clutch FORD SIERRA 1992 2.G Routine Manintenance And Servicing Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 22, PDF Size: 1.26 MB

Page 13 of 22

25Start the engine and run it at 3000 rpm for

15 seconds, ensuring that all electrical loads

(headlamps, heater blower etc) are switched

off, then allow the engine to idle and check

the CO content. Note that the CO reading will

initially rise, then fall and finally stabilise.

26If adjustment is necessary, remove the

tamperproof cap from the base of the airflow

meter, and turn the mixture screw using a

suitable Allen key to give the specified CO

content (see illustration).

27Checking and adjustment should be

completed within 30 seconds of the meter

readings stabilising. If this has not been

possible, run the engine at 3000 rpm, for 15

seconds, then allow the engine to idle. Re-

check the CO content and carry out further

adjustment if necessary.

28On completion of adjustment, stop the

engine and disconnect the tachometer and

exhaust gas analyser. Fit a new tamperproof

cap to the mixture screw.2.0 litre DOHC models

29On models with a catalytic converter, the

mixture is controlled by the EEC IV module.

No manual adjustment is possible.

30On models without a catalytic converter,

the idle mixture can be adjusted as follows:

31Run the engine until it is at normal

operating temperature.

32Stop the engine, and connect a

tachometer and an exhaust gas analyser in

accordance with the equipment

manufacturer’s instructions.

33Start the engine and run it at 3000 rpm for

15 seconds, ensuring that all electrical loads

(headlamps, heater blower, etc) are switched

off. Allow the engine to idle, and check the CO

content. Note that the reading will initially rise,

then fall and finally stabilise.

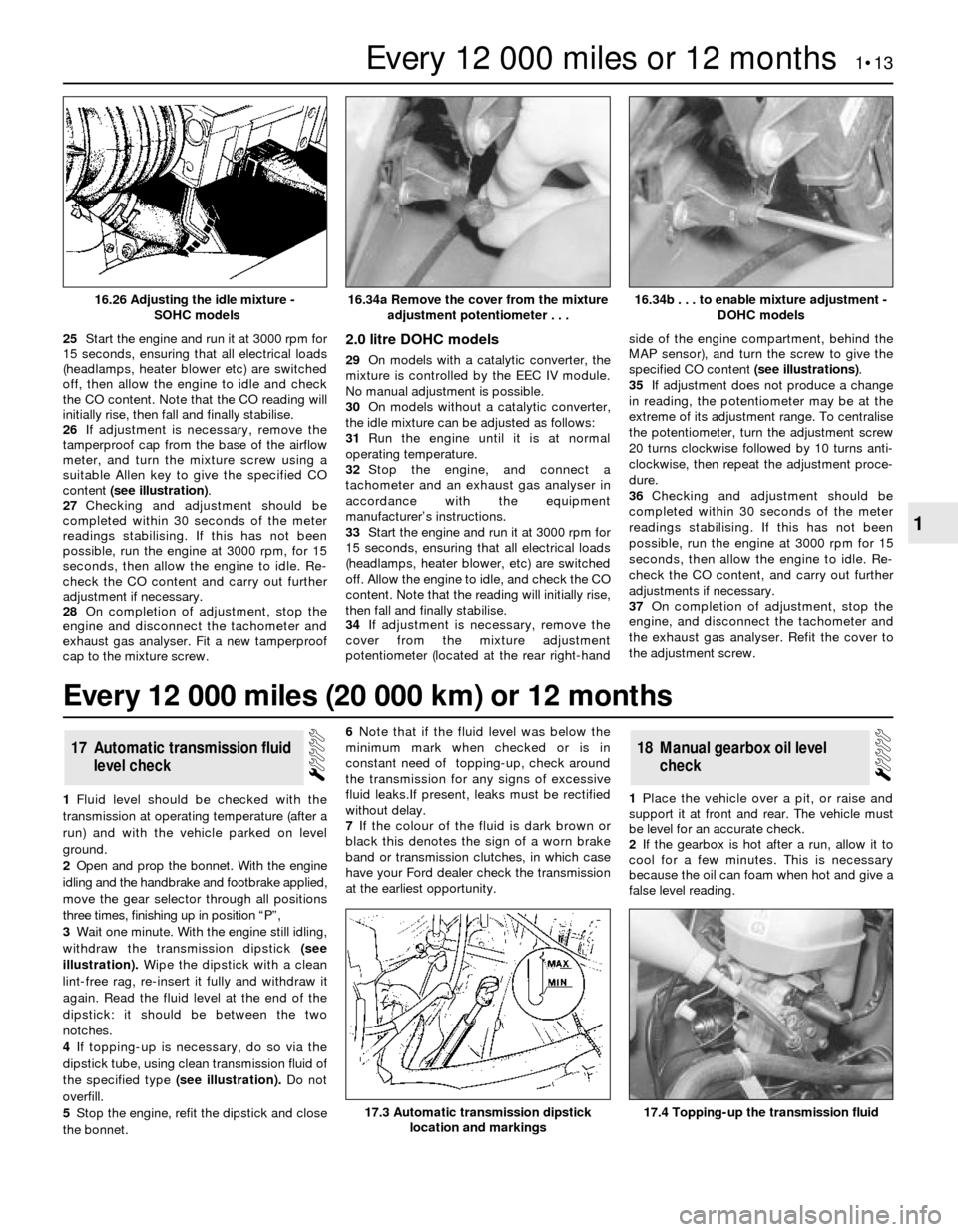

34If adjustment is necessary, remove the

cover from the mixture adjustment

potentiometer (located at the rear right-handside of the engine compartment, behind the

MAP sensor), and turn the screw to give the

specified CO content (see illustrations).

35If adjustment does not produce a change

in reading, the potentiometer may be at the

extreme of its adjustment range. To centralise

the potentiometer, turn the adjustment screw

20 turns clockwise followed by 10 turns anti-

clockwise, then repeat the adjustment proce-

dure.

36Checking and adjustment should be

completed within 30 seconds of the meter

readings stabilising. If this has not been

possible, run the engine at 3000 rpm for 15

seconds, then allow the engine to idle. Re-

check the CO content, and carry out further

adjustments if necessary.

37On completion of adjustment, stop the

engine, and disconnect the tachometer and

the exhaust gas analyser. Refit the cover to

the adjustment screw.

1Fluid level should be checked with the

transmission at operating temperature (after a

run) and with the vehicle parked on level

ground.

2Open and prop the bonnet. With the engine

idling and the handbrake and footbrake applied,

move the gear selector through all positions

three times, finishing up in position “P”,

3Wait one minute. With the engine still idling,

withdraw the transmission dipstick (see

illustration).Wipe the dipstick with a clean

lint-free rag, re-insert it fully and withdraw it

again. Read the fluid level at the end of the

dipstick: it should be between the two

notches.

4If topping-up is necessary, do so via the

dipstick tube, using clean transmission fluid of

the specified type (see illustration).Do not

overfill.

5Stop the engine, refit the dipstick and close

the bonnet.6Note that if the fluid level was below the

minimum mark when checked or is in

constant need of topping-up, check around

the transmission for any signs of excessive

fluid leaks.If present, leaks must be rectified

without delay.

7If the colour of the fluid is dark brown or

black this denotes the sign of a worn brake

band or transmission clutches, in which case

have your Ford dealer check the transmission

at the earliest opportunity.1Place the vehicle over a pit, or raise and

support it at front and rear. The vehicle must

be level for an accurate check.

2If the gearbox is hot after a run, allow it to

cool for a few minutes. This is necessary

because the oil can foam when hot and give a

false level reading.

18Manual gearbox oil level

check17Automatic transmission fluid

level check

Every 12 000 miles or 12 months 1•13

1

16.34b . . . to enable mixture adjustment -

DOHC models

17.4 Topping-up the transmission fluid17.3 Automatic transmission dipstick

location and markings

16.34a Remove the cover from the mixture

adjustment potentiometer . . .16.26 Adjusting the idle mixture -

SOHC models

Every 12 000 miles (20 000 km) or 12 months

Page 18 of 22

Steering and suspension

3Check for any abnormalities in the steering,

suspension, handling or road “feel”.

4Drive the vehicle, and check that there are

no unusual vibrations or noises.

5Check that the steering feels positive, with

no excessive “sloppiness”, or roughness, and

check for any suspension noises when

cornering, or when driving over bumps.

Drivetrain

6Check the performance of the engine,

clutch, transmission and driveshafts.

7Listen for any unusual noises from the

engine, clutch and transmission.

8Make sure that the engine runs smoothly

when idling, and that there is no hesitation

when accelerating.9Where applicable, check that the clutch

action is smooth and progressive, that the

drive is taken up smoothly, and that the pedal

travel is not excessive. Also listen for any

noises when the clutch pedal is depressed.

10Check that all gears can be engaged

smoothly, without noise, and that the gear lever

action is not abnormally vague or “notchy”.

Check the operation and

performance of the braking

system

11Make sure that the vehicle does not pull to

one side when braking, and that the wheels

do not lock prematurely when braking hard.

12Check that there is no vibration through

the steering when braking.

13Check that the handbrake operates

correctly, without excessive movement of thelever, and that it holds the vehicle stationary

on a slope.

14Test the operation of the brake servo unit

as follows. With the engine off, depress the

footbrake four or five times to exhaust the

vacuum. Start the engine, holding the brake

pedal depressed. As the engine starts, there

should be a noticeable “give” in the brake

pedal as vacuum builds up. Allow the engine

to run for at least two minutes, and then

switch it off. If the brake pedal is depressed

now, it should be possible to detect a hiss

from the servo as the pedal is depressed.

After about four or five applications, no further

hissing should be heard, and the pedal should

feel considerably firmer.

1Inspect the crankcase ventilation system

for blockage or damage. A blocked hose can

cause a build-up of crankcase pressure,

which in turn can cause oil leaks (see

illustration).

2On carburettor model SOHC engines, clean

the oil filler cap with paraffin and check that

the vent valve is not blocked by pulling it from

the oil separator and loosening the hose clip

(Section 42).

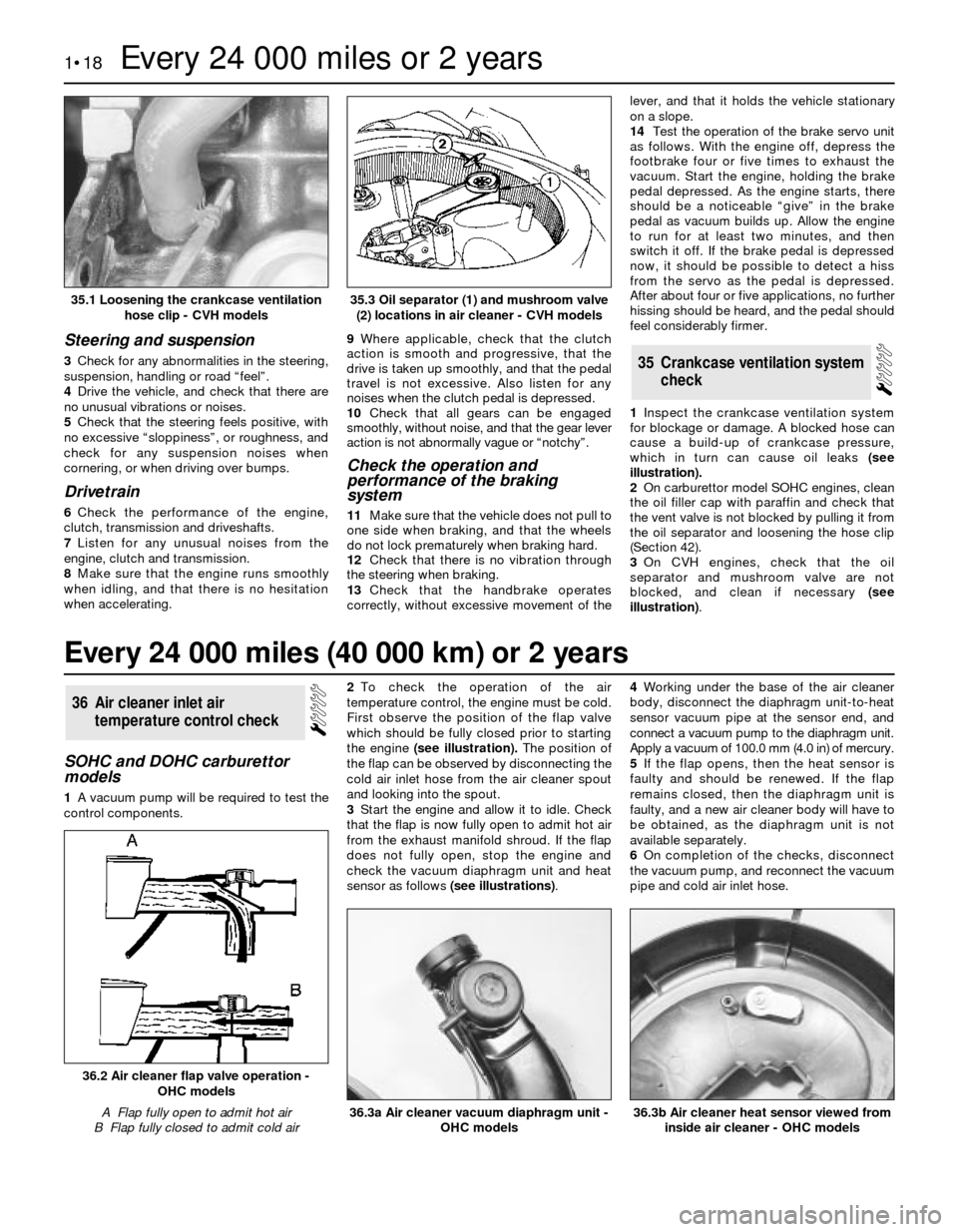

3On CVH engines, check that the oil

separator and mushroom valve are not

blocked, and clean if necessary (see

illustration).

35Crankcase ventilation system

check

SOHC and DOHC carburettor

models

1A vacuum pump will be required to test the

control components.2To check the operation of the air

temperature control, the engine must be cold.

First observe the position of the flap valve

which should be fully closed prior to starting

the engine(see illustration).The position of

the flap can be observed by disconnecting the

cold air inlet hose from the air cleaner spout

and looking into the spout.

3Start the engine and allow it to idle. Check

that the flap is now fully open to admit hot air

from the exhaust manifold shroud. If the flap

does not fully open, stop the engine and

check the vacuum diaphragm unit and heat

sensor as follows (see illustrations).4Working under the base of the air cleaner

body, disconnect the diaphragm unit-to-heat

sensor vacuum pipe at the sensor end, and

connect a vacuum pump to the diaphragm unit.

Apply a vacuum of 100.0 mm (4.0 in) of mercury.

5If the flap opens, then the heat sensor is

faulty and should be renewed. If the flap

remains closed, then the diaphragm unit is

faulty, and a new air cleaner body will have to

be obtained, as the diaphragm unit is not

available separately.

6On completion of the checks, disconnect

the vacuum pump, and reconnect the vacuum

pipe and cold air inlet hose.

36Air cleaner inlet air

temperature control check

1•18Every 24 000 miles or 2 years

35.1 Loosening the crankcase ventilation

hose clip - CVH models

36.3b Air cleaner heat sensor viewed from

inside air cleaner - OHC models36.3a Air cleaner vacuum diaphragm unit -

OHC models

36.2 Air cleaner flap valve operation -

OHC models

A Flap fully open to admit hot air

B Flap fully closed to admit cold air

35.3 Oil separator (1) and mushroom valve

(2) locations in air cleaner - CVH models

Every 24 000 miles (40 000 km) or 2 years