engine FORD SUPER DUTY 2005 1.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2005, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2005 1.GPages: 72, PDF Size: 0.52 MB

Page 13 of 72

2. When the glow plug pre-heat

indicator turns off, turn the key to 5

(START), then release the key as

soon as the engine starts. The glow

plugs will continue to be activated for two minutes after the glow plug

pre-heat indicator

has turned off. If the engine is not started

before the glow plug activation time ends, the glow plugs will need to be

reset by turning the key to 3 (OFF).

3. After the engine starts, allow it to idle for about 15 seconds. Do not

increase engine speed until the oil pressure gauge indicates normal

pressure.

STOPPING THE ENGINE

Turn the ignition to 3 (OFF). To prolong engine life (after extended high

speed or maximum GVW operation), it is recommended that a hot engine

be allowed to operate at low idle for about 7–10 minutes which would

allow sufficient time for the turbocharged engine to cool down.

COLD WEATHER OPERATION

Changing to a lighter grade engine oil also makes starting easier under

these conditions. Refer toEngine oil specificationsin theMaintenance

and Specificationssection of this supplement.

At temperatures below 20°F(–7°C), Number 2–D diesel fuel may thicken

enough to clog the fuel filter. Your vehicle is equipped with either an

FCM (E-Series) or an HFCM (F-Super Duty and Excursion) which acts

as a fuel filter/heater/water separator to keep the wax melted which will

help prevent fuel filter clogging. However, if the engine starts but stalls

after a short time and will not restart, the fuel filter(s) may be clogged.

For best results in cold weather, use Number 1–D diesel fuel or

“winterized”Number 2–D diesel fuel which has an additive to minimize

wax formation.

Your vehicle is also equipped with a bypass relief valve, located on the

fuel control module, which provides fuel flow to the engine if the fuel

pickup should become plugged by ice or wax. To allow this bypass valve

to function and avoid engine fuel starvation, it is recommended that,

during cold weather operation 32°F(0°C) or below, the fuel level in your

tank should not be allowed to drop below

1⁄4full. This will help prevent

air from entering the fuel system and stalling the engine.

In cold weather below 32°F (0°C) your diesel engine will slowly increase

to a higher idle speed if left idling in P (Park). As the engine warms-up,

Driving

13

Page 14 of 72

the engine sound level will decrease due to the activation of

PCM-controlled sound reduction features.

If your vehicle is operated in a heavy snow storm or blowing snow

conditions, the engine air induction may become partially clogged with

snow and/or ice. If this occurs, the engine may experience a significant

reduction in power output. At the earliest opportunity, clear all the snow

and/or ice away from the air induction inlet.

Operation in snow

Vehicle operation in heavy snowfall or in dry loose snow that may swirl

around the front of the vehicle may feed excessive amounts of snow into

the air intake system. This could plug the air cleaner with snow and

cause the engine to stall and/or lose power.

Refer toAir filter restriction gaugeandEngine air filterin the

Instrumentationsection of this supplement for more information.

Operation in standing water

Ingestion of water into the diesel engine can result in immediate and

severe damage to the engine. If driving through water, slow down to

avoid splashing water into the intake. If the engine stalls, and ingestion

of water into the engine is suspected, do not try to restart the engine.

Consult your dealer for service immediately.

Engine block heater (if equipped)

Refer to theDrivingchapter in theOwner’s Guide.

DUAL FUEL TANK SELECTOR CONTROL (IF EQUIPPED)

If your vehicle is equipped with dual

fuel tanks, you will have a selector

control, located to the right of the

steering wheel, which allows you to

draw fuel from either tank. Your fuel

gauge will display the amount of

fuel in the currently selected tank.

Fuel level indication is delayed for several minutes when the tank

selector switch is actuated. Fuel level indication can be obtained

immediately by turning off and restarting the engine.

Driving

14

Page 15 of 72

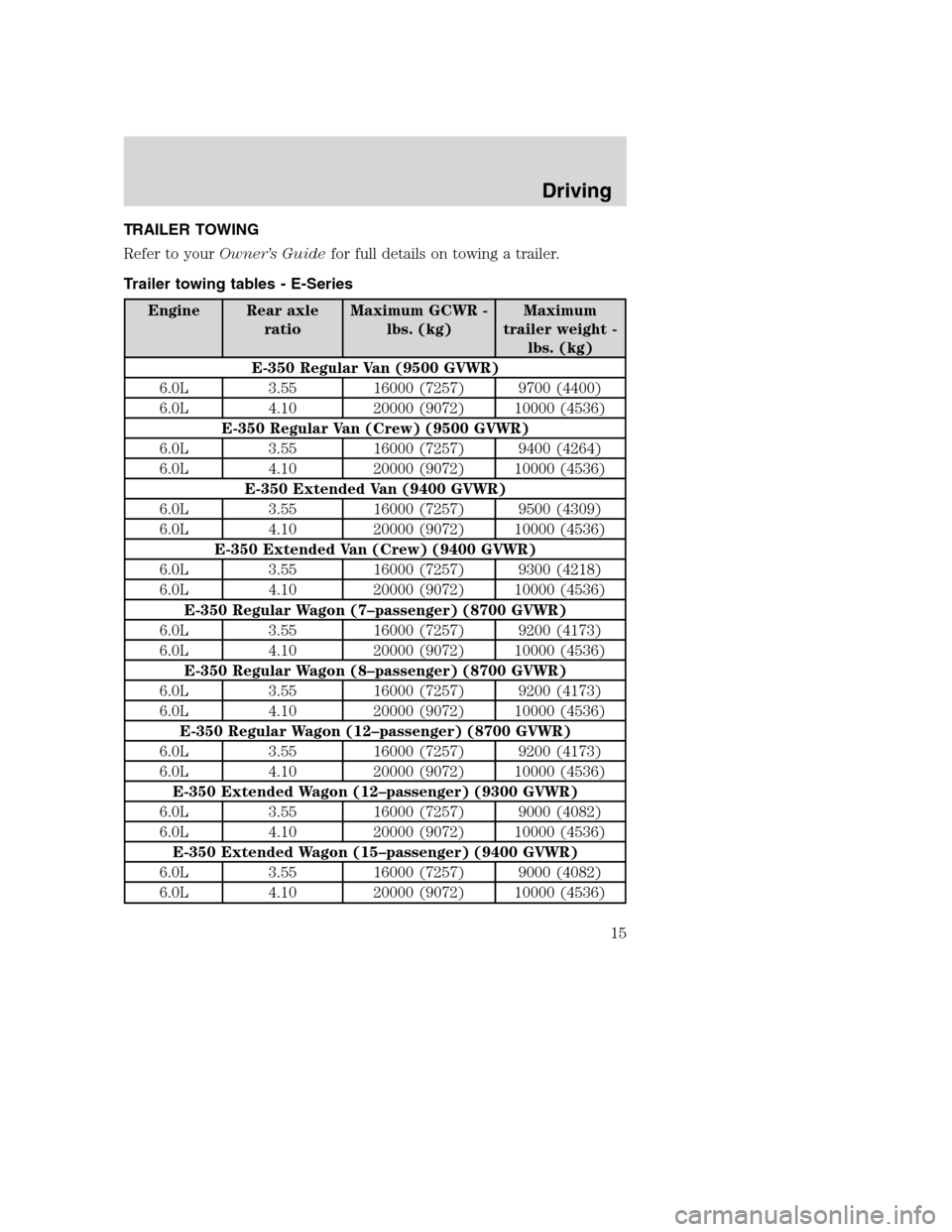

TRAILER TOWING

Refer to yourOwner’s Guidefor full details on towing a trailer.

Trailer towing tables - E-Series

Engine Rear axle

ratioMaximum GCWR -

lbs. (kg)Maximum

trailer weight -

lbs. (kg)

E-350 Regular Van (9500 GVWR)

6.0L 3.55 16000 (7257) 9700 (4400)

6.0L 4.10 20000 (9072) 10000 (4536)

E-350 Regular Van (Crew) (9500 GVWR)

6.0L 3.55 16000 (7257) 9400 (4264)

6.0L 4.10 20000 (9072) 10000 (4536)

E-350 Extended Van (9400 GVWR)

6.0L 3.55 16000 (7257) 9500 (4309)

6.0L 4.10 20000 (9072) 10000 (4536)

E-350 Extended Van (Crew) (9400 GVWR)

6.0L 3.55 16000 (7257) 9300 (4218)

6.0L 4.10 20000 (9072) 10000 (4536)

E-350 Regular Wagon (7–passenger) (8700 GVWR)

6.0L 3.55 16000 (7257) 9200 (4173)

6.0L 4.10 20000 (9072) 10000 (4536)

E-350 Regular Wagon (8–passenger) (8700 GVWR)

6.0L 3.55 16000 (7257) 9200 (4173)

6.0L 4.10 20000 (9072) 10000 (4536)

E-350 Regular Wagon (12–passenger) (8700 GVWR)

6.0L 3.55 16000 (7257) 9200 (4173)

6.0L 4.10 20000 (9072) 10000 (4536)

E-350 Extended Wagon (12–passenger) (9300 GVWR)

6.0L 3.55 16000 (7257) 9000 (4082)

6.0L 4.10 20000 (9072) 10000 (4536)

E-350 Extended Wagon (15–passenger) (9400 GVWR)

6.0L 3.55 16000 (7257) 9000 (4082)

6.0L 4.10 20000 (9072) 10000 (4536)

Driving

15

Page 16 of 72

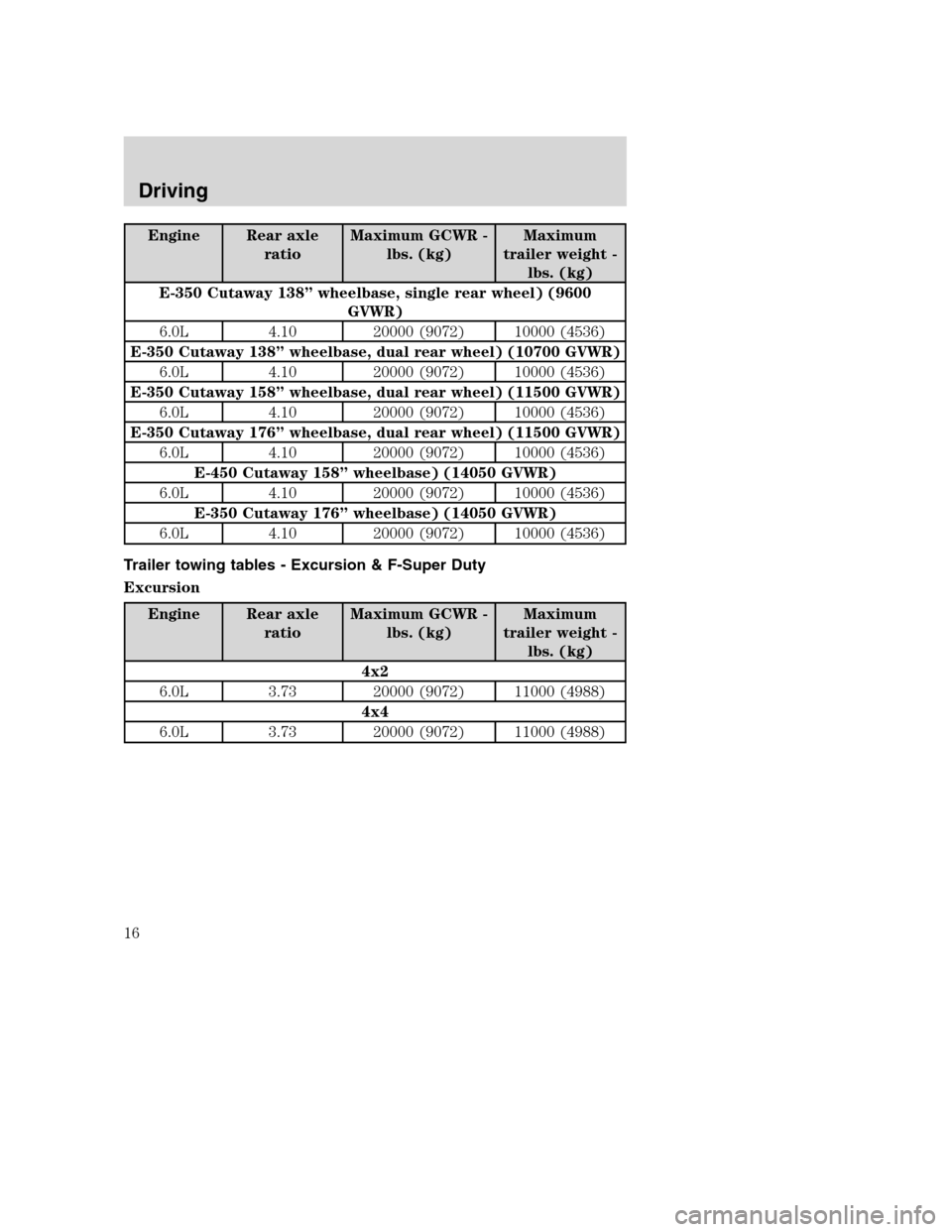

Engine Rear axle

ratioMaximum GCWR -

lbs. (kg)Maximum

trailer weight -

lbs. (kg)

E-350 Cutaway 138”wheelbase, single rear wheel) (9600

GVWR)

6.0L 4.10 20000 (9072) 10000 (4536)

E-350 Cutaway 138”wheelbase, dual rear wheel) (10700 GVWR)

6.0L 4.10 20000 (9072) 10000 (4536)

E-350 Cutaway 158”wheelbase, dual rear wheel) (11500 GVWR)

6.0L 4.10 20000 (9072) 10000 (4536)

E-350 Cutaway 176”wheelbase, dual rear wheel) (11500 GVWR)

6.0L 4.10 20000 (9072) 10000 (4536)

E-450 Cutaway 158”wheelbase) (14050 GVWR)

6.0L 4.10 20000 (9072) 10000 (4536)

E-350 Cutaway 176”wheelbase) (14050 GVWR)

6.0L 4.10 20000 (9072) 10000 (4536)

Trailer towing tables - Excursion & F-Super Duty

Excursion

Engine Rear axle

ratioMaximum GCWR -

lbs. (kg)Maximum

trailer weight -

lbs. (kg)

4x2

6.0L 3.73 20000 (9072) 11000 (4988)

4x4

6.0L 3.73 20000 (9072) 11000 (4988)

Driving

16

Page 17 of 72

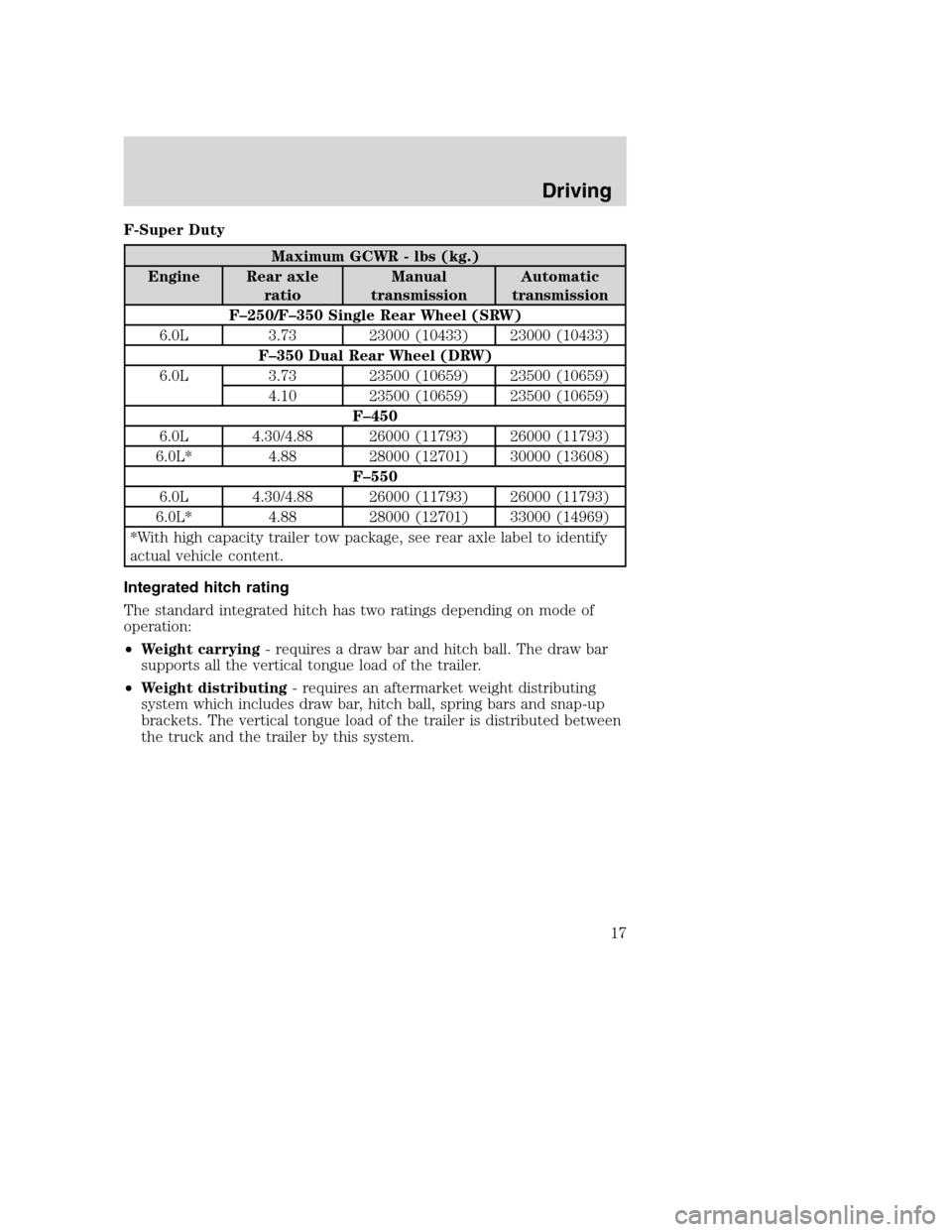

F-Super Duty

Maximum GCWR - lbs (kg.)

Engine Rear axle

ratioManual

transmissionAutomatic

transmission

F–250/F–350 Single Rear Wheel (SRW)

6.0L 3.73 23000 (10433) 23000 (10433)

F–350 Dual Rear Wheel (DRW)

6.0L 3.73 23500 (10659) 23500 (10659)

4.10 23500 (10659) 23500 (10659)

F–450

6.0L 4.30/4.88 26000 (11793) 26000 (11793)

6.0L* 4.88 28000 (12701) 30000 (13608)

F–550

6.0L 4.30/4.88 26000 (11793) 26000 (11793)

6.0L* 4.88 28000 (12701) 33000 (14969)

*With high capacity trailer tow package, see rear axle label to identify

actual vehicle content.

Integrated hitch rating

The standard integrated hitch has two ratings depending on mode of

operation:

•Weight carrying- requires a draw bar and hitch ball. The draw bar

supports all the vertical tongue load of the trailer.

•Weight distributing- requires an aftermarket weight distributing

system which includes draw bar, hitch ball, spring bars and snap-up

brackets. The vertical tongue load of the trailer is distributed between

the truck and the trailer by this system.

Driving

17

Page 19 of 72

JUMP STARTING YOUR VEHICLE (E-SERIES ONLY)

F-Super Duty and Excursion vehicles equipped with the 6.0L

diesel engine can be jump started using the same procedure as a

gasoline engine; refer to yourOwner’s guidefor the jump starting

procedure.

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes and

clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; doing so may

damage the catalytic converter.

Preparing your vehicle

When the batteries are disconnected or new batteries are installed, the

transmission must relearn its shift strategy. As a result, the transmission

may have firm and/or soft shifts. This operation is considered normal and

will not affect function or durability of the transmission. Over time, the

adaptive learning process will fully update transmission operation

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the batteries of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the passenger side of the disabled

vehicle making sure the two vehiclesdo nottouch. Set the parking

brake on both vehicles.

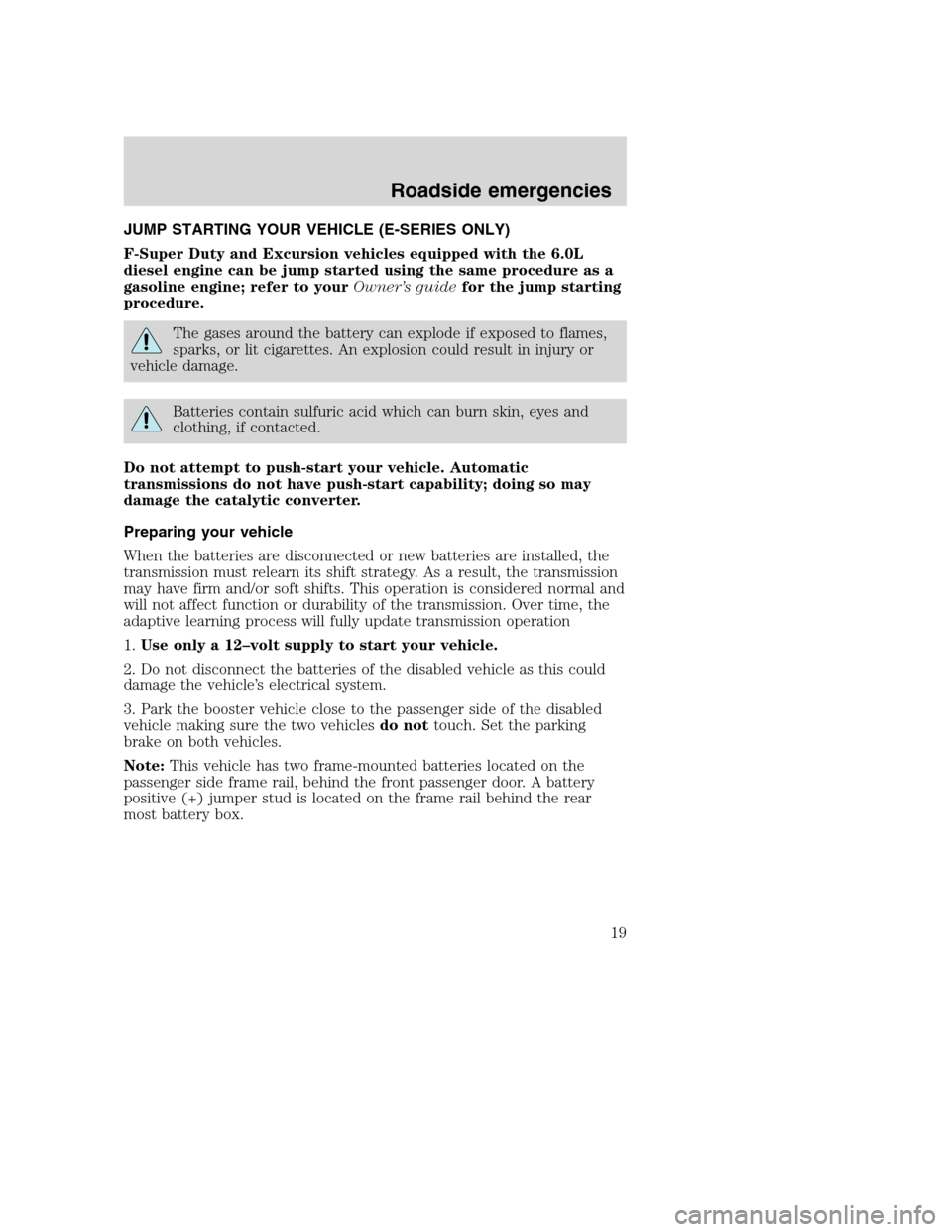

Note:This vehicle has two frame-mounted batteries located on the

passenger side frame rail, behind the front passenger door. A battery

positive (+) jumper stud is located on the frame rail behind the rear

most battery box.

Roadside emergencies

Roadside emergencies

19

Page 22 of 72

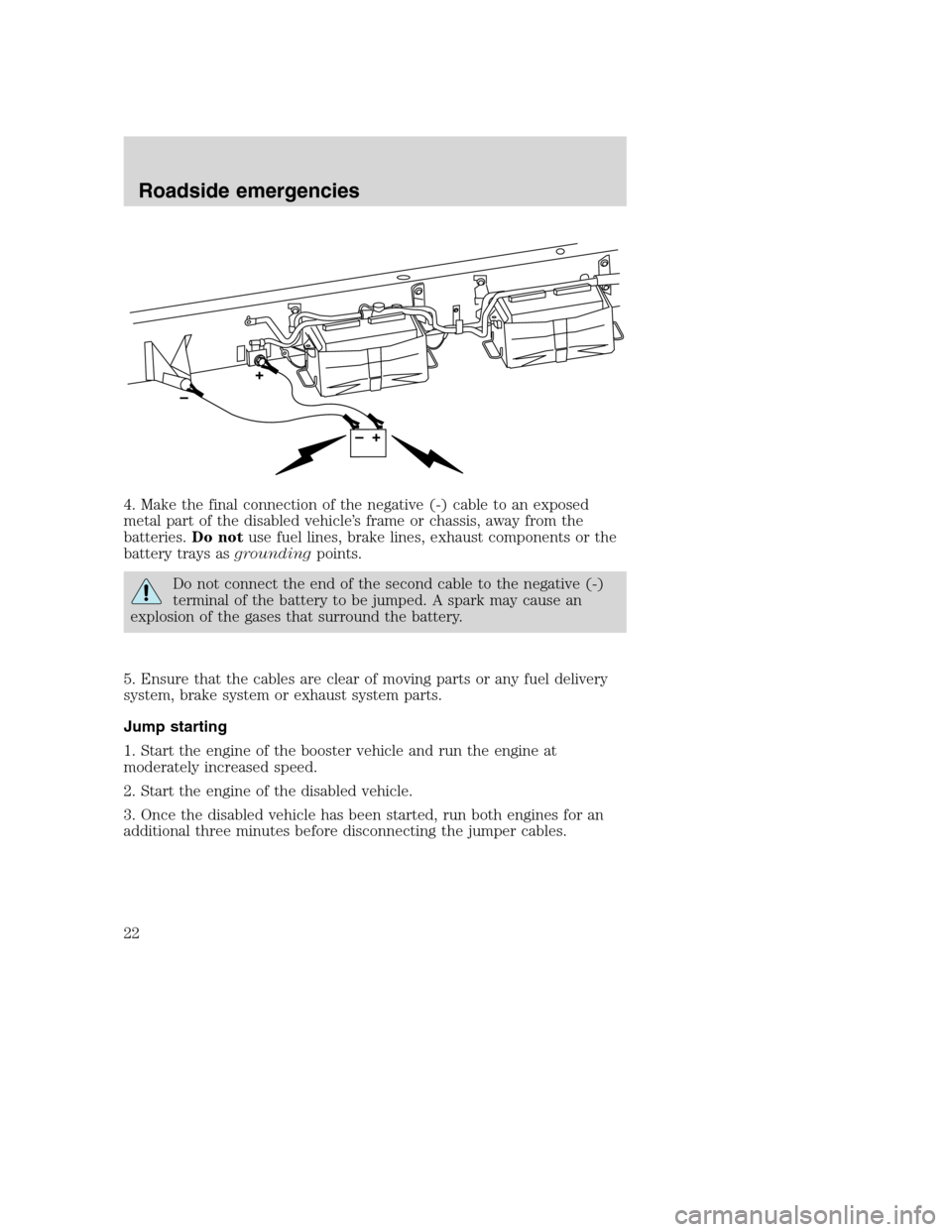

4. Make the final connection of the negative (-) cable to an exposed

metal part of the disabled vehicle’s frame or chassis, away from the

batteries.Do notuse fuel lines, brake lines, exhaust components or the

battery trays asgroundingpoints.

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

5. Ensure that the cables are clear of moving parts or any fuel delivery

system, brake system or exhaust system parts.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

Roadside emergencies

22

Page 24 of 72

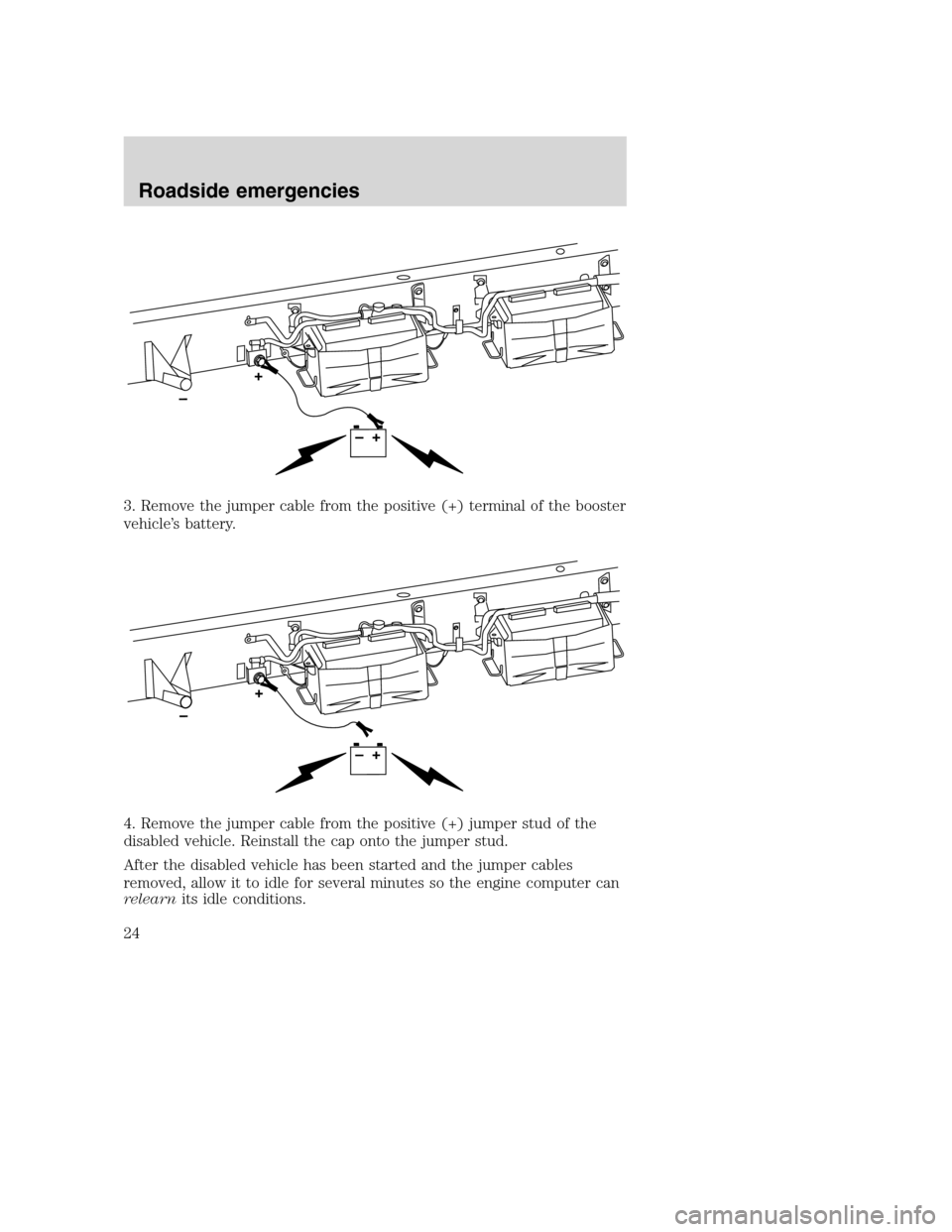

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle’s battery.

4. Remove the jumper cable from the positive (+) jumper stud of the

disabled vehicle. Reinstall the cap onto the jumper stud.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

Roadside emergencies

24

Page 25 of 72

ENGINE

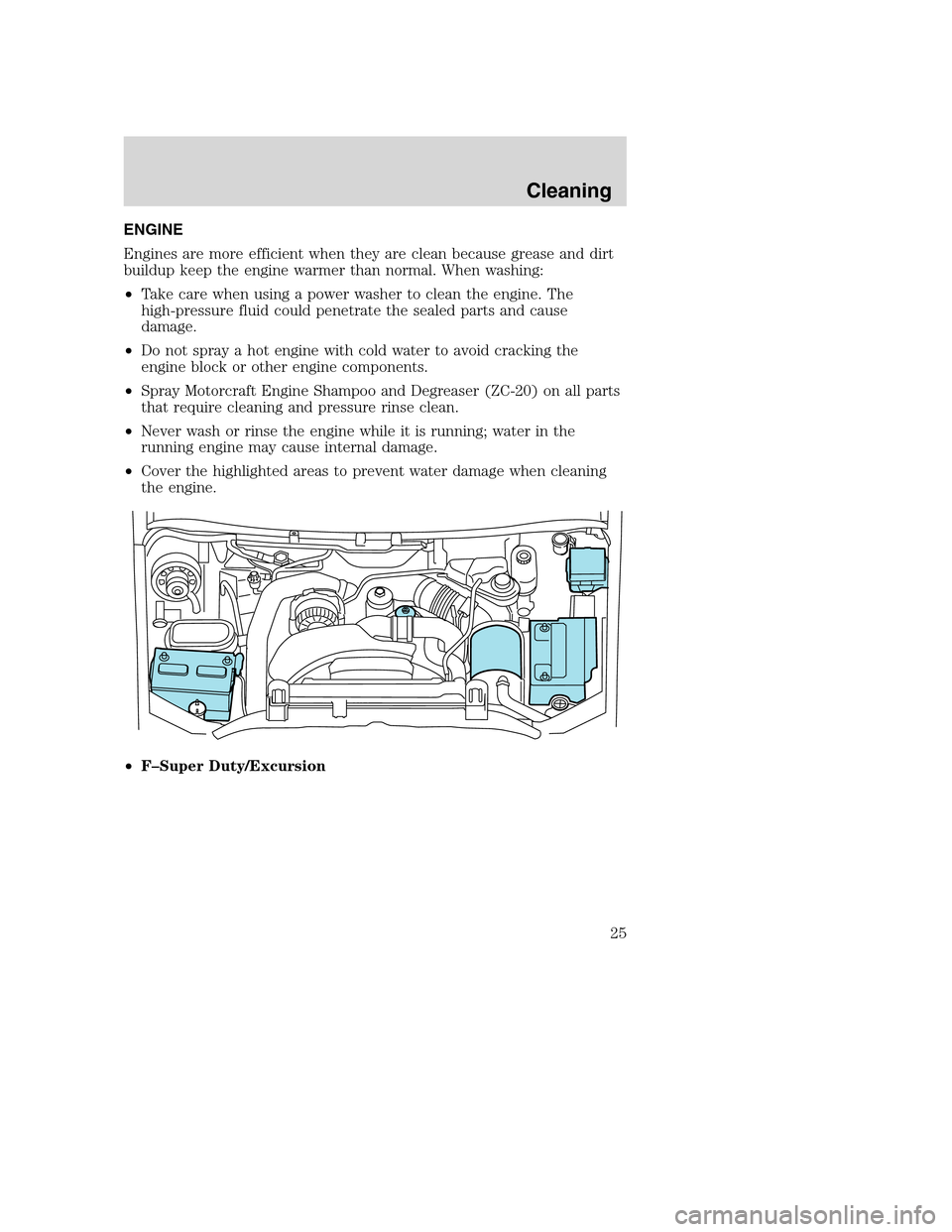

Engines are more efficient when they are clean because grease and dirt

buildup keep the engine warmer than normal. When washing:

•Take care when using a power washer to clean the engine. The

high-pressure fluid could penetrate the sealed parts and cause

damage.

•Do not spray a hot engine with cold water to avoid cracking the

engine block or other engine components.

•Spray Motorcraft Engine Shampoo and Degreaser (ZC-20) on all parts

that require cleaning and pressure rinse clean.

•Never wash or rinse the engine while it is running; water in the

running engine may cause internal damage.

•Cover the highlighted areas to prevent water damage when cleaning

the engine.

•F–Super Duty/Excursion

Cleaning

Cleaning

25

Page 27 of 72

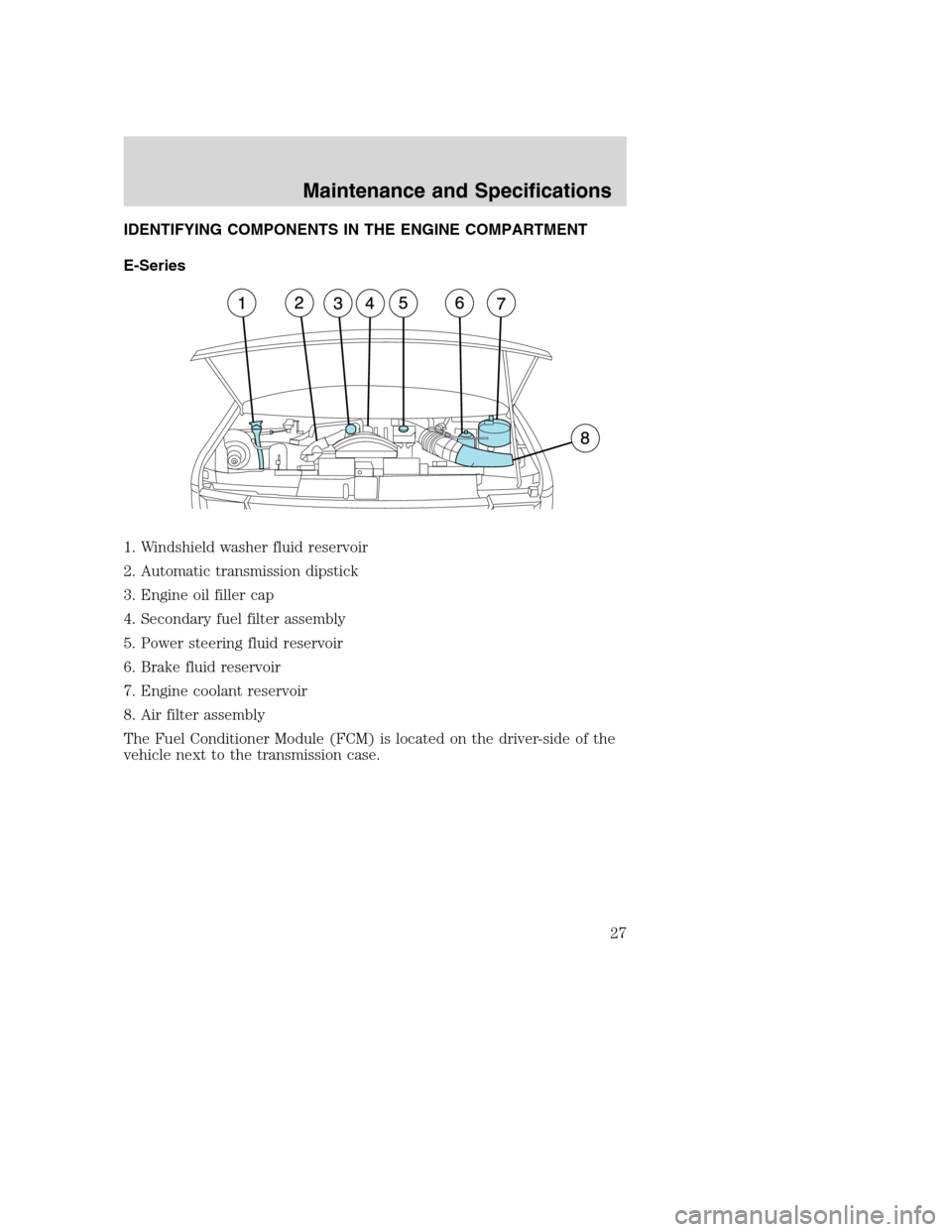

IDENTIFYING COMPONENTS IN THE ENGINE COMPARTMENT

E-Series

1. Windshield washer fluid reservoir

2. Automatic transmission dipstick

3. Engine oil filler cap

4. Secondary fuel filter assembly

5. Power steering fluid reservoir

6. Brake fluid reservoir

7. Engine coolant reservoir

8. Air filter assembly

The Fuel Conditioner Module (FCM) is located on the driver-side of the

vehicle next to the transmission case.

Maintenance and Specifications

Maintenance and Specifications

27