check engine FORD SUPER DUTY 2006 1.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2006 1.GPages: 72, PDF Size: 0.57 MB

Page 7 of 72

Glow plug pre-heat indicator

With the key in the ON position,

the

light will illuminate if

glow plug heat is necessary as a

starting aid. Wait until the light goes

off before starting. The light should always illuminate briefly, when the

ignition key is in the ON position. If the light does not illuminate, there

may be a problem. Refer toCold weather startingin theDriving

chapter of this supplement. After the engine starts, the light should

remain off. The light should always illuminate at least momentarily when

the engine is cold and the ignition is turned to ON. If it does not

illuminate, the glow plug system should be checked and repaired

promptly to avoid difficulty in cold starting.

Waterinfuel

During refueling, it is possible for water-contaminated diesel fuel to be

pumped into your tank. Your vehicle fuel system is equipped with a fuel

filter/water separator to remove water from the fuel. The WATER IN

FUEL light will illuminate when the ignition is turned to START (as part

of the light function check) and when the FCM/HFCM has a significant

quantity of water in it.

Type A

Type B

Type C

If the light illuminates when the engine is running, stop the vehicle as

soon as safely possible, shut off the engine, then drain the FCM/HFCM.

Refer toDraining the FCM/HFCM and changing the fuel filtersin the

Maintenance and Specificationschapter of this supplement for the

drain procedure. Allowing water to stay in the system could result in

extensive damage to, or failure of, the fuel injection system.

2006 Econoline(eco)

Supplement

USA(fus)

Instrument Cluster

7

Page 9 of 72

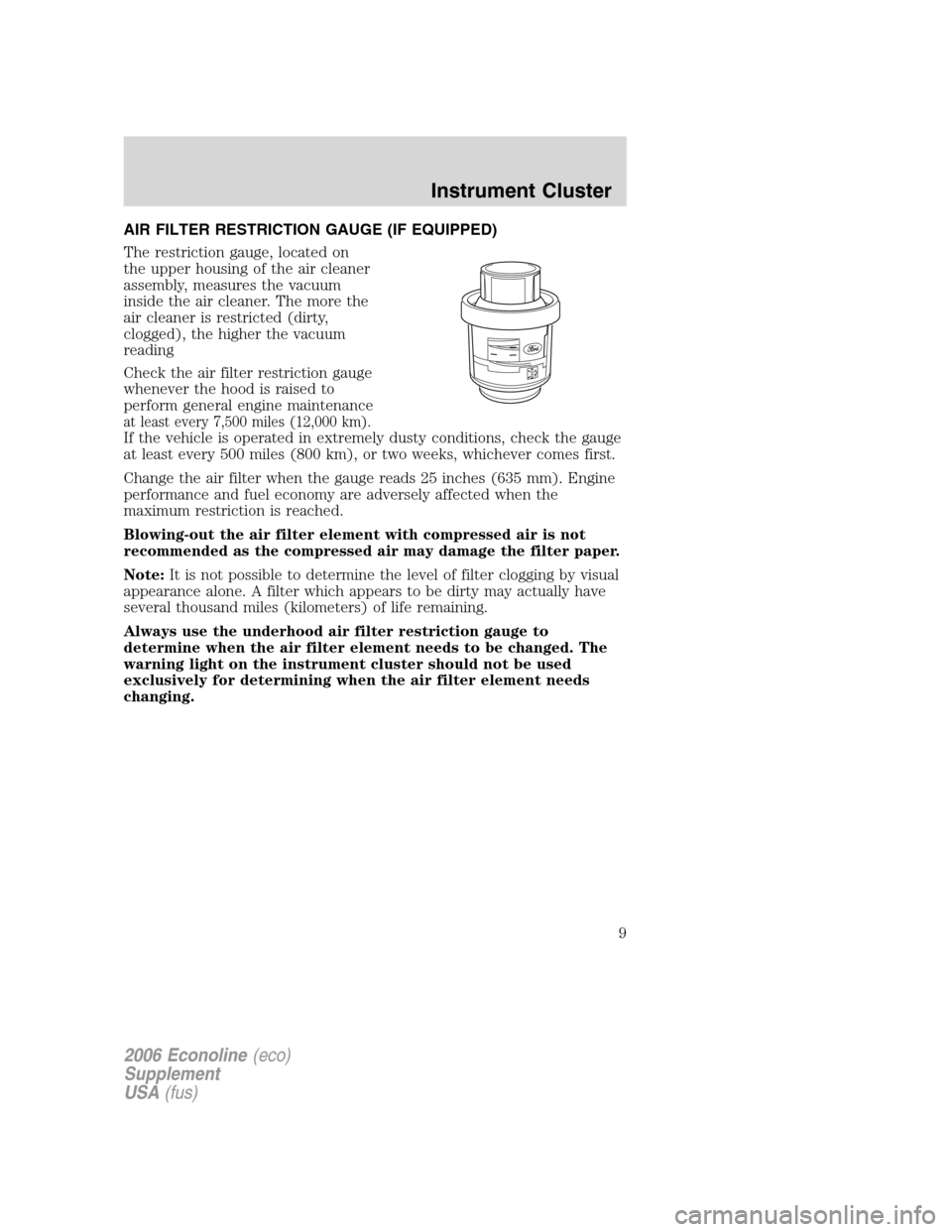

AIR FILTER RESTRICTION GAUGE (IF EQUIPPED)

The restriction gauge, located on

the upper housing of the air cleaner

assembly, measures the vacuum

inside the air cleaner. The more the

air cleaner is restricted (dirty,

clogged), the higher the vacuum

reading

Check the air filter restriction gauge

whenever the hood is raised to

perform general engine maintenance

at least every 7,500 miles (12,000 km).

If the vehicle is operated in extremely dusty conditions, check the gauge

at least every 500 miles (800 km), or two weeks, whichever comes first.

Change the air filter when the gauge reads 25 inches (635 mm). Engine

performance and fuel economy are adversely affected when the

maximum restriction is reached.

Blowing-out the air filter element with compressed air is not

recommended as the compressed air may damage the filter paper.

Note:It is not possible to determine the level of filter clogging by visual

appearance alone. A filter which appears to be dirty may actually have

several thousand miles (kilometers) of life remaining.

Always use the underhood air filter restriction gauge to

determine when the air filter element needs to be changed. The

warning light on the instrument cluster should not be used

exclusively for determining when the air filter element needs

changing.

2006 Econoline(eco)

Supplement

USA(fus)

Instrument Cluster

9

Page 29 of 72

2. Carefully turn the filler cap counterclockwise until it stops.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise until a few clicks are heard.

If the “Check Fuel Cap” message comes on and stays on after you start

the engine, the fuel filler cap may not be properly installed. Turn off the

engine, remove the fuel filler cap, align the cap properly and reinstall it.

If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The customer warranty may

be void for any damage to the fuel tank or fuel system if the

correct genuine Ford or Motorcraft fuel filler cap is not used.

The fuel system may be under pressure. If the fuel filler cap is

venting vapor or if you hear a hissing sound, wait until it stops

before completely removing the fuel filler cap. Otherwise, fuel may

spray out and injure you or others.

If you do not use the proper fuel filler cap, excessive pressure or

vacuum in the fuel tank may damage the fuel system or cause

the fuel cap to disengage in a collision, which may result in possible

personal injury.

Fuel quality

It should not be necessary to add any aftermarket additives to your fuel

tank if you use a properly formulated diesel fuel that meets the ASTM D

975 industry specification. Aftermarket additives can damage the injector

system or engine. Repairs to correct the effects of using an aftermarket

product in your fuel may not be covered by your warranty.

Do not blend used engine oil with diesel fuel under any

circumstances.Blending used oil with the fuel will significantly increase

your vehicle’s exhaust emissions and reduce engine life due to increased

internal wear.

Many of the world’s automakers approved the World-wide Fuel Charter

that recommends diesel fuel specifications to provide improved

performance and emission control system protection for your vehicle.

Diesel fuel that meets the World-wide Fuel Charter should be used when

available. Ask your fuel supplier about fuel that meets the World-wide

Fuel Charter.

2006 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

29

Page 32 of 72

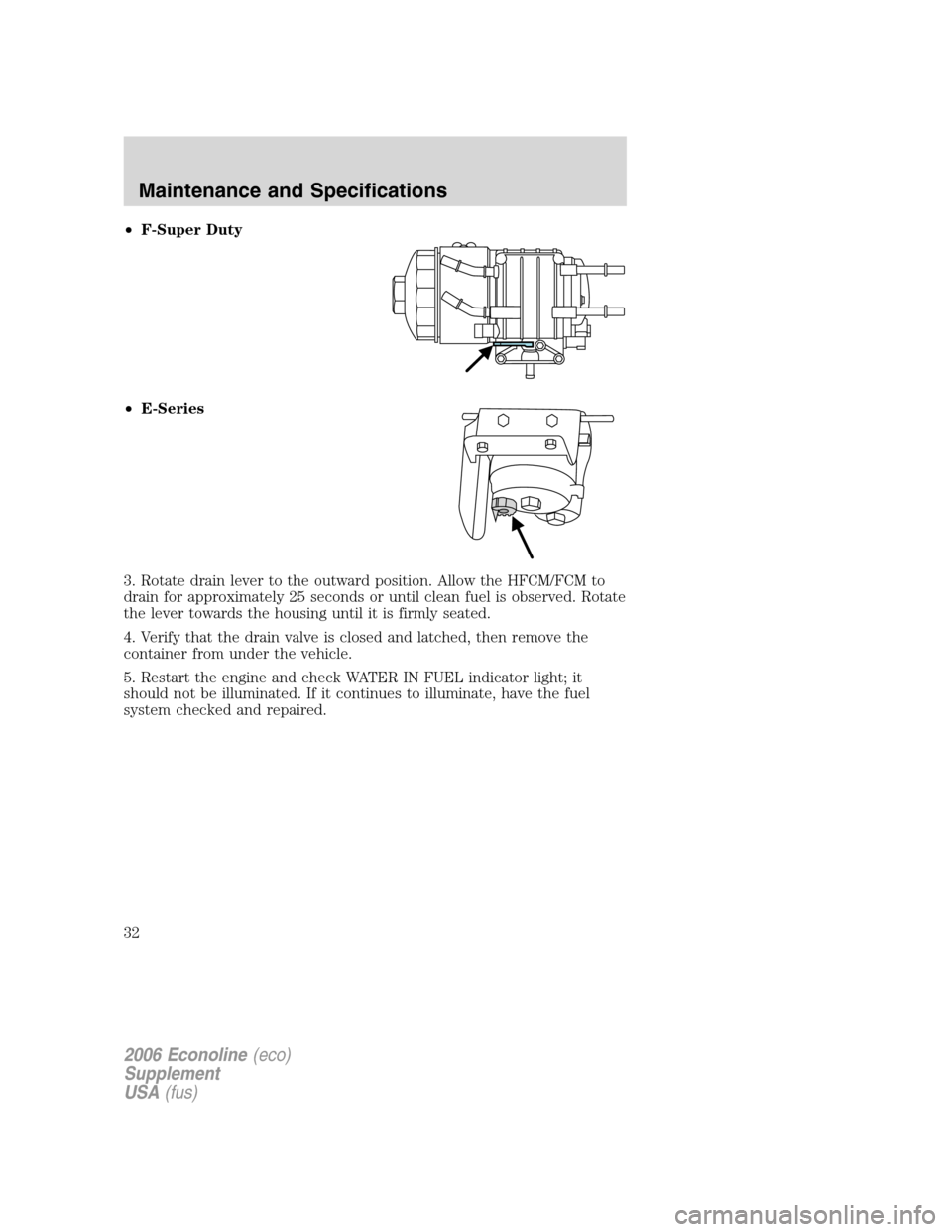

•F-Super Duty

•E-Series

3. Rotate drain lever to the outward position. Allow the HFCM/FCM to

drain for approximately 25 seconds or until clean fuel is observed. Rotate

the lever towards the housing until it is firmly seated.

4. Verify that the drain valve is closed and latched, then remove the

container from under the vehicle.

5. Restart the engine and check WATER IN FUEL indicator light; it

should not be illuminated. If it continues to illuminate, have the fuel

system checked and repaired.

2006 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

32

Page 35 of 72

2. Remove and discard the old fuel filter element.

3. Carefully clean the mating surfaces.

Installation - both

The engine will not run properly if the fuel filter is not installed

in housing.

1. Install the new fuel filter and cap seal (from Ford Part No. FD–4604)

into the fuel filter housing.

2. Tighten cap onto fuel filter housing slowly, allowing fuel to soak into

the fuel filter element. Tighten cap until it contacts the housing.

After replacing the fuel filter, the engine will purge the trapped

air as it runs. The engine may run roughly and smoke until the air

is completely eliminated.

Using a fuel which has more than average impurities may require

the fuel filter to be replaced more frequently than the service

interval specifies.

ENGINE OIL

Checking the engine oil level

Because it is normal to add some oil between oil changes, check your

engine oil level each time you stop for fuel. To check the engine oil level

consistently and accurately, the following procedure is recommended:

1. Have engine at normal operating temperature (at least into the

NORMAL range on the engine coolant temperature gauge).

2. Park the vehicle on a level surface, then turn off the engine and open

the hood.

3. Allow at least20 minutesafter engine shutdown to assure that the oil

contained in the upper parts of the engine has returned to the oil pan.

4. Protecting yourself from engine heat, pull out the dipstick, wipe it

clean and reinsert fully.

5. Read oil level on both sides of dipstick and use highest level (reading)

for the actual engine oil level.

6. Maintain the oil level between ADD and OPERATING RANGE on the

dipstick by adding oil as required. The distance from ADD to

OPERATING RANGE on the dipstick represents 2.0 quarts (1.9L). Do

not overfill. If the oil level exceeds OPERATING RANGE, oil consumption

may result.

2006 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

35

Page 41 of 72

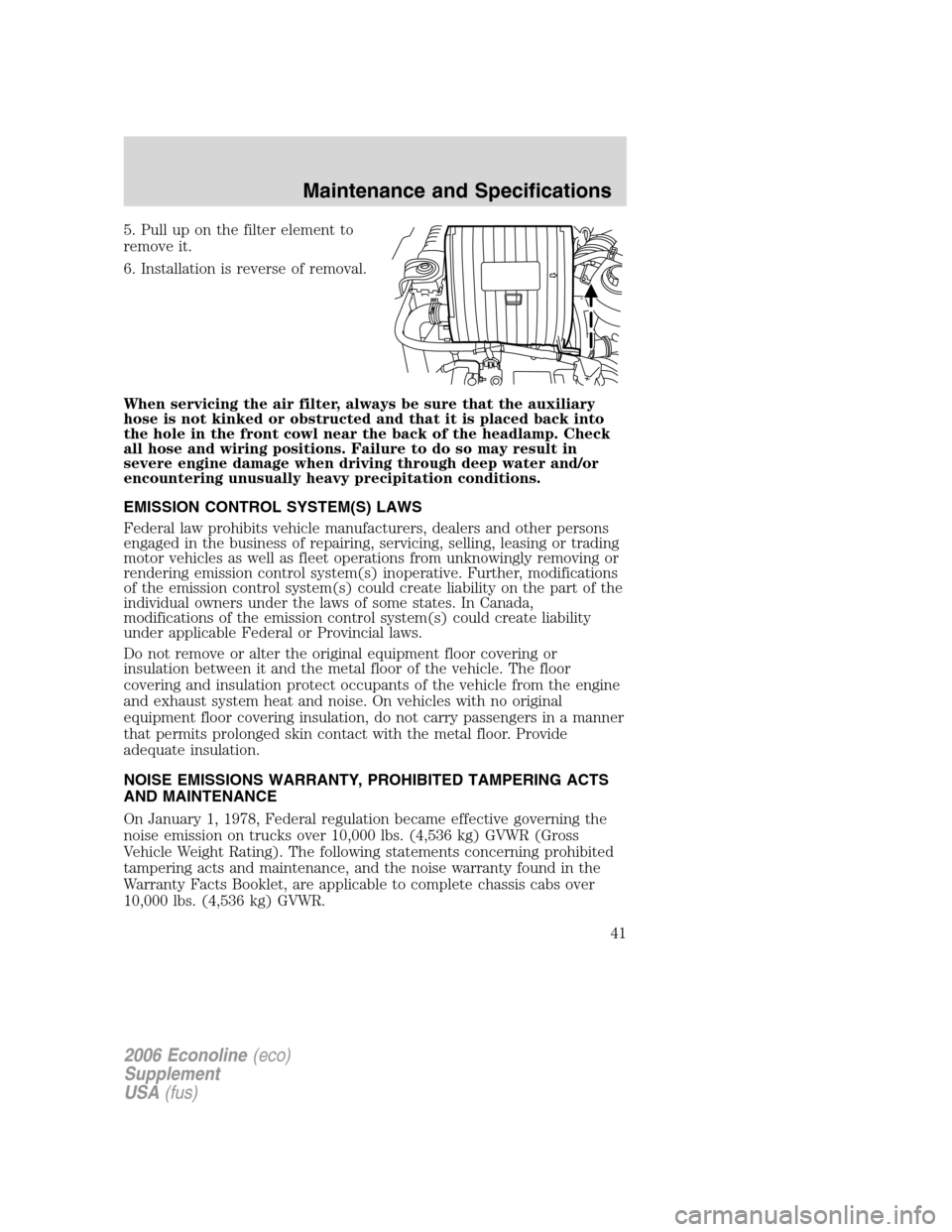

5. Pull up on the filter element to

remove it.

6. Installation is reverse of removal.

When servicing the air filter, always be sure that the auxiliary

hose is not kinked or obstructed and that it is placed back into

the hole in the front cowl near the back of the headlamp. Check

all hose and wiring positions. Failure to do so may result in

severe engine damage when driving through deep water and/or

encountering unusually heavy precipitation conditions.

EMISSION CONTROL SYSTEM(S) LAWS

Federal law prohibits vehicle manufacturers, dealers and other persons

engaged in the business of repairing, servicing, selling, leasing or trading

motor vehicles as well as fleet operations from unknowingly removing or

rendering emission control system(s) inoperative. Further, modifications

of the emission control system(s) could create liability on the part of the

individual owners under the laws of some states. In Canada,

modifications of the emission control system(s) could create liability

under applicable Federal or Provincial laws.

Do not remove or alter the original equipment floor covering or

insulation between it and the metal floor of the vehicle. The floor

covering and insulation protect occupants of the vehicle from the engine

and exhaust system heat and noise. On vehicles with no original

equipment floor covering insulation, do not carry passengers in a manner

that permits prolonged skin contact with the metal floor. Provide

adequate insulation.

NOISE EMISSIONS WARRANTY, PROHIBITED TAMPERING ACTS

AND MAINTENANCE

On January 1, 1978, Federal regulation became effective governing the

noise emission on trucks over 10,000 lbs. (4,536 kg) GVWR (Gross

Vehicle Weight Rating). The following statements concerning prohibited

tampering acts and maintenance, and the noise warranty found in the

Warranty Facts Booklet, are applicable to complete chassis cabs over

10,000 lbs. (4,536 kg) GVWR.

2006 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

41

Page 42 of 72

Tampering with noise control system prohibited

Federal law prohibits the following acts or the causing thereof: (1) The

removal or rendering inoperative by any person other than for purposes

of maintenance, repair or replacement of any device or element of design

incorporated into any new vehicle for the purpose of noise control prior

to its sale or delivery to the ultimate purchaser or while it is in use, or

(2) the use of the vehicle after such device or element of design has

been removed or rendered inoperative by any person.

Among those acts which the U.S. Environmental Protection Agency may

presume to constitute tampering are the acts listed below:

•Removal of hood blanket, fender apron absorbers, fender apron

barriers, underbody noise shields or acoustically absorptive material.

•Tampering or rendering inoperative the engine speed governor, so as

to allow engine speed to exceed manufacturer’s specifications.

The complexity of the diesel engine makes it so the owner is discouraged

from attempting to perform maintenance other than the services

described in this supplement.

If you experience difficult starting, rough idling, excessive exhaust

smoke, a decrease in engine performance or excess fuel consumption,

perform the following checks:

•a plugged air inlet system or engine air filter element.

•water in the fuel filter/water separator.

•a clogged fuel filter.

•contaminated fuel.

•air in the fuel system, due to loose connections.

•an open or pinched sensor hose.

•low engine oil level.

•wrong fuel or oil viscosity for climactic conditions.

If these checks do not help you correct the engine performance problem

you are experiencing, consult an authorized dealer.

FUELING

Do not use starting fluid such as ether or gasoline in the diesel

air intake system. Such fluids can cause immediate explosive

damage to the engine and possible personal injury.

2006 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

42

Page 43 of 72

If you fuel your vehicle at a truck stop, you may notice that the fuel

nozzle may shut off every 5–10 seconds. This is due to the flow rates

being designed for larger heavy duty trucks. You may have to fuel at a

slower rate (don’t depress the nozzle trigger fully).

Do not run your diesel vehicle out of fuel as this will allow air to enter

the fuel system which will make restarting difficult. Longer engine

cranking time may be required once air is in the fuel system. If air enters

the fuel system (either through running the fuel tank(s) empty or during

a fuel filter change), the engine will self-purge the trapped air once it

starts running. The engine may run roughly and produce white smoke

while air is in the fuel system; this is normal and should stop after a

short time.

MINOR TROUBLESHOOTING GUIDE

If the engine won’t crank

Turn on the headlights. If the lights are dim, do not go on at all or if

when the ignition is turned to 5 (START) the lights become dim or go

out, the battery connections may be loose or corroded, or the battery

may be discharged. If there is a clicking or stuttering sound coming from

the engine compartment when you turn the key to 5 (START), this may

also indicate a loose or corroded battery connection.

Check the battery connections at the battery posts, cable connection to

the engine grounding point and at the starter connection.

If a discharged battery is suspected, have it checked and corrected.

Battery posts, terminals and related accessories contain lead and

lead compounds.Wash hands after handling.

•For vehicles with manual transmissions,the clutch pedalmustbe

fully depressed in order for the starter to operate.

•For vehicles with automatic transmissions,the gearshift lever

must be in P (Park) or N (Neutral) in order for the starter to operate.

•Try operating the starter switch several times. Should the switch be

corroded, this operation may clean the contacts or make the switch

temporarily operable until you can reach the dealer.

•If all electrical connections are tight and you need assistance to start,

refer toJump startingin theRoadside Emergencieschapter of your

Owner’s Guide(F-Super Duty ) or refer to theJump starting

section in theRoadside Emergencieschapter of this supplement

(E-Series).

2006 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

43

Page 44 of 72

If engine cranks but won’t start

Prolonged starter cranking (in excess of 30 seconds) could cause

damage to the starter motor.

•Check the fuel gauge. You may be out of fuel. If the gauge shows that

there is fuel in the tank, the trouble may be in the electrical system or

the fuel system. If equipped with an auxiliary tank, be sure that the tankcontrol switch is set for the tank with fuel and not on an empty tank.

•Leaving the ignition key turned to 4 (ON) for over two minutes

without starting may make starting difficult because the glow plugs

will cease activation. Reset the system by turning the ignition key to 3

(OFF) and then back to 4 (ON) again.

If the engine runs hot

The following could cause the engine to overheat:

•Lack of coolant.

•Dirty cooling system.

•Plugged radiator fins, charge air cooler, A/C condenser and/or oil

cooler.

•Driving with frozen coolant.

•Sticking thermostat.

•Overloading or pulling heavy trailers during hot weather.

•Grill or radiator air blockage.

•Slipping or missing drive belt.

•Plugged or very dirty air cleaner element.

If fuses burn out

Burned-out or blown fuses usually indicate an electrical short-circuit,

although a fuse may occasionally burn out from vibration. Insert a second

fuse. If this fuse immediately burns out and you cannot locate the cause,

return your vehicle to your dealer for a circuit check.

Replacement fuses and circuit breakers must always be the same

rating as the original equipment shown. Never replace a fuse or

circuit breaker with one of a higher rating. Higher rated fuses or circuit

breakers could allow circuit overloading in the event of a circuit malfunction,

resulting in severe vehicle damage or personal injury due to fire.

Refer to theOwner’s Guidefor replacement of fuses.

2006 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

44

Page 49 of 72

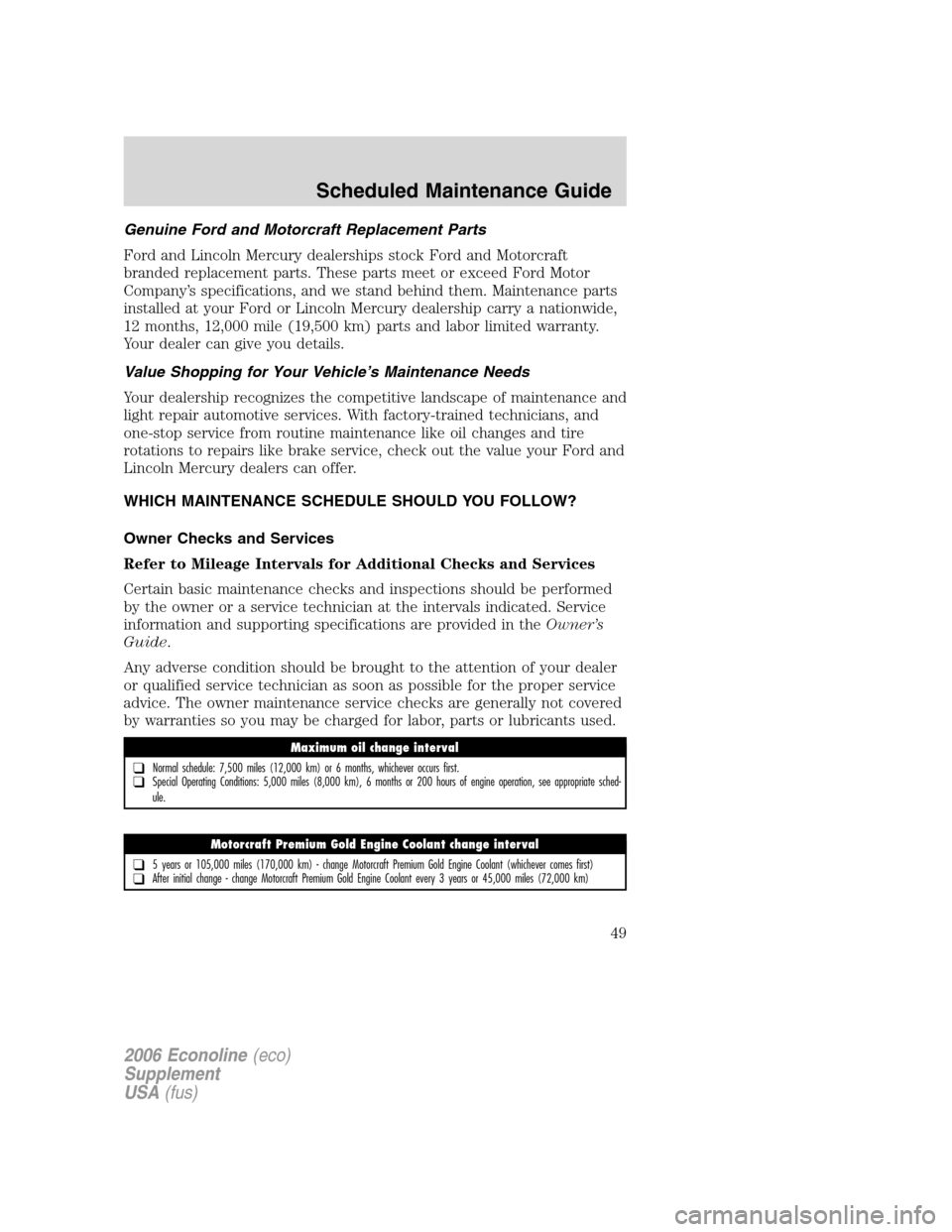

Genuine Ford and Motorcraft Replacement Parts

Ford and Lincoln Mercury dealerships stock Ford and Motorcraft

branded replacement parts. These parts meet or exceed Ford Motor

Company’s specifications, and we stand behind them. Maintenance parts

installed at your Ford or Lincoln Mercury dealership carry a nationwide,

12 months, 12,000 mile (19,500 km) parts and labor limited warranty.

Your dealer can give you details.

Value Shopping for Your Vehicle’s Maintenance Needs

Your dealership recognizes the competitive landscape of maintenance and

light repair automotive services. With factory-trained technicians, and

one-stop service from routine maintenance like oil changes and tire

rotations to repairs like brake service, check out the value your Ford and

Lincoln Mercury dealers can offer.

WHICH MAINTENANCE SCHEDULE SHOULD YOU FOLLOW?

Owner Checks and Services

Refer to Mileage Intervals for Additional Checks and Services

Certain basic maintenance checks and inspections should be performed

by the owner or a service technician at the intervals indicated. Service

information and supporting specifications are provided in theOwner’s

Guide .

Any adverse condition should be brought to the attention of your dealer

or qualified service technician as soon as possible for the proper service

advice. The owner maintenance service checks are generally not covered

by warranties so you may be charged for labor, parts or lubricants used.

Maximum oil change interval

❑Normal schedule: 7,500 miles (12,000 km) or 6 months, whichever occurs first.❑Special Operating Conditions: 5,000 miles (8,000 km), 6 months or 200 hours of engine operation, see appropriate sched-

ule.

Motorcraft Premium Gold Engine Coolant change interval

❑5 years or 105,000 miles (170,000 km) - change Motorcraft Premium Gold Engine Coolant (whichever comes first)❑After initial change - change Motorcraft Premium Gold Engine Coolant every 3 years or 45,000 miles (72,000 km)

2006 Econoline (eco)

Supplement

USA (fus)

Scheduled Maintenance Guide

49