stop start FORD SUPER DUTY 2006 1.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2006 1.GPages: 72, PDF Size: 0.57 MB

Page 7 of 72

Glow plug pre-heat indicator

With the key in the ON position,

the

light will illuminate if

glow plug heat is necessary as a

starting aid. Wait until the light goes

off before starting. The light should always illuminate briefly, when the

ignition key is in the ON position. If the light does not illuminate, there

may be a problem. Refer toCold weather startingin theDriving

chapter of this supplement. After the engine starts, the light should

remain off. The light should always illuminate at least momentarily when

the engine is cold and the ignition is turned to ON. If it does not

illuminate, the glow plug system should be checked and repaired

promptly to avoid difficulty in cold starting.

Waterinfuel

During refueling, it is possible for water-contaminated diesel fuel to be

pumped into your tank. Your vehicle fuel system is equipped with a fuel

filter/water separator to remove water from the fuel. The WATER IN

FUEL light will illuminate when the ignition is turned to START (as part

of the light function check) and when the FCM/HFCM has a significant

quantity of water in it.

Type A

Type B

Type C

If the light illuminates when the engine is running, stop the vehicle as

soon as safely possible, shut off the engine, then drain the FCM/HFCM.

Refer toDraining the FCM/HFCM and changing the fuel filtersin the

Maintenance and Specificationschapter of this supplement for the

drain procedure. Allowing water to stay in the system could result in

extensive damage to, or failure of, the fuel injection system.

2006 Econoline(eco)

Supplement

USA(fus)

Instrument Cluster

7

Page 12 of 72

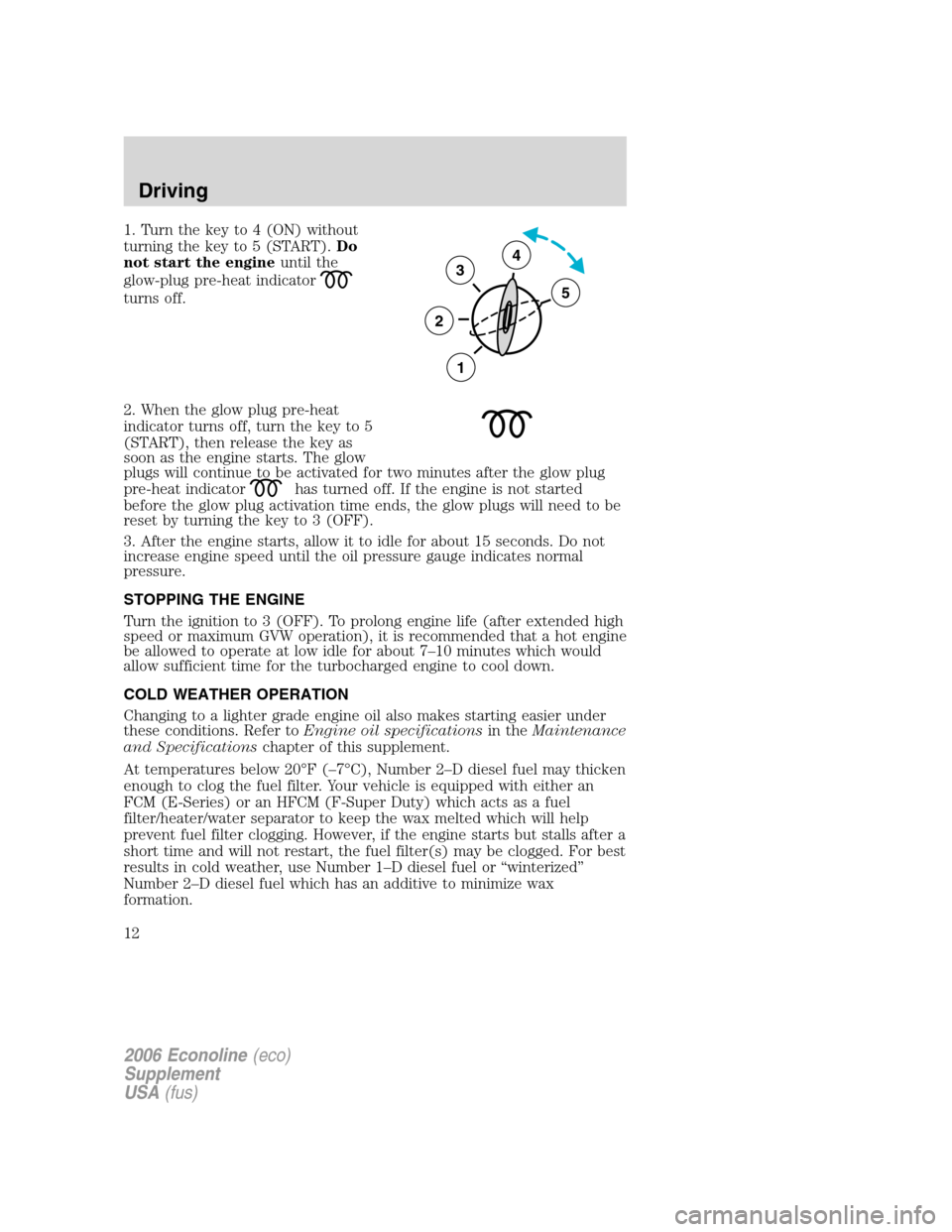

1. Turn the key to 4 (ON) without

turning the key to 5 (START).Do

not start the engineuntil the

glow-plug pre-heat indicator

turns off.

2. When the glow plug pre-heat

indicator turns off, turn the key to 5

(START), then release the key as

soon as the engine starts. The glow

plugs will continue to be activated for two minutes after the glow plug

pre-heat indicator

has turned off. If the engine is not started

before the glow plug activation time ends, the glow plugs will need to be

reset by turning the key to 3 (OFF).

3. After the engine starts, allow it to idle for about 15 seconds. Do not

increase engine speed until the oil pressure gauge indicates normal

pressure.

STOPPING THE ENGINE

Turn the ignition to 3 (OFF). To prolong engine life (after extended high

speed or maximum GVW operation), it is recommended that a hot engine

be allowed to operate at low idle for about 7–10 minutes which would

allow sufficient time for the turbocharged engine to cool down.

COLD WEATHER OPERATION

Changing to a lighter grade engine oil also makes starting easier under

these conditions. Refer toEngine oil specificationsin theMaintenance

and Specificationschapter of this supplement.

At temperatures below 20°F (–7°C), Number 2–D diesel fuel may thicken

enough to clog the fuel filter. Your vehicle is equipped with either an

FCM (E-Series) or an HFCM (F-Super Duty) which acts as a fuel

filter/heater/water separator to keep the wax melted which will help

prevent fuel filter clogging. However, if the engine starts but stalls after a

short time and will not restart, the fuel filter(s) may be clogged. For best

results in cold weather, use Number 1–D diesel fuel or “winterized”

Number 2–D diesel fuel which has an additive to minimize wax

formation.

3

2

1

5

4

2006 Econoline(eco)

Supplement

USA(fus)

Driving

12

Page 29 of 72

2. Carefully turn the filler cap counterclockwise until it stops.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise until a few clicks are heard.

If the “Check Fuel Cap” message comes on and stays on after you start

the engine, the fuel filler cap may not be properly installed. Turn off the

engine, remove the fuel filler cap, align the cap properly and reinstall it.

If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The customer warranty may

be void for any damage to the fuel tank or fuel system if the

correct genuine Ford or Motorcraft fuel filler cap is not used.

The fuel system may be under pressure. If the fuel filler cap is

venting vapor or if you hear a hissing sound, wait until it stops

before completely removing the fuel filler cap. Otherwise, fuel may

spray out and injure you or others.

If you do not use the proper fuel filler cap, excessive pressure or

vacuum in the fuel tank may damage the fuel system or cause

the fuel cap to disengage in a collision, which may result in possible

personal injury.

Fuel quality

It should not be necessary to add any aftermarket additives to your fuel

tank if you use a properly formulated diesel fuel that meets the ASTM D

975 industry specification. Aftermarket additives can damage the injector

system or engine. Repairs to correct the effects of using an aftermarket

product in your fuel may not be covered by your warranty.

Do not blend used engine oil with diesel fuel under any

circumstances.Blending used oil with the fuel will significantly increase

your vehicle’s exhaust emissions and reduce engine life due to increased

internal wear.

Many of the world’s automakers approved the World-wide Fuel Charter

that recommends diesel fuel specifications to provide improved

performance and emission control system protection for your vehicle.

Diesel fuel that meets the World-wide Fuel Charter should be used when

available. Ask your fuel supplier about fuel that meets the World-wide

Fuel Charter.

2006 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

29

Page 30 of 72

Fueling tips

If the engine fails to start in 30 seconds, turn the key to the OFF

position and wait 30 seconds before trying again.

Truck stops have pumps and nozzles designed for larger, heavy-duty

trucks. When refueling at truck stops: if the nozzle shuts off repeatedly

when refueling, wait 5–10 seconds; then use a slower rate of flow (don’t

depress the nozzle trigger as far).

If air is allowed to enter the fuel system (during fuel filter change or if

you run out of fuel) the engine will purge the trapped air as it runs. The

engine may run rough and produce white smoke while air is in the

system. This is normal and should correct itself in a short time.

An engine that suddenly becomes noisy or operates poorly after a fuel fill

could be using substandard fuel (i.e., high water content, low cetane

rating or gasoline in the fuel). Diesel fuel should be purchased from a

reputable station which sells a large amount of diesel fuel.

Care should be taken whenever diesel fuel is stored. Use only clean,

approved containers which will prevent the entry of dirt or water.

Diesel fuel must not be stored in a galvanized container. The fuel will

dissolve the zinc in a galvanized container. The zinc will then remain in

solution until it is run through the engine where it will be deposited in

the fuel injectors causing expensive-to-repair damage.

Diesel fuel dispensing nozzle fill rate

This truck is equipped with a fuel fill pipe which is able to accept fuel up

to 20 gallons per minute from an 1 1/8 inch fuel dispensing nozzle.

Pumping fuel at greater flow rates may result in premature nozzle

shut-off or spitback.

FUEL CONDITIONER MODULE (FCM - E-SERIES)/HORIZONTAL

FUEL CONDITIONING MODULE (HFCM - F-SUPER DUTY - FUEL

FILTER/WATER SEPARATOR

HFCM - F-Super Duty

The vehicle is equipped with a Horizontal Fuel Conditioning Module

(HFCM) located on the frame-rail under the driver-side floorboard near

the transmission.

2006 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

30

Page 43 of 72

If you fuel your vehicle at a truck stop, you may notice that the fuel

nozzle may shut off every 5–10 seconds. This is due to the flow rates

being designed for larger heavy duty trucks. You may have to fuel at a

slower rate (don’t depress the nozzle trigger fully).

Do not run your diesel vehicle out of fuel as this will allow air to enter

the fuel system which will make restarting difficult. Longer engine

cranking time may be required once air is in the fuel system. If air enters

the fuel system (either through running the fuel tank(s) empty or during

a fuel filter change), the engine will self-purge the trapped air once it

starts running. The engine may run roughly and produce white smoke

while air is in the fuel system; this is normal and should stop after a

short time.

MINOR TROUBLESHOOTING GUIDE

If the engine won’t crank

Turn on the headlights. If the lights are dim, do not go on at all or if

when the ignition is turned to 5 (START) the lights become dim or go

out, the battery connections may be loose or corroded, or the battery

may be discharged. If there is a clicking or stuttering sound coming from

the engine compartment when you turn the key to 5 (START), this may

also indicate a loose or corroded battery connection.

Check the battery connections at the battery posts, cable connection to

the engine grounding point and at the starter connection.

If a discharged battery is suspected, have it checked and corrected.

Battery posts, terminals and related accessories contain lead and

lead compounds.Wash hands after handling.

•For vehicles with manual transmissions,the clutch pedalmustbe

fully depressed in order for the starter to operate.

•For vehicles with automatic transmissions,the gearshift lever

must be in P (Park) or N (Neutral) in order for the starter to operate.

•Try operating the starter switch several times. Should the switch be

corroded, this operation may clean the contacts or make the switch

temporarily operable until you can reach the dealer.

•If all electrical connections are tight and you need assistance to start,

refer toJump startingin theRoadside Emergencieschapter of your

Owner’s Guide(F-Super Duty ) or refer to theJump starting

section in theRoadside Emergencieschapter of this supplement

(E-Series).

2006 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

43