sensor FORD SIERRA 1993 2.G SOHC Engines Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: SIERRA, Model: FORD SIERRA 1993 2.GPages: 24, PDF Size: 1.03 MB

Page 8 of 24

The following operations can be carried out

without removing the engine from the vehicle:

a)Removal and servicing of the cylinder

head

b)Removal of the camshaft after removal of

the cylinder head

c)Removal of the timing belt and sprockets

d)Removal of the sump

e)Removal of the oil pump

f)Removal of the pistons and connecting

rods

g)Removal of the big-end bearings

h)Removal of the engine mountings

i)Removal of the clutch and flywheel

j)Removal of crankshaft front and rear oil

seals

k)Removal of the auxiliary shaft

The following operations can only be carried

out after removing the engine from the

vehicle:

a)Removal of the crankshaft main bearings

b)Removal of the crankshaft

The engine may be lifted out either on its

own, or together with the manual

gearbox/automatic transmission. Unless work

is to be carried out on the manual

gearbox/automatic transmission, it is

recommended that the engine is removed on

its own. Where automatic transmission is

fitted, the engine should where possible be

removed on its own due to the additional

weight of the transmission. Note: The air conditioning system should

always be discharged by a Ford dealer or air

conditioning specialist.

Note: Refer to the warning in Section 8 before

proceeding. A suitable hoist and lifting tackle

will be required for this operation.

1Disconnect the battery negative lead.

2Remove the bonnet.

3On carburettor models remove the air cleaner.

4On fuel injection models, disconnect the

crankcase ventilation hose from the air inlet

hose, then disconnect the air inlet hose from

the throttle body. Depress the locking clip on

the airflow meter wiring plug and disconnect

the plug (pulling on the plug, not the wiring)

then release the four securing clips and lift off

the air cleaner lid with the airflow meter and

air inlet hose.

5Remove the four retaining clips and

unscrew the two retaining screws, then

withdraw the upper section of the cooling fan

shroud from the radiator. Unclip and remove

the lower section of the shroud.

6Remove the thermo-viscous cooling fan as

described in Chapter 3.

7Drain the cooling system.

8Disconnect the upper radiator hose and

where applicable, the expansion tank hose

from the thermostat housing.

9Disconnect the coolant hoses from the

coolant pump, and where applicable from the

inlet manifold and automatic choke. Unclip

the coolant hose from the bracket on the

exhaust manifold hot air shroud/heat shield,

or the camshaft cover, as applicable.

10On carburettor models, where applicable

disconnect the vacuum pipe from the engine

management module.

11Disconnect the brake servo vacuum pipe

from the inlet manifold.

12On carburettor models, disconnect the fuel

hoses from the carburettor and where

applicable the mechanical fuel pump and plug

the ends of the hoses to minimise petrol

spillage. Remember to take adequate fire

precautions.

13On fuel injection models, disconnect the

fuel feed line from the fuel pressure regulator,

then disconnect the fuel supply hose from thefuel rail. Position a suitable container beneath

the pressure regulator, then slowly loosen the

fuel feed union to relieve the pressure in the

fuel lines before disconnecting the union.

Take adequate fire precautions. Plug the ends

of the hoses to minimise petrol spillage.

14Disconnect the throttle cable, and where

applicable remove its bracket.

15Disconnect the HT lead from the ignition

coil.

16Disconnect the wiring from the following

components as applicable depending on

model:

Alternator

Starter motor

Distributor

Oil pressure warning lamp switch

Temperature gauge sender

Engine coolant temperature sensor

Automatic choke

Automatic choke pull-down solenoid

Carburettor anti-dieselling valve

Inlet manifold heater

Carburettor stepper motor

Fuel injection harness

Dipstick

17Where applicable, detach the power

steering pump from the cylinder block and

move it to one side.

18Unscrew and remove the top engine-to-

gearbox bolts which are accessible from the

engine compartment. Note the location of the

earth strap on one of the bolts.

19Note the location of the earth strap on the

rear inlet manifold stud, then remove the nut

and disconnect the strap.

20Apply the handbrake (if not already done),

jack up the front of the vehicle and support on

axle stands (see ÒJacking and Vehicle SupportÓ).

21Drain the engine oil into a suitable

container.

22Remove the starter motor.

23Remove the exhaust downpipe.

24Unscrew the nuts or bolts, as applicable,

securing the engine mountings to the

crossmember. Recover the washers.

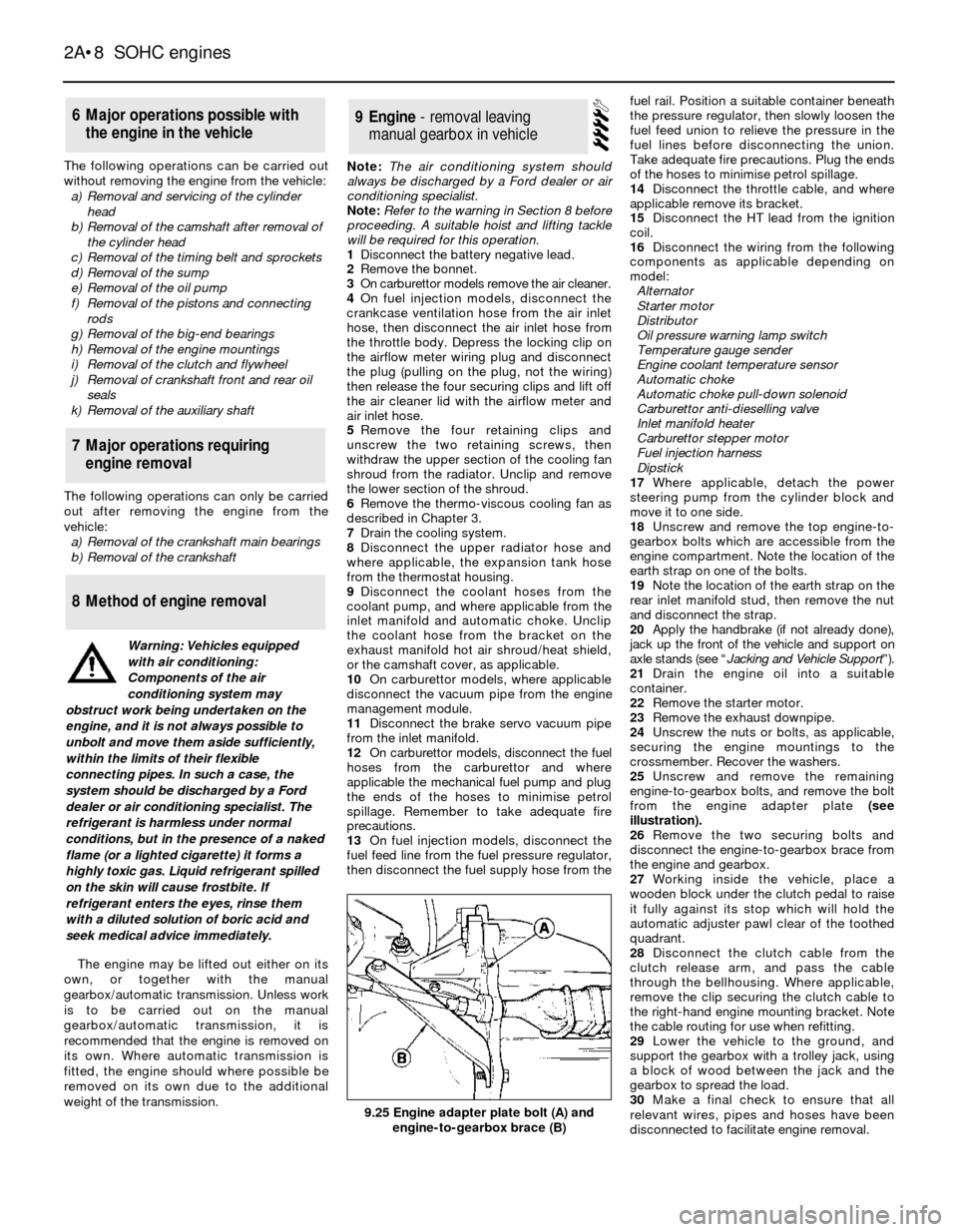

25Unscrew and remove the remaining

engine-to-gearbox bolts, and remove the bolt

from the engine adapter plate (see

illustration).

26Remove the two securing bolts and

disconnect the engine-to-gearbox brace from

the engine and gearbox.

27Working inside the vehicle, place a

wooden block under the clutch pedal to raise

it fully against its stop which will hold the

automatic adjuster pawl clear of the toothed

quadrant.

28Disconnect the clutch cable from the

clutch release arm, and pass the cable

through the bellhousing. Where applicable,

remove the clip securing the clutch cable to

the right-hand engine mounting bracket. Note

the cable routing for use when refitting.

29Lower the vehicle to the ground, and

support the gearbox with a trolley jack, using

a block of wood between the jack and the

gearbox to spread the load.

30Make a final check to ensure that all

relevant wires, pipes and hoses have been

disconnected to facilitate engine removal.

9Engine - removal leaving

manual gearbox in vehicle

8Method of engine removal

7Major operations requiring

engine removal

6Major operations possible with

the engine in the vehicle

2A¥8SOHC engines

9.25 Engine adapter plate bolt (A) and

engine-to-gearbox brace (B)

Warning: Vehicles equipped

with air conditioning:

Components of the air

conditioning system may

obstruct work being undertaken on the

engine, and it is not always possible to

unbolt and move them aside sufficiently,

within the limits of their flexible

connecting pipes. In such a case, the

system should be discharged by a Ford

dealer or air conditioning specialist. The

refrigerant is harmless under normal

conditions, but in the presence of a naked

flame (or a lighted cigarette) it forms a

highly toxic gas. Liquid refrigerant spilled

on the skin will cause frostbite. If

refrigerant enters the eyes, rinse them

with a diluted solution of boric acid and

seek medical advice immediately.