check engine light FORD SIERRA 1992 2.G Reference Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 26, PDF Size: 0.57 MB

Page 4 of 26

Whenever servicing, repair or overhaul work

is carried out on the car or its components, it

is necessary to observe the following

procedures and instructions. This will assist in

carrying out the operation efficiently and to a

professional standard of workmanship.

Joint mating faces and gaskets

When separating components at their

mating faces, never insert screwdrivers or

similar implements into the joint between the

faces in order to prise them apart. This can

cause severe damage which results in oil

leaks, coolant leaks, etc upon reassembly.

Separation is usually achieved by tapping

along the joint with a soft-faced hammer in

order to break the seal. However, note that

this method may not be suitable where

dowels are used for component location.

Where a gasket is used between the mating

faces of two components, ensure that it is

renewed on reassembly, and fit it dry unless

otherwise stated in the repair procedure.

Make sure that the mating faces are clean and

dry, with all traces of old gasket removed.

When cleaning a joint face, use a tool which is

not likely to score or damage the face, and

remove any burrs or nicks with an oilstone or

fine file.

Make sure that tapped holes are cleaned

with a pipe cleaner, and keep them free of

jointing compound, if this is being used,

unless specifically instructed otherwise.

Ensure that all orifices, channels or pipes

are clear, and blow through them, preferably

using compressed air.

Oil seals

Oil seals can be removed by levering them

out with a wide flat-bladed screwdriver or

similar implement. Alternatively, a number of

self-tapping screws may be screwed into the

seal, and these used as a purchase for pliers or

some similar device in order to pull the seal free.

Whenever an oil seal is removed from its

working location, either individually or as part

of an assembly, it should be renewed.

The very fine sealing lip of the seal is easily

damaged, and will not seal if the surface it

contacts is not completely clean and free from

scratches, nicks or grooves. If the original

sealing surface of the component cannot be

restored, and the manufacturer has not made

provision for slight relocation of the seal

relative to the sealing surface, the component

should be renewed.

Protect the lips of the seal from any surface

which may damage them in the course of

fitting. Use tape or a conical sleeve where

possible. Lubricate the seal lips with oil before

fitting and, on dual-lipped seals, fill the space

between the lips with grease.

Unless otherwise stated, oil seals must be

fitted with their sealing lips toward the

lubricant to be sealed.

Use a tubular drift or block of wood of the

appropriate size to install the seal and, if the

seal housing is shouldered, drive the seal

down to the shoulder. If the seal housing is

unshouldered, the seal should be fitted withits face flush with the housing top face (unless

otherwise instructed).

Screw threads and fastenings

Seized nuts, bolts and screws are quite a

common occurrence where corrosion has set

in, and the use of penetrating oil or releasing

fluid will often overcome this problem if the

offending item is soaked for a while before

attempting to release it. The use of an impact

driver may also provide a means of releasing

such stubborn fastening devices, when used

in conjunction with the appropriate

screwdriver bit or socket. If none of these

methods works, it may be necessary to resort

to the careful application of heat, or the use of

a hacksaw or nut splitter device.

Studs are usually removed by locking two

nuts together on the threaded part, and then

using a spanner on the lower nut to unscrew the

stud. Studs or bolts which have broken off

below the surface of the component in which

they are mounted can sometimes be removed

using a proprietary stud extractor. Always

ensure that a blind tapped hole is completely

free from oil, grease, water or other fluid before

installing the bolt or stud. Failure to do this could

cause the housing to crack due to the hydraulic

action of the bolt or stud as it is screwed in.

When tightening a castellated nut to accept

a split pin, tighten the nut to the specified

torque, where applicable, and then tighten

further to the next split pin hole. Never

slacken the nut to align the split pin hole,

unless stated in the repair procedure.

When checking or retightening a nut or bolt

to a specified torque setting, slacken the nut

or bolt by a quarter of a turn, and then

retighten to the specified setting. However,

this should not be attempted where angular

tightening has been used.

For some screw fastenings, notably

cylinder head bolts or nuts, torque wrench

settings are no longer specified for the latter

stages of tightening, “angle-tightening” being

called up instead. Typically, a fairly low torque

wrench setting will be applied to the

bolts/nuts in the correct sequence, followed

by one or more stages of tightening through

specified angles.

Locknuts, locktabs and washers

Any fastening which will rotate against a

component or housing in the course of tightening

should always have a washer between it and the

relevant component or housing.

Spring or split washers should always be

renewed when they are used to lock a critical

component such as a big-end bearing

retaining bolt or nut. Locktabs which are

folded over to retain a nut or bolt should

always be renewed.

Self-locking nuts can be re-used in non-

critical areas, providing resistance can be felt

when the locking portion passes over the bolt or

stud thread. However, it should be noted that

self-locking stiffnuts tend to lose their

effectiveness after long periods of use, and insuch cases should be renewed as a matter of

course.

Split pins must always be replaced with

new ones of the correct size for the hole.

When thread-locking compound is found

on the threads of a fastener which is to be re-

used, it should be cleaned off with a wire

brush and solvent, and fresh compound

applied on reassembly.

Special tools

Some repair procedures in this manual

entail the use of special tools such as a press,

two or three-legged pullers, spring

compressors, etc. Wherever possible, suitable

readily-available alternatives to the

manufacturer’s special tools are described,

and are shown in use. In some instances,

where no alternative is possible, it has been

necessary to resort to the use of a

manufacturer’s tool, and this has been done

for reasons of safety as well as the efficient

completion of the repair operation. Unless you

are highly-skilled and have a thorough

understanding of the procedures described,

never attempt to bypass the use of any

special tool when the procedure described

specifies its use. Not only is there a very great

risk of personal injury, but expensive damage

could be caused to the components involved.

Environmental considerations

When disposing of used engine oil, brake

fluid, antifreeze, etc, give due consideration to

any detrimental environmental effects. Do not,

for instance, pour any of the above liquids

down drains into the general sewage system,

or onto the ground to soak away. Many local

council refuse tips provide a facility for waste

oil disposal, as do some garages. If none of

these facilities are available, consult your local

Environmental Health Department for further

advice.

With the universal tightening-up of

legislation regarding the emission of

environmentally-harmful substances from

motor vehicles, most current vehicles have

tamperproof devices fitted to the main

adjustment points of the fuel system. These

devices are primarily designed to prevent

unqualified persons from adjusting the fuel/air

mixture, with the chance of a consequent

increase in toxic emissions. If such devices

are encountered during servicing or overhaul,

they should, wherever possible, be renewed

or refitted in accordance with the vehicle

manufacturer’s requirements or current

legislation.

REF•4General Repair Procedures

Note: It is

antisocial and

illegal to dump oil

down the drain. To

find the location of

your local oil

recycling bank,

call this number

free.

Page 7 of 26

MOT test checksREF•7

REF

This is a guide to getting your vehicle through the MOT test.

Obviously it will not be possible to examine the vehicle to the same

standard as the professional MOT tester. However, working through

the following checks will enable you to identify any problem areas

before submitting the vehicle for the test.

Where a testable component is in borderline condition, the tester

has discretion in deciding whether to pass or fail it. The basis of such

discretion is whether the tester would be happy for a close relative or

friend to use the vehicle with the component in that condition. If the

vehicle presented is clean and evidently well cared for, the tester may

be more inclined to pass a borderline component than if the vehicle is

scruffy and apparently neglected.

It has only been possible to summarise the test requirements here,

based on the regulations in force at the time of printing. Test standards

are becoming increasingly stringent, although there are some

exemptions for older vehicles. For full details obtain a copy of the Haynes

publication Pass the MOT! (available from stockists of Haynes manuals).

An assistant will be needed to help carry out some of these checks.

The checks have been sub-divided into four categories, as follows:

HandbrakeMTest the operation of the handbrake.

Excessive travel (too many clicks) indicates

incorrect brake or cable adjustment.

MCheck that the handbrake cannot be

released by tapping the lever sideways. Check

the security of the lever mountings.

Footbrake

MDepress the brake pedal and check that it

does not creep down to the floor, indicating a

master cylinder fault. Release the pedal, wait

a few seconds, then depress it again. If the

pedal travels nearly to the floor before firm

resistance is felt, brake adjustment or repair is

necessary. If the pedal feels spongy, there is

air in the hydraulic system which must be

removed by bleeding.MCheck that the brake pedal is secure and in

good condition. Check also for signs of fluid

leaks on the pedal, floor or carpets, which

would indicate failed seals in the brake master

cylinder.

MCheck the servo unit (when applicable) by

operating the brake pedal several times, then

keeping the pedal depressed and starting the

engine. As the engine starts, the pedal will

move down slightly. If not, the vacuum hose or

the servo itself may be faulty.

Steering wheel and column

MExamine the steering wheel for fractures or

looseness of the hub, spokes or rim.

MMove the steering wheel from side to side

and then up and down. Check that the

steering wheel is not loose on the column,

indicating wear or a loose retaining nut.

Continue moving the steering wheel as before,

but also turn it slightly from left to right.

MCheck that the steering wheel is not loose

on the column, and that there is no abnormalmovement of the steering wheel, indicating

wear in the column support bearings or

couplings.

Windscreen and mirrors

MThe windscreen must be free of cracks or

other significant damage within the driver’s

field of view. (Small stone chips are

acceptable.) Rear view mirrors must be

secure, intact, and capable of being adjusted.

1Checks carried out

FROM THE DRIVER’S SEAT

1Checks carried out

FROM THE DRIVER’S

SEAT2Checks carried out

WITH THE VEHICLE

ON THE GROUND3Checks carried out

WITH THE VEHICLE

RAISED AND THE

WHEELS FREE TO

TURN4Checks carried out on

YOUR VEHICLE’S

EXHAUST EMISSION

SYSTEM

Page 13 of 26

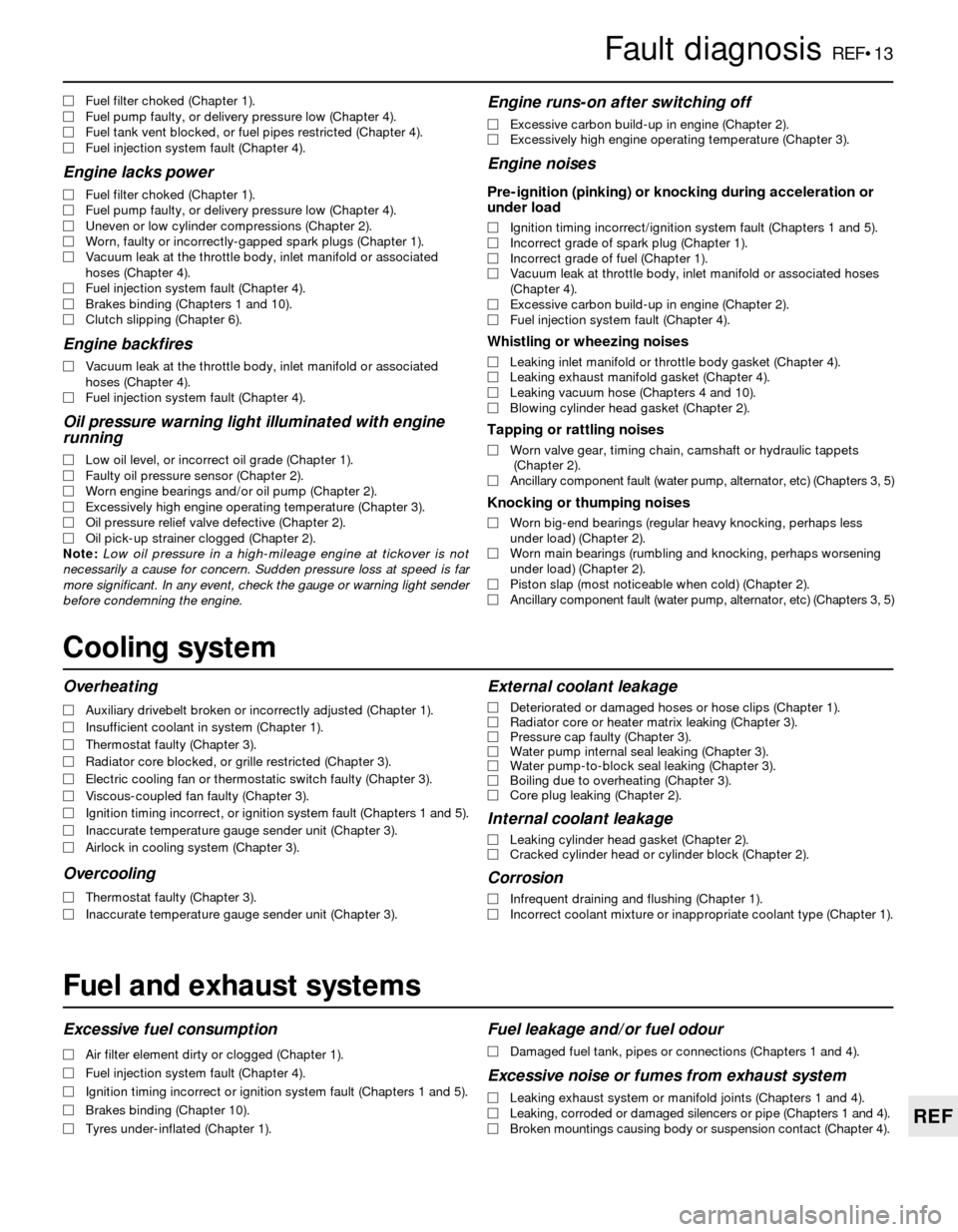

MFuel filter choked (Chapter 1).

MFuel pump faulty, or delivery pressure low (Chapter 4).

MFuel tank vent blocked, or fuel pipes restricted (Chapter 4).

MFuel injection system fault (Chapter 4).

Engine lacks power

MFuel filter choked (Chapter 1).

MFuel pump faulty, or delivery pressure low (Chapter 4).

MUneven or low cylinder compressions (Chapter 2).

MWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

MVacuum leak at the throttle body, inlet manifold or associated

hoses (Chapter 4).

MFuel injection system fault (Chapter 4).

MBrakes binding (Chapters 1 and 10).

MClutch slipping (Chapter 6).

Engine backfires

MVacuum leak at the throttle body, inlet manifold or associated

hoses (Chapter 4).

MFuel injection system fault (Chapter 4).

Oil pressure warning light illuminated with engine

running

MLow oil level, or incorrect oil grade (Chapter 1).

MFaulty oil pressure sensor (Chapter 2).

MWorn engine bearings and/or oil pump (Chapter 2).

MExcessively high engine operating temperature (Chapter 3).

MOil pressure relief valve defective (Chapter 2).

MOil pick-up strainer clogged (Chapter 2).

Note:Low oil pressure in a high-mileage engine at tickover is not

necessarily a cause for concern. Sudden pressure loss at speed is far

more significant. In any event, check the gauge or warning light sender

before condemning the engine.

Engine runs-on after switching off

MExcessive carbon build-up in engine (Chapter 2).

MExcessively high engine operating temperature (Chapter 3).

Engine noises

Pre-ignition (pinking) or knocking during acceleration or

under load

MIgnition timing incorrect/ignition system fault (Chapters 1 and 5).

MIncorrect grade of spark plug (Chapter 1).

MIncorrect grade of fuel (Chapter 1).

MVacuum leak at throttle body, inlet manifold or associated hoses

(Chapter 4).

MExcessive carbon build-up in engine (Chapter 2).

MFuel injection system fault (Chapter 4).

Whistling or wheezing noises

MLeaking inlet manifold or throttle body gasket (Chapter 4).

MLeaking exhaust manifold gasket (Chapter 4).

MLeaking vacuum hose (Chapters 4 and 10).

MBlowing cylinder head gasket (Chapter 2).

Tapping or rattling noises

MWorn valve gear, timing chain, camshaft or hydraulic tappets

(Chapter 2).

MAncillary component fault (water pump, alternator, etc) (Chapters 3, 5)

Knocking or thumping noises

MWorn big-end bearings (regular heavy knocking, perhaps less

under load) (Chapter 2).

MWorn main bearings (rumbling and knocking, perhaps worsening

under load) (Chapter 2).

MPiston slap (most noticeable when cold) (Chapter 2).

MAncillary component fault (water pump, alternator, etc) (Chapters 3, 5)

Overheating

MAuxiliary drivebelt broken or incorrectly adjusted (Chapter 1).

MInsufficient coolant in system (Chapter 1).

MThermostat faulty (Chapter 3).

MRadiator core blocked, or grille restricted (Chapter 3).

MElectric cooling fan or thermostatic switch faulty (Chapter 3).

MViscous-coupled fan faulty (Chapter 3).

MIgnition timing incorrect, or ignition system fault (Chapters 1 and 5).

MInaccurate temperature gauge sender unit (Chapter 3).

MAirlock in cooling system (Chapter 3).

Overcooling

MThermostat faulty (Chapter 3).

MInaccurate temperature gauge sender unit (Chapter 3).

External coolant leakage

MDeteriorated or damaged hoses or hose clips (Chapter 1).

MRadiator core or heater matrix leaking (Chapter 3).

MPressure cap faulty (Chapter 3).

MWater pump internal seal leaking (Chapter 3).

MWater pump-to-block seal leaking (Chapter 3).

MBoiling due to overheating (Chapter 3).

MCore plug leaking (Chapter 2).

Internal coolant leakage

MLeaking cylinder head gasket (Chapter 2).

MCracked cylinder head or cylinder block (Chapter 2).

Corrosion

MInfrequent draining and flushing (Chapter 1).

MIncorrect coolant mixture or inappropriate coolant type (Chapter 1).

Fault diagnosisREF•13

REF

Cooling system

Excessive fuel consumption

MAir filter element dirty or clogged (Chapter 1).

MFuel injection system fault (Chapter 4).

MIgnition timing incorrect or ignition system fault (Chapters 1 and 5).

MBrakes binding (Chapter 10).

MTyres under-inflated (Chapter 1).

Fuel leakage and/or fuel odour

MDamaged fuel tank, pipes or connections (Chapters 1 and 4).

Excessive noise or fumes from exhaust system

MLeaking exhaust system or manifold joints (Chapters 1 and 4).

MLeaking, corroded or damaged silencers or pipe (Chapters 1 and 4).

MBroken mountings causing body or suspension contact (Chapter 4).

Fuel and exhaust systems

Page 23 of 26

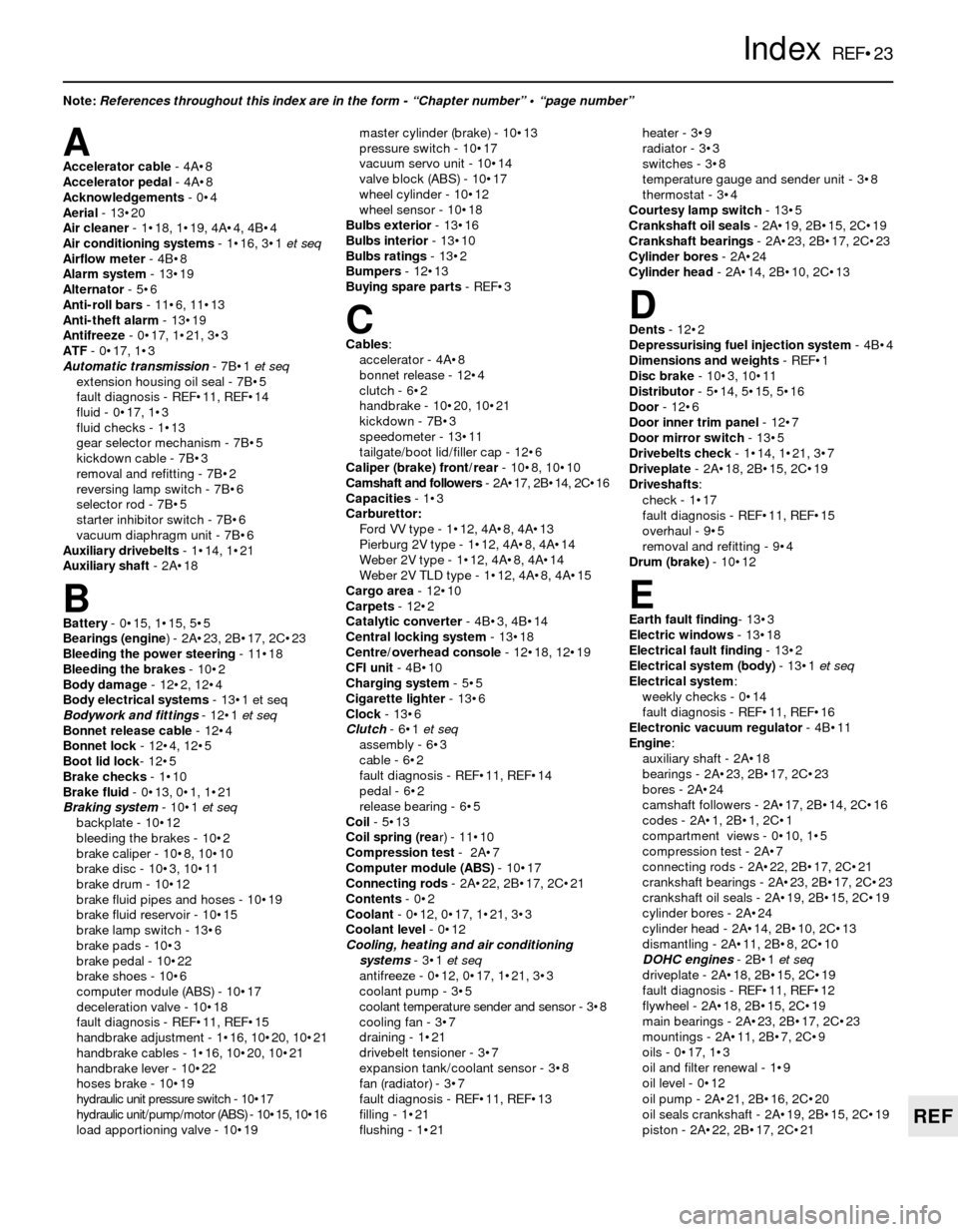

AAccelerator cable- 4A•8

Accelerator pedal- 4A•8

Acknowledgements- 0•4

Aerial- 13•20

Air cleaner- 1•18, 1•19, 4A•4, 4B•4

Air conditioning systems- 1•16, 3•1 et seq

Airflow meter- 4B•8

Alarm system- 13•19

Alternator- 5•6

Anti-roll bars- 11•6, 11•13

Anti-theft alarm- 13•19

Antifreeze- 0•17, 1•21, 3•3

ATF- 0•17, 1•3

Automatic transmission- 7B•1 et seq

extension housing oil seal - 7B•5

fault diagnosis - REF•11, REF•14

fluid - 0•17, 1•3

fluid checks - 1•13

gear selector mechanism - 7B•5

kickdown cable - 7B•3

removal and refitting - 7B•2

reversing lamp switch - 7B•6

selector rod - 7B•5

starter inhibitor switch - 7B•6

vacuum diaphragm unit - 7B•6

Auxiliary drivebelts- 1•14, 1•21

Auxiliary shaft- 2A•18

BBattery- 0•15, 1•15, 5•5

Bearings (engine) - 2A•23, 2B•17, 2C•23

Bleeding the power steering- 11•18

Bleeding the brakes- 10•2

Body damage- 12•2, 12•4

Body electrical systems - 13•1 et seq

Bodywork and fittings- 12•1 et seq

Bonnet release cable- 12•4

Bonnet lock- 12•4, 12•5

Boot lid lock- 12•5

Brake checks- 1•10

Brake fluid- 0•13, 0•1, 1•21

Braking system- 10•1 et seq

backplate - 10•12

bleeding the brakes - 10•2

brake caliper - 10•8, 10•10

brake disc - 10•3, 10•11

brake drum - 10•12

brake fluid pipes and hoses - 10•19

brake fluid reservoir - 10•15

brake lamp switch - 13•6

brake pads - 10•3

brake pedal - 10•22

brake shoes - 10•6

computer module (ABS) - 10•17

deceleration valve - 10•18

fault diagnosis - REF•11, REF•15

handbrake adjustment - 1•16, 10•20, 10•21

handbrake cables - 1•16, 10•20, 10•21

handbrake lever - 10•22

hoses brake - 10•19

hydraulic unit pressure switch - 10•17

hydraulic unit/pump/motor (ABS) - 10•15, 10•16

load apportioning valve - 10•19master cylinder (brake) - 10•13

pressure switch - 10•17

vacuum servo unit - 10•14

valve block (ABS) - 10•17

wheel cylinder - 10•12

wheel sensor - 10•18

Bulbs exterior- 13•16

Bulbs interior- 13•10

Bulbs ratings- 13•2

Bumpers- 12•13

Buying spare parts - REF•3

CCables:

accelerator - 4A•8

bonnet release - 12•4

clutch - 6•2

handbrake - 10•20, 10•21

kickdown - 7B•3

speedometer - 13•11

tailgate/boot lid/filler cap - 12•6

Caliper (brake) front/rear- 10•8, 10•10

Camshaft and followers- 2A•17, 2B•14, 2C•16

Capacities- 1•3

Carburettor:

Ford VV type - 1•12, 4A•8, 4A•13

Pierburg 2V type - 1•12, 4A•8, 4A•14

Weber 2V type - 1•12, 4A•8, 4A•14

Weber 2V TLD type - 1•12, 4A•8, 4A•15

Cargo area- 12•10

Carpets- 12•2

Catalytic converter- 4B•3, 4B•14

Central locking system- 13•18

Centre/overhead console- 12•18, 12•19

CFI unit- 4B•10

Charging system- 5•5

Cigarette lighter- 13•6

Clock- 13•6

Clutch- 6•1 et seq

assembly - 6•3

cable - 6•2

fault diagnosis - REF•11, REF•14

pedal - 6•2

release bearing - 6•5

Coil- 5•13

Coil spring (rear) - 11•10

Compression test- 2A•7

Computer module (ABS)- 10•17

Connecting rods- 2A•22, 2B•17, 2C•21

Contents- 0•2

Coolant- 0•12, 0•17, 1•21, 3•3

Coolant level- 0•12

Cooling, heating and air conditioning

systems- 3•1 et seq

antifreeze - 0•12, 0•17, 1•21, 3•3

coolant pump - 3•5

coolant temperature sender and sensor - 3•8

cooling fan - 3•7

draining - 1•21

drivebelt tensioner - 3•7

expansion tank/coolant sensor - 3•8

fan (radiator) - 3•7

fault diagnosis - REF•11, REF•13

filling - 1•21

flushing - 1•21heater - 3•9

radiator - 3•3

switches - 3•8

temperature gauge and sender unit - 3•8

thermostat - 3•4

Courtesy lamp switch- 13•5

Crankshaft oil seals- 2A•19, 2B•15, 2C•19

Crankshaft bearings- 2A•23, 2B•17, 2C•23

Cylinder bores- 2A•24

Cylinder head- 2A•14, 2B•10, 2C•13

DDents- 12•2

Depressurising fuel injection system- 4B•4

Dimensions and weights- REF•1

Disc brake - 10•3, 10•11

Distributor- 5•14, 5•15, 5•16

Door- 12•6

Door inner trim panel- 12•7

Door mirror switch- 13•5

Drivebelts check- 1•14, 1•21, 3•7

Driveplate- 2A•18, 2B•15, 2C•19

Driveshafts:

check - 1•17

fault diagnosis - REF•11, REF•15

overhaul - 9•5

removal and refitting - 9•4

Drum (brake)- 10•12

EEarth fault finding- 13•3

Electric windows- 13•18

Electrical fault finding- 13•2

Electrical system (body)- 13•1 et seq

Electrical system:

weekly checks - 0•14

fault diagnosis - REF•11, REF•16

Electronic vacuum regulator- 4B•11

Engine:

auxiliary shaft - 2A•18

bearings - 2A•23, 2B•17, 2C•23

bores - 2A•24

camshaft followers - 2A•17, 2B•14, 2C•16

codes - 2A•1, 2B•1, 2C•1

compartment views - 0•10, 1•5

compression test - 2A•7

connecting rods - 2A•22, 2B•17, 2C•21

crankshaft bearings - 2A•23, 2B•17, 2C•23

crankshaft oil seals - 2A•19, 2B•15, 2C•19

cylinder bores - 2A•24

cylinder head - 2A•14, 2B•10, 2C•13

dismantling - 2A•11, 2B•8, 2C•10

DOHC engines- 2B•1 et seq

driveplate - 2A•18, 2B•15, 2C•19

fault diagnosis - REF•11, REF•12

flywheel - 2A•18, 2B•15, 2C•19

main bearings - 2A•23, 2B•17, 2C•23

mountings - 2A•11, 2B•7, 2C•9

oils - 0•17, 1•3

oil and filter renewal - 1•9

oil level - 0•12

oil pump - 2A•21, 2B•16, 2C•20

oil seals crankshaft - 2A•19, 2B•15, 2C•19

piston - 2A•22, 2B•17, 2C•21

IndexREF•23

REF

Note: References throughout this index are in the form - “Chapter number” • “page number”

Page 24 of 26

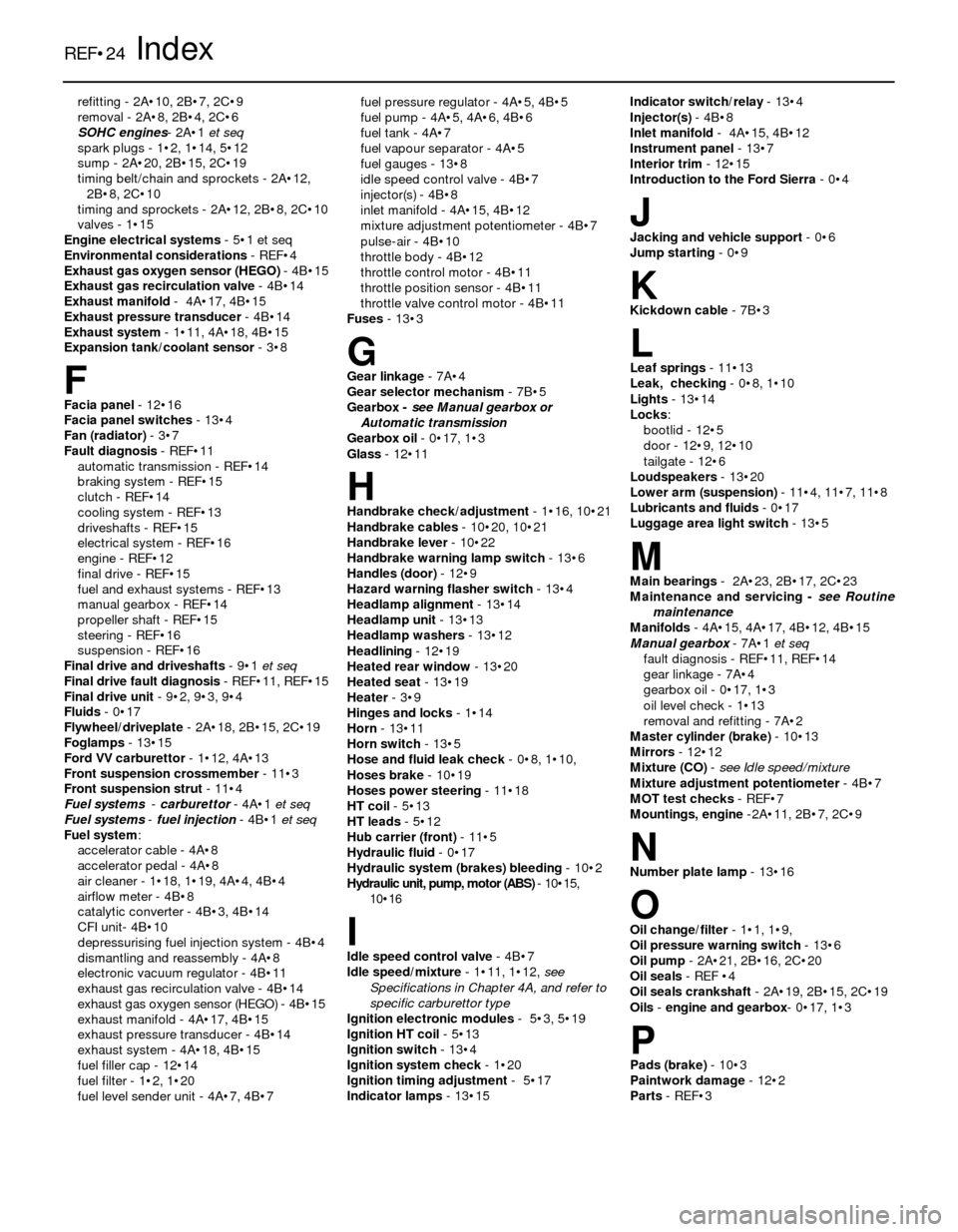

refitting - 2A•10, 2B•7, 2C•9

removal - 2A•8, 2B•4, 2C•6

SOHC engines- 2A•1et seq

spark plugs - 1•2, 1•14, 5•12

sump - 2A•20, 2B•15, 2C•19

timing belt/chain and sprockets - 2A•12,

2B•8, 2C•10

timing and sprockets - 2A•12, 2B•8, 2C•10

valves - 1•15

Engine electrical systems - 5•1 et seq

Environmental considerations- REF•4

Exhaust gas oxygen sensor (HEGO)- 4B•15

Exhaust gas recirculation valve- 4B•14

Exhaust manifold- 4A•17, 4B•15

Exhaust pressure transducer- 4B•14

Exhaust system- 1•11, 4A•18, 4B•15

Expansion tank/coolant sensor- 3•8

FFacia panel- 12•16

Facia panel switches- 13•4

Fan (radiator)- 3•7

Fault diagnosis- REF•11

automatic transmission - REF•14

braking system - REF•15

clutch - REF•14

cooling system - REF•13

driveshafts - REF•15

electrical system - REF•16

engine - REF•12

final drive - REF•15

fuel and exhaust systems - REF•13

manual gearbox - REF•14

propeller shaft - REF•15

steering - REF•16

suspension - REF•16

Final drive and driveshafts- 9•1 et seq

Final drive fault diagnosis- REF•11, REF•15

Final drive unit- 9•2, 9•3, 9•4

Fluids- 0•17

Flywheel/driveplate- 2A•18, 2B•15, 2C•19

Foglamps- 13•15

Ford VV carburettor- 1•12, 4A•13

Front suspension crossmember- 11•3

Front suspension strut- 11•4

Fuel systems- carburettor - 4A•1 et seq

Fuel systems- fuel injection - 4B•1 et seq

Fuel system:

accelerator cable - 4A•8

accelerator pedal - 4A•8

air cleaner - 1•18, 1•19, 4A•4, 4B•4

airflow meter - 4B•8

catalytic converter - 4B•3, 4B•14

CFI unit- 4B•10

depressurising fuel injection system - 4B•4

dismantling and reassembly - 4A•8

electronic vacuum regulator - 4B•11

exhaust gas recirculation valve - 4B•14

exhaust gas oxygen sensor (HEGO) - 4B•15

exhaust manifold - 4A•17, 4B•15

exhaust pressure transducer - 4B•14

exhaust system - 4A•18, 4B•15

fuel filler cap - 12•14

fuel filter - 1•2, 1•20

fuel level sender unit - 4A•7, 4B•7fuel pressure regulator - 4A•5, 4B•5

fuel pump - 4A•5, 4A•6, 4B•6

fuel tank - 4A•7

fuel vapour separator - 4A•5

fuel gauges - 13•8

idle speed control valve - 4B•7

injector(s) - 4B•8

inlet manifold - 4A•15, 4B•12

mixture adjustment potentiometer - 4B•7

pulse-air - 4B•10

throttle body - 4B•12

throttle control motor - 4B•11

throttle position sensor - 4B•11

throttle valve control motor - 4B•11

Fuses- 13•3

GGear linkage- 7A•4

Gear selector mechanism- 7B•5

Gearbox - see Manual gearbox or

Automatic transmission

Gearbox oil- 0•17, 1•3

Glass- 12•11

HHandbrake check/adjustment- 1•16, 10•21

Handbrake cables- 10•20, 10•21

Handbrake lever - 10•22

Handbrake warning lamp switch- 13•6

Handles (door)- 12•9

Hazard warning flasher switch- 13•4

Headlamp alignment- 13•14

Headlamp unit- 13•13

Headlamp washers- 13•12

Headlining - 12•19

Heated rear window- 13•20

Heated seat- 13•19

Heater- 3•9

Hinges and locks- 1•14

Horn- 13•11

Horn switch- 13•5

Hose and fluid leak check- 0•8, 1•10,

Hoses brake- 10•19

Hoses power steering- 11•18

HT coil- 5•13

HT leads- 5•12

Hub carrier (front) - 11•5

Hydraulic fluid- 0•17

Hydraulic system (brakes) bleeding- 10•2

Hydraulic unit, pump, motor (ABS)- 10•15,

10•16

IIdle speed control valve- 4B•7

Idle speed/mixture- 1•11, 1•12, see

Specifications in Chapter 4A, and refer to

specific carburettor type

Ignition electronic modules- 5•3, 5•19

Ignition HT coil- 5•13

Ignition switch- 13•4

Ignition system check- 1•20

Ignition timing adjustment- 5•17

Indicator lamps- 13•15Indicator switch/relay- 13•4

Injector(s)- 4B•8

Inlet manifold- 4A•15, 4B•12

Instrument panel- 13•7

Interior trim- 12•15

Introduction to the Ford Sierra- 0•4

JJacking and vehicle support- 0•6

Jump starting- 0•9

KKickdown cable - 7B•3

LLeaf springs- 11•13

Leak, checking- 0•8, 1•10

Lights- 13•14

Locks:

bootlid - 12•5

door - 12•9, 12•10

tailgate - 12•6

Loudspeakers- 13•20

Lower arm (suspension)- 11•4, 11•7, 11•8

Lubricants and fluids- 0•17

Luggage area light switch- 13•5

MMain bearings- 2A•23, 2B•17, 2C•23

Maintenance and servicing - see Routine

maintenance

Manifolds- 4A•15, 4A•17, 4B•12, 4B•15

Manual gearbox- 7A•1 et seq

fault diagnosis - REF•11, REF•14

gear linkage - 7A•4

gearbox oil - 0•17, 1•3

oil level check - 1•13

removal and refitting - 7A•2

Master cylinder (brake)- 10•13

Mirrors- 12•12

Mixture (CO)- see Idle speed/mixture

Mixture adjustment potentiometer- 4B•7

MOT test checks- REF•7

Mountings, engine-2A•11, 2B•7, 2C•9

NNumber plate lamp- 13•16

OOil change/filter- 1•1, 1•9,

Oil pressure warning switch- 13•6

Oil pump- 2A•21, 2B•16, 2C•20

Oil seals- REF •4

Oil seals crankshaft- 2A•19, 2B•15, 2C•19

Oils- engine and gearbox- 0•17, 1•3

PPads (brake) - 10•3

Paintwork damage- 12•2

Parts- REF•3

REF•24Index