tow FORD SIERRA 1993 2.G Engine Electrical Systems Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: SIERRA, Model: FORD SIERRA 1993 2.GPages: 24, PDF Size: 0.93 MB

Page 6 of 24

Removal

1Disconnect the battery leads.

2Disconnect the multi-plug, or disconnect

the wires from their terminals on the rear of

the alternator, noting their locations (as

applicable), then slacken the mounting and

adjustment bolts and tilt the alternator

towards the engine (see illustrations).

3Remove the drivebelt(s) from the alternator

pulley(s).

4Remove the mounting and adjustment nuts

and bolts, and withdraw the alternator from

the engine.

Refitting

5Refitting is a reversal of removal, noting the

following points.

6To avoid breakage of the alternator

mounting bracket lugs, it is important that the

following procedure is adhered to when

refitting the mounting bolts.

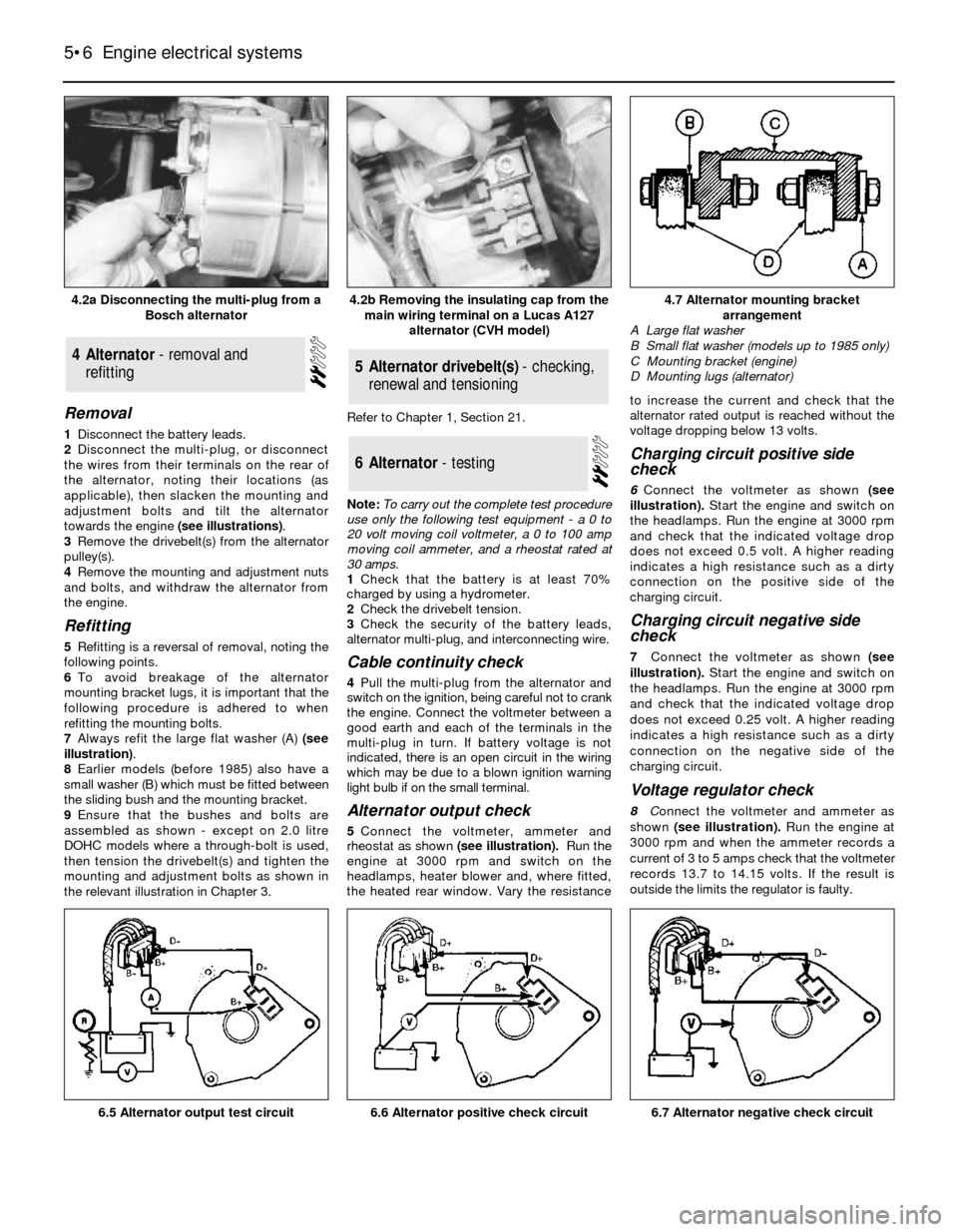

7Always refit the large flat washer (A) (see

illustration).

8Earlier models (before 1985) also have a

small washer (B) which must be fitted between

the sliding bush and the mounting bracket.

9Ensure that the bushes and bolts are

assembled as shown - except on 2.0 litre

DOHC models where a through-bolt is used,

then tension the drivebelt(s) and tighten the

mounting and adjustment bolts as shown in

the relevant illustration in Chapter 3.Refer to Chapter 1, Section 21.

Note: To carry out the complete test procedure

use only the following test equipment - a 0 to

20 volt moving coil voltmeter, a 0 to 100 amp

moving coil ammeter, and a rheostat rated at

30 amps.

1Check that the battery is at least 70%

charged by using a hydrometer.

2Check the drivebelt tension.

3Check the security of the battery leads,

alternator multi-plug, and interconnecting wire.

Cable continuity check

4Pull the multi-plug from the alternator and

switch on the ignition, being careful not to crank

the engine. Connect the voltmeter between a

good earth and each of the terminals in the

multi-plug in turn. If battery voltage is not

indicated, there is an open circuit in the wiring

which may be due to a blown ignition warning

light bulb if on the small terminal.

Alternator output check

5Connect the voltmeter, ammeter and

rheostat as shown (see illustration).Run the

engine at 3000 rpm and switch on the

headlamps, heater blower and, where fitted,

the heated rear window. Vary the resistanceto increase the current and check that the

alternator rated output is reached without the

voltage dropping below 13 volts.

Charging circuit positive side

check

6Connect the voltmeter as shown (see

illustration).Start the engine and switch on

the headlamps. Run the engine at 3000 rpm

and check that the indicated voltage drop

does not exceed 0.5 volt. A higher reading

indicates a high resistance such as a dirty

connection on the positive side of the

charging circuit.

Charging circuit negative side

check

7Connect the voltmeter as shown (see

illustration).Start the engine and switch on

the headlamps. Run the engine at 3000 rpm

and check that the indicated voltage drop

does not exceed 0.25 volt. A higher reading

indicates a high resistance such as a dirty

connection on the negative side of the

charging circuit.

Voltage regulator check

8Connect the voltmeter and ammeter as

shown(see illustration).Run the engine at

3000 rpm and when the ammeter records a

current of 3 to 5 amps check that the voltmeter

records 13.7 to 14.15 volts. If the result is

outside the limits the regulator is faulty.

6Alternator - testing

5Alternator drivebelt(s) - checking,

renewal and tensioning4Alternator - removal and

refitting

5•6Engine electrical systems

4.2a Disconnecting the multi-plug from a

Bosch alternator4.7 Alternator mounting bracket

arrangement

A Large flat washer

B Small flat washer (models up to 1985 only)

C Mounting bracket (engine)

D Mounting lugs (alternator)

6.7 Alternator negative check circuit6.6 Alternator positive check circuit6.5 Alternator output test circuit

4.2b Removing the insulating cap from the

main wiring terminal on a Lucas A127

alternator (CVH model)

Page 9 of 24

8Connect the voltmeter between the battery

positive terminal and the terminal on the

starter motor. With the coil low tension lead

disconnected operate the starter for two or

three seconds. Battery voltage should be

indicated initially, then dropping to less than 1

volt. If the reading is more than 1 volt, there is

a high resistance in the wiring from the battery

to the starter and the check in paragraph 9

should be made. If the reading is less than 1

volt proceed to paragraph 10.

9Connect the voltmeter between the two

main solenoid terminals and operate the

starter for two or three seconds. Battery

voltage should be indicated initially, then

dropping to less than 0.5 volt. If the reading is

more than 0.5 volt, the ignition switch and

connections may be faulty.

10Connect the voltmeter between the

battery negative terminal and the starter

motor body, and operate the starter for two or

three seconds. A reading of less than 0.5 volt

should be recorded. If the reading is more

than 0.5 volt, there is a fault in the earth

circuit, and the earth connections to the

battery and body should be checked.

Bosch long frame and JF, and

Cajavec types

1With the starter motor removed from the

vehicle and cleaned, grip the unit in a vice

fitted with soft jaw protectors.

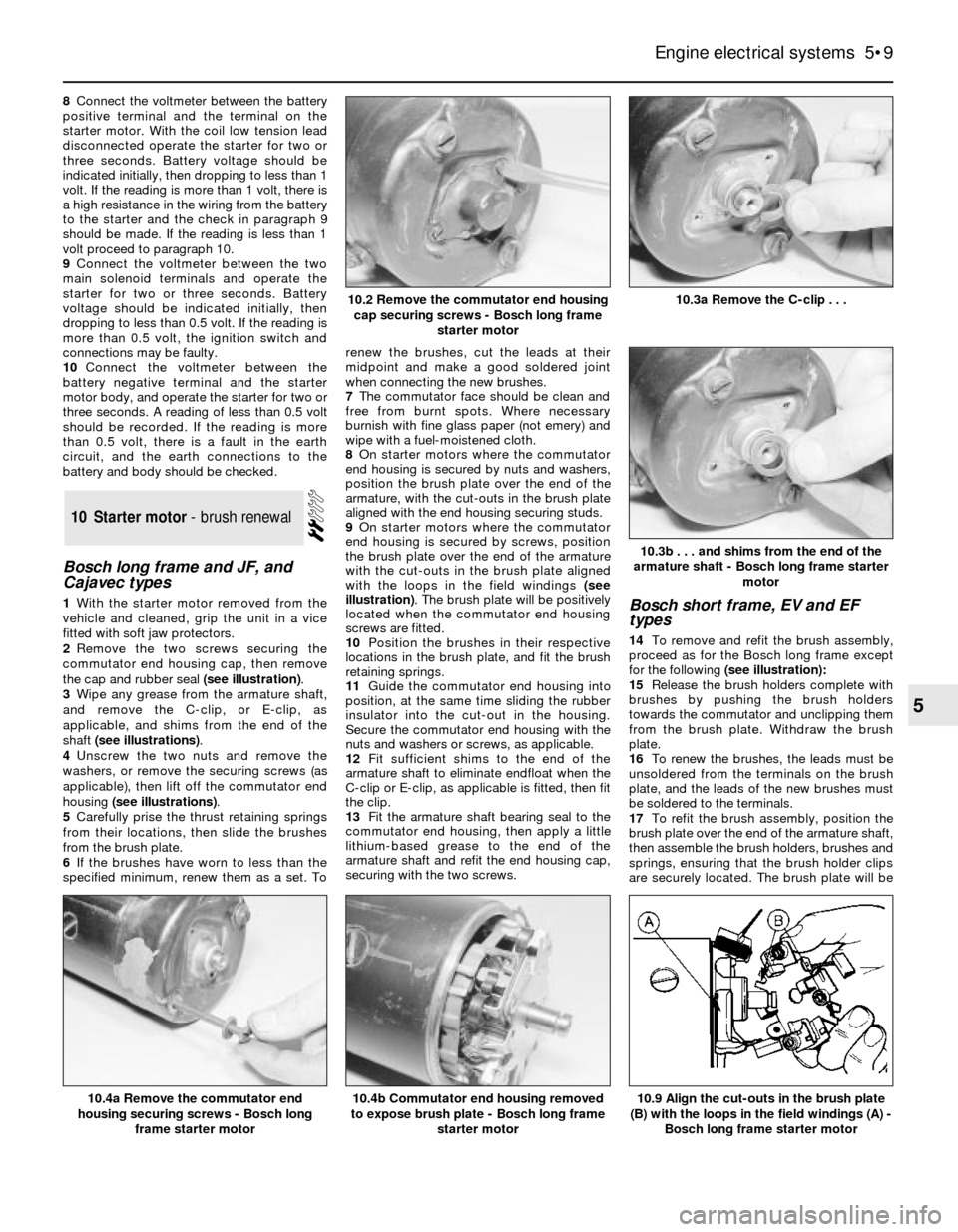

2Remove the two screws securing the

commutator end housing cap, then remove

the cap and rubber seal (see illustration).

3Wipe any grease from the armature shaft,

and remove the C-clip, or E-clip, as

applicable, and shims from the end of the

shaft (see illustrations).

4Unscrew the two nuts and remove the

washers, or remove the securing screws (as

applicable), then lift off the commutator end

housing (see illustrations).

5Carefully prise the thrust retaining springs

from their locations, then slide the brushes

from the brush plate.

6If the brushes have worn to less than the

specified minimum, renew them as a set. Torenew the brushes, cut the leads at their

midpoint and make a good soldered joint

when connecting the new brushes.

7The commutator face should be clean and

free from burnt spots. Where necessary

burnish with fine glass paper (not emery) and

wipe with a fuel-moistened cloth.

8On starter motors where the commutator

end housing is secured by nuts and washers,

position the brush plate over the end of the

armature, with the cut-outs in the brush plate

aligned with the end housing securing studs.

9On starter motors where the commutator

end housing is secured by screws, position

the brush plate over the end of the armature

with the cut-outs in the brush plate aligned

with the loops in the field windings (see

illustration). The brush plate will be positively

located when the commutator end housing

screws are fitted.

10Position the brushes in their respective

locations in the brush plate, and fit the brush

retaining springs.

11Guide the commutator end housing into

position, at the same time sliding the rubber

insulator into the cut-out in the housing.

Secure the commutator end housing with the

nuts and washers or screws, as applicable.

12Fit sufficient shims to the end of the

armature shaft to eliminate endfloat when the

C-clip or E-clip, as applicable is fitted, then fit

the clip.

13Fit the armature shaft bearing seal to the

commutator end housing, then apply a little

lithium-based grease to the end of the

armature shaft and refit the end housing cap,

securing with the two screws.Bosch short frame, EV and EF

types

14To remove and refit the brush assembly,

proceed as for the Bosch long frame except

for the following(see illustration):

15Release the brush holders complete with

brushes by pushing the brush holders

towards the commutator and unclipping them

from the brush plate. Withdraw the brush

plate.

16To renew the brushes, the leads must be

unsoldered from the terminals on the brush

plate, and the leads of the new brushes must

be soldered to the terminals.

17To refit the brush assembly, position the

brush plate over the end of the armature shaft,

then assemble the brush holders, brushes and

springs, ensuring that the brush holder clips

are securely located. The brush plate will be

10Starter motor - brush renewal

Engine electrical systems 5•9

5

10.3b . . . and shims from the end of the

armature shaft - Bosch long frame starter

motor

10.9 Align the cut-outs in the brush plate

(B) with the loops in the field windings (A) -

Bosch long frame starter motor10.4b Commutator end housing removed

to expose brush plate - Bosch long frame

starter motor10.4a Remove the commutator end

housing securing screws - Bosch long

frame starter motor

10.3a Remove the C-clip . . .10.2 Remove the commutator end housing

cap securing screws - Bosch long frame

starter motor

Page 13 of 24

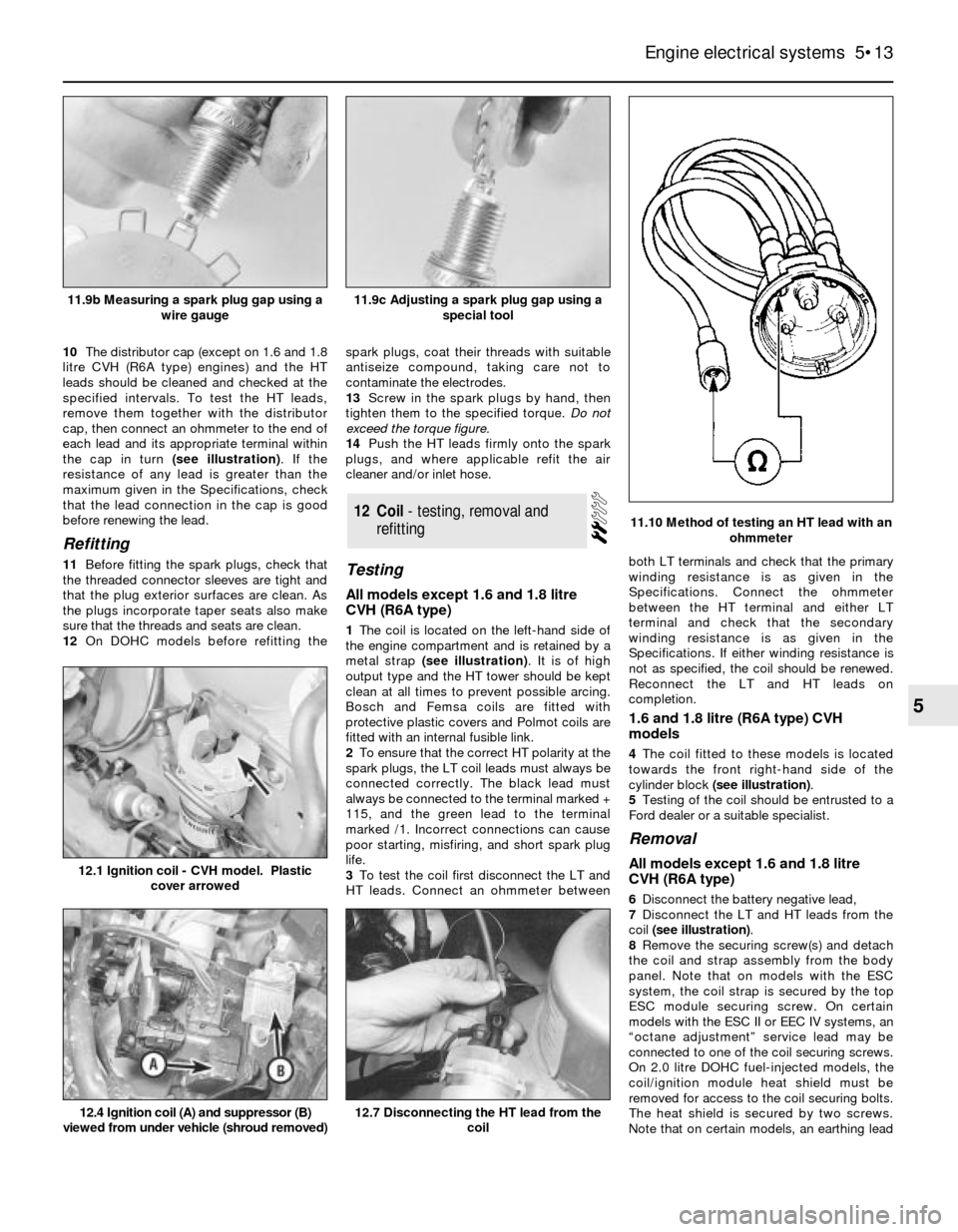

10The distributor cap (except on 1.6 and 1.8

litre CVH (R6A type) engines) and the HT

leads should be cleaned and checked at the

specified intervals. To test the HT leads,

remove them together with the distributor

cap, then connect an ohmmeter to the end of

each lead and its appropriate terminal within

the cap in turn (see illustration). If the

resistance of any lead is greater than the

maximum given in the Specifications, check

that the lead connection in the cap is good

before renewing the lead.

Refitting

11Before fitting the spark plugs, check that

the threaded connector sleeves are tight and

that the plug exterior surfaces are clean. As

the plugs incorporate taper seats also make

sure that the threads and seats are clean.

12On DOHC models before refitting thespark plugs, coat their threads with suitable

antiseize compound, taking care not to

contaminate the electrodes.

13Screw in the spark plugs by hand, then

tighten them to the specified torque. Do not

exceed the torque figure.

14Push the HT leads firmly onto the spark

plugs, and where applicable refit the air

cleaner and/or inlet hose.Testing

All models except 1.6 and 1.8 litre

CVH (R6A type)

1The coil is located on the left-hand side of

the engine compartment and is retained by a

metal strap (see illustration). It is of high

output type and the HT tower should be kept

clean at all times to prevent possible arcing.

Bosch and Femsa coils are fitted with

protective plastic covers and Polmot coils are

fitted with an internal fusible link.

2To ensure that the correct HT polarity at the

spark plugs, the LT coil leads must always be

connected correctly. The black lead must

always be connected to the terminal marked +

115, and the green lead to the terminal

marked /1. Incorrect connections can cause

poor starting, misfiring, and short spark plug

life.

3To test the coil first disconnect the LT and

HT leads. Connect an ohmmeter betweenboth LT terminals and check that the primary

winding resistance is as given in the

Specifications. Connect the ohmmeter

between the HT terminal and either LT

terminal and check that the secondary

winding resistance is as given in the

Specifications. If either winding resistance is

not as specified, the coil should be renewed.

Reconnect the LT and HT leads on

completion.

1.6 and 1.8 litre (R6A type) CVH

models

4The coil fitted to these models is located

towards the front right-hand side of the

cylinder block (see illustration).

5Testing of the coil should be entrusted to a

Ford dealer or a suitable specialist.

Removal

All models except 1.6 and 1.8 litre

CVH (R6A type)

6Disconnect the battery negative lead,

7Disconnect the LT and HT leads from the

coil (see illustration).

8Remove the securing screw(s) and detach

the coil and strap assembly from the body

panel. Note that on models with the ESC

system, the coil strap is secured by the top

ESC module securing screw. On certain

models with the ESC II or EEC IV systems, an

“octane adjustment” service lead may be

connected to one of the coil securing screws.

On 2.0 litre DOHC fuel-injected models, the

coil/ignition module heat shield must be

removed for access to the coil securing bolts.

The heat shield is secured by two screws.

Note that on certain models, an earthing lead

12Coil - testing, removal and

refitting

Engine electrical systems 5•13

5

11.10 Method of testing an HT lead with an

ohmmeter

12.4 Ignition coil (A) and suppressor (B)

viewed from under vehicle (shroud removed)12.7 Disconnecting the HT lead from the

coil

12.1 Ignition coil - CVH model. Plastic

cover arrowed

11.9c Adjusting a spark plug gap using a

special tool11.9b Measuring a spark plug gap using a

wire gauge

Page 24 of 24

Vehicle speed sensor

1.6 and 1.8 litre CVH (R6A type) and

2.0 litre DOHC fuel injection models

27The sensor is located in the left-hand side

of the gearbox/transmission.

28Disconnect the battery negative lead.

29Jack up the vehicle and support it

securely on axle stands (see “Jacking and

Vehicle Support”).

30Detach the sensor wiring connector from

its bracket, and separate the two halves of the

connector.

31Unscrew the securing bolt, and withdraw

the wiring connector bracket, noting its

orientation.

32Withdraw the sensor from the

gearbox/transmission casing (see

illustration).

33Before refitting the sensor, examine the

O-ring, and renew if damaged or worn.

34Refitting is a reversal of removal, ensuring

that the wiring connector bracket is correctly

located.

Manifold absolute pressure (MAP)

sensor

1.6 and 1.8 litre CVH (R6A type) and

2.0 litre DOHC fuel injection models

35The sensor is located at the rear right-

hand side of the engine compartment (see

illustration).

36Disconnect the battery negative lead.

37Remove the two screws securing the

sensor to the body panel, and carefully

withdraw the sensor, taking care not to strainthe wiring.

38Disconnect the wiring plug from the

sensor, pulling on the plug, not the wiring,

then disconnect the vacuum hose and remove

the sensor.

39Refitting is a reversal of removal.

Fuel temperature sensor -

removal and refitting

2.0 litre DOHC fuel injection models

40The sensor is located in the top of the fuel

rail.

41Disconnect the battery negative lead, and

to improve access, disconnect the wiring plug

from the air charge temperature sensor (in the

inlet manifold). Disconnect the sensor wiring

plug by pulling on the plug, not the wiring.

42Disconnect the fuel temperature sensor

wiring plug, again pulling on the plug (see

illustration).

43Unscrew the sensor from the fuel rail, and

remove it.

44Refitting is a reversal of removal, noting

the torque setting for the sensor.

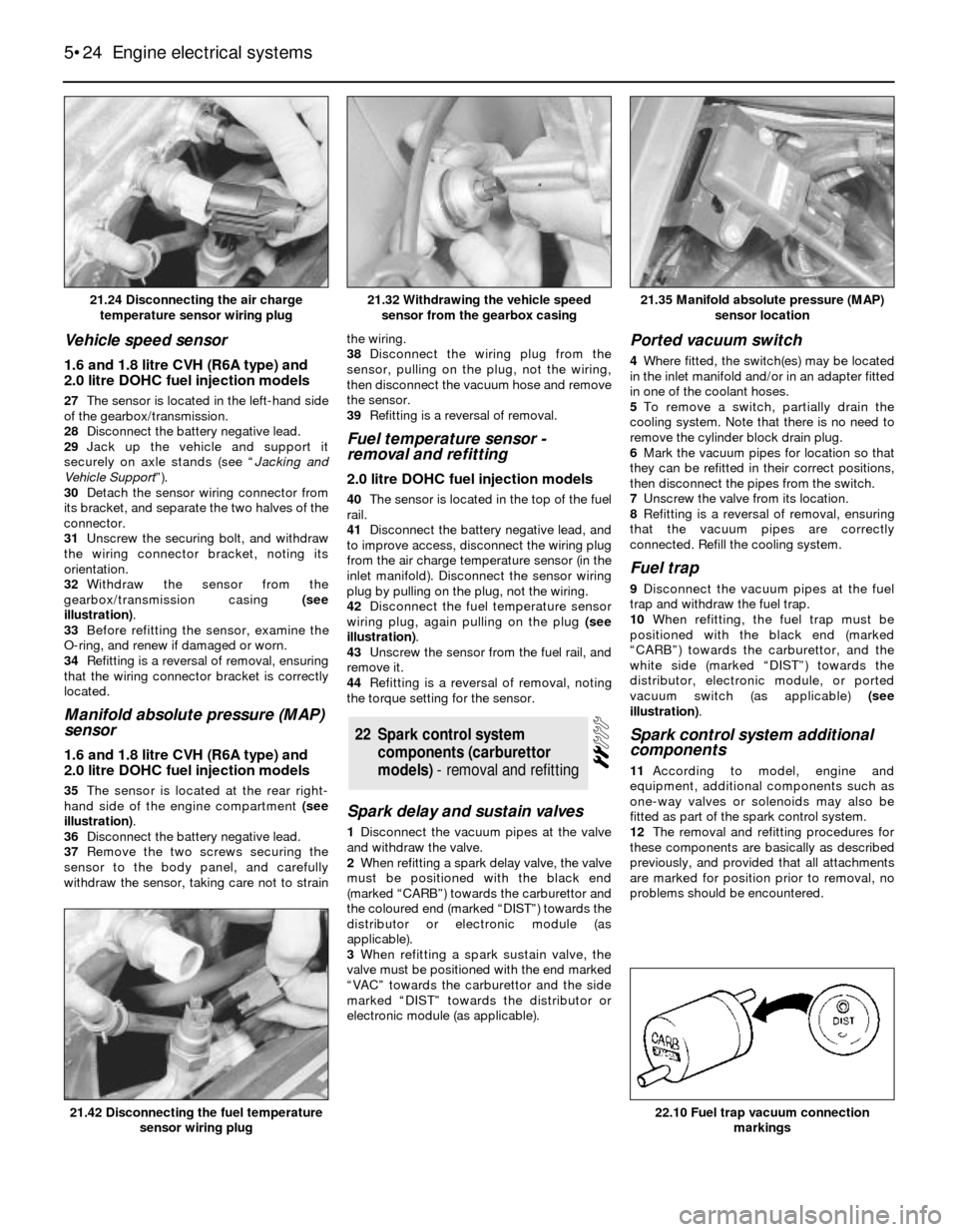

Spark delay and sustain valves

1Disconnect the vacuum pipes at the valve

and withdraw the valve.

2When refitting a spark delay valve, the valve

must be positioned with the black end

(marked “CARB”) towards the carburettor and

the coloured end (marked “DIST”) towards the

distributor or electronic module (as

applicable).

3When refitting a spark sustain valve, the

valve must be positioned with the end marked

“VAC” towards the carburettor and the side

marked “DIST” towards the distributor or

electronic module (as applicable).

Ported vacuum switch

4Where fitted, the switch(es) may be located

in the inlet manifold and/or in an adapter fitted

in one of the coolant hoses.

5To remove a switch, partially drain the

cooling system. Note that there is no need to

remove the cylinder block drain plug.

6Mark the vacuum pipes for location so that

they can be refitted in their correct positions,

then disconnect the pipes from the switch.

7Unscrew the valve from its location.

8Refitting is a reversal of removal, ensuring

that the vacuum pipes are correctly

connected. Refill the cooling system.

Fuel trap

9Disconnect the vacuum pipes at the fuel

trap and withdraw the fuel trap.

10When refitting, the fuel trap must be

positioned with the black end (marked

“CARB”) towards the carburettor, and the

white side (marked “DIST”) towards the

distributor, electronic module, or ported

vacuum switch (as applicable) (see

illustration).

Spark control system additional

components

11According to model, engine and

equipment, additional components such as

one-way valves or solenoids may also be

fitted as part of the spark control system.

12The removal and refitting procedures for

these components are basically as described

previously, and provided that all attachments

are marked for position prior to removal, no

problems should be encountered.

22Spark control system

components (carburettor

models) - removal and refitting

5•24Engine electrical systems

21.24 Disconnecting the air charge

temperature sensor wiring plug21.35 Manifold absolute pressure (MAP)

sensor location

22.10 Fuel trap vacuum connection

markings21.42 Disconnecting the fuel temperature

sensor wiring plug

21.32 Withdrawing the vehicle speed

sensor from the gearbox casing