tow bar FORD SIERRA 1992 2.G SOHC Engines Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 24, PDF Size: 1.03 MB

Page 13 of 24

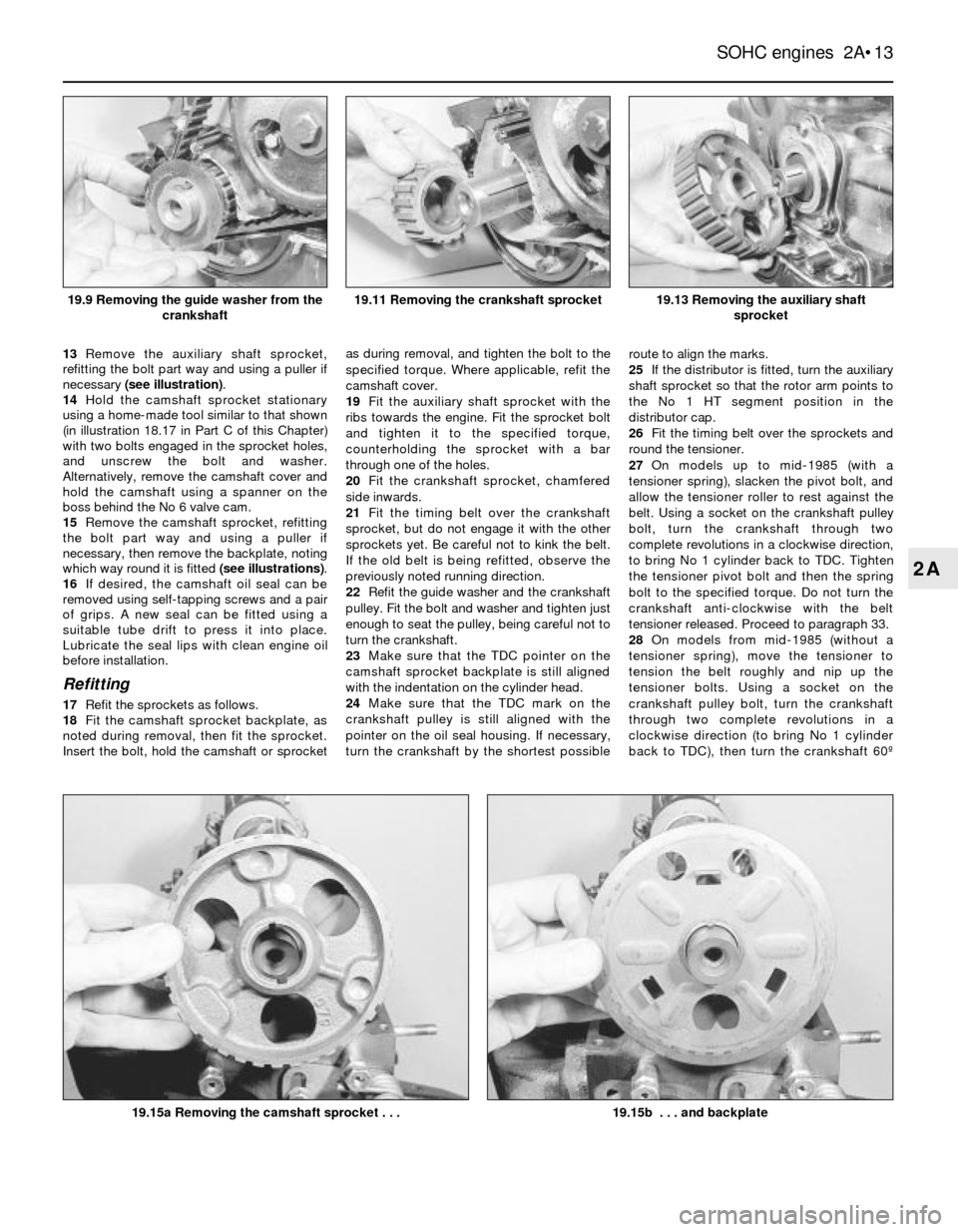

13Remove the auxiliary shaft sprocket,

refitting the bolt part way and using a puller if

necessary (see illustration).

14Hold the camshaft sprocket stationary

using a home-made tool similar to that shown

(in illustration 18.17 in Part C of this Chapter)

with two bolts engaged in the sprocket holes,

and unscrew the bolt and washer.

Alternatively, remove the camshaft cover and

hold the camshaft using a spanner on the

boss behind the No 6 valve cam.

15Remove the camshaft sprocket, refitting

the bolt part way and using a puller if

necessary, then remove the backplate, noting

which way round it is fitted (see illustrations).

16If desired, the camshaft oil seal can be

removed using self-tapping screws and a pair

of grips. A new seal can be fitted using a

suitable tube drift to press it into place.

Lubricate the seal lips with clean engine oil

before installation.

Refitting

17Refit the sprockets as follows.

18Fit the camshaft sprocket backplate, as

noted during removal, then fit the sprocket.

Insert the bolt, hold the camshaft or sprocketas during removal, and tighten the bolt to the

specified torque. Where applicable, refit the

camshaft cover.

19Fit the auxiliary shaft sprocket with the

ribs towards the engine. Fit the sprocket bolt

and tighten it to the specified torque,

counterholding the sprocket with a bar

through one of the holes.

20Fit the crankshaft sprocket, chamfered

side inwards.

21Fit the timing belt over the crankshaft

sprocket, but do not engage it with the other

sprockets yet. Be careful not to kink the belt.

If the old belt is being refitted, observe the

previously noted running direction.

22Refit the guide washer and the crankshaft

pulley. Fit the bolt and washer and tighten just

enough to seat the pulley, being careful not to

turn the crankshaft.

23Make sure that the TDC pointer on the

camshaft sprocket backplate is still aligned

with the indentation on the cylinder head.

24Make sure that the TDC mark on the

crankshaft pulley is still aligned with the

pointer on the oil seal housing. If necessary,

turn the crankshaft by the shortest possibleroute to align the marks.

25If the distributor is fitted, turn the auxiliary

shaft sprocket so that the rotor arm points to

the No 1 HT segment position in the

distributor cap.

26Fit the timing belt over the sprockets and

round the tensioner.

27On models up to mid-1985 (with a

tensioner spring), slacken the pivot bolt, and

allow the tensioner roller to rest against the

belt. Using a socket on the crankshaft pulley

bolt, turn the crankshaft through two

complete revolutions in a clockwise direction,

to bring No 1 cylinder back to TDC. Tighten

the tensioner pivot bolt and then the spring

bolt to the specified torque. Do not turn the

crankshaft anti-clockwise with the belt

tensioner released. Proceed to paragraph 33.

28On models from mid-1985 (without a

tensioner spring), move the tensioner to

tension the belt roughly and nip up the

tensioner bolts. Using a socket on the

crankshaft pulley bolt, turn the crankshaft

through two complete revolutions in a

clockwise direction (to bring No 1 cylinder

back to TDC), then turn the crankshaft 60¼

SOHC engines 2A¥13

2A

19.13 Removing the auxiliary shaft

sprocket

19.15b . . . and backplate19.15a Removing the camshaft sprocket . . .

19.11 Removing the crankshaft sprocket19.9 Removing the guide washer from the

crankshaft