FORD SUPER DUTY 2003 1.G Diesel Supplement Manual

Manufacturer: FORD, Model Year: 2003, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2003 1.GPages: 64, PDF Size: 0.31 MB

Page 21 of 64

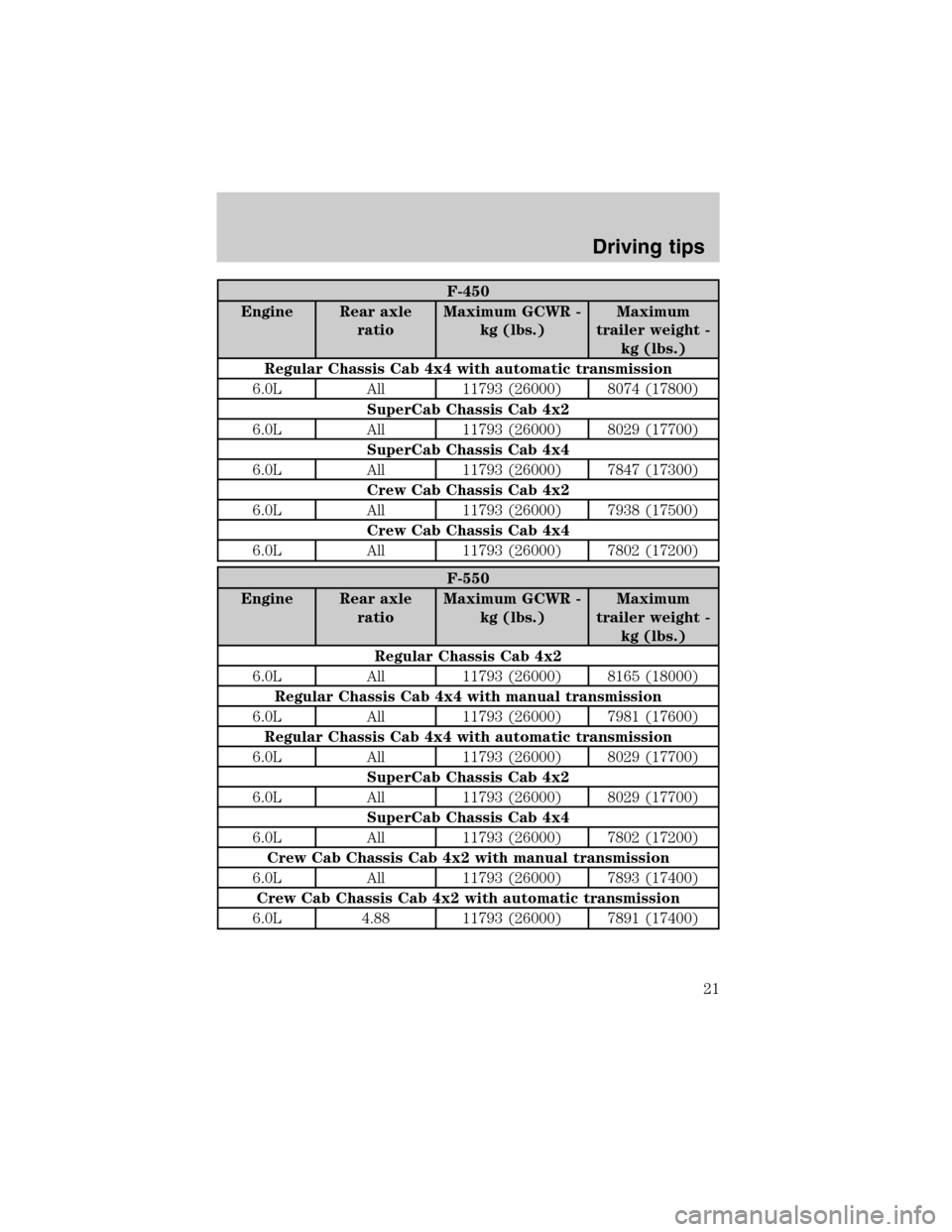

F-450

Engine Rear axle

ratioMaximum GCWR -

kg (lbs.)Maximum

trailer weight -

kg (lbs.)

Regular Chassis Cab 4x4 with automatic transmission

6.0L All 11793 (26000) 8074 (17800)

SuperCab Chassis Cab 4x2

6.0L All 11793 (26000) 8029 (17700)

SuperCab Chassis Cab 4x4

6.0L All 11793 (26000) 7847 (17300)

Crew Cab Chassis Cab 4x2

6.0L All 11793 (26000) 7938 (17500)

Crew Cab Chassis Cab 4x4

6.0L All 11793 (26000) 7802 (17200)

F-550

Engine Rear axle

ratioMaximum GCWR -

kg (lbs.)Maximum

trailer weight -

kg (lbs.)

Regular Chassis Cab 4x2

6.0L All 11793 (26000) 8165 (18000)

Regular Chassis Cab 4x4 with manual transmission

6.0L All 11793 (26000) 7981 (17600)

Regular Chassis Cab 4x4 with automatic transmission

6.0L All 11793 (26000) 8029 (17700)

SuperCab Chassis Cab 4x2

6.0L All 11793 (26000) 8029 (17700)

SuperCab Chassis Cab 4x4

6.0L All 11793 (26000) 7802 (17200)

Crew Cab Chassis Cab 4x2 with manual transmission

6.0L All 11793 (26000) 7893 (17400)

Crew Cab Chassis Cab 4x2 with automatic transmission

6.0L 4.88 11793 (26000) 7891 (17400)

Driving tips

21

Page 22 of 64

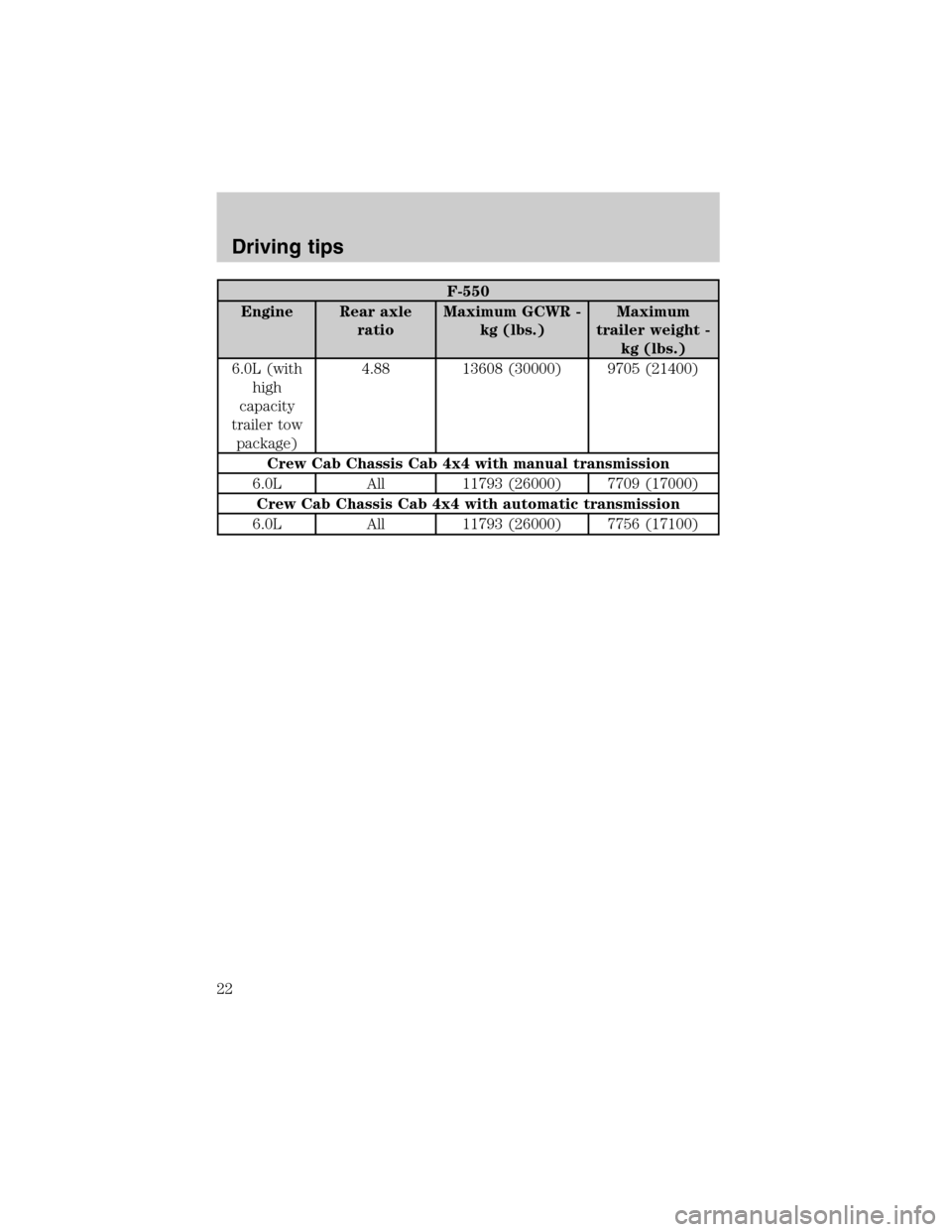

F-550

Engine Rear axle

ratioMaximum GCWR -

kg (lbs.)Maximum

trailer weight -

kg (lbs.)

6.0L (with

high

capacity

trailer tow

package)4.88 13608 (30000) 9705 (21400)

Crew Cab Chassis Cab 4x4 with manual transmission

6.0L All 11793 (26000) 7709 (17000)

Crew Cab Chassis Cab 4x4 with automatic transmission

6.0L All 11793 (26000) 7756 (17100)

Driving tips

22

Page 23 of 64

SCHEDULED MAINTENANCE

The scheduled maintenance services in theScheduled maintenance

guidesection are required because they are considered essential to the

life and performance of your vehicle.

Use only recommended fuel, lubricants, fluids and service parts

conforming to Ford specifications. Motorcraft parts are designed and

built for best performance in your vehicle.

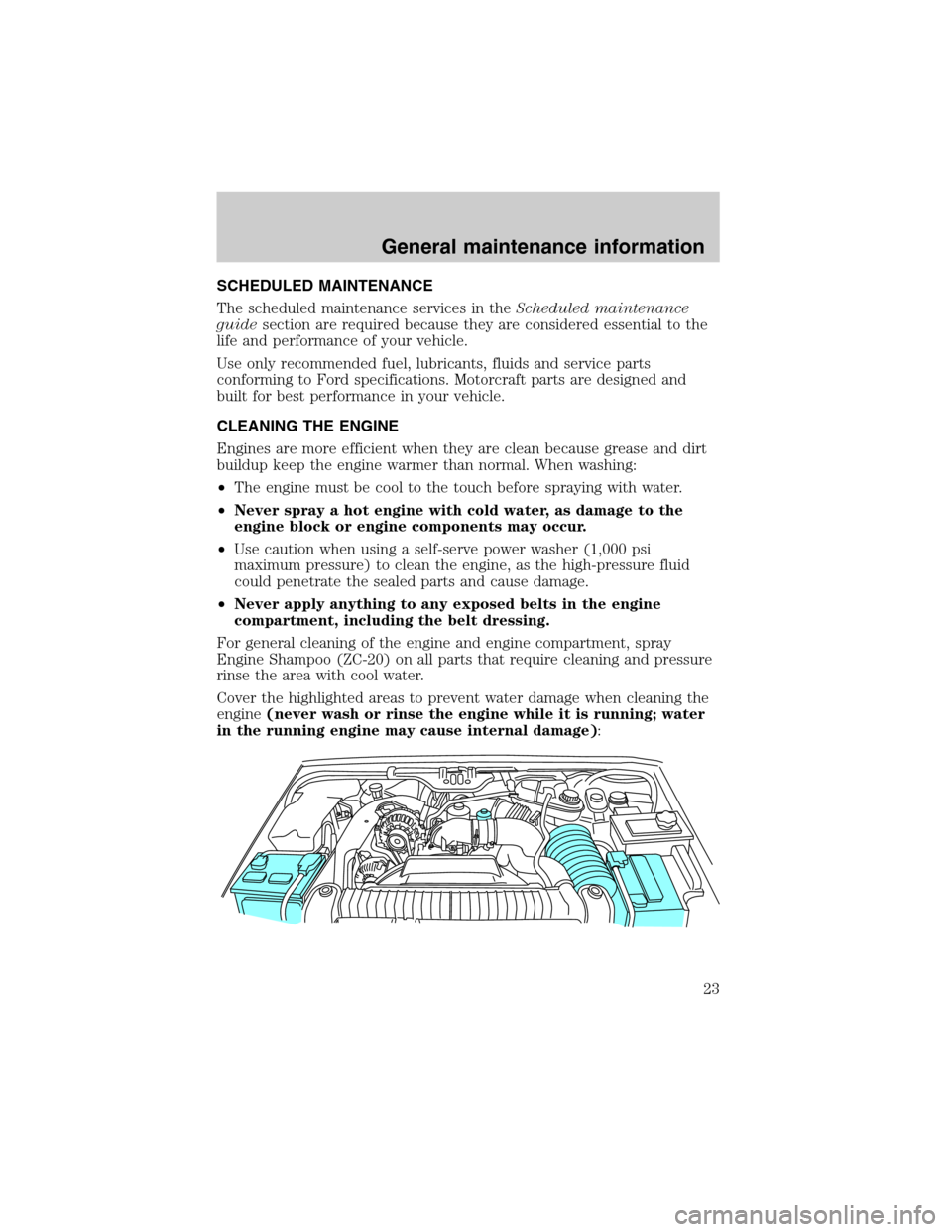

CLEANING THE ENGINE

Engines are more efficient when they are clean because grease and dirt

buildup keep the engine warmer than normal. When washing:

•The engine must be cool to the touch before spraying with water.

•Never spray a hot engine with cold water, as damage to the

engine block or engine components may occur.

•Use caution when using a self-serve power washer (1,000 psi

maximum pressure) to clean the engine, as the high-pressure fluid

could penetrate the sealed parts and cause damage.

•Never apply anything to any exposed belts in the engine

compartment, including the belt dressing.

For general cleaning of the engine and engine compartment, spray

Engine Shampoo (ZC-20) on all parts that require cleaning and pressure

rinse the area with cool water.

Cover the highlighted areas to prevent water damage when cleaning the

engine(never wash or rinse the engine while it is running; water

in the running engine may cause internal damage):

General maintenance information

23

Page 24 of 64

FUEL REQUIREMENTS

The engine is designed to use low sulfur number 1–Dor2–D Diesel fuel

only. At temperatures below -7°C (20°F), number 1–D or winter blend

number 2–D fuel is recommended. (SeeCold weather operationin the

Startingchapter.)

Do not use fuel intended for agricultural use (agricultural fuel is

dyed red), home heating oil or any Diesel fuel not intended for

highway use. Damage to the fuel injection system, engine and

exhaust catalyst can occur if an improper fuel is used.

Do not add gasoline, gasohol or alcohol to Diesel fuel. This

practice creates a serious fire hazard and engine performance

problems.

It should not be necessary to add any aftermarket additives to your fuel

tank if you use a properly formulated Diesel fuel that meets the ASTM D

975 industry specification. Aftermarket additives can damage the injector

system or engine.

Do not blend used engine oil with Diesel fuel under any

circumstances.Blending used oil with the fuel will significantly increase

your vehicle’s exhaust emissions and reduce engine life due to increased

internal wear.

Do not crank the engine for more than 30 seconds at a time as

damage to the starter motor may result.

If the engine fails to start in 30 seconds, turn the key to the OFF

position and wait 30 seconds before trying again.

If air is allowed to enter the fuel system (during fuel filter change or if

you run out of fuel) the engine will purge the trapped air as it runs. The

engine may run rough and produce white smoke while air is in the

system. This is normal and should correct itself in a short time.

An engine that suddenly becomes noisy or operates poorly after a fuel fill

could be using substandard fuel (i.e., high water content, low cetane

rating or gasoline in the fuel). Diesel fuel should be purchased from a

reputable station which sells a large amount of Diesel fuel.

Care should be taken whenever Diesel fuel is stored. Use only clean,

approved containers which will prevent the entry of dirt or water.

General maintenance information

24

Page 25 of 64

Diesel fuel must not be stored in a galvanized container. The fuel will

dissolve the zinc in a galvanized container. The zinc will then remain in

solution until it is run through the engine where it will be deposited in

the fuel injectors causing expensive-to-repair damage.

Diesel fuel dispensing nozzle fill rate

Truck stops have pumps and nozzles designed for larger, heavy-duty

trucks. When refueling at truck stops: if the nozzle shuts off repeatedly

when refueling, wait 5–10 seconds; then use a slower rate of flow (don’t

depress the nozzle trigger as far).

This truck is equipped with a fuel fill pipe which is able to accept fuel up

to 20 gallons per minute from an 1 1/8 inch fuel dispensing nozzle.

Pumping fuel at greater flow rates may result in premature nozzle

shut-off or spitback.

HORIZONTAL FUEL CONDITIONING MODULE (HFCM) (FUEL

FILTER/WATER SEPARATOR)

The vehicle is equipped with a Horizontal Fuel Conditioning Module

(HFCM) located on the frame-rail under the driver-side floorboard near

the transmission.

Water should be drained from the

module assembly whenever the

warning light comes on. The WATER

IN FUEL light will come on when

approximately 100 cc (0.2 pints) of water accumulates in the module.

Replace the fuel filters with Ford Part No. 3C3Z-9N184–CA. This part

number includes filters and seals for both the engine-mounted and

frame-mounted filters.

DRIAINING THE HFCM AND CHANGING THE FUEL FILTERS

Your vehicle is equipped with two fuel filters; one mounted on top of the

engine and the other, the HFCM, mounted inside the frame rail under

the driver-side floorboard near the transmission. Both filters should be

replaced at the same time.

HFCM drain procedure

1. Stop the vehicle andshut offthe engine.

The vehicle must be stopped with the engine off when draining

the HFCM. Fuel may ignite if separator is drained while the

engine is running or vehicle is moving.

General maintenance information

25

Page 26 of 64

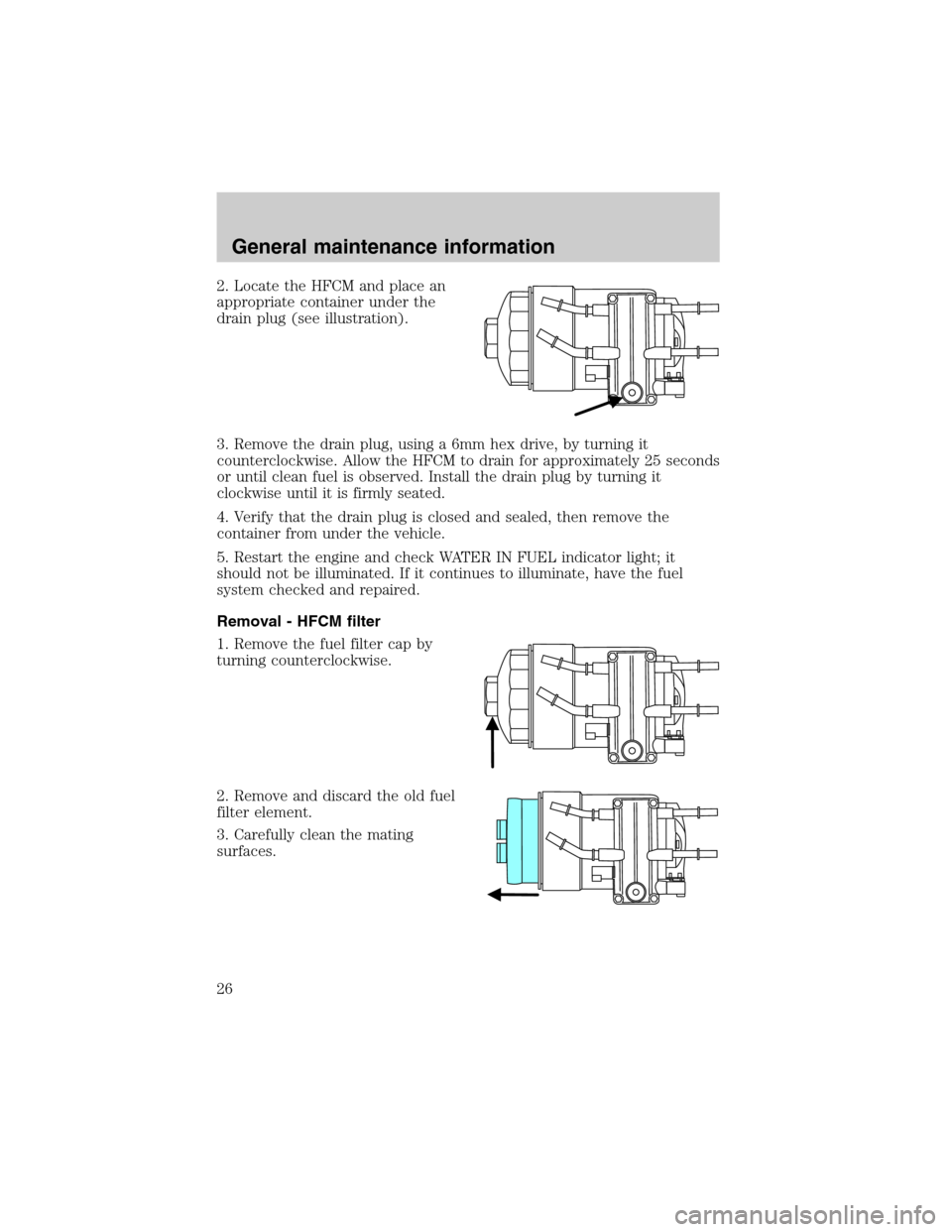

2. Locate the HFCM and place an

appropriate container under the

drain plug (see illustration).

3. Remove the drain plug, using a 6mm hex drive, by turning it

counterclockwise. Allow the HFCM to drain for approximately 25 seconds

or until clean fuel is observed. Install the drain plug by turning it

clockwise until it is firmly seated.

4. Verify that the drain plug is closed and sealed, then remove the

container from under the vehicle.

5. Restart the engine and check WATER IN FUEL indicator light; it

should not be illuminated. If it continues to illuminate, have the fuel

system checked and repaired.

Removal - HFCM filter

1. Remove the fuel filter cap by

turning counterclockwise.

2. Remove and discard the old fuel

filter element.

3. Carefully clean the mating

surfaces.

General maintenance information

26

Page 27 of 64

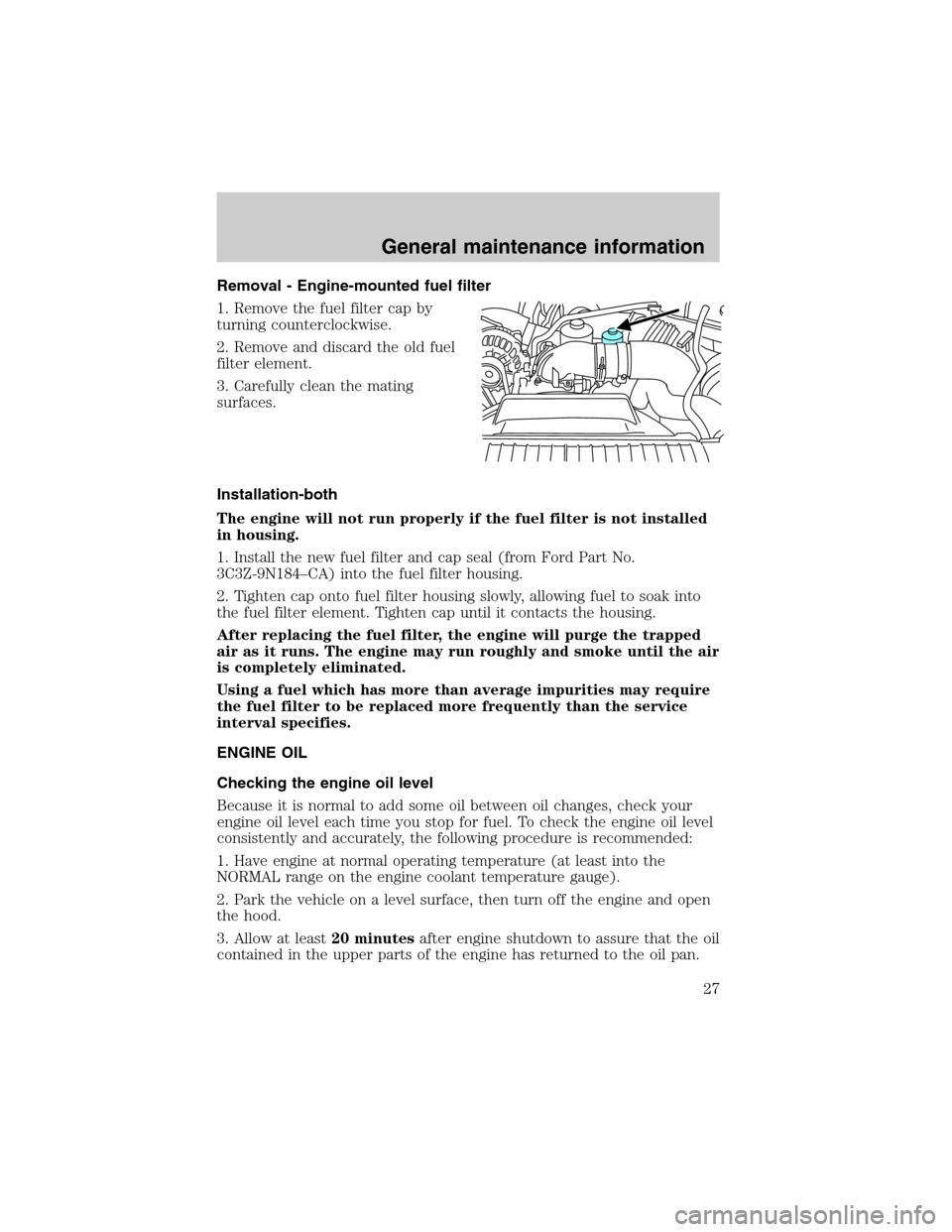

Removal - Engine-mounted fuel filter

1. Remove the fuel filter cap by

turning counterclockwise.

2. Remove and discard the old fuel

filter element.

3. Carefully clean the mating

surfaces.

Installation-both

The engine will not run properly if the fuel filter is not installed

in housing.

1. Install the new fuel filter and cap seal (from Ford Part No.

3C3Z-9N184–CA) into the fuel filter housing.

2. Tighten cap onto fuel filter housing slowly, allowing fuel to soak into

the fuel filter element. Tighten cap until it contacts the housing.

After replacing the fuel filter, the engine will purge the trapped

air as it runs. The engine may run roughly and smoke until the air

is completely eliminated.

Using a fuel which has more than average impurities may require

the fuel filter to be replaced more frequently than the service

interval specifies.

ENGINE OIL

Checking the engine oil level

Because it is normal to add some oil between oil changes, check your

engine oil level each time you stop for fuel. To check the engine oil level

consistently and accurately, the following procedure is recommended:

1. Have engine at normal operating temperature (at least into the

NORMAL range on the engine coolant temperature gauge).

2. Park the vehicle on a level surface, then turn off the engine and open

the hood.

3. Allow at least20 minutesafter engine shutdown to assure that the oil

contained in the upper parts of the engine has returned to the oil pan.

General maintenance information

27

Page 28 of 64

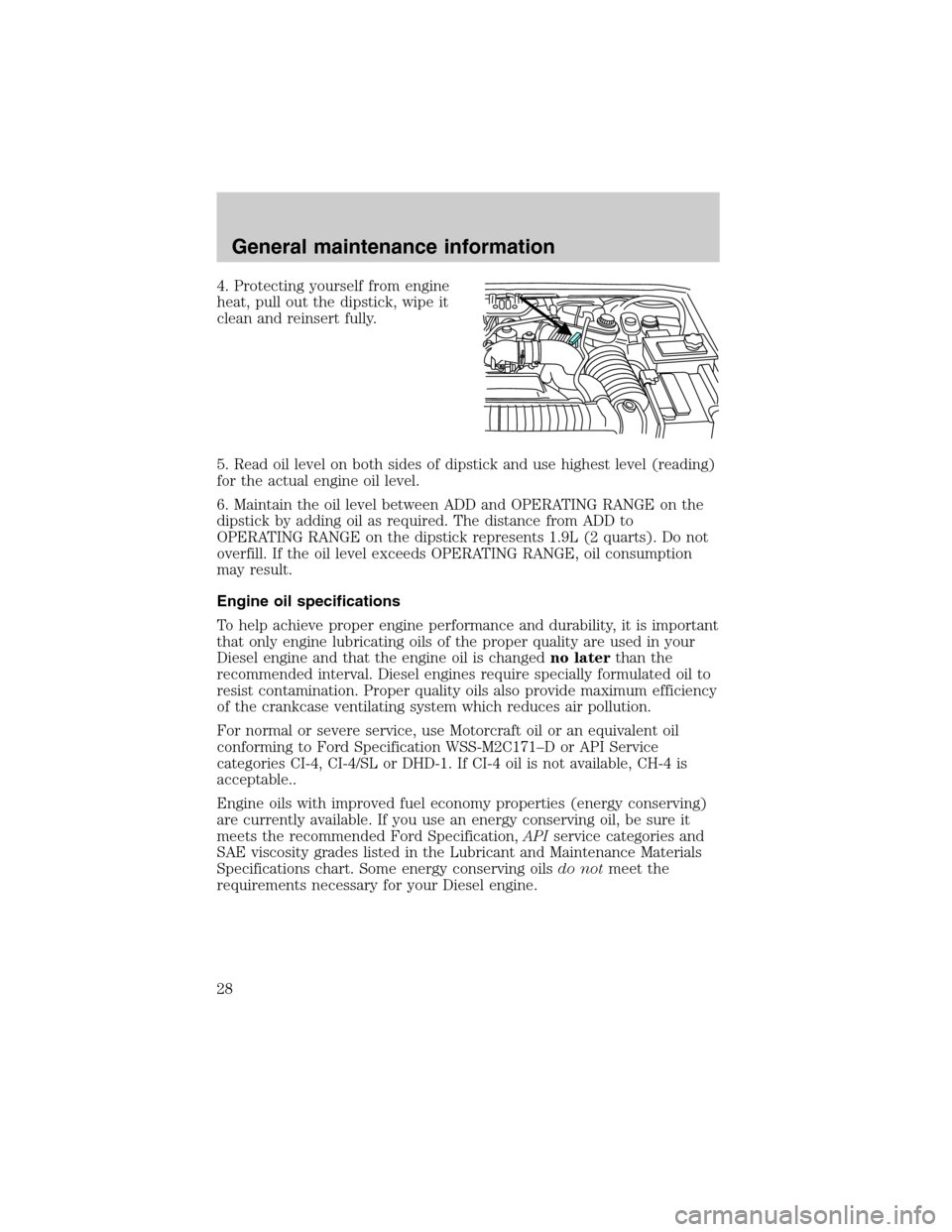

4. Protecting yourself from engine

heat, pull out the dipstick, wipe it

clean and reinsert fully.

5. Read oil level on both sides of dipstick and use highest level (reading)

for the actual engine oil level.

6. Maintain the oil level between ADD and OPERATING RANGE on the

dipstick by adding oil as required. The distance from ADD to

OPERATING RANGE on the dipstick represents 1.9L (2 quarts). Do not

overfill. If the oil level exceeds OPERATING RANGE, oil consumption

may result.

Engine oil specifications

To help achieve proper engine performance and durability, it is important

that only engine lubricating oils of the proper quality are used in your

Diesel engine and that the engine oil is changedno laterthan the

recommended interval. Diesel engines require specially formulated oil to

resist contamination. Proper quality oils also provide maximum efficiency

of the crankcase ventilating system which reduces air pollution.

For normal or severe service, use Motorcraft oil or an equivalent oil

conforming to Ford Specification WSS-M2C171–D or API Service

categories CI-4, CI-4/SL or DHD-1. If CI-4 oil is not available, CH-4 is

acceptable..

Engine oils with improved fuel economy properties (energy conserving)

are currently available. If you use an energy conserving oil, be sure it

meets the recommended Ford Specification,APIservice categories and

SAE viscosity grades listed in the Lubricant and Maintenance Materials

Specifications chart. Some energy conserving oilsdo notmeet the

requirements necessary for your Diesel engine.

General maintenance information

28

Page 29 of 64

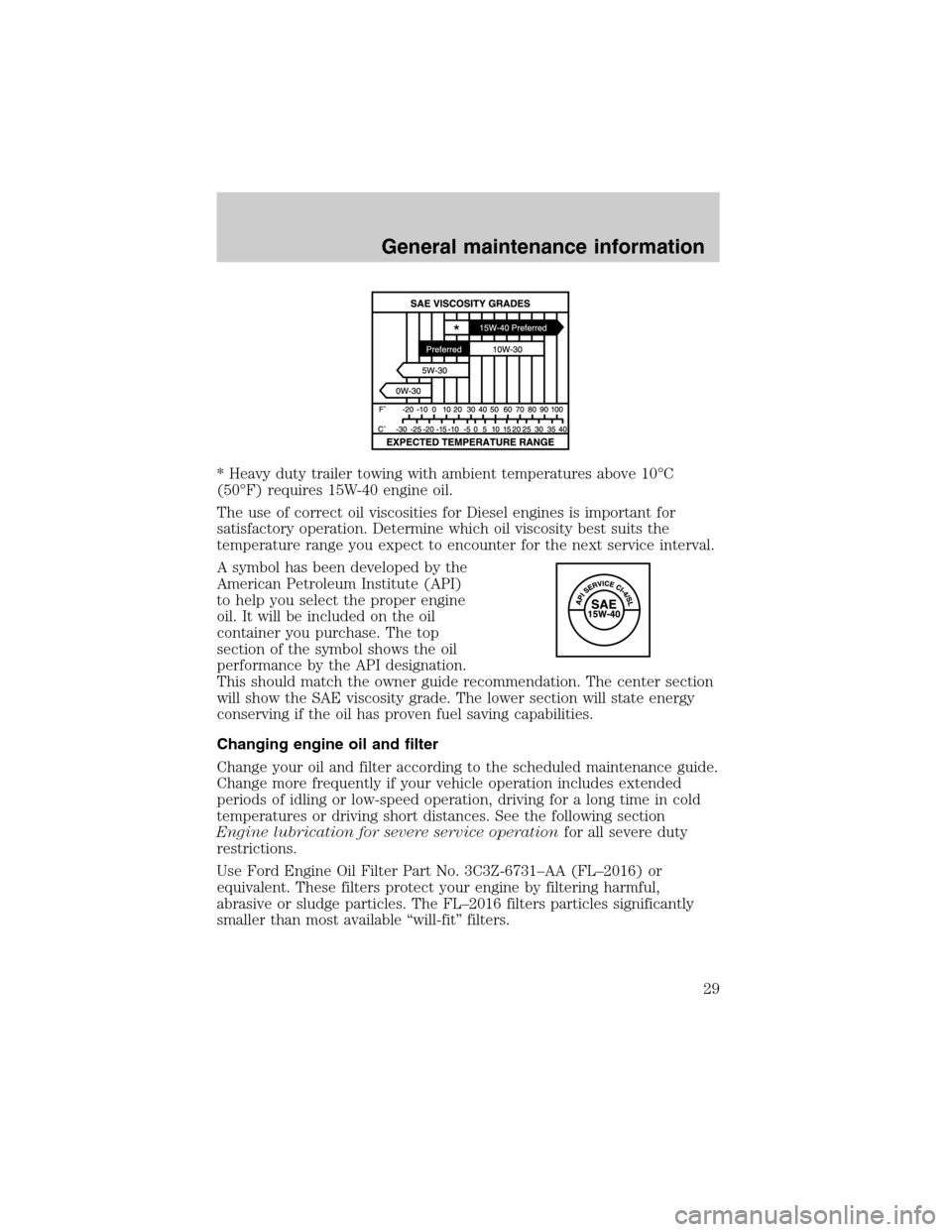

* Heavy duty trailer towing with ambient temperatures above 10°C

(50°F) requires 15W-40 engine oil.

The use of correct oil viscosities for Diesel engines is important for

satisfactory operation. Determine which oil viscosity best suits the

temperature range you expect to encounter for the next service interval.

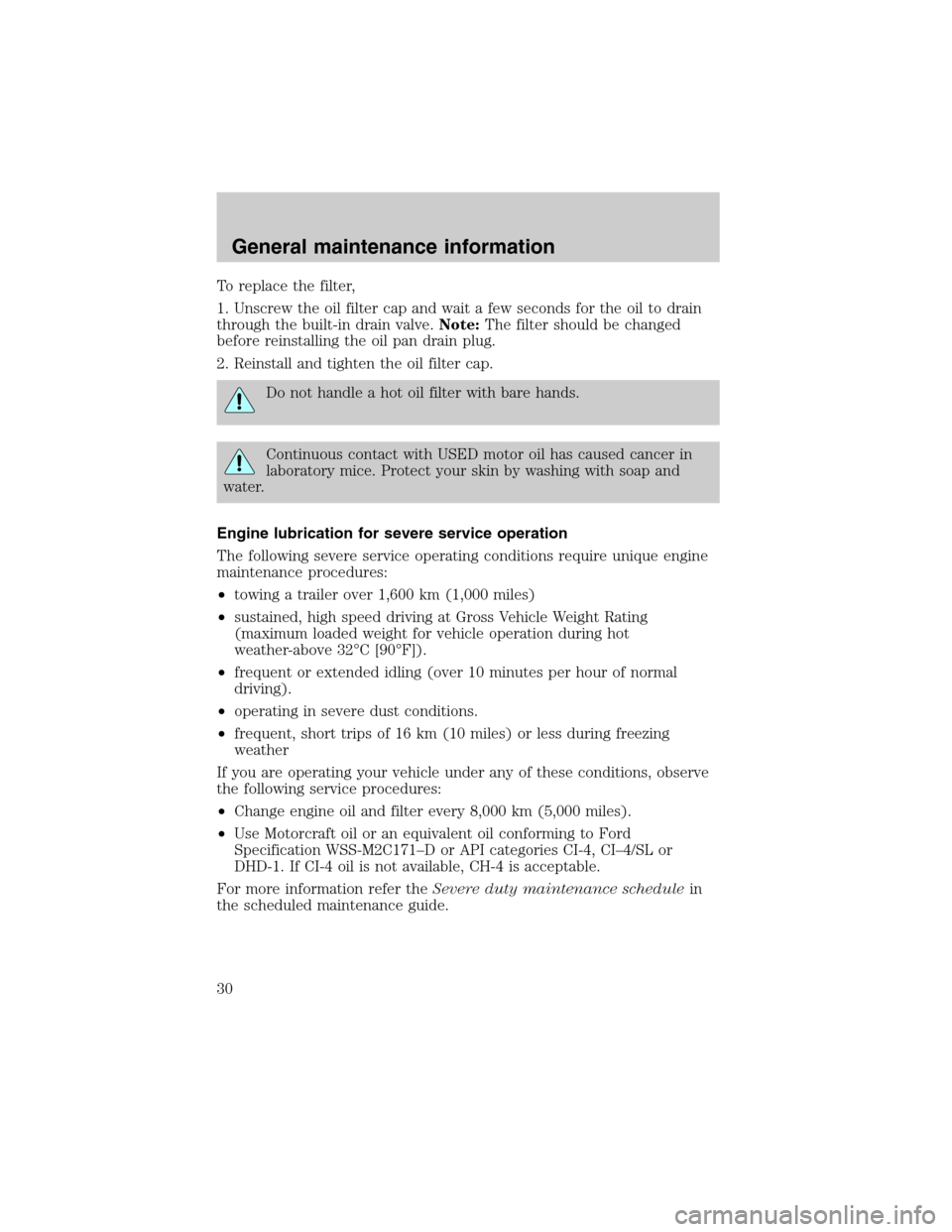

A symbol has been developed by the

American Petroleum Institute (API)

to help you select the proper engine

oil. It will be included on the oil

container you purchase. The top

section of the symbol shows the oil

performance by the API designation.

This should match the owner guide recommendation. The center section

will show the SAE viscosity grade. The lower section will state energy

conserving if the oil has proven fuel saving capabilities.

Changing engine oil and filter

Change your oil and filter according to the scheduled maintenance guide.

Change more frequently if your vehicle operation includes extended

periods of idling or low-speed operation, driving for a long time in cold

temperatures or driving short distances. See the following section

Engine lubrication for severe service operationfor all severe duty

restrictions.

Use Ford Engine Oil Filter Part No. 3C3Z-6731–AA (FL–2016) or

equivalent. These filters protect your engine by filtering harmful,

abrasive or sludge particles. The FL–2016 filters particles significantly

smaller than most available“will-fit”filters.

General maintenance information

29

Page 30 of 64

To replace the filter,

1. Unscrew the oil filter cap and wait a few seconds for the oil to drain

through the built-in drain valve.Note:The filter should be changed

before reinstalling the oil pan drain plug.

2. Reinstall and tighten the oil filter cap.

Do not handle a hot oil filter with bare hands.

Continuous contact with USED motor oil has caused cancer in

laboratory mice. Protect your skin by washing with soap and

water.

Engine lubrication for severe service operation

The following severe service operating conditions require unique engine

maintenance procedures:

•towing a trailer over 1,600 km (1,000 miles)

•sustained, high speed driving at Gross Vehicle Weight Rating

(maximum loaded weight for vehicle operation during hot

weather-above 32°C [90°F]).

•frequent or extended idling (over 10 minutes per hour of normal

driving).

•operating in severe dust conditions.

•frequent, short trips of 16 km (10 miles) or less during freezing

weather

If you are operating your vehicle under any of these conditions, observe

the following service procedures:

•Change engine oil and filter every 8,000 km (5,000 miles).

•Use Motorcraft oil or an equivalent oil conforming to Ford

Specification WSS-M2C171–D or API categories CI-4, CI–4/SL or

DHD-1. If CI-4 oil is not available, CH-4 is acceptable.

For more information refer theSevere duty maintenance schedulein

the scheduled maintenance guide.

General maintenance information

30