check engine light FORD SUPER DUTY 2006 1.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2006 1.GPages: 72, PDF Size: 0.57 MB

Page 7 of 72

Glow plug pre-heat indicator

With the key in the ON position,

the

light will illuminate if

glow plug heat is necessary as a

starting aid. Wait until the light goes

off before starting. The light should always illuminate briefly, when the

ignition key is in the ON position. If the light does not illuminate, there

may be a problem. Refer toCold weather startingin theDriving

chapter of this supplement. After the engine starts, the light should

remain off. The light should always illuminate at least momentarily when

the engine is cold and the ignition is turned to ON. If it does not

illuminate, the glow plug system should be checked and repaired

promptly to avoid difficulty in cold starting.

Waterinfuel

During refueling, it is possible for water-contaminated diesel fuel to be

pumped into your tank. Your vehicle fuel system is equipped with a fuel

filter/water separator to remove water from the fuel. The WATER IN

FUEL light will illuminate when the ignition is turned to START (as part

of the light function check) and when the FCM/HFCM has a significant

quantity of water in it.

Type A

Type B

Type C

If the light illuminates when the engine is running, stop the vehicle as

soon as safely possible, shut off the engine, then drain the FCM/HFCM.

Refer toDraining the FCM/HFCM and changing the fuel filtersin the

Maintenance and Specificationschapter of this supplement for the

drain procedure. Allowing water to stay in the system could result in

extensive damage to, or failure of, the fuel injection system.

2006 Econoline(eco)

Supplement

USA(fus)

Instrument Cluster

7

Page 9 of 72

AIR FILTER RESTRICTION GAUGE (IF EQUIPPED)

The restriction gauge, located on

the upper housing of the air cleaner

assembly, measures the vacuum

inside the air cleaner. The more the

air cleaner is restricted (dirty,

clogged), the higher the vacuum

reading

Check the air filter restriction gauge

whenever the hood is raised to

perform general engine maintenance

at least every 7,500 miles (12,000 km).

If the vehicle is operated in extremely dusty conditions, check the gauge

at least every 500 miles (800 km), or two weeks, whichever comes first.

Change the air filter when the gauge reads 25 inches (635 mm). Engine

performance and fuel economy are adversely affected when the

maximum restriction is reached.

Blowing-out the air filter element with compressed air is not

recommended as the compressed air may damage the filter paper.

Note:It is not possible to determine the level of filter clogging by visual

appearance alone. A filter which appears to be dirty may actually have

several thousand miles (kilometers) of life remaining.

Always use the underhood air filter restriction gauge to

determine when the air filter element needs to be changed. The

warning light on the instrument cluster should not be used

exclusively for determining when the air filter element needs

changing.

2006 Econoline(eco)

Supplement

USA(fus)

Instrument Cluster

9

Page 32 of 72

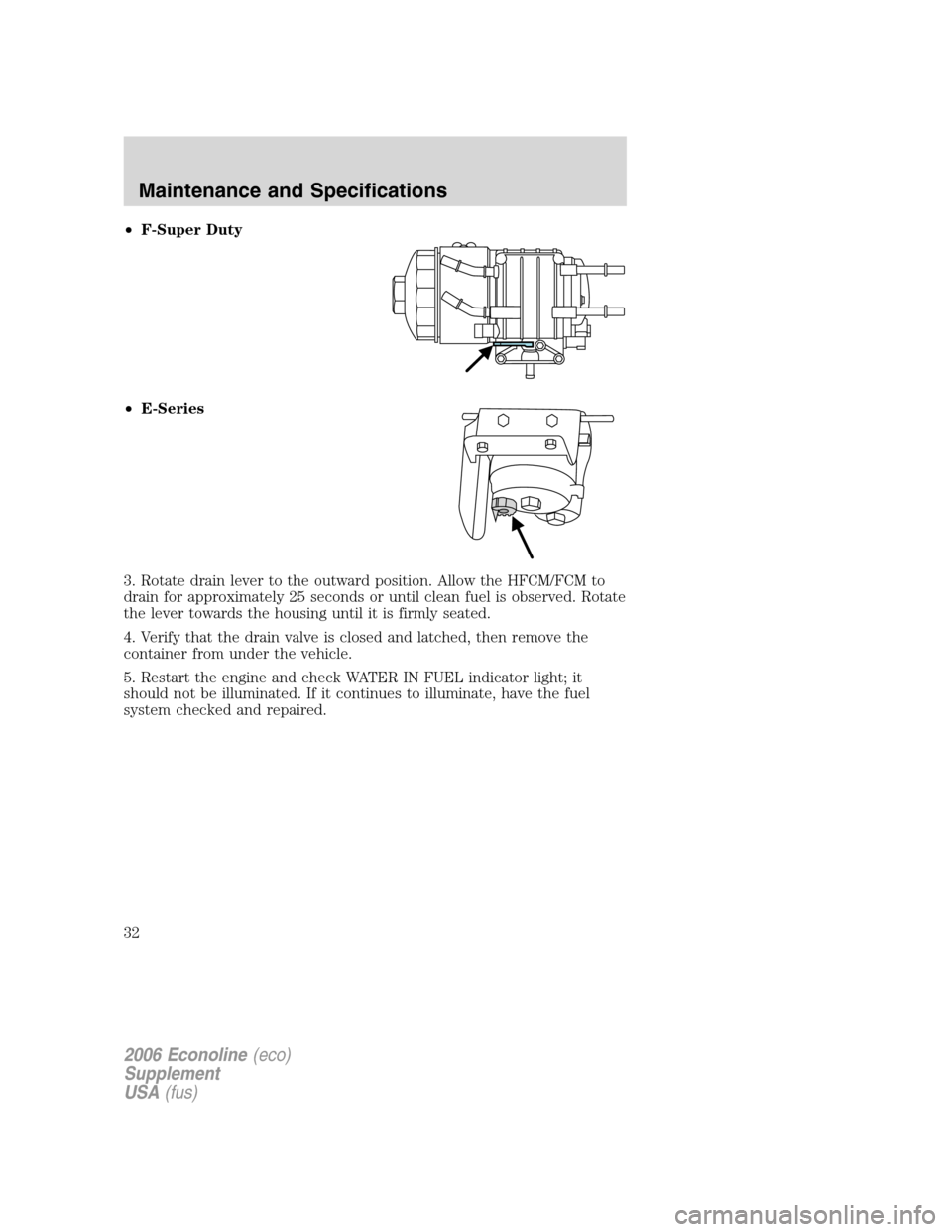

•F-Super Duty

•E-Series

3. Rotate drain lever to the outward position. Allow the HFCM/FCM to

drain for approximately 25 seconds or until clean fuel is observed. Rotate

the lever towards the housing until it is firmly seated.

4. Verify that the drain valve is closed and latched, then remove the

container from under the vehicle.

5. Restart the engine and check WATER IN FUEL indicator light; it

should not be illuminated. If it continues to illuminate, have the fuel

system checked and repaired.

2006 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

32

Page 43 of 72

If you fuel your vehicle at a truck stop, you may notice that the fuel

nozzle may shut off every 5–10 seconds. This is due to the flow rates

being designed for larger heavy duty trucks. You may have to fuel at a

slower rate (don’t depress the nozzle trigger fully).

Do not run your diesel vehicle out of fuel as this will allow air to enter

the fuel system which will make restarting difficult. Longer engine

cranking time may be required once air is in the fuel system. If air enters

the fuel system (either through running the fuel tank(s) empty or during

a fuel filter change), the engine will self-purge the trapped air once it

starts running. The engine may run roughly and produce white smoke

while air is in the fuel system; this is normal and should stop after a

short time.

MINOR TROUBLESHOOTING GUIDE

If the engine won’t crank

Turn on the headlights. If the lights are dim, do not go on at all or if

when the ignition is turned to 5 (START) the lights become dim or go

out, the battery connections may be loose or corroded, or the battery

may be discharged. If there is a clicking or stuttering sound coming from

the engine compartment when you turn the key to 5 (START), this may

also indicate a loose or corroded battery connection.

Check the battery connections at the battery posts, cable connection to

the engine grounding point and at the starter connection.

If a discharged battery is suspected, have it checked and corrected.

Battery posts, terminals and related accessories contain lead and

lead compounds.Wash hands after handling.

•For vehicles with manual transmissions,the clutch pedalmustbe

fully depressed in order for the starter to operate.

•For vehicles with automatic transmissions,the gearshift lever

must be in P (Park) or N (Neutral) in order for the starter to operate.

•Try operating the starter switch several times. Should the switch be

corroded, this operation may clean the contacts or make the switch

temporarily operable until you can reach the dealer.

•If all electrical connections are tight and you need assistance to start,

refer toJump startingin theRoadside Emergencieschapter of your

Owner’s Guide(F-Super Duty ) or refer to theJump starting

section in theRoadside Emergencieschapter of this supplement

(E-Series).

2006 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

43

Page 49 of 72

Genuine Ford and Motorcraft Replacement Parts

Ford and Lincoln Mercury dealerships stock Ford and Motorcraft

branded replacement parts. These parts meet or exceed Ford Motor

Company’s specifications, and we stand behind them. Maintenance parts

installed at your Ford or Lincoln Mercury dealership carry a nationwide,

12 months, 12,000 mile (19,500 km) parts and labor limited warranty.

Your dealer can give you details.

Value Shopping for Your Vehicle’s Maintenance Needs

Your dealership recognizes the competitive landscape of maintenance and

light repair automotive services. With factory-trained technicians, and

one-stop service from routine maintenance like oil changes and tire

rotations to repairs like brake service, check out the value your Ford and

Lincoln Mercury dealers can offer.

WHICH MAINTENANCE SCHEDULE SHOULD YOU FOLLOW?

Owner Checks and Services

Refer to Mileage Intervals for Additional Checks and Services

Certain basic maintenance checks and inspections should be performed

by the owner or a service technician at the intervals indicated. Service

information and supporting specifications are provided in theOwner’s

Guide .

Any adverse condition should be brought to the attention of your dealer

or qualified service technician as soon as possible for the proper service

advice. The owner maintenance service checks are generally not covered

by warranties so you may be charged for labor, parts or lubricants used.

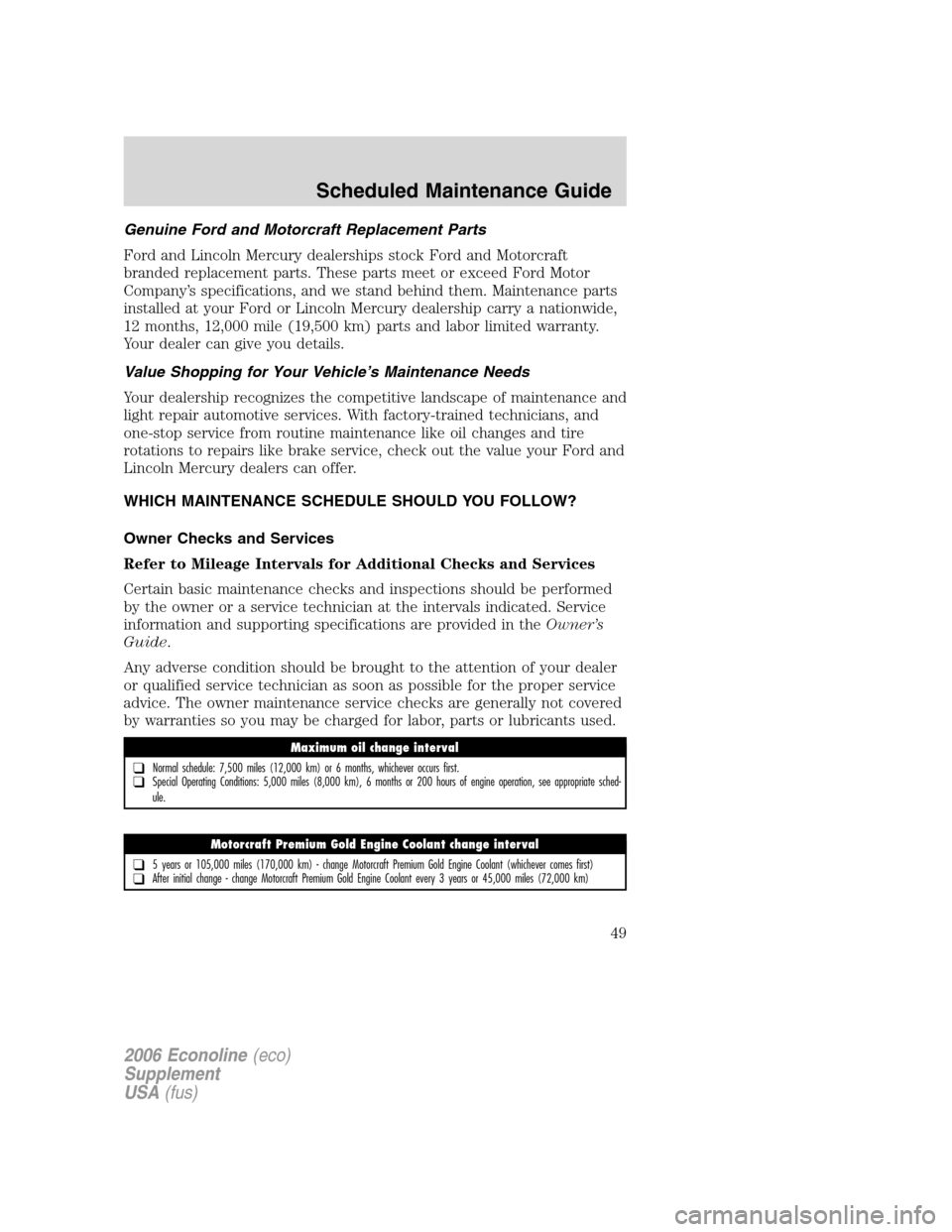

Maximum oil change interval

❑Normal schedule: 7,500 miles (12,000 km) or 6 months, whichever occurs first.❑Special Operating Conditions: 5,000 miles (8,000 km), 6 months or 200 hours of engine operation, see appropriate sched-

ule.

Motorcraft Premium Gold Engine Coolant change interval

❑5 years or 105,000 miles (170,000 km) - change Motorcraft Premium Gold Engine Coolant (whichever comes first)❑After initial change - change Motorcraft Premium Gold Engine Coolant every 3 years or 45,000 miles (72,000 km)

2006 Econoline (eco)

Supplement

USA (fus)

Scheduled Maintenance Guide

49

Page 50 of 72

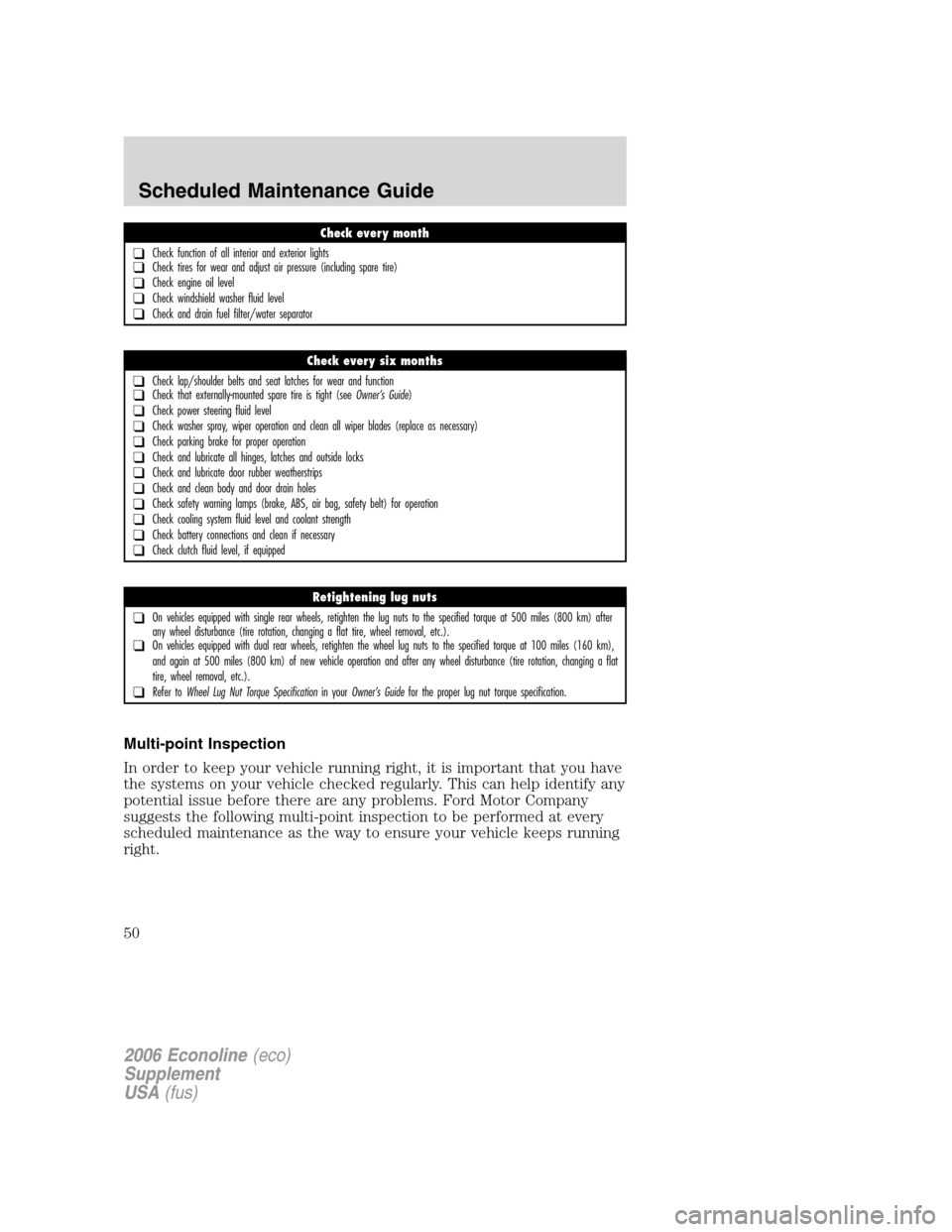

Multi-point Inspection

In order to keep your vehicle running right, it is important that you have

the systems on your vehicle checked regularly. This can help identify any

potential issue before there are any problems. Ford Motor Company

suggests the following multi-point inspection to be performed at every

scheduled maintenance as the way to ensure your vehicle keeps running

right.

Check every month

❑Check function of all interior and exterior lights❑Check tires for wear and adjust air pressure (including spare tire)

❑Check engine oil level

❑Check windshield washer fluid level

❑Check and drain fuel filter/water separator

Check every six months

❑Check lap/shoulder belts and seat latches for wear and function❑Check that externally-mounted spare tire is tight (seeOwner’s Guide)

❑Check power steering fluid level

❑Check washer spray, wiper operation and clean all wiper blades (replace as necessary)

❑Check parking brake for proper operation

❑Check and lubricate all hinges, latches and outside locks

❑Check and lubricate door rubber weatherstrips

❑Check and clean body and door drain holes

❑Check safety warning lamps (brake, ABS, air bag, safety belt) for operation

❑Check cooling system fluid level and coolant strength

❑Check battery connections and clean if necessary

❑Check clutch fluid level, if equipped

Retightening lug nuts

❑On vehicles equipped with single rear wheels, retighten the lug nuts to the specified torque at 500 miles (800 km) after

any wheel disturbance (tire rotation, changing a flat tire, wheel removal, etc.).

❑On vehicles equipped with dual rear wheels, retighten the wheel lug nuts to the specified torque at 100 miles (160 km),

and again at 500 miles (800 km) of new vehicle operation and after any wheel disturbance (tire rotation, changing a flat

tire, wheel removal, etc.).

❑Refer toWheel Lug Nut Torque Specificationin yourOwner’s Guidefor the proper lug nut torque specification.

2006 Econoline (eco)

Supplement

USA (fus)

Scheduled Maintenance Guide

50

Page 51 of 72

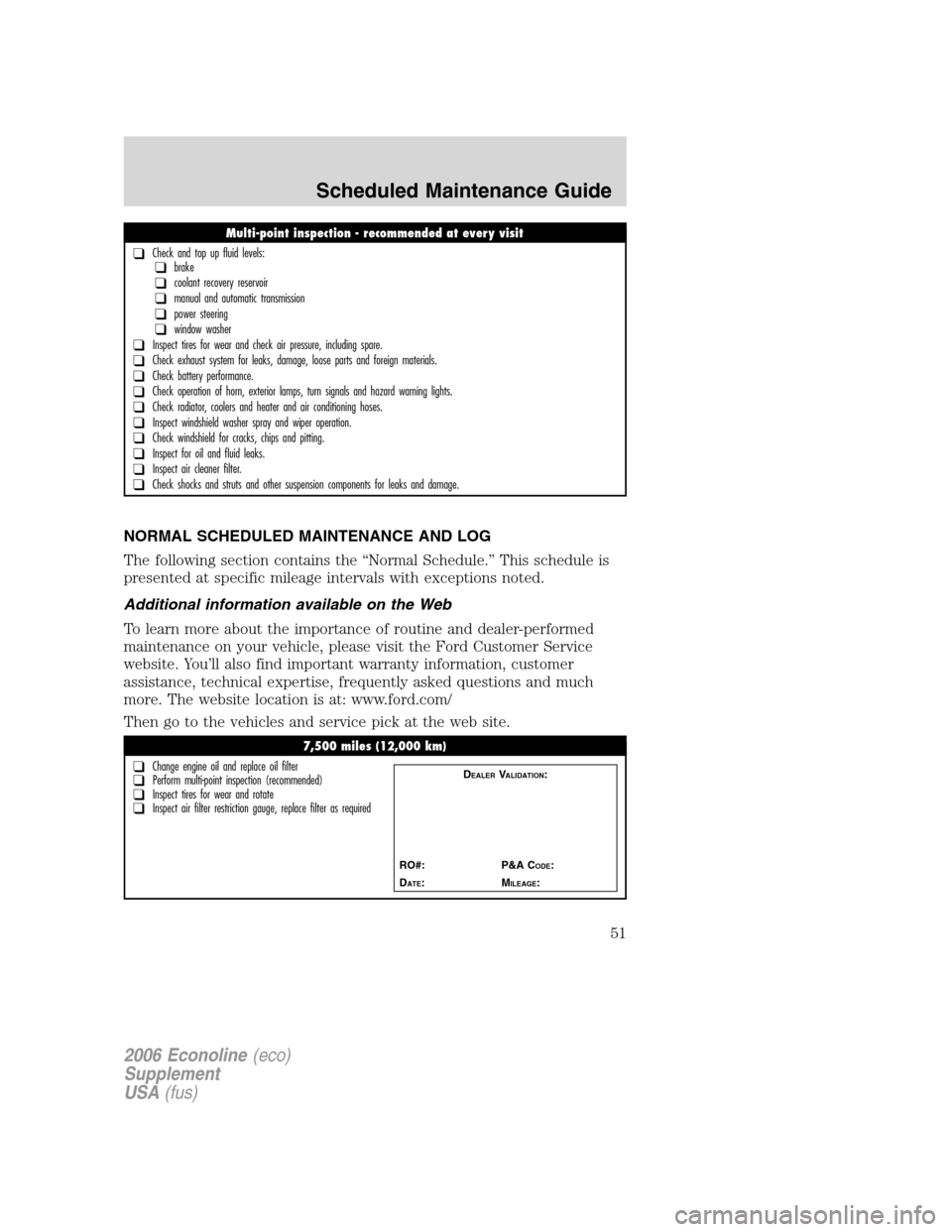

NORMAL SCHEDULED MAINTENANCE AND LOG

The following section contains the “Normal Schedule.” This schedule is

presented at specific mileage intervals with exceptions noted.

Additional information available on the Web

To learn more about the importance of routine and dealer-performed

maintenance on your vehicle, please visit the Ford Customer Service

website. You’ll also find important warranty information, customer

assistance, technical expertise, frequently asked questions and much

more. The website location is at: www.ford.com/

Then go to the vehicles and service pick at the web site.

Multi-point inspection - recommended at every visit

❑Check and top up fluid levels:❑brake

❑coolant recovery reservoir

❑manual and automatic transmission

❑power steering

❑window washer

❑Inspect tires for wear and check air pressure, including spare.

❑Check exhaust system for leaks, damage, loose parts and foreign materials.

❑Check battery performance.

❑Check operation of horn, exterior lamps, turn signals and hazard warning lights.

❑Check radiator, coolers and heater and air conditioning hoses.

❑Inspect windshield washer spray and wiper operation.

❑Check windshield for cracks, chips and pitting.

❑Inspect for oil and fluid leaks.

❑Inspect air cleaner filter.

❑Check shocks and struts and other suspension components for leaks and damage.

7,500 miles (12,000 km)

❑Change engine oil and replace oil filter❑Perform multi-point inspection (recommended)❑Inspect tires for wear and rotate❑Inspect air filter restriction gauge, replace filter as required

DEALERVALIDATION:

RO#: P&A C

ODE:

D

ATE:MILEAGE:

2006 Econoline (eco)

Supplement

USA (fus)

Scheduled Maintenance Guide

51

Page 59 of 72

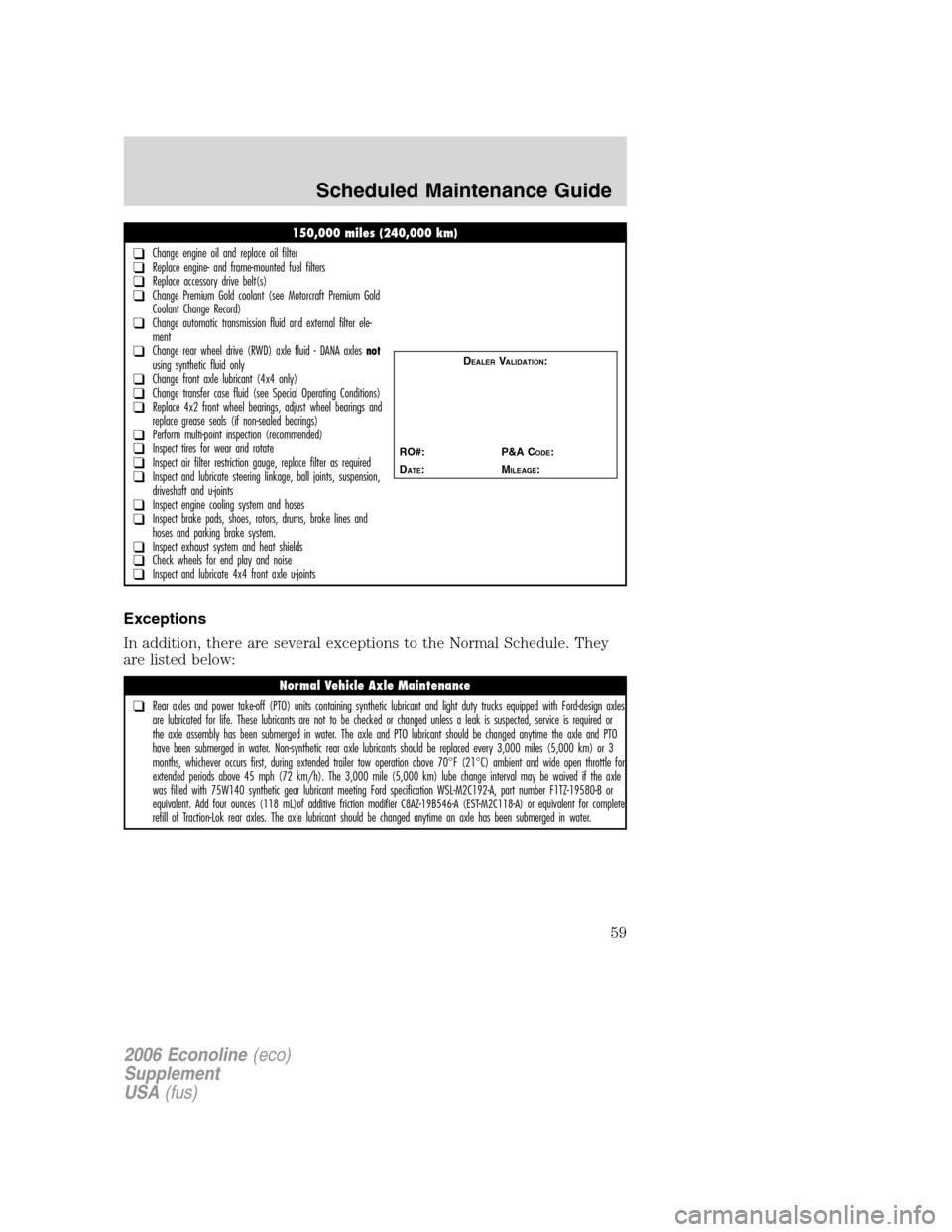

Exceptions

In addition, there are several exceptions to the Normal Schedule. They

are listed below:

150,000 miles (240,000 km)

❑Change engine oil and replace oil filter❑Replace engine- and frame-mounted fuel filters❑Replace accessory drive belt(s)❑Change Premium Gold coolant (see Motorcraft Premium Gold

Coolant Change Record)

❑Change automatic transmission fluid and external filter ele-

ment

❑Change rear wheel drive (RWD) axle fluid - DANA axles not

using synthetic fluid only

❑Change front axle lubricant (4x4 only)❑Change transfer case fluid (see Special Operating Conditions)❑Replace 4x2 front wheel bearings, adjust wheel bearings and

replace grease seals (if non-sealed bearings)

❑Perform multi-point inspection (recommended)❑Inspect tires for wear and rotate❑Inspect air filter restriction gauge, replace filter as required❑Inspect and lubricate steering linkage, ball joints, suspension,

driveshaft and u-joints

❑Inspect engine cooling system and hoses❑Inspect brake pads, shoes, rotors, drums, brake lines and

hoses and parking brake system.

❑Inspect exhaust system and heat shields❑Check wheels for end play and noise❑Inspect and lubricate 4x4 front axle u-joints

DEALERVALIDATION:

RO#: P&A C

ODE:

D

ATE:MILEAGE:

Normal Vehicle Axle Maintenance

❑Rear axles and power take-off (PTO) units containing synthetic lubricant and light duty trucks equipped with Ford-design axles

are lubricated for life. These lubricants are not to be checked or changed unless a leak is suspected, service is required or

the axle assembly has been submerged in water. The axle and PTO lubricant should be changed anytime the axle and PTO

have been submerged in water. Non-synthetic rear axle lubricants should be replaced every 3,000 miles (5,000 km) or 3

months, whichever occurs first, during extended trailer tow operation above 70°F (21°C) ambient and wide open throttle for

extended periods above 45 mph (72 km/h). The 3,000 mile (5,000 km) lube change interval may be waived if the axle

was filled with 75W140 synthetic gear lubricant meeting Ford specification WSL-M2C192-A, part number F1TZ-19580-B or

equivalent. Add four ounces (118 mL)of additive friction modifier C8AZ-19B546-A (EST-M2C118-A) or equivalent for complete

refill of Traction-Lok rear axles. The axle lubricant should be changed anytime an axle has been submerged in water.

2006 Econoline (eco)

Supplement

USA (fus)

Scheduled Maintenance Guide

59