air filter FORD SUPER DUTY 2008 2.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2008, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2008 2.GPages: 96, PDF Size: 0.64 MB

Page 33 of 96

equivalent. The customer warranty may be void from using additives that

do not meet or exceed Ford specifications.

Fueling tips

If the engine fails to start in 30 seconds, turn the key to the OFF

position and wait 30 seconds before trying again.

Truck stops have pumps and nozzles designed for larger, heavy-duty

trucks. When refueling at truck stops: if the nozzle shuts off repeatedly

when refueling, wait 5–10 seconds; then use a slower rate of flow (don’t

depress the nozzle trigger as far).

If air is allowed to enter the fuel system (during fuel filter change or if

you run out of fuel) the engine will purge the trapped air as it runs. The

engine may run rough and produce white smoke while air is in the

system. This is normal and should correct itself in a short time.

An engine that suddenly becomes noisy or operates poorly after a fuel fill

could be using substandard fuel (i.e., high water content, low cetane

rating or gasoline in the fuel). Diesel fuel should be purchased from a

reputable station which sells a large amount of diesel fuel.

Care should be taken whenever diesel fuel is stored. Use only clean,

approved containers which will prevent the entry of dirt or water.

Diesel fuel must not be stored in a galvanized container. The fuel will

dissolve the zinc in a galvanized container. The zinc will then remain in

solution until it is run through the engine where it will be deposited in

the fuel injectors causing expensive-to-repair damage.

Diesel fuel dispensing nozzle fill rate

This truck is equipped with a fuel fill pipe which is able to accept fuel up

to 20 gallons per minute from an 1

1�8” fuel dispensing nozzle. Pumping

fuel at greater flow rates may result in premature nozzle shut-off or

spitback.

Fuel filler cap

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise until it stops.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise until a few clicks are heard.

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

33

Page 36 of 96

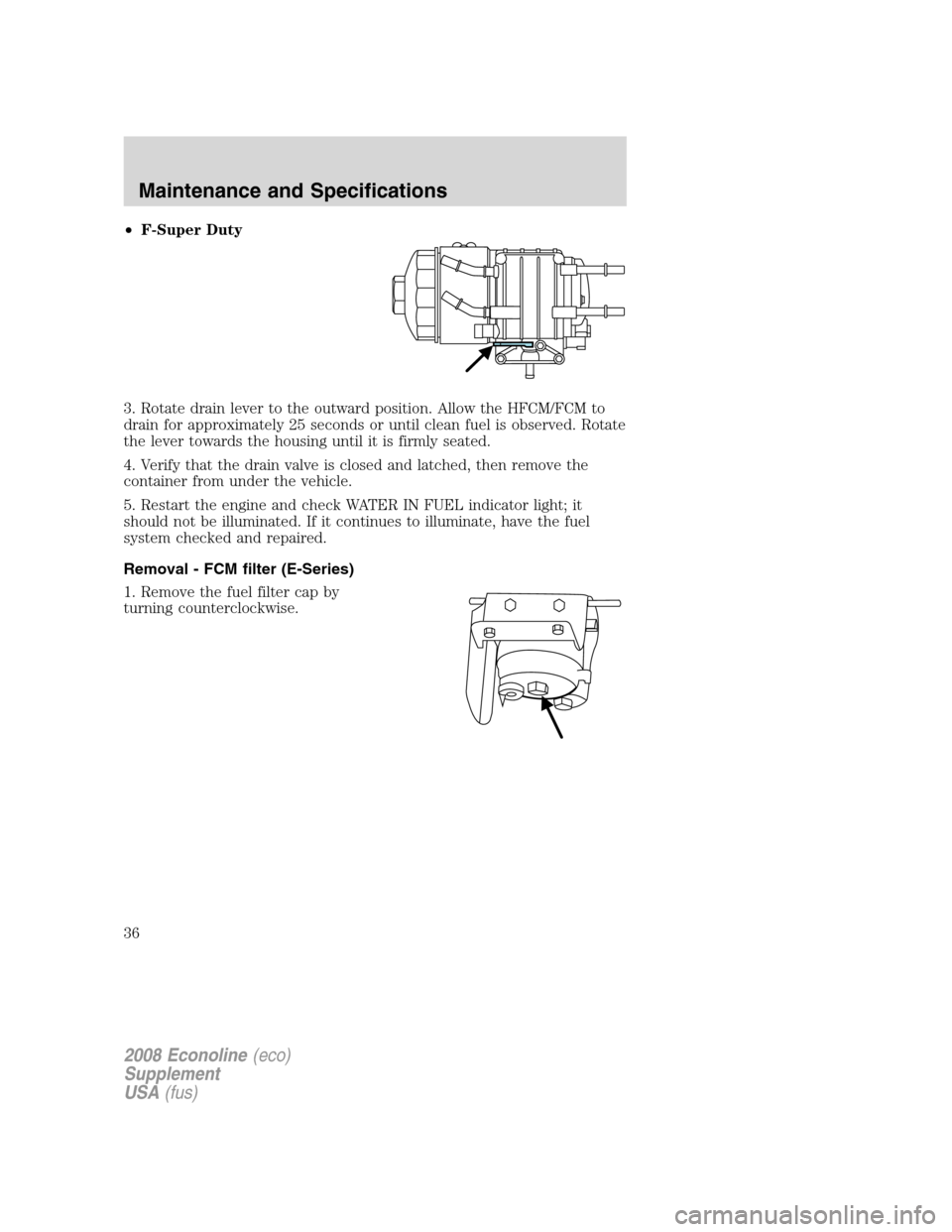

•F-Super Duty

3. Rotate drain lever to the outward position. Allow the HFCM/FCM to

drain for approximately 25 seconds or until clean fuel is observed. Rotate

the lever towards the housing until it is firmly seated.

4. Verify that the drain valve is closed and latched, then remove the

container from under the vehicle.

5. Restart the engine and check WATER IN FUEL indicator light; it

should not be illuminated. If it continues to illuminate, have the fuel

system checked and repaired.

Removal - FCM filter (E-Series)

1. Remove the fuel filter cap by

turning counterclockwise.

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

36

Page 39 of 96

On E-Series vehicles:After replacing the fuel filter, the engine will

purge the trapped air as it runs. The engine may run roughly and smoke

until the air is completely eliminated.

On F-Super Duty vehicles:Turn the ignition key to ON for 30 seconds,

then turn it to OFF. Do this a total of six times in a row to purge any

trapped air from the fuel system.

Using a fuel which has more than average impurities may require

the fuel filter to be replaced more frequently than the service

interval specifies.

ENGINE OIL

Checking the engine oil level

Because it is normal to add some oil between oil changes, check your

engine oil level each time you stop for fuel. To check the engine oil level

consistently and accurately, the following procedure is recommended:

1. Have engine at normal operating temperature (at least into the

NORMAL range on the engine coolant temperature gauge).

2. Park the vehicle on a level surface, then turn off the engine and open

the hood.

3. Allow at least20 minutesafter engine shutdown to ensure that the

oil contained in the upper parts of the engine has returned to the oil

pan.

4. Protecting yourself from engine heat, pull out the dipstick, wipe it

clean and reinsert fully.

5. Read oil level on both sides of dipstick and use highest level (reading)

for the actual engine oil level.

6. Maintain the oil level between MIN and MAX or the ADD and

OPERATING RANGE on the dipstick by adding oil as required. The

distance from MIN to MAX or ADD to OPERATING RANGE on the

dipstick represents 2.0 quarts (1.9L). Do not overfill. If the oil level

exceeds MAX or OPERATING RANGE, oil consumption may result.

Engine oil specifications

To help achieve acceptable engine performance and durability, it is

important that only engine oils of good quality are used in your diesel

engine and it is changed at the recommended interval. For normal or

severe service, use Motorcraft oil or an equivalent oil conforming to Ford

specification WSS-M2C171–E or API service categories CJ-4 or CJ-4/SM.

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

39

Page 43 of 96

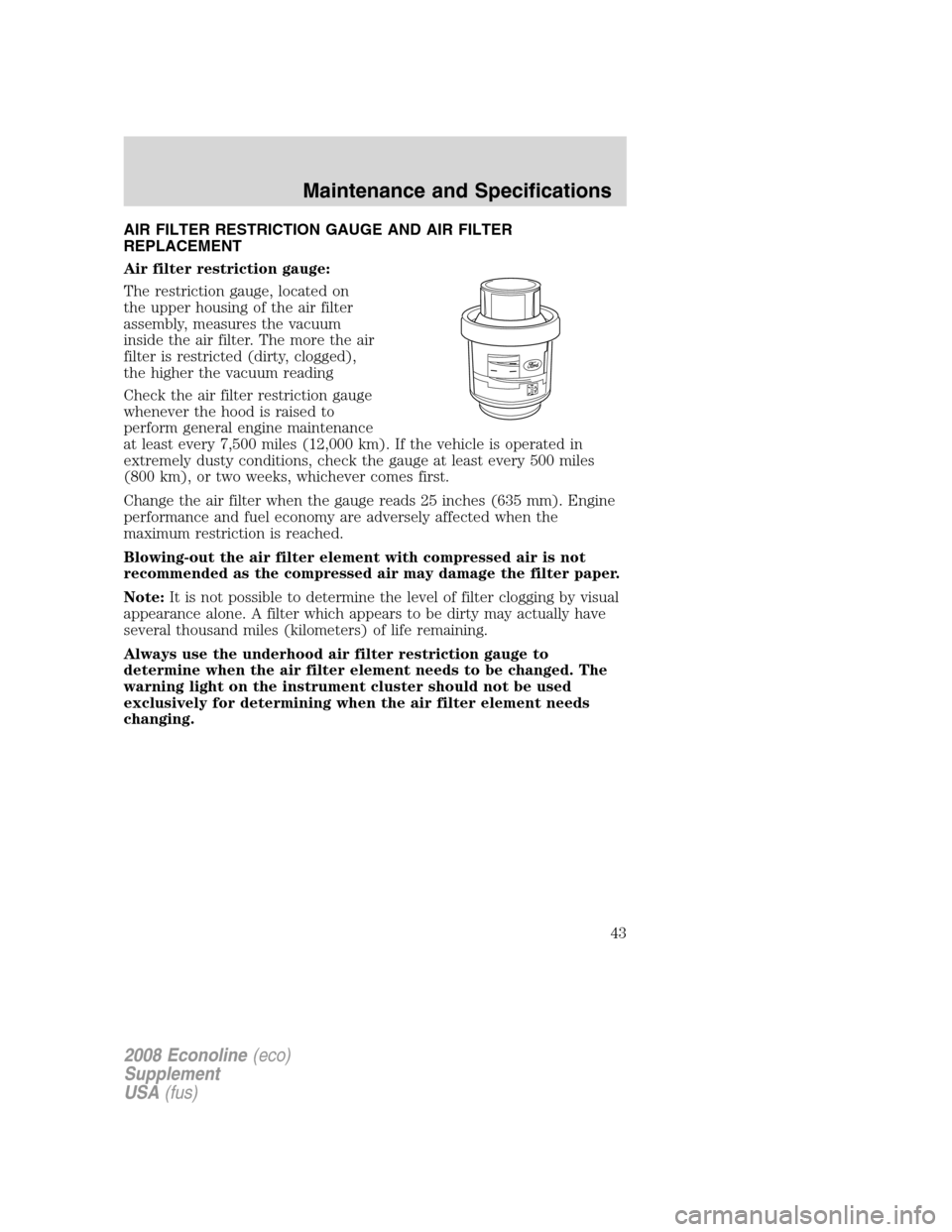

AIR FILTER RESTRICTION GAUGE AND AIR FILTER

REPLACEMENT

Air filter restriction gauge:

The restriction gauge, located on

the upper housing of the air filter

assembly, measures the vacuum

inside the air filter. The more the air

filter is restricted (dirty, clogged),

the higher the vacuum reading

Check the air filter restriction gauge

whenever the hood is raised to

perform general engine maintenance

at least every 7,500 miles (12,000 km). If the vehicle is operated in

extremely dusty conditions, check the gauge at least every 500 miles

(800 km), or two weeks, whichever comes first.

Change the air filter when the gauge reads 25 inches (635 mm). Engine

performance and fuel economy are adversely affected when the

maximum restriction is reached.

Blowing-out the air filter element with compressed air is not

recommended as the compressed air may damage the filter paper.

Note:It is not possible to determine the level of filter clogging by visual

appearance alone. A filter which appears to be dirty may actually have

several thousand miles (kilometers) of life remaining.

Always use the underhood air filter restriction gauge to

determine when the air filter element needs to be changed. The

warning light on the instrument cluster should not be used

exclusively for determining when the air filter element needs

changing.

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

43

Page 44 of 96

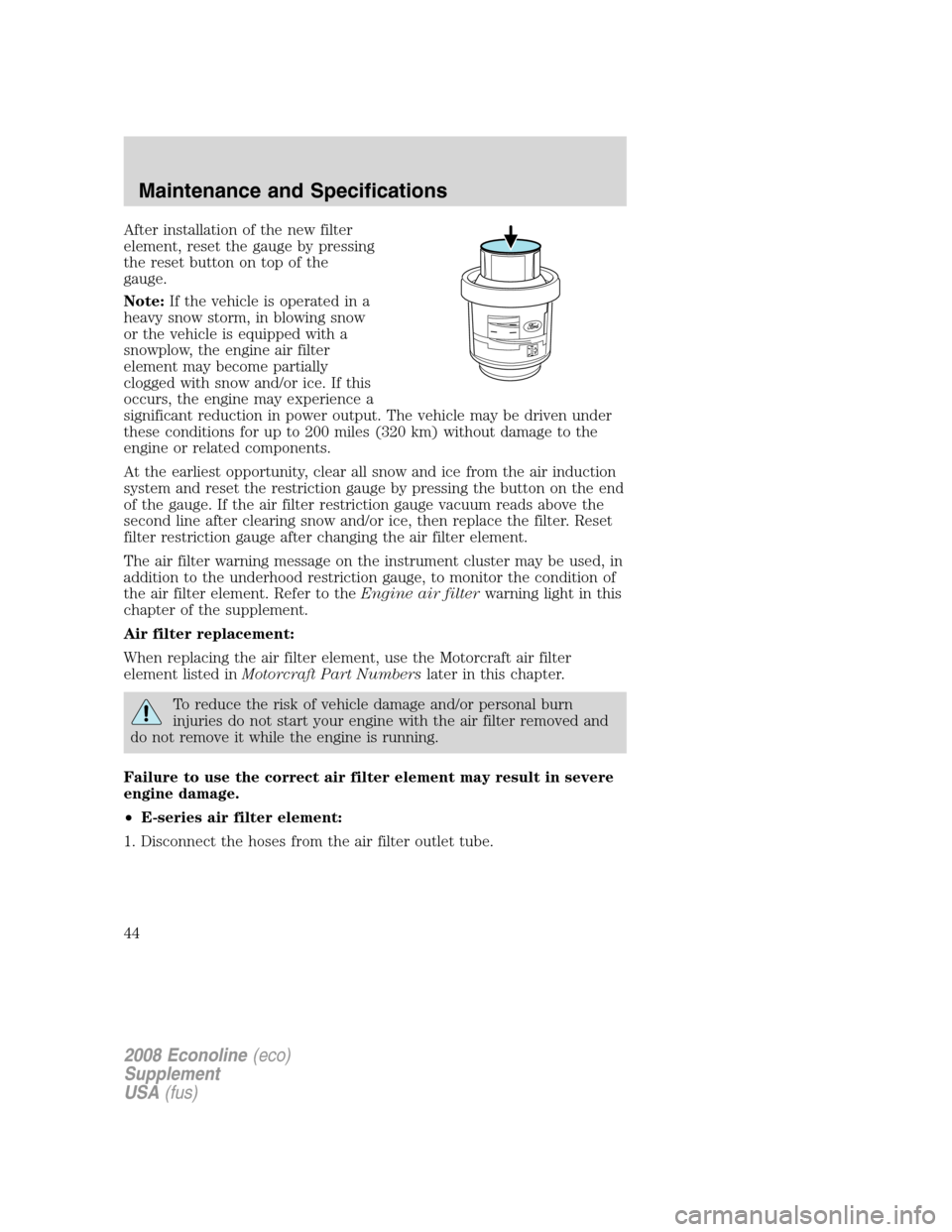

After installation of the new filter

element, reset the gauge by pressing

the reset button on top of the

gauge.

Note:If the vehicle is operated in a

heavy snow storm, in blowing snow

or the vehicle is equipped with a

snowplow, the engine air filter

element may become partially

clogged with snow and/or ice. If this

occurs, the engine may experience a

significant reduction in power output. The vehicle may be driven under

these conditions for up to 200 miles (320 km) without damage to the

engine or related components.

At the earliest opportunity, clear all snow and ice from the air induction

system and reset the restriction gauge by pressing the button on the end

of the gauge. If the air filter restriction gauge vacuum reads above the

second line after clearing snow and/or ice, then replace the filter. Reset

filter restriction gauge after changing the air filter element.

The air filter warning message on the instrument cluster may be used, in

addition to the underhood restriction gauge, to monitor the condition of

the air filter element. Refer to theEngine air filterwarning light in this

chapter of the supplement.

Air filter replacement:

When replacing the air filter element, use the Motorcraft air filter

element listed inMotorcraft Part Numberslater in this chapter.

To reduce the risk of vehicle damage and/or personal burn

injuries do not start your engine with the air filter removed and

do not remove it while the engine is running.

Failure to use the correct air filter element may result in severe

engine damage.

•E-series air filter element:

1. Disconnect the hoses from the air filter outlet tube.

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

44

Page 45 of 96

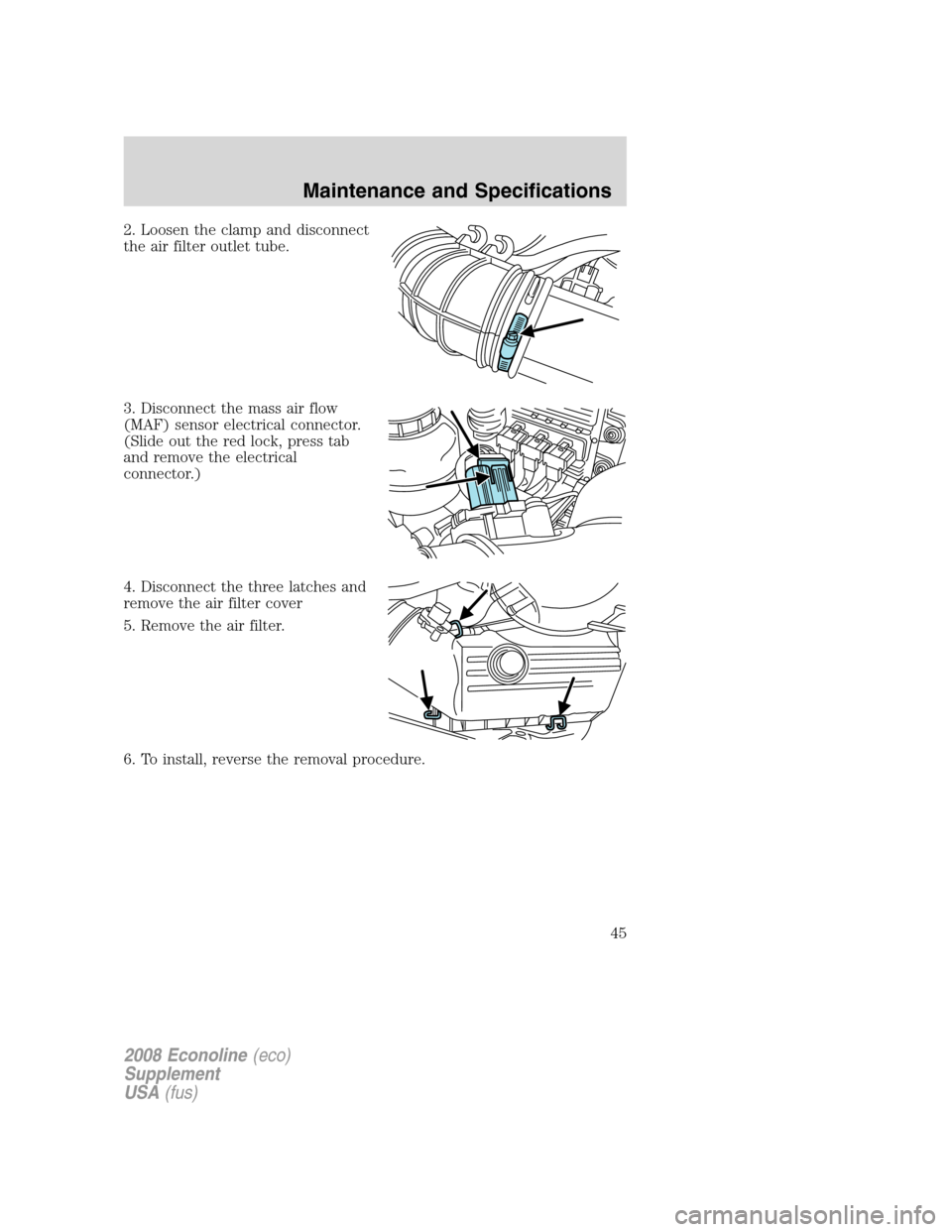

2. Loosen the clamp and disconnect

the air filter outlet tube.

3. Disconnect the mass air flow

(MAF) sensor electrical connector.

(Slide out the red lock, press tab

and remove the electrical

connector.)

4. Disconnect the three latches and

remove the air filter cover

5. Remove the air filter.

6. To install, reverse the removal procedure.

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

45

Page 46 of 96

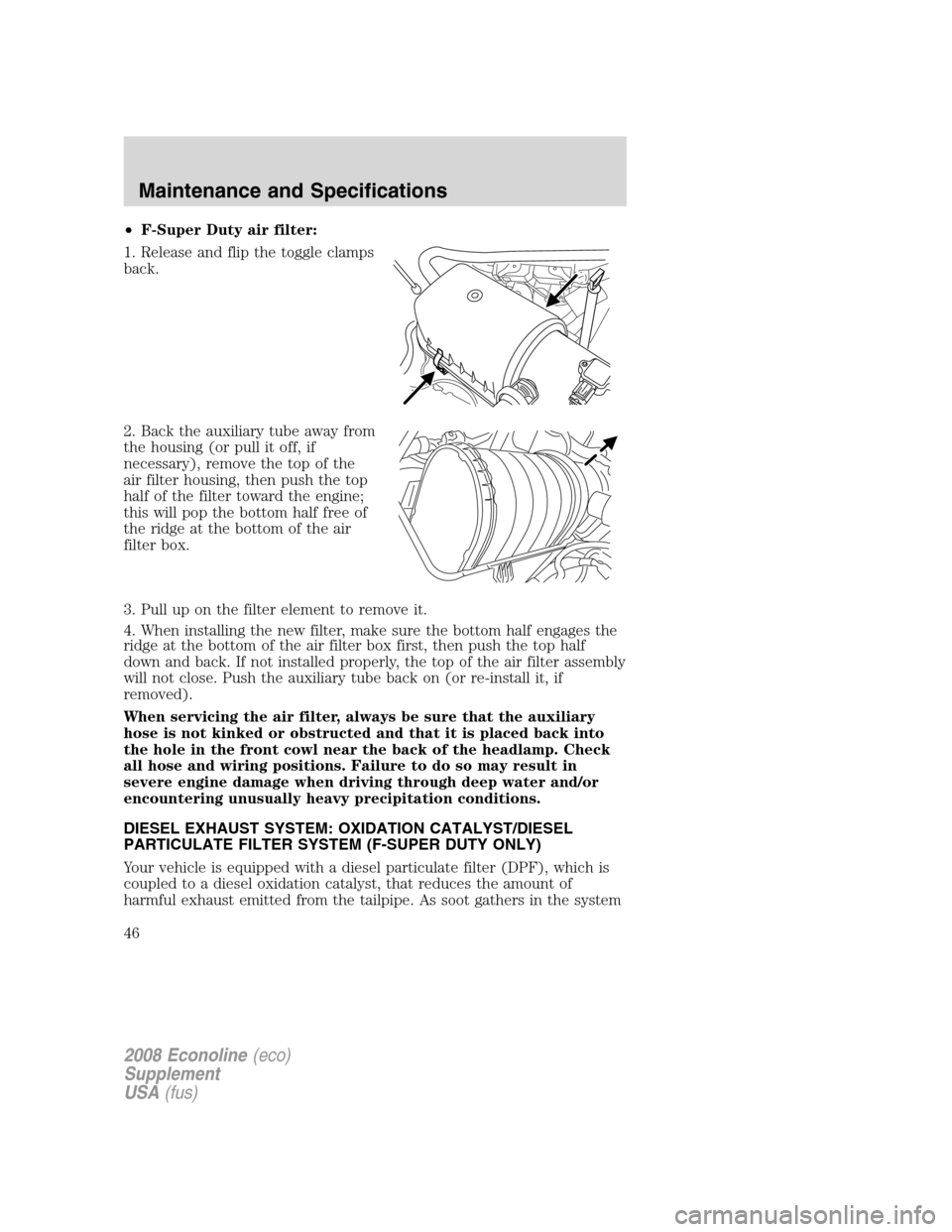

•F-Super Duty air filter:

1. Release and flip the toggle clamps

back.

2. Back the auxiliary tube away from

the housing (or pull it off, if

necessary), remove the top of the

air filter housing, then push the top

half of the filter toward the engine;

this will pop the bottom half free of

the ridge at the bottom of the air

filter box.

3. Pull up on the filter element to remove it.

4. When installing the new filter, make sure the bottom half engages the

ridge at the bottom of the air filter box first, then push the top half

down and back. If not installed properly, the top of the air filter assembly

will not close. Push the auxiliary tube back on (or re-install it, if

removed).

When servicing the air filter, always be sure that the auxiliary

hose is not kinked or obstructed and that it is placed back into

the hole in the front cowl near the back of the headlamp. Check

all hose and wiring positions. Failure to do so may result in

severe engine damage when driving through deep water and/or

encountering unusually heavy precipitation conditions.

DIESEL EXHAUST SYSTEM: OXIDATION CATALYST/DIESEL

PARTICULATE FILTER SYSTEM (F-SUPER DUTY ONLY)

Your vehicle is equipped with a diesel particulate filter (DPF), which is

coupled to a diesel oxidation catalyst, that reduces the amount of

harmful exhaust emitted from the tailpipe. As soot gathers in the system

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

46

Page 48 of 96

Resonator/Tailpipe assembly maintenance

The diesel resonator tail-pipe assembly is a uniquely functioning device

that accompanies the Oxidation Catalyst/DPF assembly. The assembly

serves multiple functions. First it serves as an acoustic device to

attenuate exhaust noise. Second it provides an exit path for the exhaust

from the vehicle. It also is designed to help control the temperature of

the exhaust during DPF regeneration events. The visible holes in each

leg of the twin tip and the holes under the shield just inboard of the

right rear tire(s) are functional. The holes need to be kept clear of

mud/debris or foreign material to maintain proper function of the

exhaust system. Clean and remove debris or foreign material if present

as needed. Spraying with a hose during regular washing of vehicle should

help keep holes clean/clear of debris or foreign material.

Note:Additions of aftermarket devices or modifications to the exhaust

system can reduce the effectiveness of the exhaust system as well as

cause damage to the exhaust system and/or engine. These actions may

also affect the vehicle’s warranty. See the vehicle’s warranty guide for

more information.

Failure to maintain the functional holes, in the tailpipe section of

the exhaust, clean and free of debris or foreign material may

result in the holes becoming blocked or plugged. Do not modify or

remove the tail-pipe section. Blocked or plugged holes or

removal/modification of the system could result in elevated exhaust gas

temperatures which may result in vehicle/property damage or personal

injury.

The normal operating temperature of the exhaust system is very

high. Never work around or attempt to repair any part of the

exhaust system until it has cooled. Use special care when working

around the diesel oxidation catalytic converter and/or the diesel

particulate filter (DPF). The diesel oxidation catalytic converter and/or

the DPF heats up to a high temperature after only a short period of

engine operation and can stay hot even after the engine is turned off.

Failure to follow these instructions may result in personal injury.

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

48

Page 50 of 96

The complexity of the diesel engine makes it so the owner is discouraged

from attempting to perform maintenance other than the services

described in this supplement.

If you experience difficult starting, rough idling, excessive exhaust

smoke, a decrease in engine performance or excess fuel consumption,

perform the following checks:

•a plugged air inlet system or engine air filter element.

•water in the fuel filter/water separator.

•a clogged fuel filter.

•contaminated fuel.

•air in the fuel system, due to loose connections.

•an open or pinched sensor hose.

•low engine oil level.

•wrong fuel or oil viscosity for climactic conditions.

If these checks do not help you correct the engine performance problem

you are experiencing, consult an authorized dealer.

FUELING

Do not use starting fluid such as ether or gasoline in the diesel

air intake system. Such fluids can cause immediate explosive

damage to the engine and possible personal injury.

If you fuel your vehicle at a truck stop, you may notice that the fuel

nozzle may shut off every 5–10 seconds. This is due to the flow rates

being designed for larger heavy duty trucks. You may have to fuel at a

slower rate (don’t depress the nozzle trigger fully).

Do not run your diesel vehicle out of fuel as this will allow air to enter

the fuel system which will make restarting difficult. The engine is

designed to run roughly as the fuel tank nears Empty. This is a warning

to the driver to add fuel as soon as possible. Longer engine cranking

time may be required once air is in the fuel system. If air enters the fuel

system (either through running the fuel tank(s) empty or during a fuel

filter change), the engine will self-purge the trapped air once it starts

running. The engine may run roughly and produce white smoke while air

is in the fuel system; this is normal and should stop after a short time.

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

50

Page 52 of 96

•Leaving the ignition key turned to ON for over two minutes without

starting may make starting difficult because the glow plugs will cease

activation. Reset the system by turning the ignition key to OFF and

then back to ON again.

If the engine runs hot

The following could cause the engine to overheat:

•Lack of coolant.

•Dirty cooling system.

•Plugged radiator fins, charge air cooler, A/C condenser and/or oil

cooler.

•Driving with frozen coolant.

•Sticking thermostat.

•Overloading or pulling heavy trailers during hot weather.

•Grill or radiator air blockage.

•Slipping or missing drive belt.

•Plugged or very dirty air filter.

If fuses burn out

Burned-out or blown fuses usually indicate an electrical short-circuit,

although a fuse may occasionally burn out from vibration. Insert a second

fuse. If this fuse immediately burns out and you cannot locate the cause,

return your vehicle to your dealer for a circuit check.

Replacement fuses and circuit breakers must always be the same

rating as the original equipment shown. Never replace a fuse or

circuit breaker with one of a higher rating. Higher rated fuses or circuit

breakers could allow circuit overloading in the event of a circuit

malfunction, resulting in severe vehicle damage or personal injury due

to fire.

Refer to theOwner’s Guidefor replacement of fuses.

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

52