light FORD SUPER DUTY 2008 2.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2008, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2008 2.GPages: 96, PDF Size: 0.64 MB

Page 36 of 96

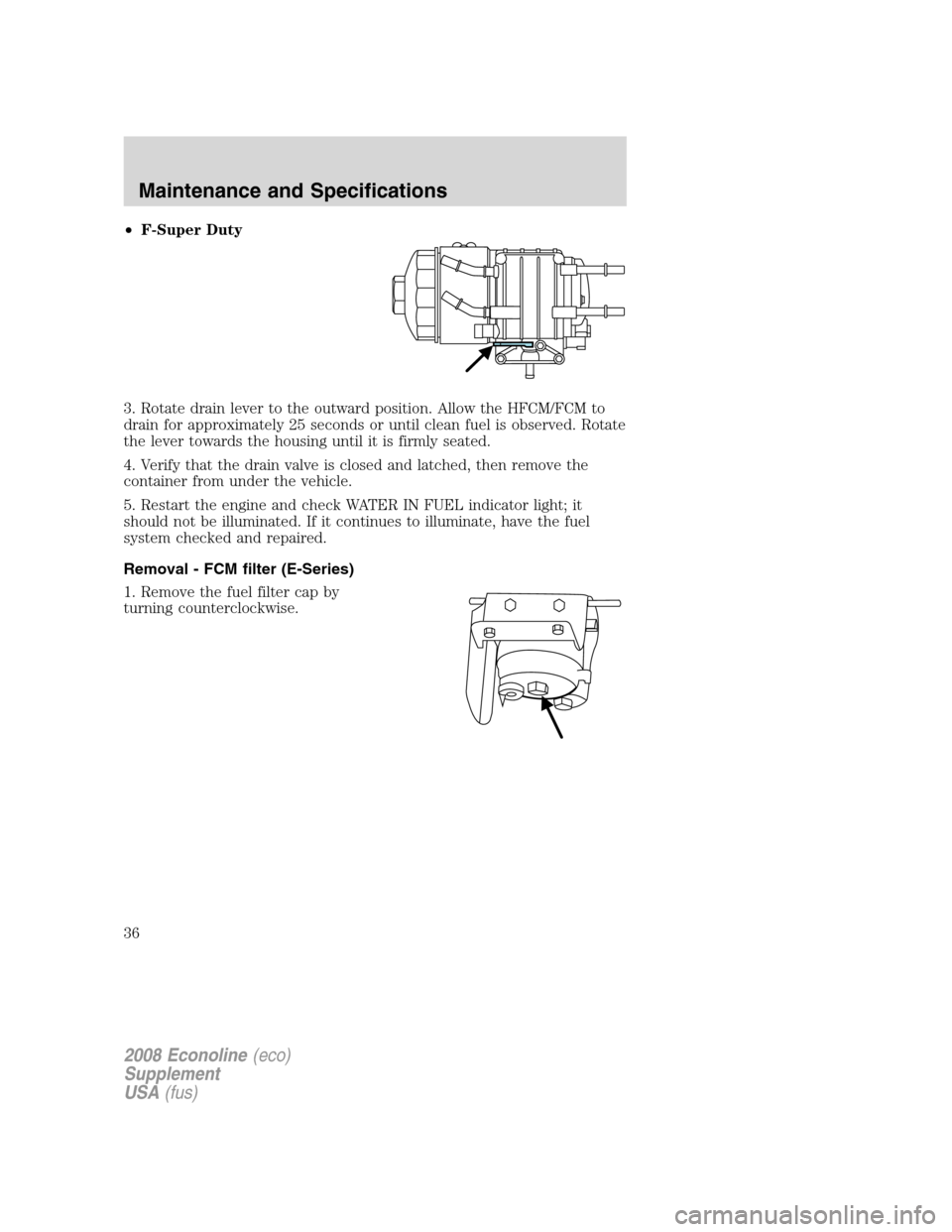

•F-Super Duty

3. Rotate drain lever to the outward position. Allow the HFCM/FCM to

drain for approximately 25 seconds or until clean fuel is observed. Rotate

the lever towards the housing until it is firmly seated.

4. Verify that the drain valve is closed and latched, then remove the

container from under the vehicle.

5. Restart the engine and check WATER IN FUEL indicator light; it

should not be illuminated. If it continues to illuminate, have the fuel

system checked and repaired.

Removal - FCM filter (E-Series)

1. Remove the fuel filter cap by

turning counterclockwise.

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

36

Page 43 of 96

AIR FILTER RESTRICTION GAUGE AND AIR FILTER

REPLACEMENT

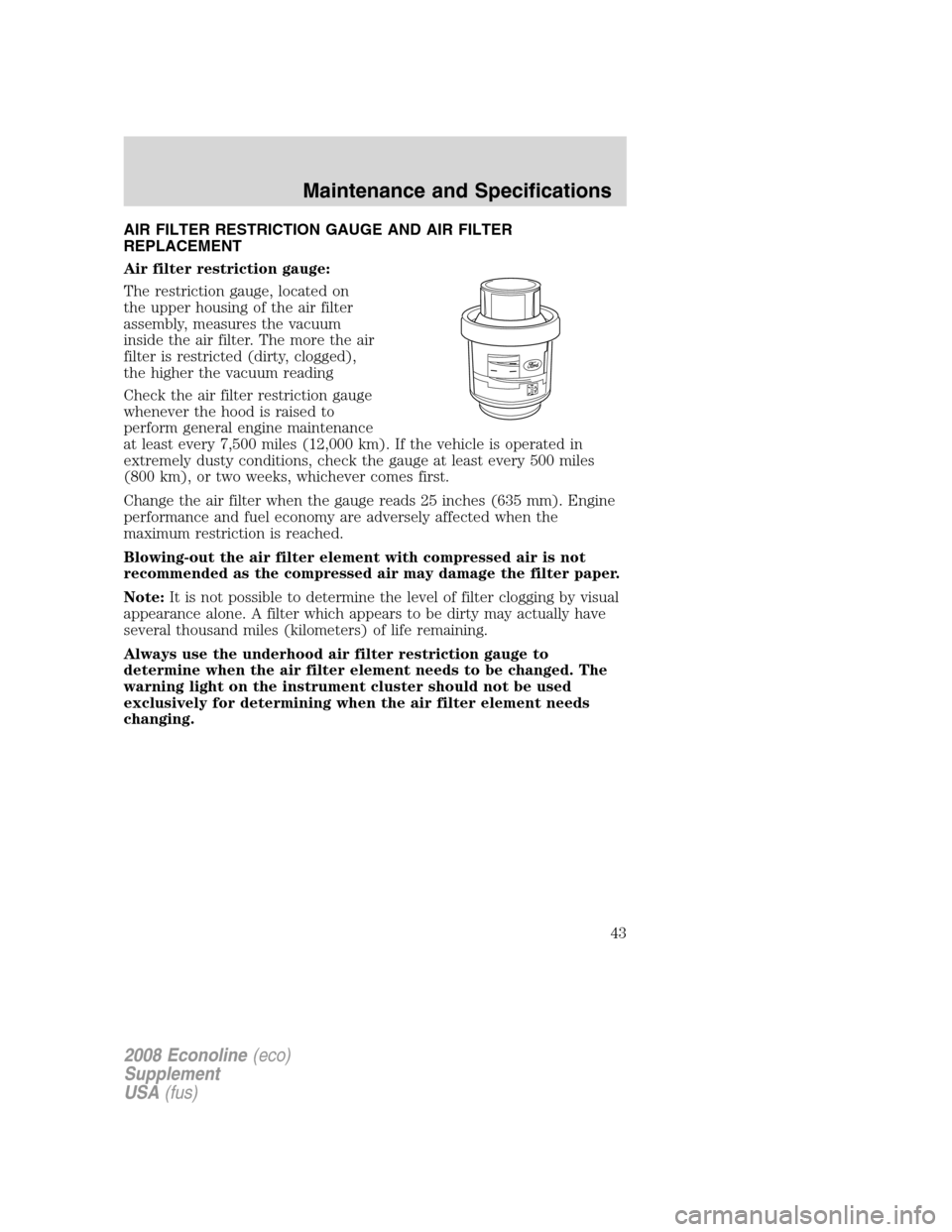

Air filter restriction gauge:

The restriction gauge, located on

the upper housing of the air filter

assembly, measures the vacuum

inside the air filter. The more the air

filter is restricted (dirty, clogged),

the higher the vacuum reading

Check the air filter restriction gauge

whenever the hood is raised to

perform general engine maintenance

at least every 7,500 miles (12,000 km). If the vehicle is operated in

extremely dusty conditions, check the gauge at least every 500 miles

(800 km), or two weeks, whichever comes first.

Change the air filter when the gauge reads 25 inches (635 mm). Engine

performance and fuel economy are adversely affected when the

maximum restriction is reached.

Blowing-out the air filter element with compressed air is not

recommended as the compressed air may damage the filter paper.

Note:It is not possible to determine the level of filter clogging by visual

appearance alone. A filter which appears to be dirty may actually have

several thousand miles (kilometers) of life remaining.

Always use the underhood air filter restriction gauge to

determine when the air filter element needs to be changed. The

warning light on the instrument cluster should not be used

exclusively for determining when the air filter element needs

changing.

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

43

Page 44 of 96

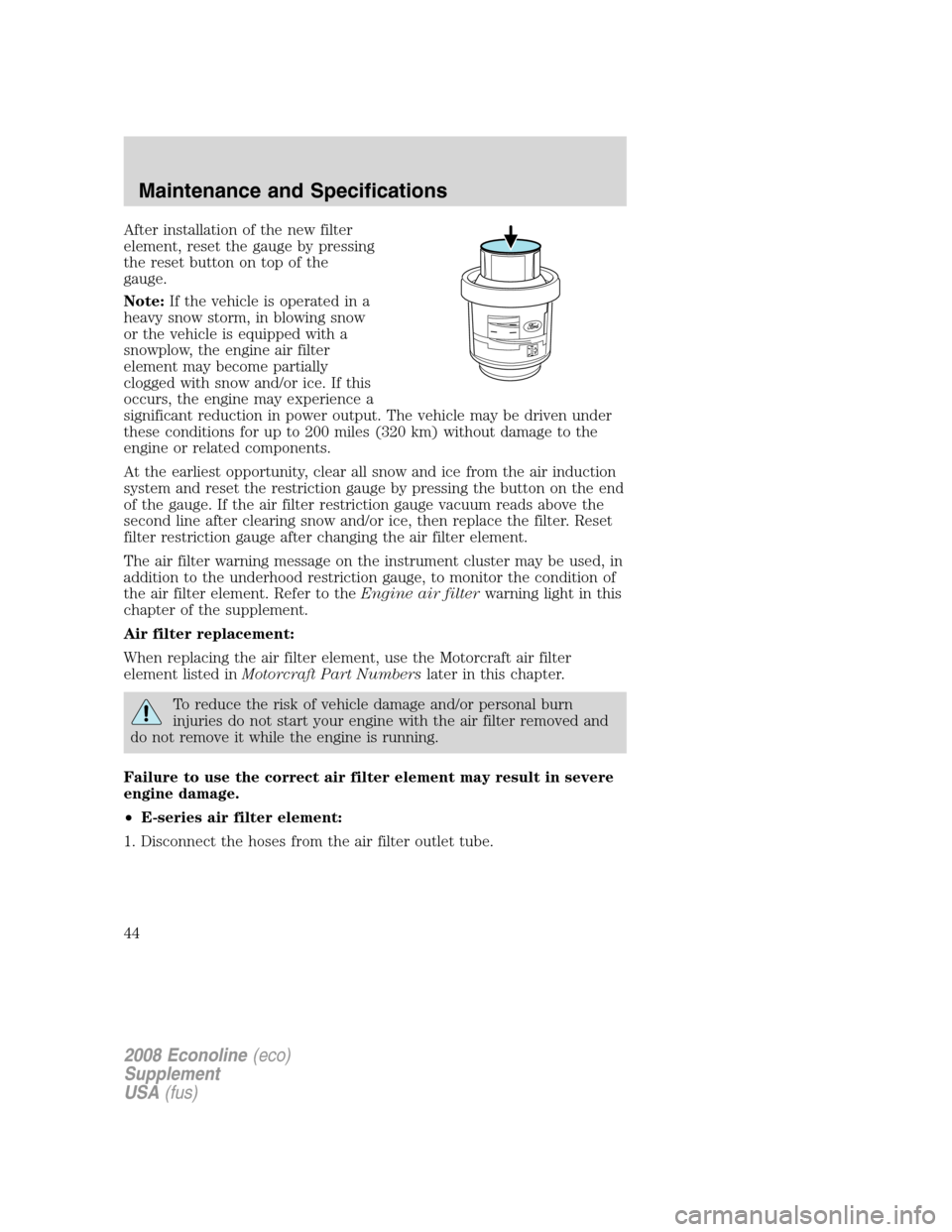

After installation of the new filter

element, reset the gauge by pressing

the reset button on top of the

gauge.

Note:If the vehicle is operated in a

heavy snow storm, in blowing snow

or the vehicle is equipped with a

snowplow, the engine air filter

element may become partially

clogged with snow and/or ice. If this

occurs, the engine may experience a

significant reduction in power output. The vehicle may be driven under

these conditions for up to 200 miles (320 km) without damage to the

engine or related components.

At the earliest opportunity, clear all snow and ice from the air induction

system and reset the restriction gauge by pressing the button on the end

of the gauge. If the air filter restriction gauge vacuum reads above the

second line after clearing snow and/or ice, then replace the filter. Reset

filter restriction gauge after changing the air filter element.

The air filter warning message on the instrument cluster may be used, in

addition to the underhood restriction gauge, to monitor the condition of

the air filter element. Refer to theEngine air filterwarning light in this

chapter of the supplement.

Air filter replacement:

When replacing the air filter element, use the Motorcraft air filter

element listed inMotorcraft Part Numberslater in this chapter.

To reduce the risk of vehicle damage and/or personal burn

injuries do not start your engine with the air filter removed and

do not remove it while the engine is running.

Failure to use the correct air filter element may result in severe

engine damage.

•E-series air filter element:

1. Disconnect the hoses from the air filter outlet tube.

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

44

Page 47 of 96

it begins to restrict the filter. The soot gathered inside the filter needs to

be periodically cleaned. The soot can be cleaned in two different ways;

passive regeneration and active regeneration. Both methods occur

automatically and require no actions from the driver/operator. During

either one of these regeneration methods you may notice an

increase/change in exhaust noise/tone.

Passive regeneration

In passive regeneration, the exhaust constituents / temperature are at an

appropriate level where some soot can be reduced or oxidized (burned)

thus cleaning the filter. This method occurs naturally as a result of

normal engine operating conditions (at varying levels due to drive

patterns).

Active regeneration

If there is not enough passive regeneration naturally occurring due to

vehicle drive patterns, the engine control system will initiate an active

regeneration. In an active regeneration, the filter is cleaned by raising

the exhaust temperature to a point where the soot is burned away. This

is accomplished through various engine actions which raise the exhaust

temperature in the oxidation catalyst/DPF system to an appropriate high

level where the soot is burned off. After the soot is burned off, the

exhaust temperature and back-pressure (restriction) fall back to normal

levels.

Filter service/maintenance

Over time a slight amount of ash will build up in the DPF which is not

removed during the regeneration process. The DPF may need to be

removed for ash cleaning at approximately 120,000 miles (193,000 km)

or greater (actual mileage can vary greatly depending upon

engine/vehicle operating conditions) and replaced with a new or

remanufactured (ash cleaned) part. The filter may need to be replaced

at approximately 250,000 miles (400,000 km) depending upon

engine/vehicle operating conditions. In both cases the engine control

system will set a service light (

) to inform you to bring the vehicle

to the dealer for service.

If there are any issues with the oxidation catalyst/DPF system a service

light (

or) will be set by the engine control system to inform

you to bring the vehicle into a dealership for service.

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

47

Page 51 of 96

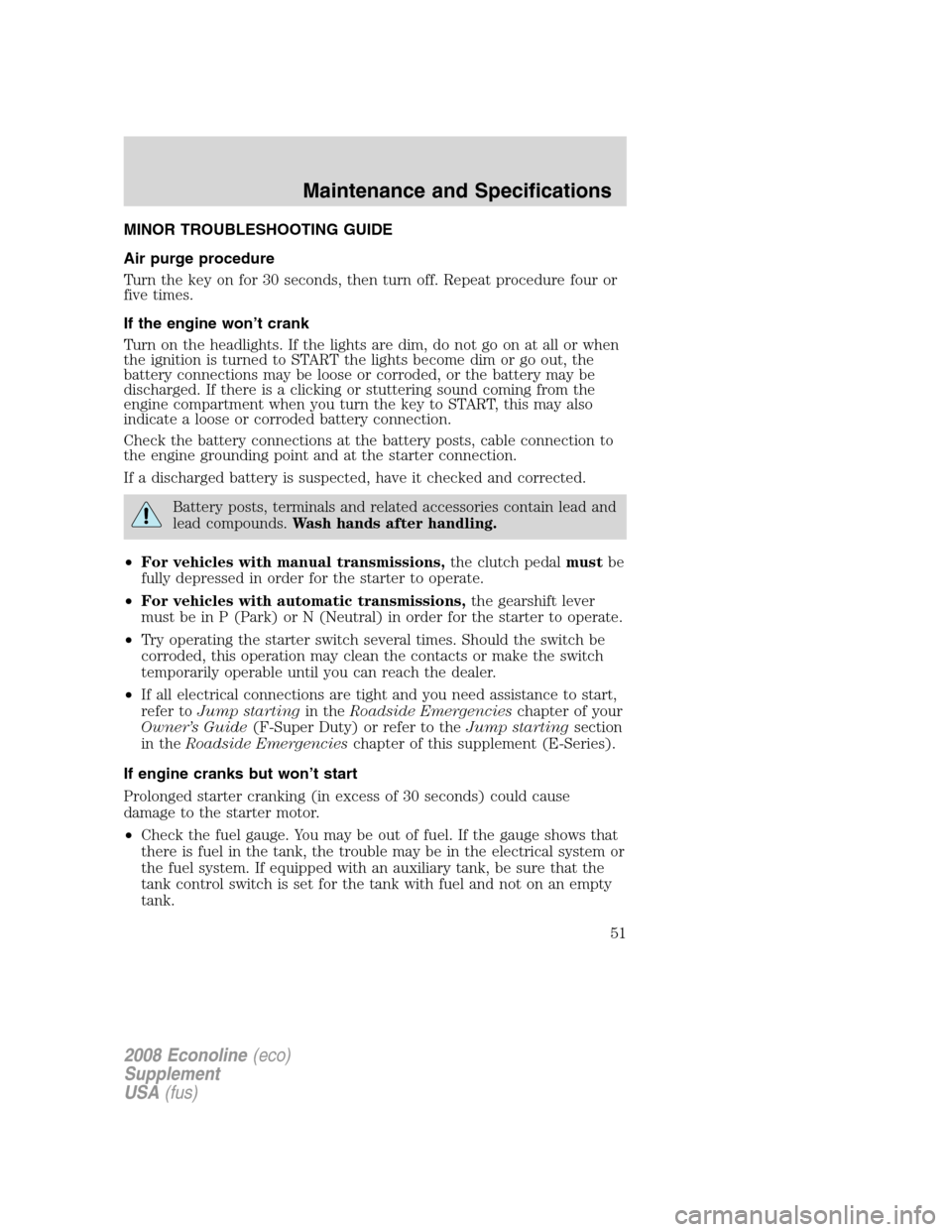

MINOR TROUBLESHOOTING GUIDE

Air purge procedure

Turn the key on for 30 seconds, then turn off. Repeat procedure four or

five times.

If the engine won’t crank

Turn on the headlights. If the lights are dim, do not go on at all or when

the ignition is turned to START the lights become dim or go out, the

battery connections may be loose or corroded, or the battery may be

discharged. If there is a clicking or stuttering sound coming from the

engine compartment when you turn the key to START, this may also

indicate a loose or corroded battery connection.

Check the battery connections at the battery posts, cable connection to

the engine grounding point and at the starter connection.

If a discharged battery is suspected, have it checked and corrected.

Battery posts, terminals and related accessories contain lead and

lead compounds.Wash hands after handling.

•For vehicles with manual transmissions,the clutch pedalmustbe

fully depressed in order for the starter to operate.

•For vehicles with automatic transmissions,the gearshift lever

must be in P (Park) or N (Neutral) in order for the starter to operate.

•Try operating the starter switch several times. Should the switch be

corroded, this operation may clean the contacts or make the switch

temporarily operable until you can reach the dealer.

•If all electrical connections are tight and you need assistance to start,

refer toJump startingin theRoadside Emergencieschapter of your

Owner’s Guide(F-Super Duty) or refer to theJump startingsection

in theRoadside Emergencieschapter of this supplement (E-Series).

If engine cranks but won’t start

Prolonged starter cranking (in excess of 30 seconds) could cause

damage to the starter motor.

•Check the fuel gauge. You may be out of fuel. If the gauge shows that

there is fuel in the tank, the trouble may be in the electrical system or

the fuel system. If equipped with an auxiliary tank, be sure that the

tank control switch is set for the tank with fuel and not on an empty

tank.

2008 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

51

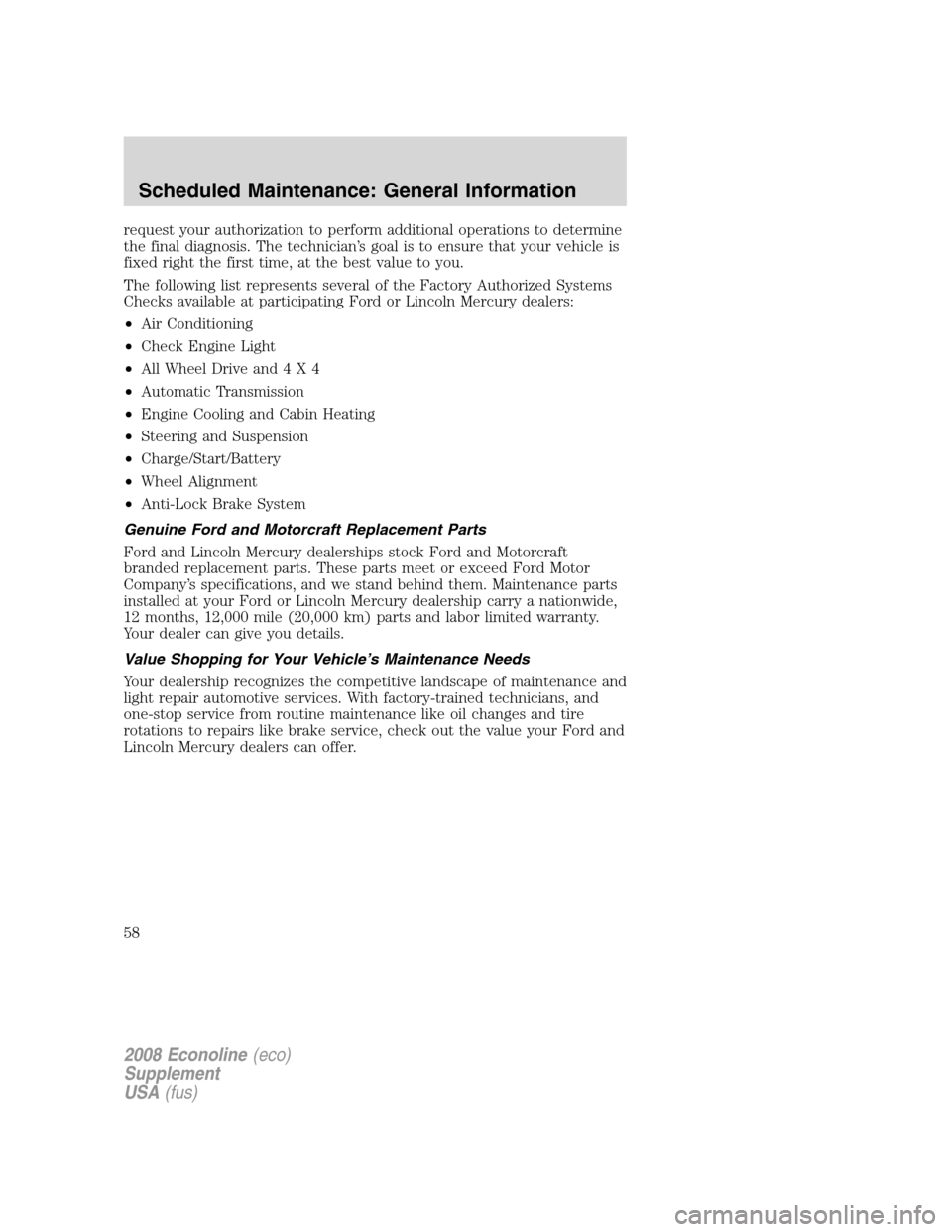

Page 58 of 96

request your authorization to perform additional operations to determine

the final diagnosis. The technician’s goal is to ensure that your vehicle is

fixed right the first time, at the best value to you.

The following list represents several of the Factory Authorized Systems

Checks available at participating Ford or Lincoln Mercury dealers:

•Air Conditioning

•Check Engine Light

•All Wheel Drive and4X4

•Automatic Transmission

•Engine Cooling and Cabin Heating

•Steering and Suspension

•Charge/Start/Battery

•Wheel Alignment

•Anti-Lock Brake System

Genuine Ford and Motorcraft Replacement Parts

Ford and Lincoln Mercury dealerships stock Ford and Motorcraft

branded replacement parts. These parts meet or exceed Ford Motor

Company’s specifications, and we stand behind them. Maintenance parts

installed at your Ford or Lincoln Mercury dealership carry a nationwide,

12 months, 12,000 mile (20,000 km) parts and labor limited warranty.

Your dealer can give you details.

Value Shopping for Your Vehicle’s Maintenance Needs

Your dealership recognizes the competitive landscape of maintenance and

light repair automotive services. With factory-trained technicians, and

one-stop service from routine maintenance like oil changes and tire

rotations to repairs like brake service, check out the value your Ford and

Lincoln Mercury dealers can offer.

2008 Econoline(eco)

Supplement

USA(fus)

Scheduled Maintenance: General Information

58

Page 60 of 96

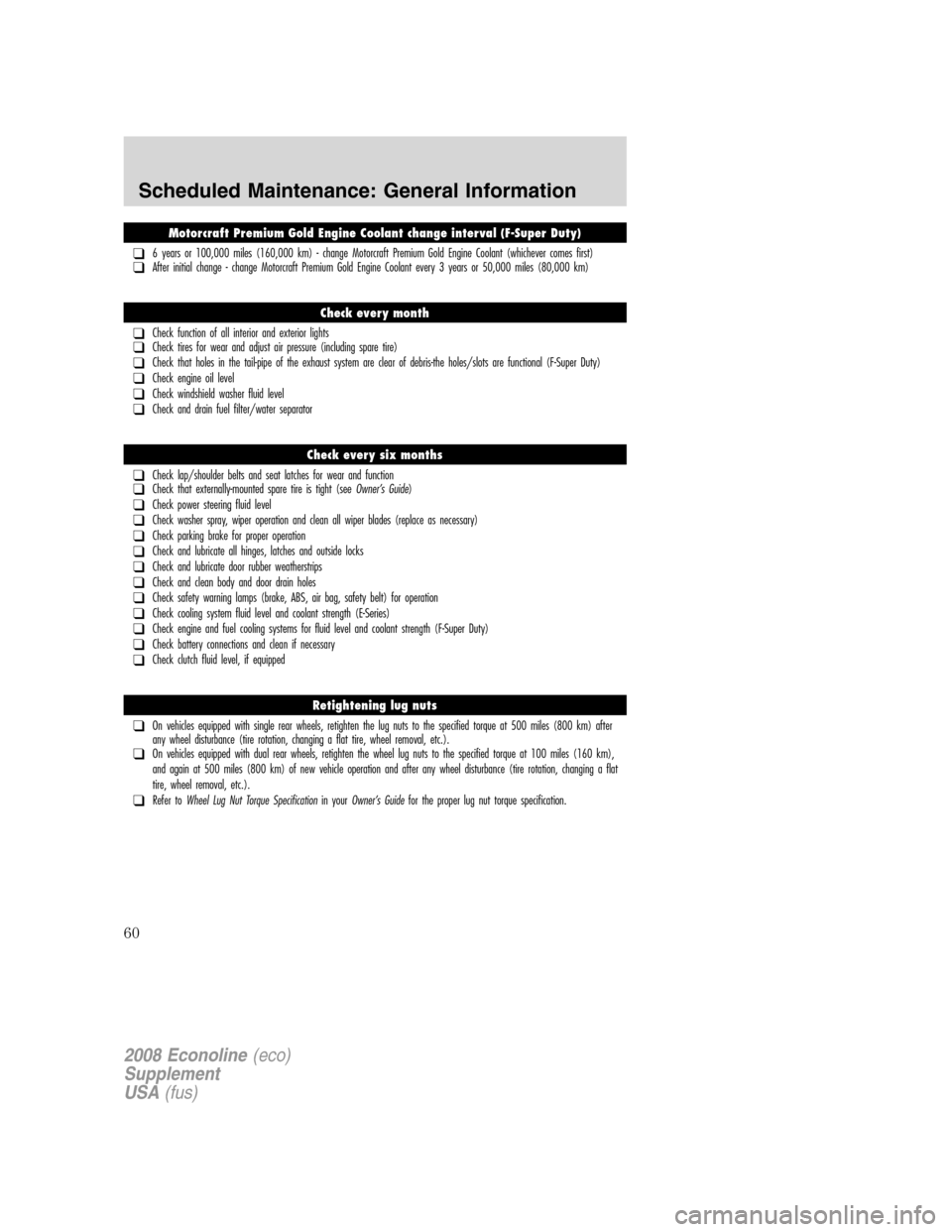

Motorcraft Premium Gold Engine Coolant change interval (F-Super Duty)

❑6 years or 100,000 miles (160,000 km) - change Motorcraft Premium Gold Engine Coolant (whichever comes first)❑After initial change - change Motorcraft Premium Gold Engine Coolant every 3 years or 50,000 miles (80,000 km)

Check every month

❑Check function of all interior and exterior lights❑Check tires for wear and adjust air pressure (including spare tire)

❑Check that holes in the tail-pipe of the exhaust system are clear of debris-the holes/slots are functional (F-Super Duty)

❑Check engine oil level

❑Check windshield washer fluid level

❑Check and drain fuel filter/water separator

Check every six months

❑Check lap/shoulder belts and seat latches for wear and function❑Check that externally-mounted spare tire is tight (seeOwner’s Guide)

❑Check power steering fluid level

❑Check washer spray, wiper operation and clean all wiper blades (replace as necessary)

❑Check parking brake for proper operation

❑Check and lubricate all hinges, latches and outside locks

❑Check and lubricate door rubber weatherstrips

❑Check and clean body and door drain holes

❑Check safety warning lamps (brake, ABS, air bag, safety belt) for operation

❑Check cooling system fluid level and coolant strength (E-Series)

❑Check engine and fuel cooling systems for fluid level and coolant strength (F-Super Duty)

❑Check battery connections and clean if necessary

❑Check clutch fluid level, if equipped

Retightening lug nuts

❑On vehicles equipped with single rear wheels, retighten the lug nuts to the specified torque at 500 miles (800 km) after

any wheel disturbance (tire rotation, changing a flat tire, wheel removal, etc.).

❑On vehicles equipped with dual rear wheels, retighten the wheel lug nuts to the specified torque at 100 miles (160 km),

and again at 500 miles (800 km) of new vehicle operation and after any wheel disturbance (tire rotation, changing a flat

tire, wheel removal, etc.).

❑Refer toWheel Lug Nut Torque Specificationin yourOwner’s Guidefor the proper lug nut torque specification.

2008 Econoline(eco)

Supplement

USA(fus)

Scheduled Maintenance: General Information

60

Page 61 of 96

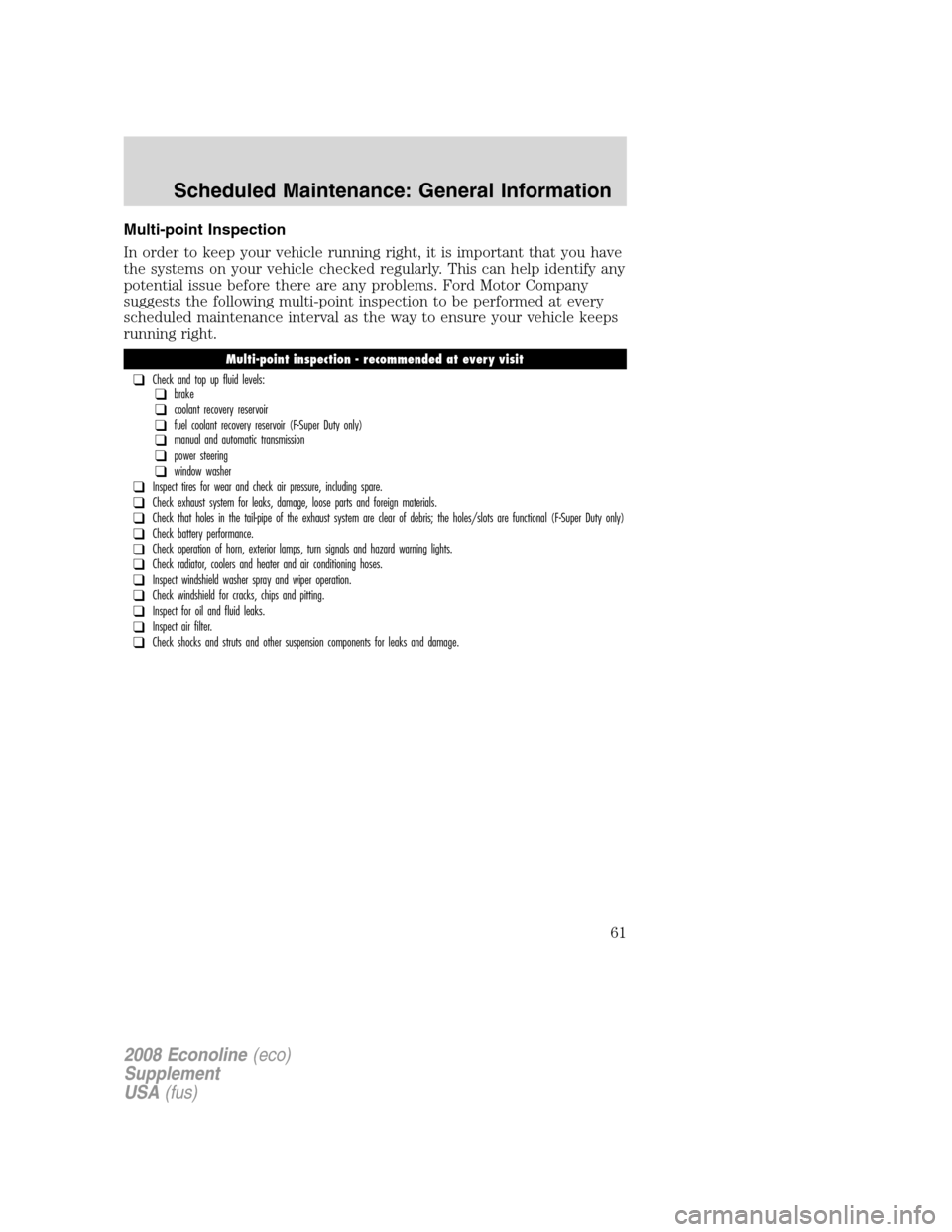

Multi-point Inspection

In order to keep your vehicle running right, it is important that you have

the systems on your vehicle checked regularly. This can help identify any

potential issue before there are any problems. Ford Motor Company

suggests the following multi-point inspection to be performed at every

scheduled maintenance interval as the way to ensure your vehicle keeps

running right.

Multi-point inspection - recommended at every visit

❑Check and top up fluid levels:❑brake

❑coolant recovery reservoir

❑fuel coolant recovery reservoir (F-Super Duty only)

❑manual and automatic transmission

❑power steering

❑window washer

❑Inspect tires for wear and check air pressure, including spare.

❑Check exhaust system for leaks, damage, loose parts and foreign materials.

❑Check that holes in the tail-pipe of the exhaust system are clear of debris; the holes/slots are functional (F-Super Duty only)

❑Check battery performance.

❑Check operation of horn, exterior lamps, turn signals and hazard warning lights.

❑Check radiator, coolers and heater and air conditioning hoses.

❑Inspect windshield washer spray and wiper operation.

❑Check windshield for cracks, chips and pitting.

❑Inspect for oil and fluid leaks.

❑Inspect air filter.

❑Check shocks and struts and other suspension components for leaks and damage.

2008 Econoline(eco)

Supplement

USA(fus)

Scheduled Maintenance: General Information

61

Page 91 of 96

EXCEPTIONS

In addition, there are several exceptions to the Normal Schedule. They

are listed below:

Normal Vehicle Axle Maintenance

❑Rear axles and power take-off (PTO) units containing synthetic lubricant and light duty trucks equipped with Ford-design axles

are lubricated for life. These lubricants are not to be checked or changed unless a leak is suspected, service is required or

the axle assembly has been submerged in water. The axle and PTO lubricant should be changed anytime the axle and PTO

have been submerged in water. Non-synthetic rear axle lubricants should be replaced every 3,000 miles (5,000 km) or 3

months, whichever occurs first, during extended trailer tow operation above 70°F (21°C) ambient and wide open throttle for

extended periods above 45 mph (72 km/h). The 3,000 mile (5,000 km) lube change interval may be waived if the axle

was filled with 75W140 synthetic gear lubricant meeting Ford specification WSL-M2C192-A, part number F1TZ-19580-B or

equivalent. Add four ounces (118 mL) of additive friction modifier C8AZ-19B546-A (EST-M2C118-A) or equivalent for com-

plete refill of Traction-Lok rear axles. The axle lubricant should be changed anytime an axle has been submerged in water.

E-450, F-450 and F-550 Axle Maintenance

❑Replace rear axle lubricant every 100,000 miles (160,000 km) under normal driving conditions on all F-450 and F-550

commercial applications. For F-450 and F-550 trucks operated at or near maximum Gross Vehicle Weights, the rear axle

lubricant should be replaced every 50,000 miles (80,000 km). In addition, this 50,000 mile (80,000 km) schedule should

be observed when the vehicles are operated under the Special Operating Conditions, where noted.

Diesel Particulate Filter (DPF) (F-Super Duty only)

❑The DPF may need to be removed for ash cleaning at approximately 120,000 miles (193,000 km) or greater (actual mile-

age can vary greatly depending upon engine/vehicle operating conditions) and replaced with a new or remanufactured (ash

cleaned) part. The filter may need to be replaced at approximately 250,000 miles (400,000 km) depending upon engine/

vehicle operating conditions. In both cases the engine control system will set a service light (

) to inform you to

bring the vehicle to the dealer for service. If there are any issues with the oxidation catalyst/DPF system a service light

(

or) will be set by the engine control system to inform you to bring the vehicle into a dealership for

service.

Biodiesel (E-Series only)

❑Biodiesel may be blended with petroleum-based diesel fuel. Such biodiesel blends are designated as BXX, where XX repre-

sents the percentage of pure biodiesel contained within the blend (e.g., B5, B20, and B100). To maintain the desired level

of performance and longevity of the engine, vehicles using biodiesel up to and including B5 should change the engine oil

and filter every 5,000 miles (8,000 km) or 200 hours of engine operation (whichever comes first).

2008 Econoline(eco)

Supplement

USA(fus)

Scheduled Maintenance: Special Information

91