FORD SUPER DUTY 2006 1.G Special Off-Road Package Supplement Manual

Manufacturer: FORD, Model Year: 2006, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2006 1.GPages: 28, PDF Size: 0.22 MB

Page 11 of 28

9. Slowly wind the wire rope until no slack remains by using the winch

switch. Once the wire rope is under tension, stand clear and never step

over it.

10. Check the anchor point. Make sure all connections are secured and

free of debris before continuing with the winching procedure.

Never use the winch as a hoist. Never use the winch's wire rope

to tow another vehicle.

11. Check the wire rope. It should be neatly wound around the drum.

Improper winding can cause damage to the wire rope.

12. Lay something over the wire rope to absorb energy should the rope

snap. Tree limbs, heavy jackets, chain and the like may be used for this

purpose.

Note:Always avoid continuous side pulls which can pile up wire rope at

one end of the drum. This pile can damage the wire rope or the winch.

13. Make sure everyone in the immediate area is aware of the winching

operation. Tell them where they shouldn't stand; never behind or in front

of the vehicle and never near the wire rope.

14. With the vehicle's engine on and light tension on the wire rope, begin

winching slowly and steadily. Be sure the wire rope is winding evenly

and tightly around the drum. For assistance, the winched vehicle can be

slowly driven while being pulled by the winch.

Note:Avoid overheating of the winch motor. For extended winching,

stop at reasonable intervals to allow the winch motor to cool down.

What to look for under load

The wire rope must always spool onto the drum as indicated by the

drum rotation decal on the winch. As you power in, make sure the rope

winds evenly and tightly on the drum. This prevents the outer wrap from

drawing into the inner wraps, binding and damaging the rope. Avoid

shock loads by using the control switch intermittently to take up wire

rope slack. During side pulls, the wire rope tends to stack up at one end

of the drum. This stack can become large enough to cause serious

damage to the winch. Line up pulls as straight as possible and stop

winching if the wire rope comes close to the tie rods or mounting plate.

Note:To fix an uneven stack, spool out that section of the rope and

reposition it to the opposite end of the drum; this will free up space for

continued winching.

15. For vehicle recovery, continue pulling until the vehicle is on stable

ground. If the vehicle is able to be driven, the winching operation is

complete.

Driver Controls

11

Page 12 of 28

16. Once recovery of the vehicle is complete, be sure to secure the

vehicle's brakes and put the transmission in P (Park) (automatic

transmission) or 1 (First) (manual transmission). Release tension in the

wire rope.

17. Disconnect the wire rope from the anchor.

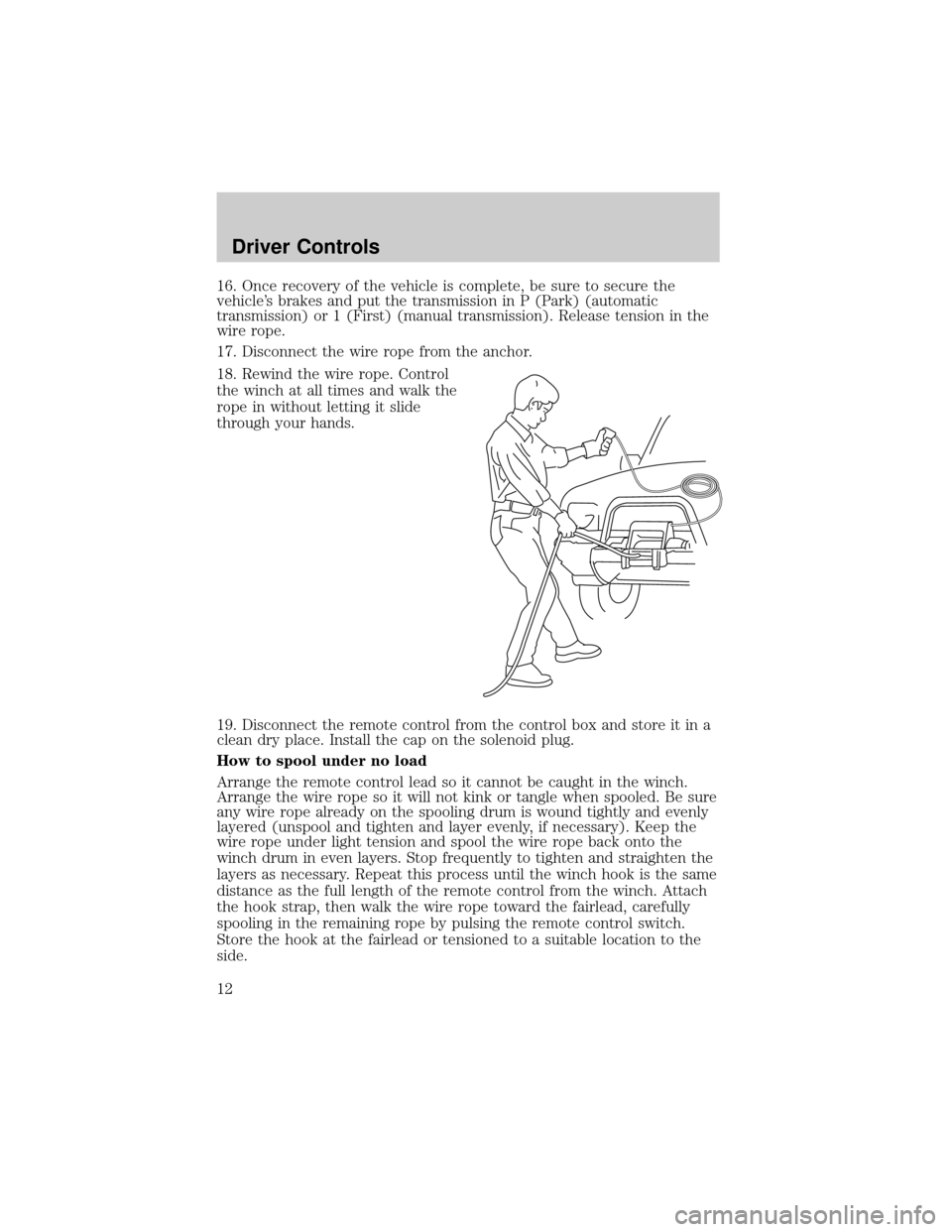

18. Rewind the wire rope. Control

the winch at all times and walk the

rope in without letting it slide

through your hands.

19. Disconnect the remote control from the control box and store it in a

clean dry place. Install the cap on the solenoid plug.

How to spool under no load

Arrange the remote control lead so it cannot be caught in the winch.

Arrange the wire rope so it will not kink or tangle when spooled. Be sure

any wire rope already on the spooling drum is wound tightly and evenly

layered (unspool and tighten and layer evenly, if necessary). Keep the

wire rope under light tension and spool the wire rope back onto the

winch drum in even layers. Stop frequently to tighten and straighten the

layers as necessary. Repeat this process until the winch hook is the same

distance as the full length of the remote control from the winch. Attach

the hook strap, then walk the wire rope toward the fairlead, carefully

spooling in the remaining rope by pulsing the remote control switch.

Store the hook at the fairlead or tensioned to a suitable location to the

side.

Driver Controls

12

Page 13 of 28

If you do not have the hook strap, use a length of cord or something

similar.

To help prevent serious injury,neverput your fingers inside the

hook area as you are powering in.

Rigging techniques

Various winching situations will require unique winching techniques.

These could range from too little distance to achieve maximum pull

using straight line rigging, simply increasing pulling power or maintaining

a straight-line pulling situation.

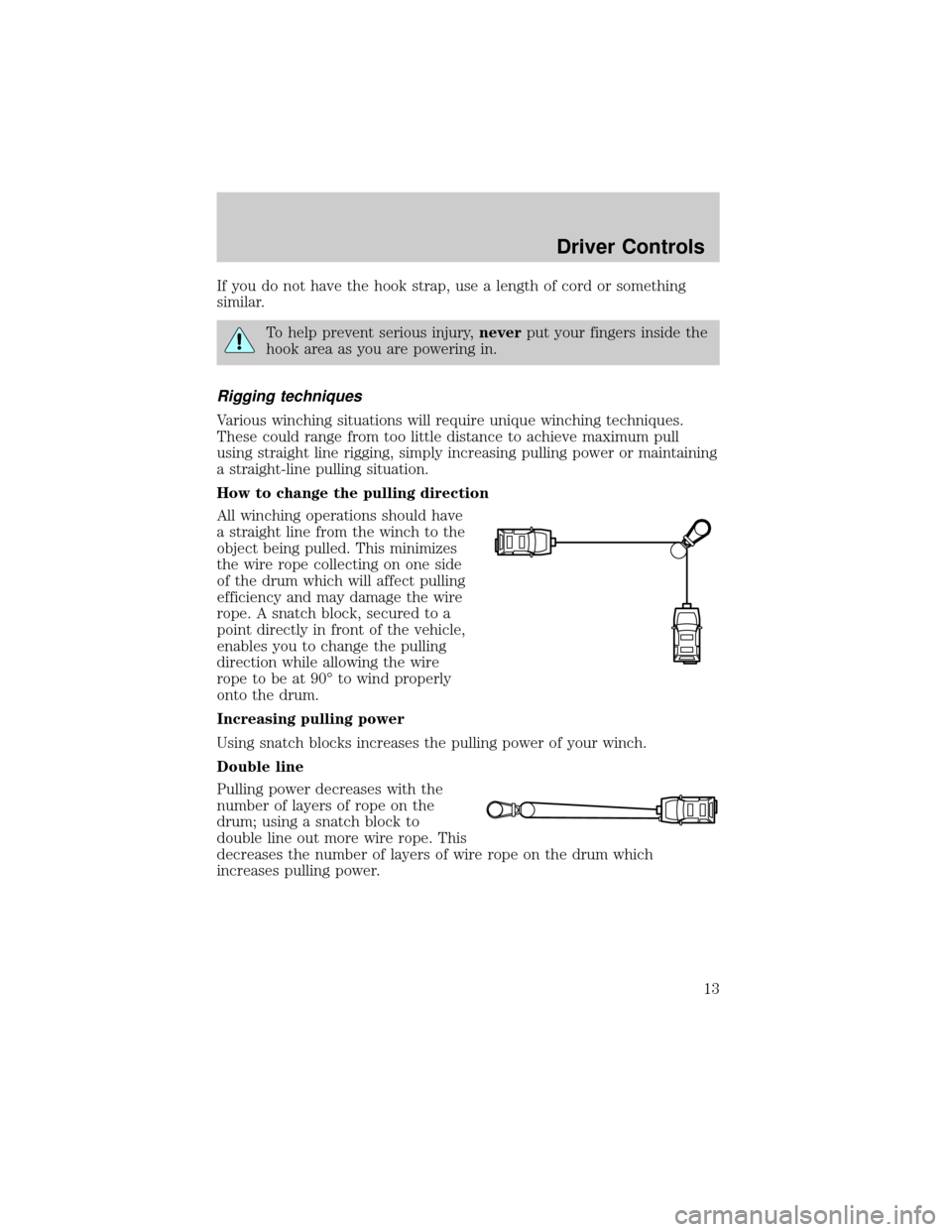

How to change the pulling direction

All winching operations should have

a straight line from the winch to the

object being pulled. This minimizes

the wire rope collecting on one side

of the drum which will affect pulling

efficiency and may damage the wire

rope. A snatch block, secured to a

point directly in front of the vehicle,

enables you to change the pulling

direction while allowing the wire

rope to be at 90É to wind properly

onto the drum.

Increasing pulling power

Using snatch blocks increases the pulling power of your winch.

Double line

Pulling power decreases with the

number of layers of rope on the

drum; using a snatch block to

double line out more wire rope. This

decreases the number of layers of wire rope on the drum which

increases pulling power.

Driver Controls

13

Page 14 of 28

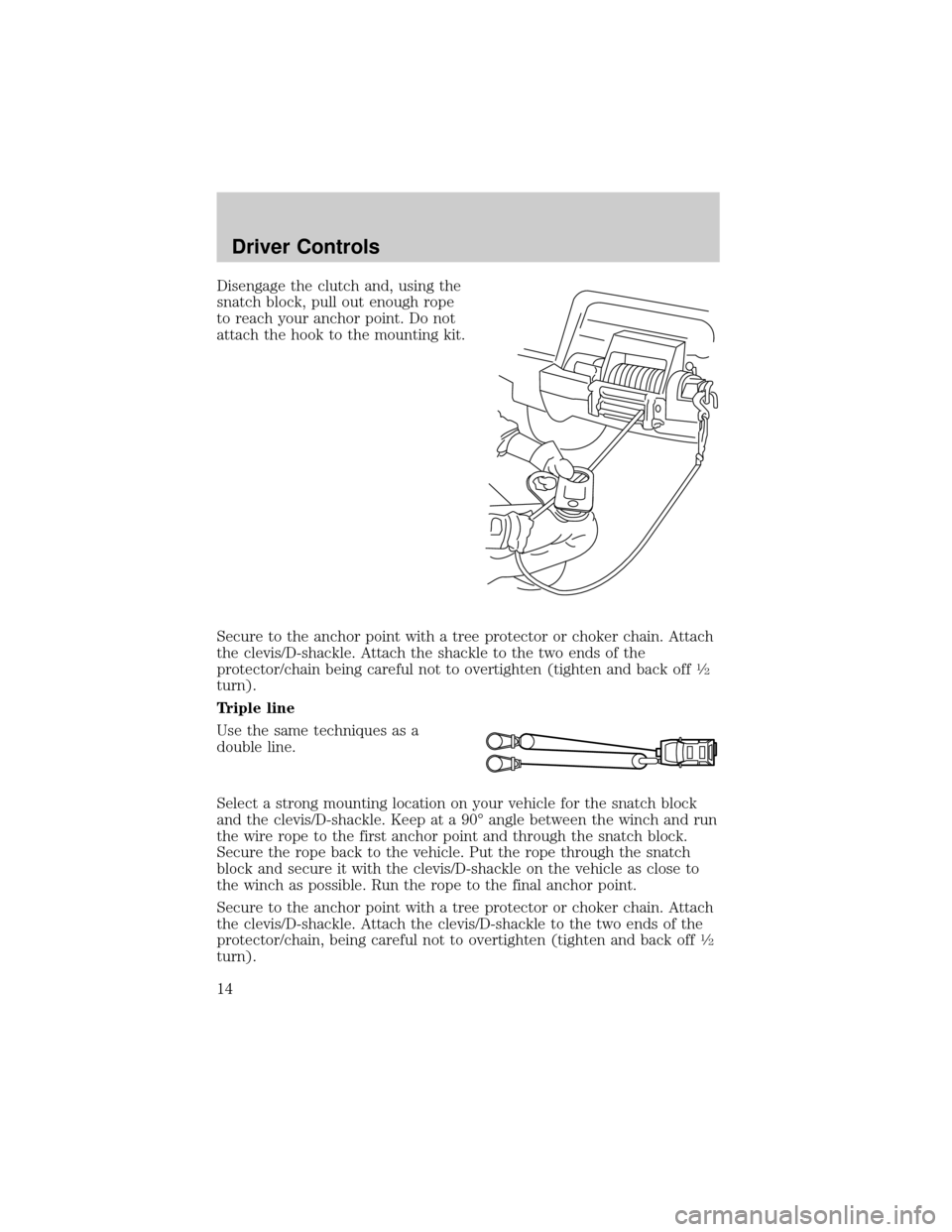

Disengage the clutch and, using the

snatch block, pull out enough rope

to reach your anchor point. Do not

attach the hook to the mounting kit.

Secure to the anchor point with a tree protector or choker chain. Attach

the clevis/D-shackle. Attach the shackle to the two ends of the

protector/chain being careful not to overtighten (tighten and back off

1¤2

turn).

Triple line

Use the same techniques as a

double line.

Select a strong mounting location on your vehicle for the snatch block

and the clevis/D-shackle. Keep at a 90É angle between the winch and run

the wire rope to the first anchor point and through the snatch block.

Secure the rope back to the vehicle. Put the rope through the snatch

block and secure it with the clevis/D-shackle on the vehicle as close to

the winch as possible. Run the rope to the final anchor point.

Secure to the anchor point with a tree protector or choker chain. Attach

the clevis/D-shackle. Attach the clevis/D-shackle to the two ends of the

protector/chain, being careful not to overtighten (tighten and back off

1¤2

turn).

Driver Controls

14

Page 15 of 28

Secure the winch hook. While keeping the line near the ground, insert

the winch hook through the clevis/D-shackle. Check the anchor. Make

sure all connections are secured and free of debris before continuing

with the winching procedure.

Maintenance

²Inspect the wire rope before and after each winching operation. If the

wire rope has become kinked or frayed, it needs to be replaced. Be

sure to also inspect the winch hook and hook pin for signs of wear or

damage. Replace as necessary.

²Keep winch, wire rope and switch control free from contaminants. Use

a clean rag or towel to remove any dirt and debris. If necessary,

unwind the winch completely (leaving a minimum of five wraps of

rope on the drum) and wipe it clean before rewinding it. Using a light

oil on the rope and winch hook can keep rust and corrosion from

forming.

²Operating the winch for an extended period of time places an

additional load on your vehicle battery. Be sure to check and maintain

your battery and battery cables according to manufacturer guidelines.

Also, inspect the switch control and all electrical connections to be

certain they are clean and tight fitting.

²Inspect the remote control, if so equipped, for damage. Be sure to cap

the remote socket to prevent dirt and debris from entering the

connections. Store the remote control in a dry, protected area.

²No lubrication is required for the life of the winch.

Driver Controls

15

Page 16 of 28

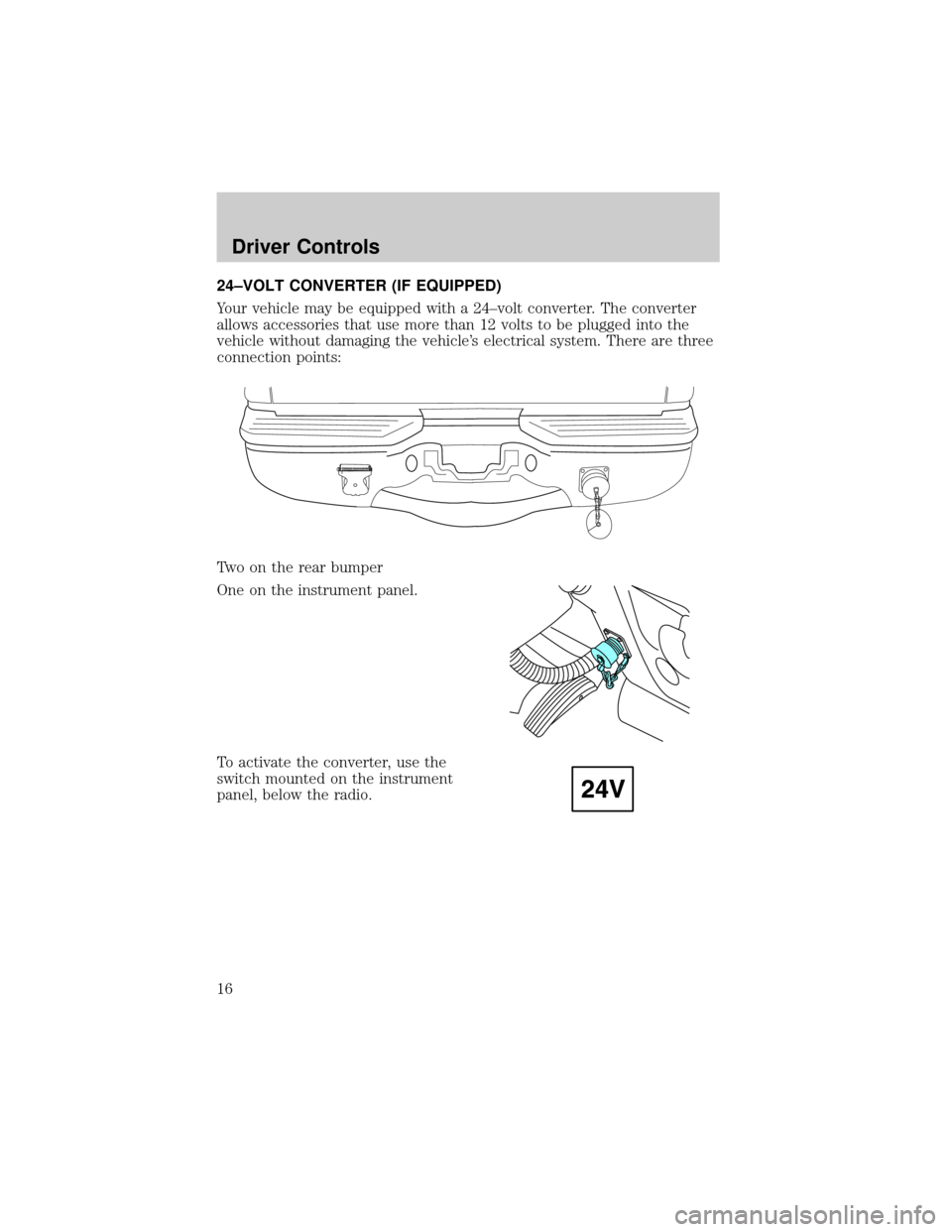

24±VOLT CONVERTER (IF EQUIPPED)

Your vehicle may be equipped with a 24±volt converter. The converter

allows accessories that use more than 12 volts to be plugged into the

vehicle without damaging the vehicle's electrical system. There are three

connection points:

Two on the rear bumper

One on the instrument panel.

To activate the converter, use the

switch mounted on the instrument

panel, below the radio.

Driver Controls

16

Page 17 of 28

AIRBAGS

Refer to the label on the front of the sun visors regarding airbag and

seatbelt usage.

This vehicle is not equipped with airbags. Always wear your

seatbelt.

Safety Restraints

17

Page 18 of 28

ANTI-LOCK BRAKE SYSTEM (ABS) DEACTIVATION IN 4WD

(IF EQUIPPED)

Refer to the label on the back of the sun visor mirror regarding Anti-lock

Brake System (ABS) operation.

Your vehicle may be equipped with a feature that deactivates the

Anti-lock Brake System (ABS) when 4WD Low is engaged. The ABS

indicator (

ABS) illuminates, to indicate that ABS is deactivated, and

stays on as long as 4WD Low is engaged.

When 4WD Low is disengaged, the ABS light turns off and the system is

active again.

SUSPENSION UPGRADE PACKAGE

Your vehicle is equipped with a special suspension package that will

enhance the vehicle's off-road performance. The vehicle will handle

differently, both on and off-road, from a factory-equipped passenger car

or truck.

Vehicles with a higher center of gravity such as utility and

four-wheel drive vehicles handle differently than vehicles with a

lower center of gravity. Utility and four-wheel drive vehicles are not

designed for cornering at speeds as high as passenger cars any more

than low-slung sports cars are designed to perform satisfactorily under

off-road conditions. Avoid sharp turns, excessive speed and abrupt

maneuvers in these vehicles. Failure to drive cautiously could result in

an increased risk of loss of vehicle control, vehicle rollover, personal

injury and death.

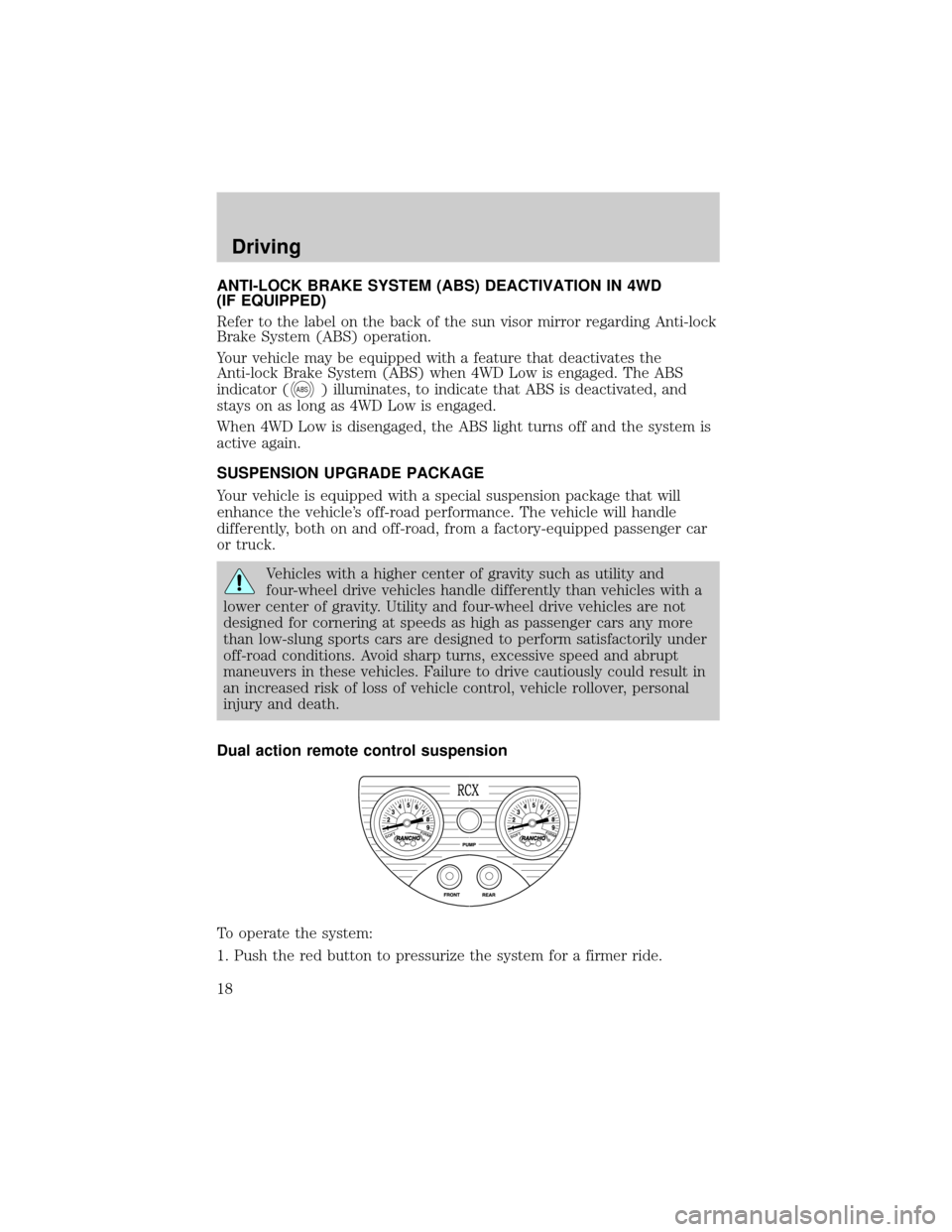

Dual action remote control suspension

To operate the system:

1. Push the red button to pressurize the system for a firmer ride.

Driving

18

Page 19 of 28

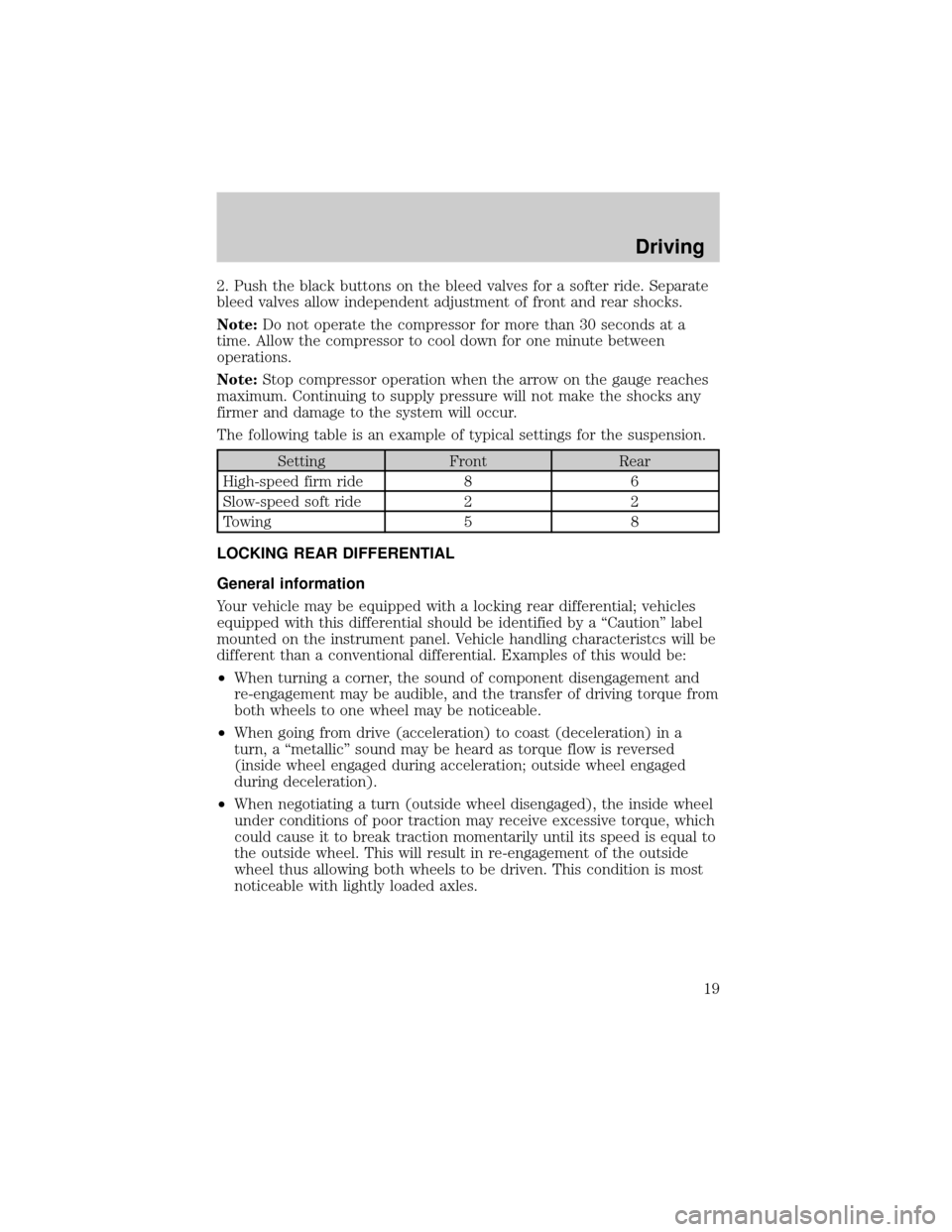

2. Push the black buttons on the bleed valves for a softer ride. Separate

bleed valves allow independent adjustment of front and rear shocks.

Note:Do not operate the compressor for more than 30 seconds at a

time. Allow the compressor to cool down for one minute between

operations.

Note:Stop compressor operation when the arrow on the gauge reaches

maximum. Continuing to supply pressure will not make the shocks any

firmer and damage to the system will occur.

The following table is an example of typical settings for the suspension.

Setting Front Rear

High-speed firm ride 8 6

Slow-speed soft ride 2 2

Towing 5 8

LOCKING REAR DIFFERENTIAL

General information

Your vehicle may be equipped with a locking rear differential; vehicles

equipped with this differential should be identified by a ªCautionº label

mounted on the instrument panel. Vehicle handling characteristcs will be

different than a conventional differential. Examples of this would be:

²When turning a corner, the sound of component disengagement and

re-engagement may be audible, and the transfer of driving torque from

both wheels to one wheel may be noticeable.

²When going from drive (acceleration) to coast (deceleration) in a

turn, a ªmetallicº sound may be heard as torque flow is reversed

(inside wheel engaged during acceleration; outside wheel engaged

during deceleration).

²When negotiating a turn (outside wheel disengaged), the inside wheel

under conditions of poor traction may receive excessive torque, which

could cause it to break traction momentarily until its speed is equal to

the outside wheel. This will result in re-engagement of the outside

wheel thus allowing both wheels to be driven. This condition is most

noticeable with lightly loaded axles.

Driving

19

Page 20 of 28

Use extreme caution when accelerating or decelerating on

slippery or unstable surfaces. Vehicles/axles equipped with

traction differentials are inherently more sensitive to side-slip than

vehicles equipped with conventional differentials. Stability can be

retained if side-slip occurs by decelerating (letting off the accelerator).

Do not apply the brake. To do so may result in loss of vehicle control.

The vehicle's braking capacity is reduced when a turn is made while

coasting downhill because the inside wheel is then disconnected from the

driveline. Operating in low gear will allow the engine to act as a retarder

and will improve braking capacity.

Inspection and lubrication

When servicing any driveline components on a vehicle equipped

with a locking rear differential, ensure that the engine is off and

all wheels are off the ground to prevent the vehicle from moving. Axles

equipped with a locking rear differential deliver power to both wheels,

even when only one wheel is on the ground. Failure to observe these

cautionary measures may cause the vehicle to move which can result

in property damage, personal injury, even death.

This differential is designed to operate in the lubricant recommended by

the vehicle/axle manufacturer; no special lubricant is needed. Refer to

theLubricant Specificationsin yourOwner's Guidefor the proper axle

lubricant. For very cold weather applications, use the lightest oil the axle

manufacturer will allow to overcome possible sluggish reengagement of

the driven clutch assemblies.

No adjustments or alterations should be made to the differential. Refer to

the vehicle/axle manufacturer's instructions for adjustments to other

components in the axle.

SAND INGESTION

When driving through sand, traction or brake capability may be limited.

Also, sand may enter your engine's air intake and severely damage your

engine or your vehicle may stall. Driving through sand where the

transmission vent tube or external breather kit is submerged may allow

sand into the transmission and cause internal transmission damage.

Driving

20