instrument panel FORD SUPER DUTY 2006 1.G Special Off-Road Package Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2006 1.GPages: 28, PDF Size: 0.22 MB

Page 2 of 28

BLACKOUT LIGHTING (IF EQUIPPED)

If your vehicle is equipped with blackout lighting it will turn off all

interior and exterior lighting, regardless of ignition position or if any

doors are open.

The switch is mounted on the

instrument panel below the radio.

The courtesy/dome/exterior lights are deactivated when the vehicle is

turned off regardless of which position the blackout lighting switch is in;

these lights are activated when the vehicle's ignition is turned to

on/auxiliary.

Note:Battery saver mode is enabled when the vehicle is turned off.

There is no delayed timer on this feature.

Note:Black-out lighting will conflict with U.S. Federal Motor Vehicle

Safety Standards (FMVSS). By selecting this option, the

customer/operator has and is exercising Governmental Privilege to

exempt vehicles from full FMVSS compliance.

When blackout lighting is enabled, it will turn off ALL interior

and exterior lights (i.e.headlamps, stop lamps, backup lamps,

interior warning lights, etc). Proceed with caution.

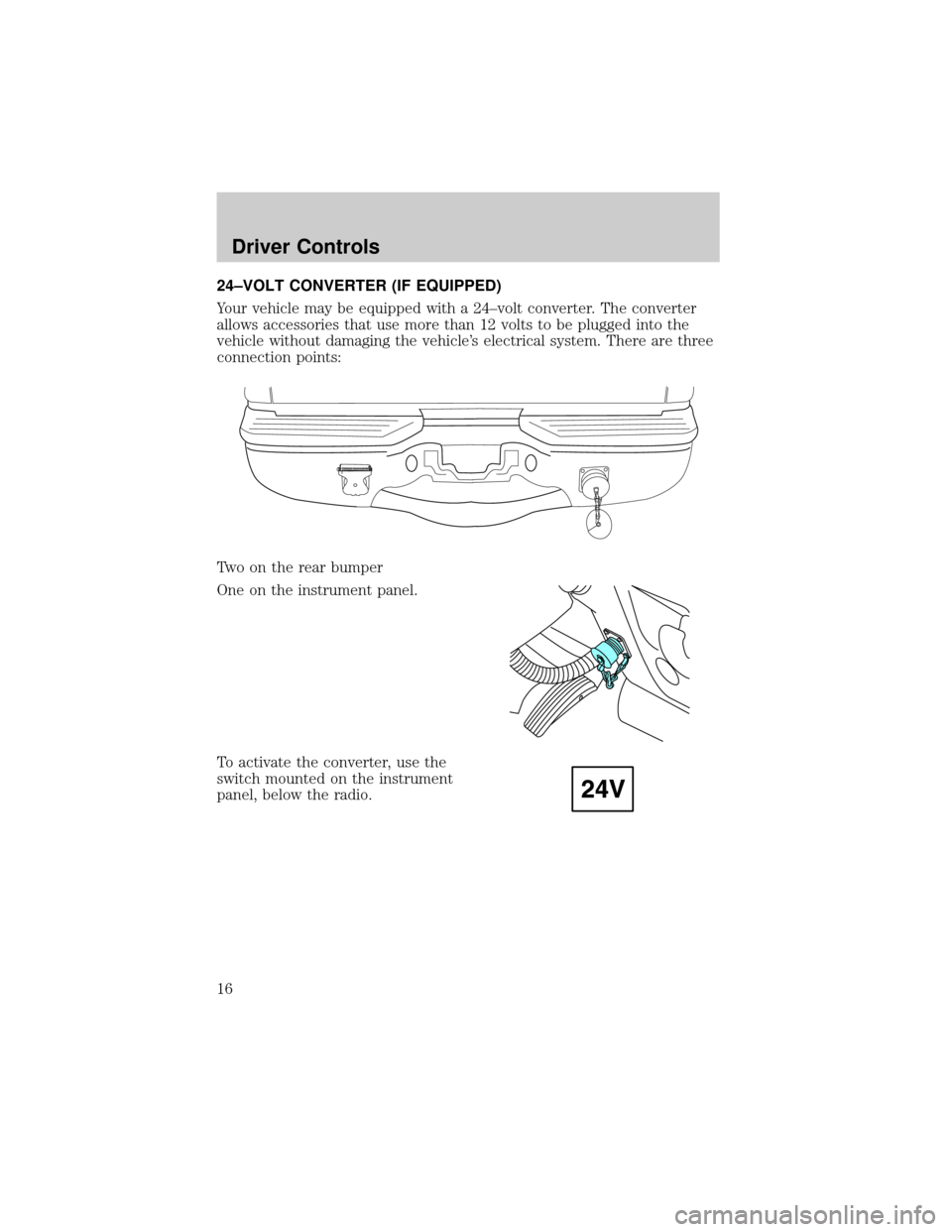

FOG LAMPS

Your vehicle may be equipped with

fog lamps in the front bumper.

The fog lamps can be activated by

using the switch located below the

radio.

Lights

2

Page 16 of 28

24±VOLT CONVERTER (IF EQUIPPED)

Your vehicle may be equipped with a 24±volt converter. The converter

allows accessories that use more than 12 volts to be plugged into the

vehicle without damaging the vehicle's electrical system. There are three

connection points:

Two on the rear bumper

One on the instrument panel.

To activate the converter, use the

switch mounted on the instrument

panel, below the radio.

Driver Controls

16

Page 19 of 28

2. Push the black buttons on the bleed valves for a softer ride. Separate

bleed valves allow independent adjustment of front and rear shocks.

Note:Do not operate the compressor for more than 30 seconds at a

time. Allow the compressor to cool down for one minute between

operations.

Note:Stop compressor operation when the arrow on the gauge reaches

maximum. Continuing to supply pressure will not make the shocks any

firmer and damage to the system will occur.

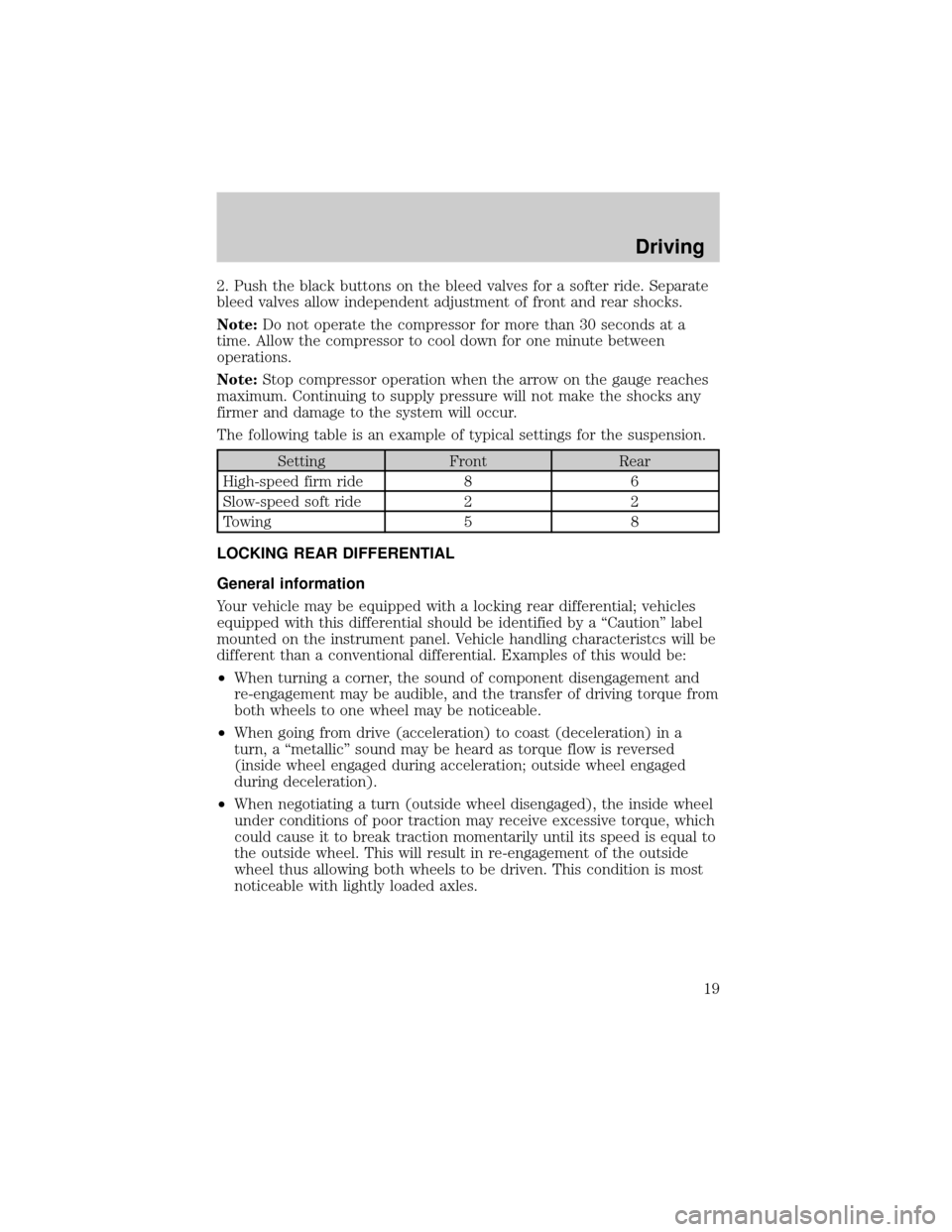

The following table is an example of typical settings for the suspension.

Setting Front Rear

High-speed firm ride 8 6

Slow-speed soft ride 2 2

Towing 5 8

LOCKING REAR DIFFERENTIAL

General information

Your vehicle may be equipped with a locking rear differential; vehicles

equipped with this differential should be identified by a ªCautionº label

mounted on the instrument panel. Vehicle handling characteristcs will be

different than a conventional differential. Examples of this would be:

²When turning a corner, the sound of component disengagement and

re-engagement may be audible, and the transfer of driving torque from

both wheels to one wheel may be noticeable.

²When going from drive (acceleration) to coast (deceleration) in a

turn, a ªmetallicº sound may be heard as torque flow is reversed

(inside wheel engaged during acceleration; outside wheel engaged

during deceleration).

²When negotiating a turn (outside wheel disengaged), the inside wheel

under conditions of poor traction may receive excessive torque, which

could cause it to break traction momentarily until its speed is equal to

the outside wheel. This will result in re-engagement of the outside

wheel thus allowing both wheels to be driven. This condition is most

noticeable with lightly loaded axles.

Driving

19

Page 22 of 28

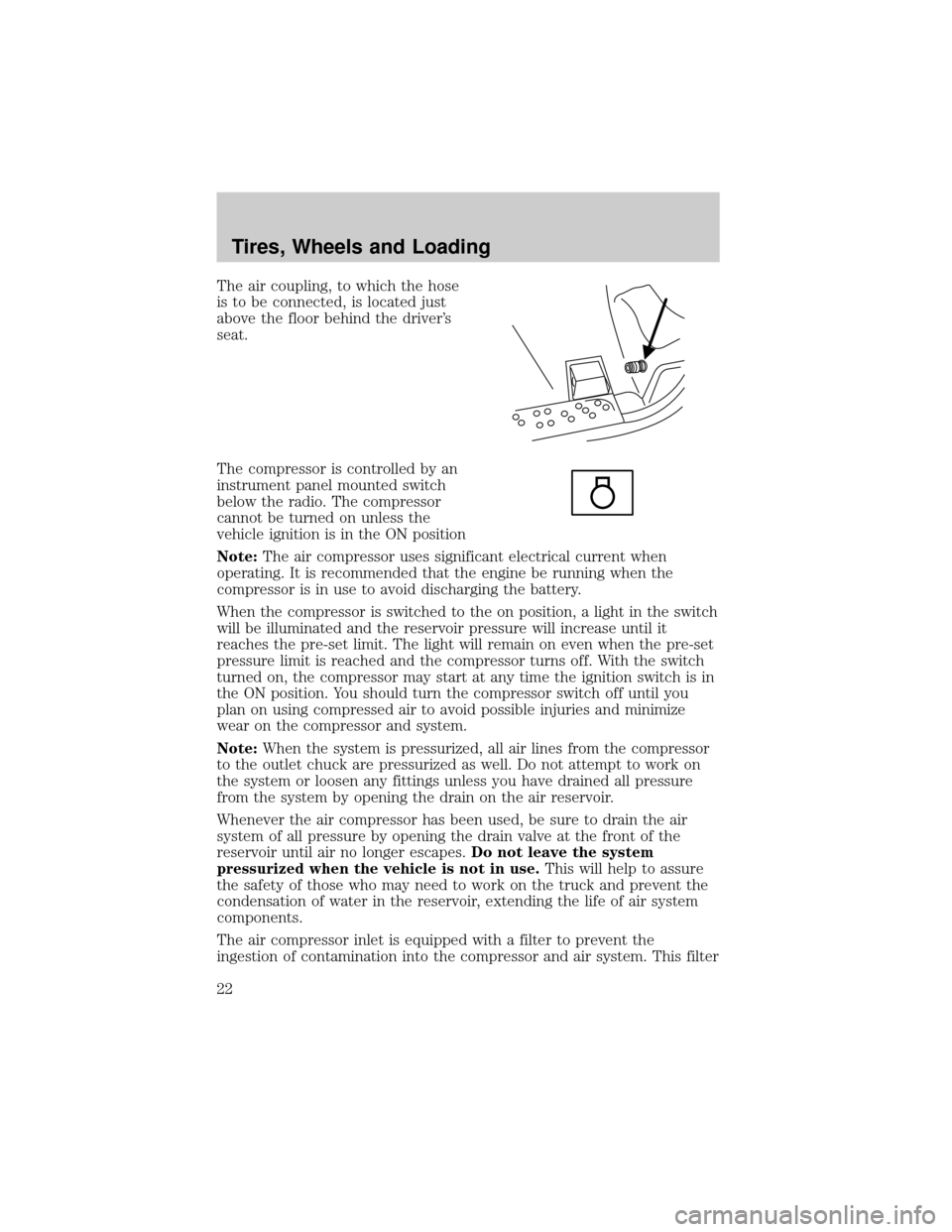

The air coupling, to which the hose

is to be connected, is located just

above the floor behind the driver's

seat.

The compressor is controlled by an

instrument panel mounted switch

below the radio. The compressor

cannot be turned on unless the

vehicle ignition is in the ON position

Note:The air compressor uses significant electrical current when

operating. It is recommended that the engine be running when the

compressor is in use to avoid discharging the battery.

When the compressor is switched to the on position, a light in the switch

will be illuminated and the reservoir pressure will increase until it

reaches the pre-set limit. The light will remain on even when the pre-set

pressure limit is reached and the compressor turns off. With the switch

turned on, the compressor may start at any time the ignition switch is in

the ON position. You should turn the compressor switch off until you

plan on using compressed air to avoid possible injuries and minimize

wear on the compressor and system.

Note:When the system is pressurized, all air lines from the compressor

to the outlet chuck are pressurized as well. Do not attempt to work on

the system or loosen any fittings unless you have drained all pressure

from the system by opening the drain on the air reservoir.

Whenever the air compressor has been used, be sure to drain the air

system of all pressure by opening the drain valve at the front of the

reservoir until air no longer escapes.Do not leave the system

pressurized when the vehicle is not in use.This will help to assure

the safety of those who may need to work on the truck and prevent the

condensation of water in the reservoir, extending the life of air system

components.

The air compressor inlet is equipped with a filter to prevent the

ingestion of contamination into the compressor and air system. This filter

Tires, Wheels and Loading

22

Page 23 of 28

is located underneath the truck, by the forward stake pocket on the left

side of the bed. If operating the air system in dusty areas, periodically

inspect this filter and replace it if found to be clogged or damaged, or if

the time needed to pressurize the system starts to become extended.

Using the air system to fill tires

To fill your tires, first be sure to stop the truck in a safe place. You

should be far enough off the road that passing traffic will not be a danger

to you. You should have an accurate tire pressure gauge to measure the

pressure in the tires and inflate them to the settings on the tire pressure

placard, which is usually inside the door on the truck.

Remove the air hose from under the clamp on the floor of the truck.

Attach the connector end of the hose to the coupling in the trim panel

behind the driver's seat by using one hand to slide the coupling collar

toward the trim panel and the other to insert the fitting on the end of

the hose into the coupling. When the fitting is seated in the coupling,

slide the collar back to its original position.

Extend the hose to reach the tire needing air. Remove the cap from the

tire valve stem and attach the clamp-on air chuck by squeezing the

locking mechanism while placing the chuck over the valve stem. Release

the locking mechanism when the air chuck is seated on the stem. Air will

flow from the system to the tire until you remove the chuck. Be sure to

use your gauge to set the pressure according to the placard. When the

tire pressure is correct, disconnect the hose and re-stow it under the

clamp on the floor behind the passenger seat. Do not forget to re-install

the cap on the valve stem.

CENTRAL TIRE INFLATION SYSTEM (CTIS) (IF EQUIPPED)

Your vehicle may be equipped with a

Central Tire Inflation System

(CTIS). The CTIS adjusts and

maintains tire pressure for enhanced

vehicle traction, reduced vehicle

maintenance and improved driver

comfort. The system is operated

through instrument panel-mounted

controls.

Operating the CTIS

The CTIS is operated and observed through the Driver Display Module

(DDM) and the LOAD AND TERRAIN controls.

Tires, Wheels and Loading

23

Page 28 of 28

CHANGING A FLAT TIRE

Refer to yourOwner's Guidefor the tire changing procedure. Follow the

F-350 Dual Rear Wheel (DRW) jacking instructions.

FUSING

Note:Fuse 29 in the instrument panel box, located below and to the left

of the steering wheel, should be a 15A mini fuse. Always replace the fuse

you removed with a fuse with the same amperage rating.

Roadside emergencies

28