wheel FORD SUPER DUTY 2003 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2003, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2003 1.GPages: 256, PDF Size: 2.3 MB

Page 161 of 256

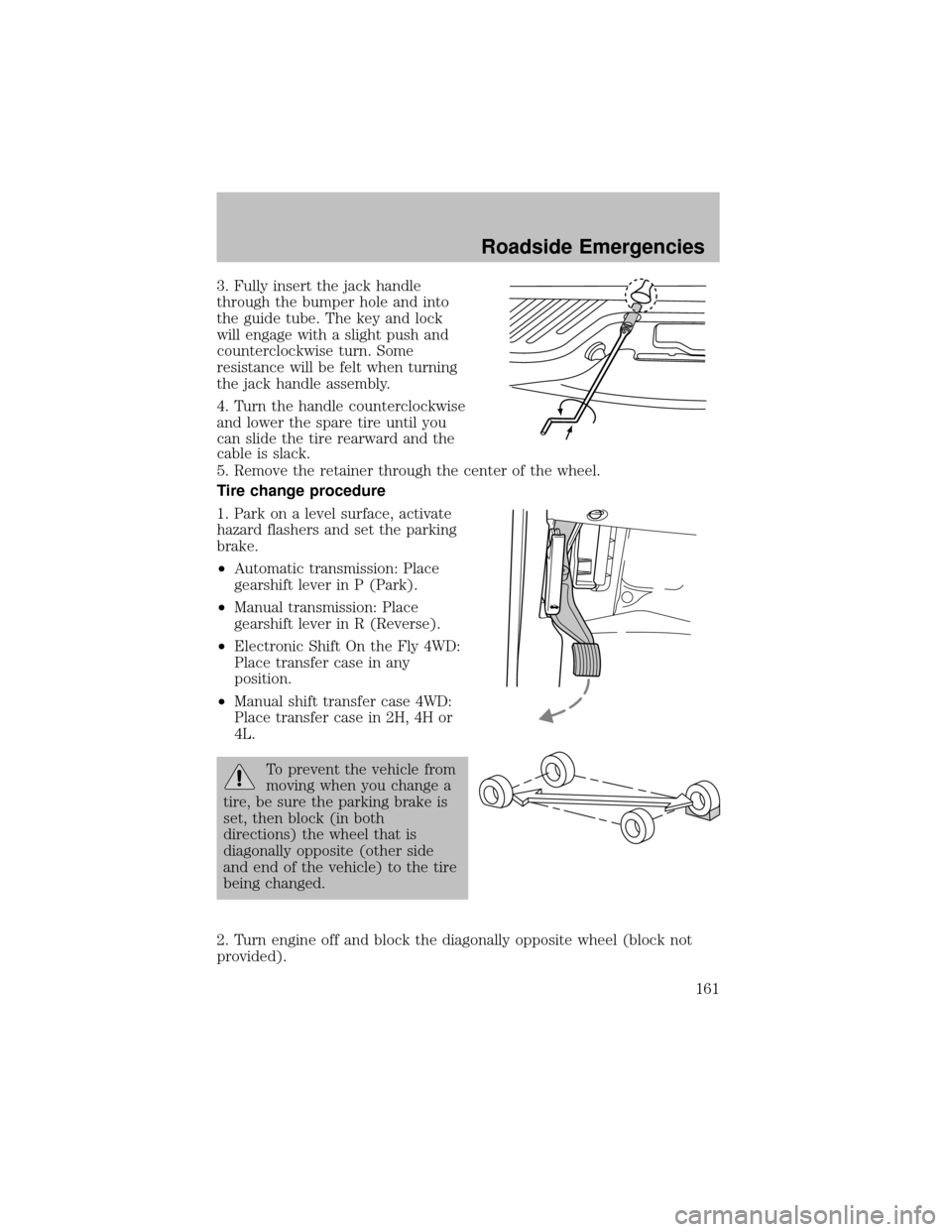

3. Fullyinsert the jack handle

through the bumper hole and into

the guide tube. The keyand lock

will engage with a slight push and

counterclockwise turn. Some

resistance will be felt when turning

the jack handle assembly.

4. Turn the handle counterclockwise

and lower the spare tire until you

can slide the tire rearward and the

cable is slack.

5. Remove the retainer through the center of the wheel.

Tire change procedure

1. Park on a level surface, activate

hazard flashers and set the parking

brake.

•Automatic transmission: Place

gearshift lever in P (Park).

•Manual transmission: Place

gearshift lever in R (Reverse).

•Electronic Shift On the Fly4WD:

Place transfer case in any

position.

•Manual shift transfer case 4WD:

Place transfer case in 2H, 4H or

4L.

To prevent the vehicle from

moving when you change a

tire, be sure the parking brake is

set, then block (in both

directions) the wheel that is

diagonallyopposite (other side

and end of the vehicle) to the tire

being changed.

2. Turn engine off and block the diagonallyopposite wheel (block not

provided).

Roadside Emergencies

161

Page 162 of 256

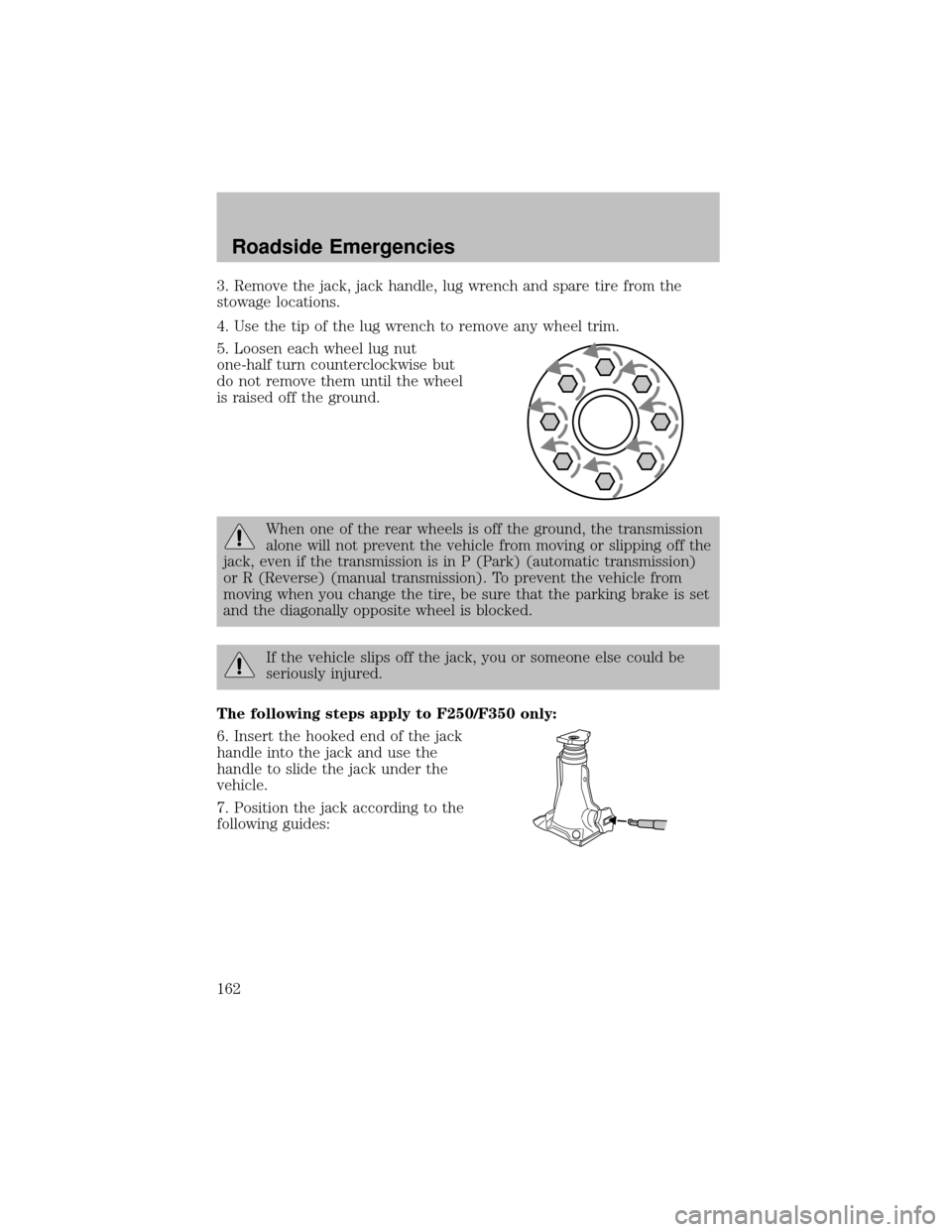

3. Remove the jack, jack handle, lug wrench and spare tire from the

stowage locations.

4. Use the tip of the lug wrench to remove anywheel trim.

5. Loosen each wheel lug nut

one-half turn counterclockwise but

do not remove them until the wheel

is raised off the ground.

When one of the rear wheels is off the ground, the transmission

alone will not prevent the vehicle from moving or slipping off the

jack, even if the transmission is in P (Park) (automatic transmission)

or R (Reverse) (manual transmission). To prevent the vehicle from

moving when you change the tire, be sure that the parking brake is set

and the diagonallyopposite wheel is blocked.

If the vehicle slips off the jack, you or someone else could be

seriouslyinjured.

The following steps apply to F250/F350 only:

6. Insert the hooked end of the jack

handle into the jack and use the

handle to slide the jack under the

vehicle.

7. Position the jack according to the

following guides:

Roadside Emergencies

162

Page 164 of 256

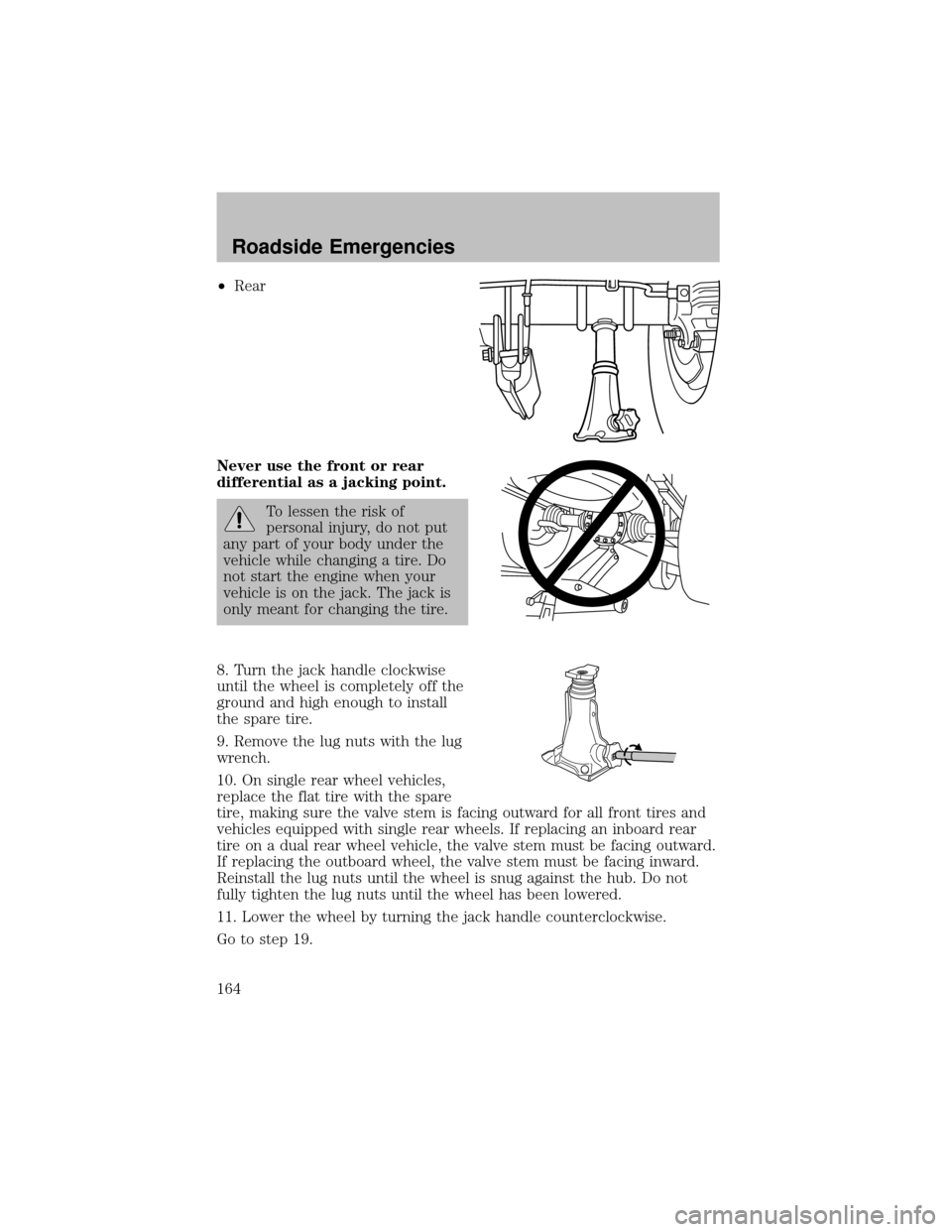

•Rear

Never use the front or rear

differential as a jacking point.

To lessen the risk of

personal injury, do not put

anypart of your bodyunder the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

onlymeant for changing the tire.

8. Turn the jack handle clockwise

until the wheel is completelyoff the

ground and high enough to install

the spare tire.

9. Remove the lug nuts with the lug

wrench.

10. On single rear wheel vehicles,

replace the flat tire with the spare

tire, making sure the valve stem is facing outward for all front tires and

vehicles equipped with single rear wheels. If replacing an inboard rear

tire on a dual rear wheel vehicle, the valve stem must be facing outward.

If replacing the outboard wheel, the valve stem must be facing inward.

Reinstall the lug nuts until the wheel is snug against the hub. Do not

fullytighten the lug nuts until the wheel has been lowered.

11. Lower the wheel byturning the jack handle counterclockwise.

Go to step 19.

Roadside Emergencies

164

Page 166 of 256

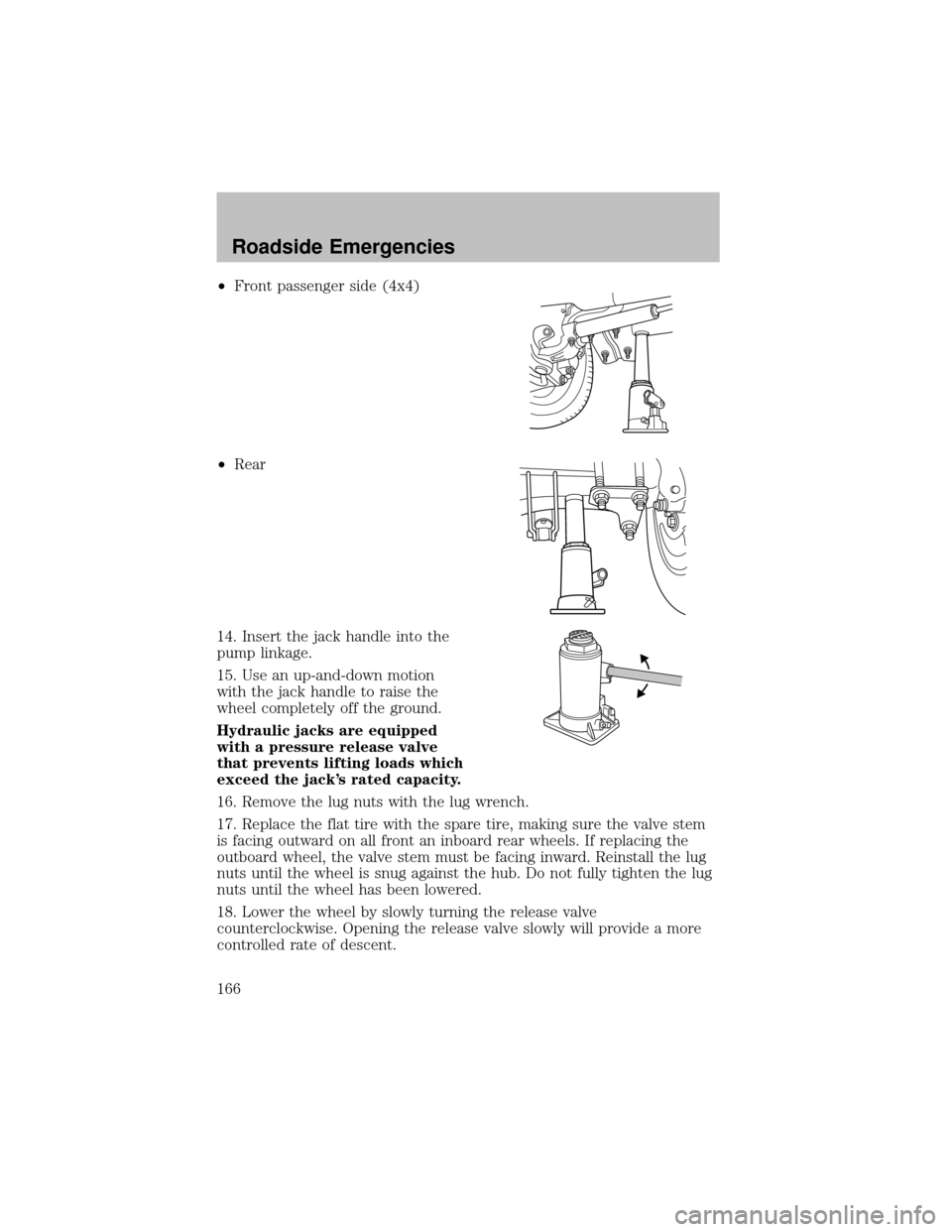

•Front passenger side (4x4)

•Rear

14. Insert the jack handle into the

pump linkage.

15. Use an up-and-down motion

with the jack handle to raise the

wheel completelyoff the ground.

Hydraulicjacks are equipped

with a pressure release valve

that prevents lifting loads which

exceed the jack’s rated capacity.

16. Remove the lug nuts with the lug wrench.

17. Replace the flat tire with the spare tire, making sure the valve stem

is facing outward on all front an inboard rear wheels. If replacing the

outboard wheel, the valve stem must be facing inward. Reinstall the lug

nuts until the wheel is snug against the hub. Do not fullytighten the lug

nuts until the wheel has been lowered.

18. Lower the wheel byslowlyturning the release valve

counterclockwise. Opening the release valve slowlywill provide a more

controlled rate of descent.

Roadside Emergencies

166

Page 167 of 256

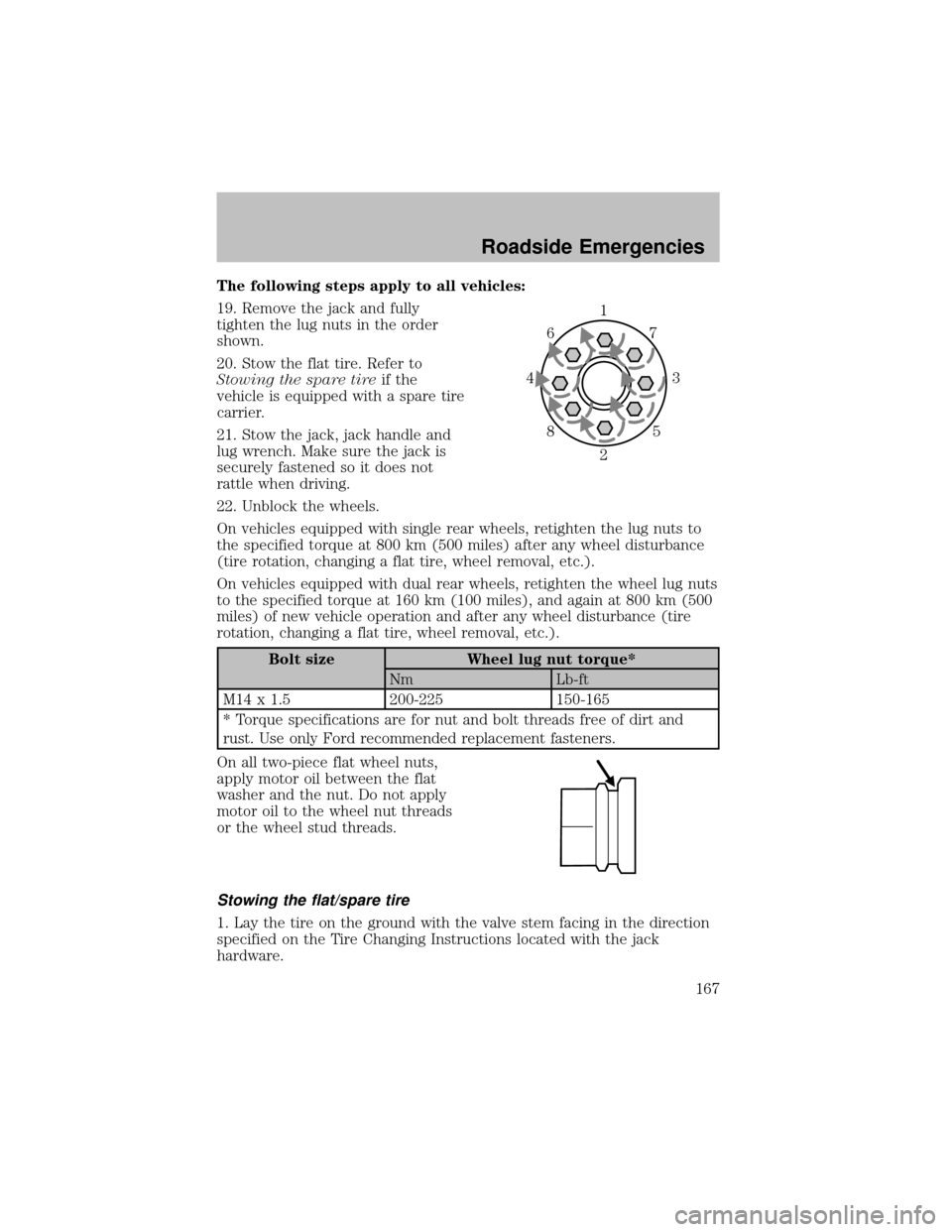

The following steps apply to all vehicles:

19. Remove the jack and fully

tighten the lug nuts in the order

shown.

20. Stow the flat tire. Refer to

Stowing the spare tireif the

vehicle is equipped with a spare tire

carrier.

21. Stow the jack, jack handle and

lug wrench. Make sure the jack is

securelyfastened so it does not

rattle when driving.

22. Unblock the wheels.

On vehicles equipped with single rear wheels, retighten the lug nuts to

the specified torque at 800 km (500 miles) after anywheel disturbance

(tire rotation, changing a flat tire, wheel removal, etc.).

On vehicles equipped with dual rear wheels, retighten the wheel lug nuts

to the specified torque at 160 km (100 miles), and again at 800 km (500

miles) of new vehicle operation and after anywheel disturbance (tire

rotation, changing a flat tire, wheel removal, etc.).

Bolt size Wheel lug nut torque*

Nm Lb-ft

M14 x 1.5 200-225 150-165

* Torque specifications are for nut and bolt threads free of dirt and

rust. Use onlyFord recommended replacement fasteners.

On all two-piece flat wheel nuts,

applymotor oil between the flat

washer and the nut. Do not apply

motor oil to the wheel nut threads

or the wheel stud threads.

Stowing the flat/spare tire

1. Laythe tire on the ground with the valve stem facing in the direction

specified on the Tire Changing Instructions located with the jack

hardware.

1

3 4

27 6

5 8

Roadside Emergencies

167

Page 168 of 256

2. Slide the wheel partiallyunder the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

3. Turn the jack handle clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

increases significantlyand the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your dealer for

assistance at your earliest convenience.

4. Check that the tire lies flat against the frame and is properly

tightened. Tryto push or pull, then turn the tire to be sure it will not

move. Loosen and retighten, if necessary. Failure to properly stow the

spare tire mayresult in failure of the winch cable and loss of the tire.

5. Repeat this tightness check procedure when servicing the spare tire

pressure (everysix months, per scheduled maintenance guide), or at any

time that the spare tire is disturbed through service of other

components.

6. If removed, install the spare tire lock (if equipped) into the bumper

drive tube with the spare tire lock key(if equipped) and jack handle.

JUMP STARTING YOUR VEHICLE

The gases around the batterycan explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injuryor

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes and

clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; also, the

catalytic converter may become damaged.

Preparing your vehicle

When the batteryis disconnected or a new batteryis installed, the

transmission must relearn its shift strategy. As a result, the transmission

mayhave firm and/or soft shifts. This operation is considered normal and

will not affect function or durabilityof the transmission. Over time, the

adaptive learning process will fullyupdate transmission operation.

Roadside Emergencies

168

Page 173 of 256

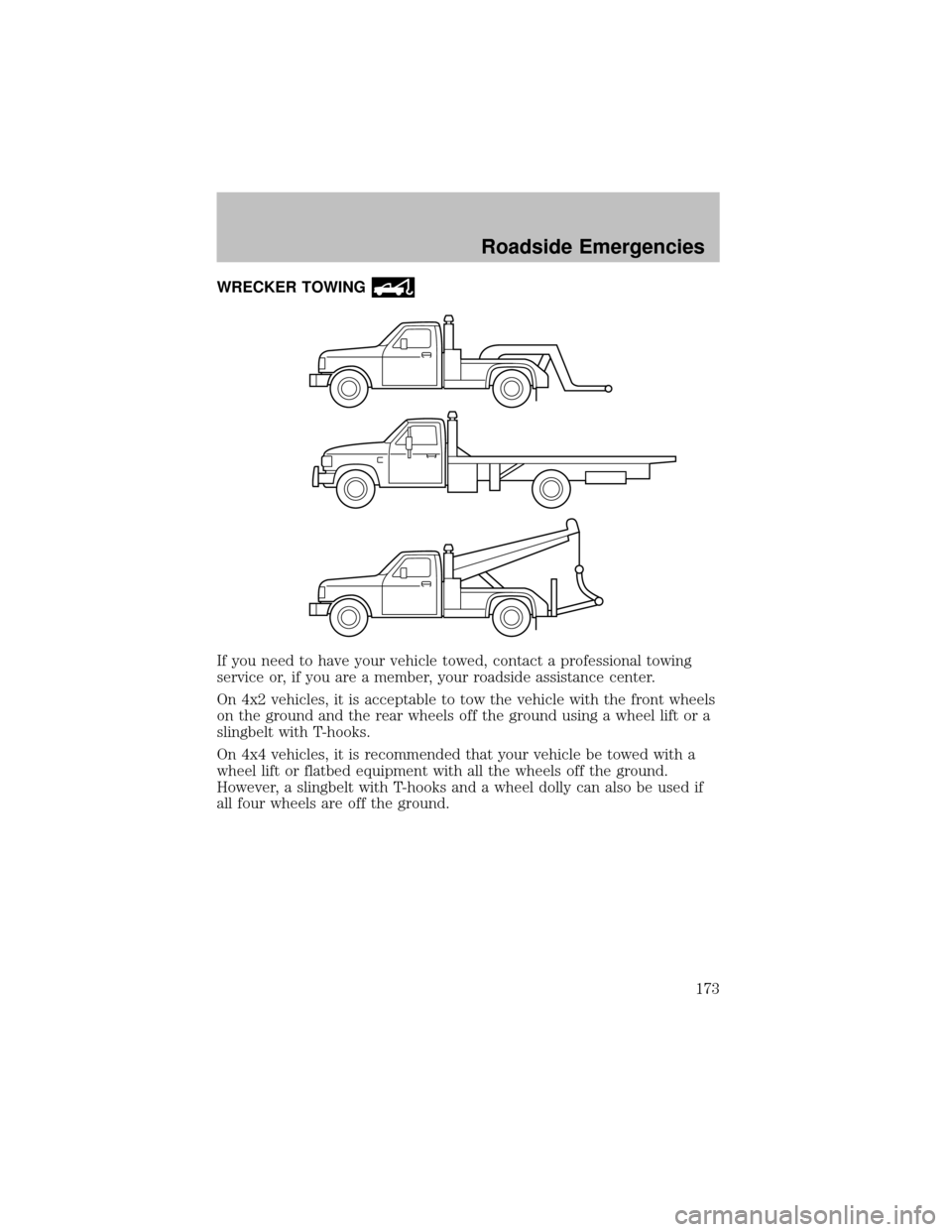

WRECKER TOWING

If you need to have your vehicle towed, contact a professional towing

service or, if you are a member, your roadside assistance center.

On 4x2 vehicles, it is acceptable to tow the vehicle with the front wheels

on the ground and the rear wheels off the ground using a wheel lift or a

slingbelt with T-hooks.

On 4x4 vehicles, it is recommended that your vehicle be towed with a

wheel lift or flatbed equipment with all the wheels off the ground.

However, a slingbelt with T-hooks and a wheel dollycan also be used if

all four wheels are off the ground.

Roadside Emergencies

173

Page 174 of 256

An alternative for towing a 4x4 vehicle is to:

•put the transfer case in neutral. On manual 4WD systems, put the

4WD shift lever in N (Neutral); on electronic shift on the fly4WD

systems, press the 2WD portion of the 4WD control.

•unlock the front hub locks (refer toFour wheel drive [4WD]

Operation [if equipped]in theDrivingchapter).

•lift the rear wheels of the vehicle using a wheel lift or a sling belt with

T-hooks.

If the vehicle is towed by other means or incorrectly, vehicle

damage may occur.

Ford Motor Companyproduces a towing manual for all authorized tow

truck operators. Have your tow truck operator refer to this manual for

proper hook-up and towing procedures for your vehicle.

Roadside Emergencies

174

Page 185 of 256

PAINT CHIPS

Your dealer has touch-up paint and sprays to match your vehicle’s color.

Take your color code (printed on a sticker in the driver’s door jam) to

your dealer to ensure you get the correct color.

•Remove particles such as bird droppings, tree sap, insect deposits, tar

spots, road salt and industrial fallout before repairing paint chips.

•Always read the instructions before using the products.

ALUMINUM WHEELS AND WHEEL COVERS

Aluminum wheels and wheel covers are coated with a clearcoat paint

finish. In order to maintain their shine:

•Clean weeklywith Motorcraft Wheel and Tire Cleaner (ZC-37–A),

which is available from your dealer. Heavy dirt and brake dust

accumulation mayrequire agitation with a sponge. Rinse thoroughly

with a strong stream of water.

•Never applyanycleaning chemical to hot or warm wheel rims or

covers.

•Some automatic car washes maycause damage to the finish on your

wheel rims or covers. Chemical-strength cleaners, or cleaning

chemicals, in combination with brush agitation to remove brake dust

and dirt, could wear awaythe clearcoat finish over time.

•Do not use hydrofluoric acid-based or high caustic-based wheel

cleaners, steel wool, fuels or strong household detergent.

•To remove tar and grease, use Ford Extra Strength Tar and Road Oil

Removal (B7A-19520–AA), available from your dealer.

ENGINE

Engines are more efficient when theyare clean because grease and dirt

buildup keep the engine warmer than normal. When washing:

•Take care when using a power washer to clean the engine. The

high-pressure fluid could penetrate the sealed parts and cause

damage.

•Do not spraya hot engine with cold water to avoid cracking the

engine block or other engine components.

•SprayMotorcraft Engine Shampoo and Degreaser (ZC-20) on all parts

that require cleaning and pressure rinse clean.

•Cover the highlighted areas to prevent water damage when cleaning

the engine.

Cleaning

185

Page 187 of 256

INSTRUMENT PANEL AND CLUSTER LENS

Clean the instrument panel with a damp cloth, then drywith a drycloth.

•Avoid cleaners or polish that increase the gloss of the upper portion of

the instrument panel. The dull finish in this area helps protect the

driver from undesirable windshield reflection.

Do not use chemical solvents or strong detergents when cleaning

the steering wheel or instrument panel to avoid contamination of

the air bag system.

•Be certain to wash or wipe your hands clean if you have been in

contact with certain products such as insect repellent and suntan

lotion in order to avoid possible damage to the painted surfaces.

INTERIOR TRIM

•Clean the interior trim areas with a damp cloth, then drybywiping

with a dry, soft, clean cloth.

•Do not use household or glass cleaners as these maydamage the

finish.

INTERIOR

For fabric, carpets, cloth seats and safetybelts:

•Remove dust and loose dirt with a vacuum cleaner.

•Remove light stains and soil with Ford Extra Strength Upholstery

Cleaner (E8AZ-19523–AA).

•If grease or tar is present on the material, spot-clean the area first

with Motorcraft Spot and Stain Remover (ZC-14).

•Never saturate the seat covers with cleaning solution.

•Do not use household cleaning products or glass cleaners, which can

stain and discolor the fabric and affect the flame retardant abilities of

the seat materials.

Do not use cleaning solvents, bleach or dye on the vehicle’s

seatbelts, as these actions mayweaken the belt webbing.

Cleaning

187