 9

Oil pick-up tube/strainer-to-cylinder block bolt . . . . . . . . . . . . . . . . . . .17 to 2313 to 17

Camshaft thrustplate bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

Crankshaft rear oil seal housing bolts . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

1.8 litre (R2A type) engine

General

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Four-cylinder, in-line, single overhead camshaft

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3-4-2

Engine code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .R2A

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80.00 mm

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88.00 mm

Cubic capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1769 cc

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.3:1

Compression pressure at starter motor speed . . . . . . . . . . . . . . . . . . . .11 to 13 bar

Maximum continuous engine speed . . . . . . . . . . . . . . . . . . . . . . . . . . . .5850 rpm

Maximum engine power (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66 kW at 5250 rpm

Maximum engine torque (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147 Nm at 3000 rpm

Cylinder bore diameter

Standard class 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.940 to 79.950 mm

Standard class 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.950 to 79.960 mm

Standard class 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.960 to 79.970 mm

Standard class 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.970 to 79.980 mm

Standard class 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.980 to 79.990 mm

Standard class 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.990 to 80.000 mm

Oversize class A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80.000 to 80.010 mm

Oversize class B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80.010 to 80.020 mm

Oversize class C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80.020 to 80.030 mm

Crankshaft

Endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.10 to 0.20 mm (0.004 to 0.008 in)

Main bearing running clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.028 to 0.067 mm

Main bearing journal diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.980 to 54.000 mm

Undersize 0.25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.730 to 54.750 mm

Undersize 0.50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.480 to 53.500 mm

Undersize 0.75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.230 to 53.250 mm

Centre main thrust bearing shell width:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28.825 to 28.875 mm

Undersize 0.15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28.675 to 28.725 mm

Big-end bearing running clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.020 to 0.065 mm

Big-end bearing journal diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.890 to 43.910 mm

Undersize 0.25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.640 to 43.660 mm

Undersize 0.50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.390 to 43.410 mm

Undersize 0.75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.140 to 43.160 mm

Undersize 1.00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42.890 to 42.910 mm

CVH engines 2C•3

2C

Page 24 of 24

23Check that the crankshaft rotates freely.

Some stiffness is to be expected with new

components, but there must be no tight spots

or binding.

24Check that the crankshaft endfloat is

within the specified limits by inserting a feeler

blade between the centre crankshaft web and

the thrust bearing cap.

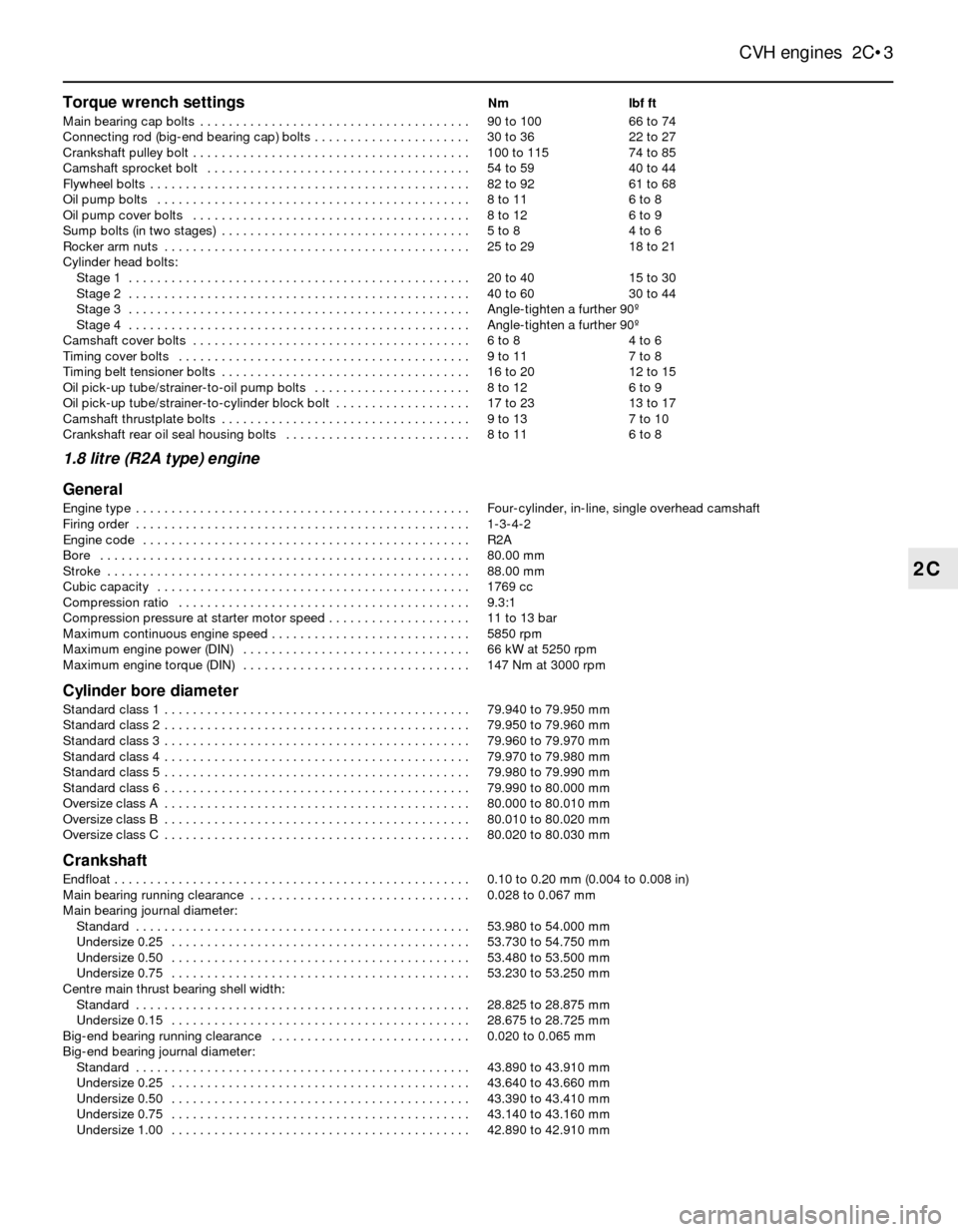

25Lubricate the oil seal lip with clean engine

oil, then carefully fit the crankshaft rear oil seal

housing. Using a straight-edge, ensure that

the bottom face of the oil seal housing is

aligned with the bottom face of the cylinder

block before finally tightening the securing

bolts (see illustration).

26Carefully prise the crankshaft front oil seal

from the oil pump housing, then refit the oil

pump, oil strainer/pick-up tube and

crankshaft front oil seal.

27Refit the pistons and connecting rods.

28Refit the thrustwasher, crankshaft

sprocket and timing belt.

1.6 and 1.8 litre (R6A type)

29Proceed as described above, noting the

following point:

On the 1.6 litre engine, note that

thrustwashers are used at the centre main

bearing (one each side of the bearing)

instead of a thrust bearing shell to control

crankshaft endfloat. Oversize

thrustwashers are available to

compensate for wear if necessary. The

thrustwashers should be fitted with the oil

grooves visible

1.8 litre (R2A type)

1Examine the bearing surfaces of the

crankshaft for scratches or scoring and, using

a micrometer, check each journal and

crankpin for ovality. Where this is found to be

in excess of 0.0254 mm (0.001 in) the

crankshaft will have to be reground and

undersize bearings fitted.

2Crankshaft regrinding should be carried out

by a suitable engineering works, who will

normally supply the matching undersize main

and big-end shell bearings.

3Note that undersize bearings may already

have been fitted either in production or by a

previous repairer. Check the markings on the

backs of the old bearing shells, and if in doubt

take them along when buying new ones.

4If the crankshaft endfloat is more than the

maximum specified amount, a new thrust

bearing shell should be fitted to the centre

main bearing.

5An accurate method of determining bearing

wear is by the use of Plastigage. The

crankshaft is located in the main bearings

(and big-end bearings if necessary) and the

Plastigage filament located across the journal

which must be dry. The cap is then fitted and

the bolts/nuts tightened to the specified

torque. On removal of the cap the width of the

filament is checked with a plastic gauge andthe running clearance compared with that

given in the Specifications.

6If the spigot bearing in the rear of the

crankshaft requires renewal extract it with a

suitable puller. Alternatively fill it with heavy

grease and use a close fitting metal dowel

driven into the centre of the bearing. Drive the

new bearing into the crankshaft with a soft

metal drift.

1.6 and 1.8 litre (R6A type)

7Proceed as described above but note that if

the crankshaft endfloat is more than the

maximum specified amount, new

thrustwashers should be fitted to the centre

main bearing.

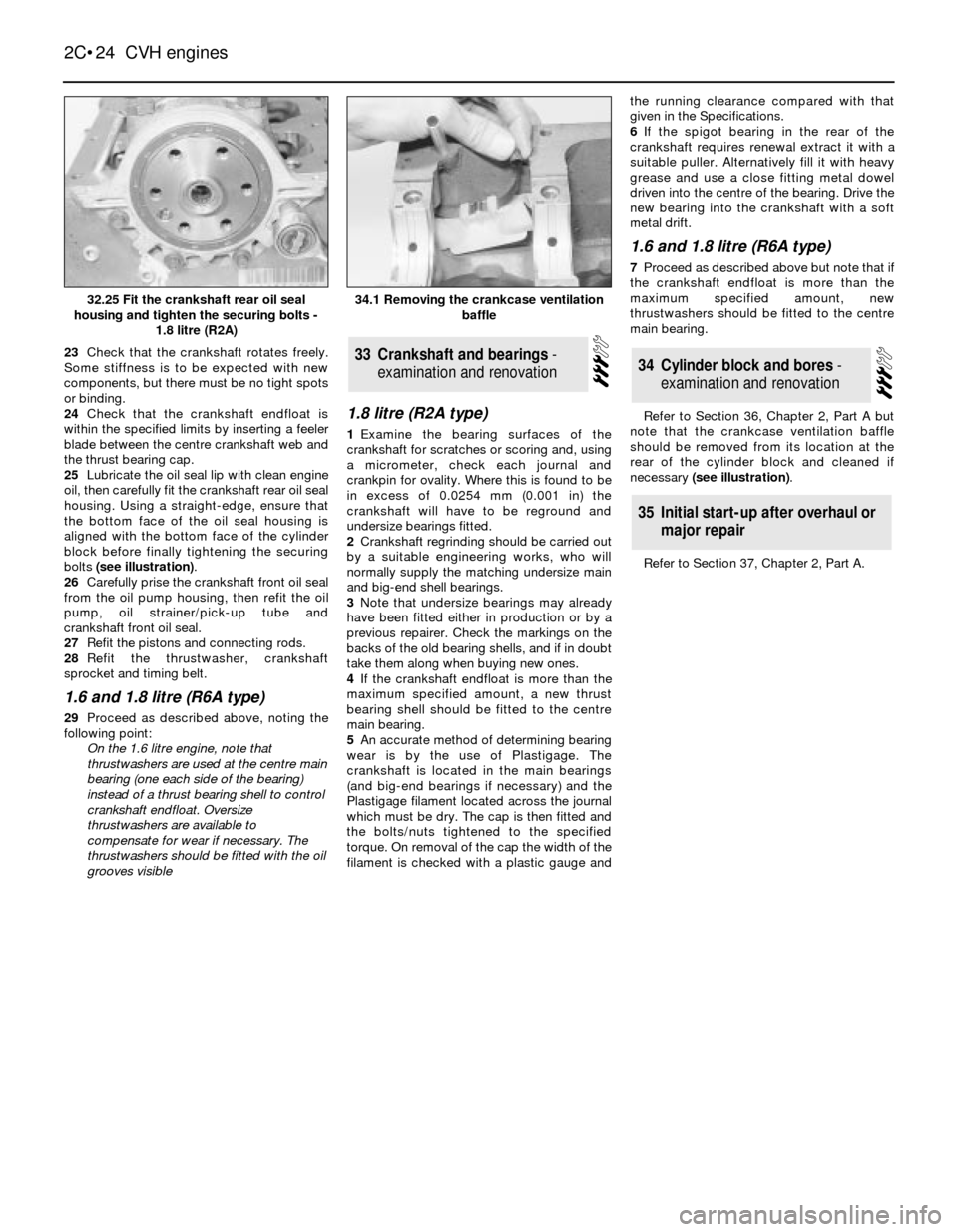

Refer to Section 36, Chapter 2, Part A but

note that the crankcase ventilation baffle

should be removed from its location at the

rear of the cylinder block and cleaned if

necessary (see illustration).

Refer to Section 37, Chapter 2, Part A.

35Initial start-up after overhaul or

major repair

34Cylinder block and bores -

examination and renovation33Crankshaft and bearings -

examination and renovation

2C•24CVH engines

32.25 Fit the crankshaft rear oil seal

housing and tighten the securing bolts -

1.8 litre (R2A)34.1 Removing the crankcase ventilation

baffle