remote control FORD SUPER DUTY 2008 2.G Special Off-Road Package Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2008, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2008 2.GPages: 25, PDF Size: 0.2 MB

Page 5 of 25

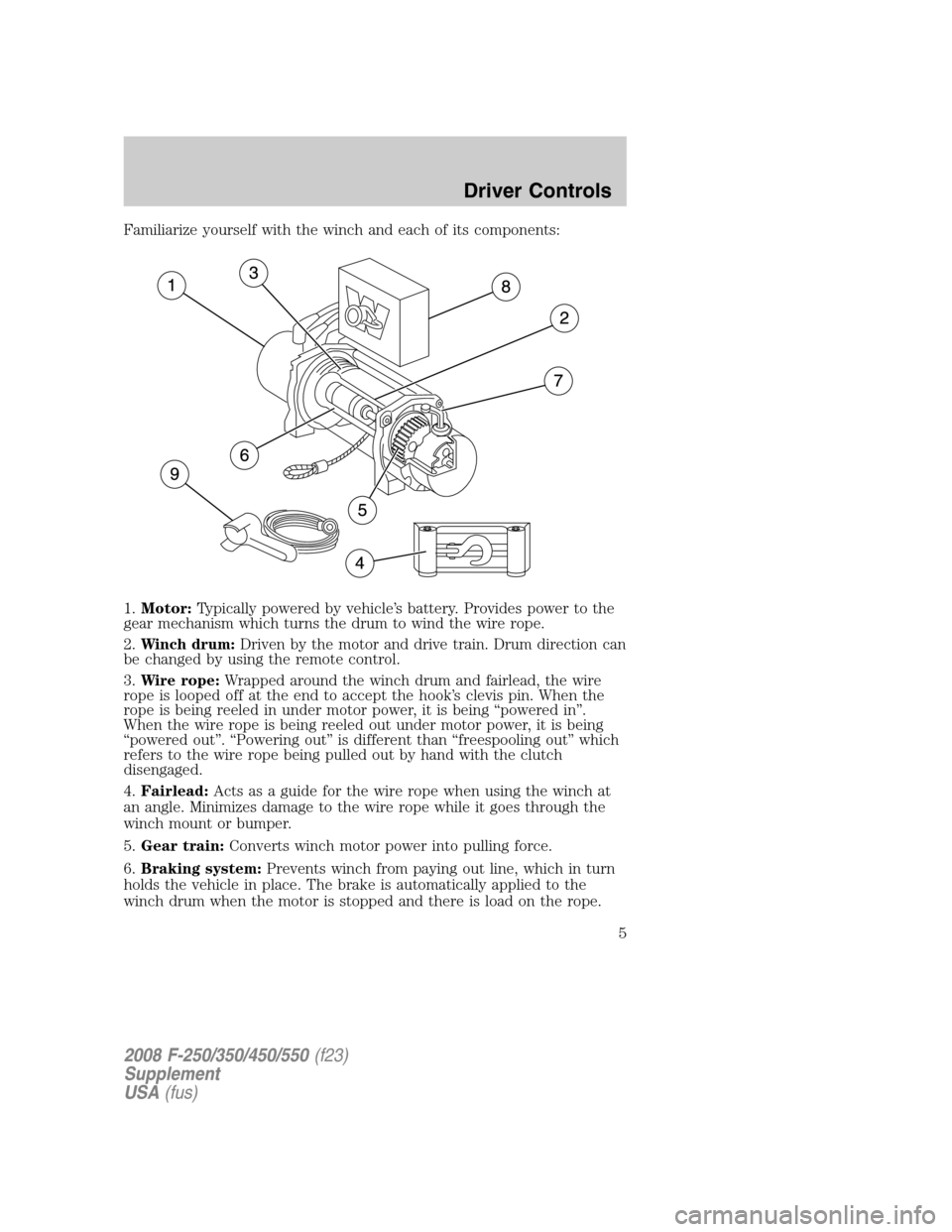

Familiarize yourself with the winch and each of its components:

1.Motor:Typically powered by vehicle’s battery. Provides power to the

gear mechanism which turns the drum to wind the wire rope.

2.Winch drum:Driven by the motor and drive train. Drum direction can

be changed by using the remote control.

3.Wire rope:Wrapped around the winch drum and fairlead, the wire

rope is looped off at the end to accept the hook’s clevis pin. When the

rope is being reeled in under motor power, it is being “powered in”.

When the wire rope is being reeled out under motor power, it is being

“powered out”. “Powering out” is different than “freespooling out” which

refers to the wire rope being pulled out by hand with the clutch

disengaged.

4.Fairlead:Acts as a guide for the wire rope when using the winch at

an angle. Minimizes damage to the wire rope while it goes through the

winch mount or bumper.

5.Gear train:Converts winch motor power into pulling force.

6.Braking system:Prevents winch from paying out line, which in turn

holds the vehicle in place. The brake is automatically applied to the

winch drum when the motor is stopped and there is load on the rope.

2008 F-250/350/450/550(f23)

Supplement

USA(fus)

Driver Controls

5

Page 6 of 25

7.Clutch:Allows the operator to manually disengage the winch drum

from the gear train, enabling the drum to freely rotate (“freespooling”).

Engaging the clutch “locks” the winch drum back onto the gear train.

Never engage or disengage the clutch if the winch is under load,

the wire rope is in tension or the winch drum is moving.

8.Control box:Enables the operator to change the direction of the

winch drum rotation.

9.Remote control:Plugs into the control box allowing the operator to

control the winch direction as well as stand clear of the wire rope while

operating the winch.

Winch accessories

Some of the following accessories are items you’ll want to have with you

to ensure safe operation of your winch; some are enhancements to add

versatility and convenience to your winch:

•Gloves:

It is extremely important to wear protective gloves while

operating the winch or handling wire rope since the rope will,

through normal use, develop sharp barbs which can slice through skin.

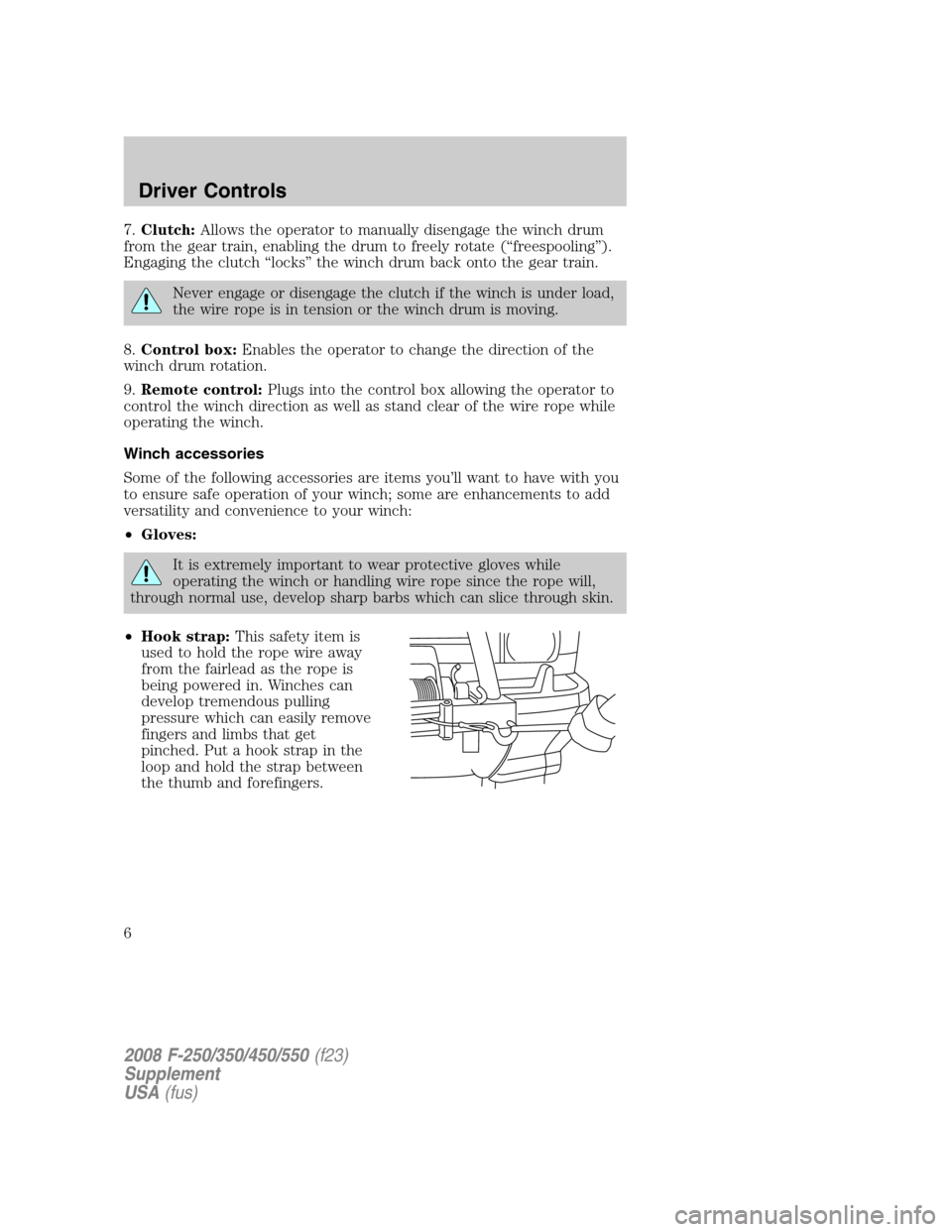

•Hook strap:This safety item is

used to hold the rope wire away

from the fairlead as the rope is

being powered in. Winches can

develop tremendous pulling

pressure which can easily remove

fingers and limbs that get

pinched. Put a hook strap in the

loop and hold the strap between

the thumb and forefingers.

2008 F-250/350/450/550(f23)

Supplement

USA(fus)

Driver Controls

6

Page 8 of 25

•Backup parts:Extra items such as an extra clevis/D-shackle or a

remote control unit should be carried in case of emergency. For

severe and/or continuous winch use, you may want to consider

including an extra wire rope and winch hook.

•Toolbox items:Always bring along hand wrenches, screwdrivers,

pliers and tools to change wire rope.

•Jumper cables:It’s always a good idea to carry jumper cables in case

your battery becomes drained during a winching operation. Also, a

dual battery system and a battery isolator kit can be installed to

prevent draining the electrical source during winching operation.

A fully charged conventional automotive battery with a minimum of 650

cold cranking amp is recommended to obtain peak performance from

your winch. Make sure all electrical connections are clean and tight.

Winch operation

Before you pull

Make sure the new rope is stretched before its first use. Unspool the

wire rope, leaving five wraps on the drum. Apply at least 500 lbs.

(227 kg) of tension. This can be done by setting up an anchor point and

pulling your vehicle to it at a slightly inclined, flat surface and letting the

vehicle roll.

Before you use your winch, remember these key points:

1. Think safety at all times.

2. Always take your time to assess your situation and plan your pull

carefully.

3. Always take your time when using the winch.

4. Use the right equipment for your situation.

5. Always wear leather gloves and do not allow the wire rope to slide

through your hands.

6. You and only you should handle the wire rope and operate the remote

control switch.

7. Practice. Practice and practice the steps.

Choosing an anchor point

A secure anchor is critical to winching operations. The anchor must be

strong enough to hold while winching. Natural anchors include trees,

stumps and rocks. Hook the rope as low as possible. If no natural

anchors are available, when recovering another vehicle, your vehicle

2008 F-250/350/450/550(f23)

Supplement

USA(fus)

Driver Controls

8

Page 10 of 25

3. Point your forefinger down and draw circles in the air about waist

height to indicate feeding more wire from the winch.

4. Tells the driver to wind the winch in short, quick bursts. Open and

close the two fingertips until you want the winch to stop.

5. To signal to stop the winch, clench fist, palm to driver, held high

enough for the driver to see and other arm straight out at shoulder

height.

6. Cross palms together to tell the driver to apply the foot brake.

7. Tells driver to give the tires more drive force to assist the winch

process.

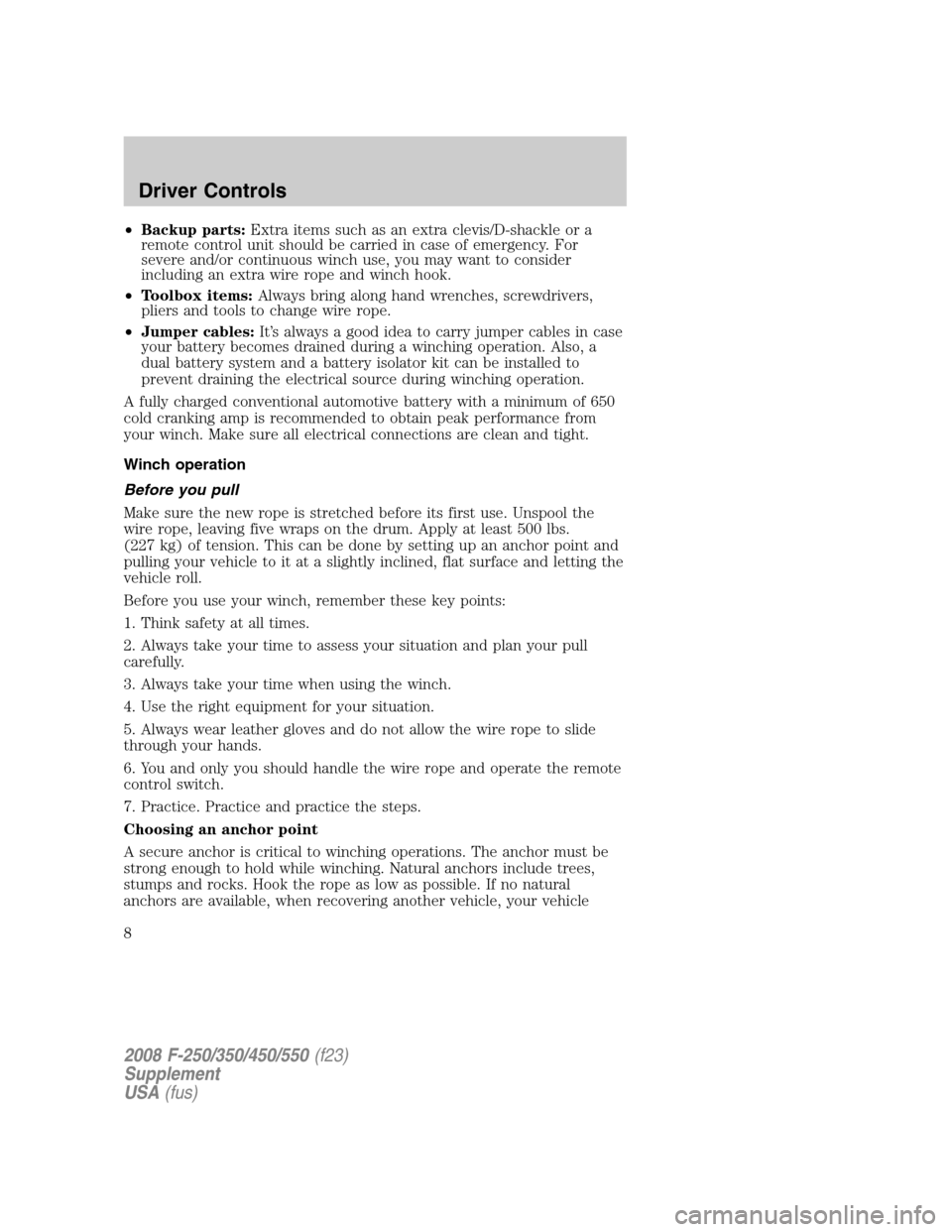

Vehicle recovery (single line)

The following steps outline how to recover your vehicle with a single

line; multiple lines follow the same basic steps but use a snatch block to

assist the process. Refer toRigging Techniqueslater in this chapter.

1. Put on leather gloves.

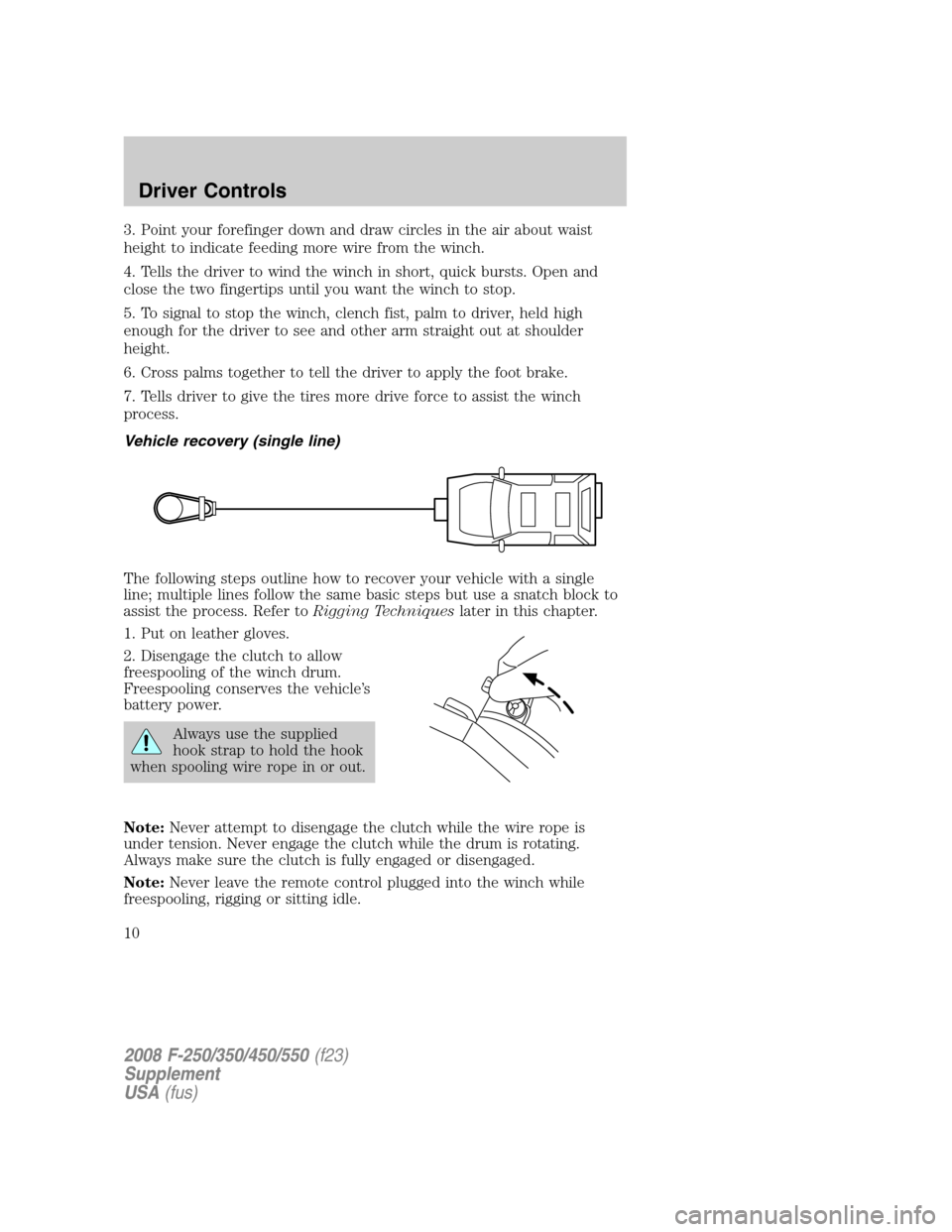

2. Disengage the clutch to allow

freespooling of the winch drum.

Freespooling conserves the vehicle’s

battery power.

Always use the supplied

hook strap to hold the hook

when spooling wire rope in or out.

Note:Never attempt to disengage the clutch while the wire rope is

under tension. Never engage the clutch while the drum is rotating.

Always make sure the clutch is fully engaged or disengaged.

Note:Never leave the remote control plugged into the winch while

freespooling, rigging or sitting idle.

2008 F-250/350/450/550(f23)

Supplement

USA(fus)

Driver Controls

10

Page 12 of 25

8. Connect the remote control. Be

careful not to let the remote control

cord dangle in front of the winch.

Always disconnect the remote

control when not in use.

9. Slowly wind the wire rope until no slack remains by using the winch

switch. Once the wire rope is under tension, stand clear and never step

over it.

10. Check the anchor point. Make sure all connections are secured and

free of debris before continuing with the winching procedure.

Note:Never use the winch as a hoist. Never use the winch’s wire rope to

tow another vehicle.

11. Check the wire rope. It should be neatly wound around the drum.

Improper winding can cause damage to the wire rope.

12. Lay something over the wire rope to absorb energy should the rope

snap. Tree limbs, heavy jackets, chain and the like may be used for this

purpose.

Note:Always avoid continuous side pulls which can pile up wire rope at

one end of the drum. This pile can damage the wire rope or the winch.

13. Make sure everyone in the immediate area is aware of the winching

operation. Tell them where they shouldn’t stand; never behind or in front

of the vehicle and never near the wire rope.

14. With the vehicle’s engine on and light tension on the wire rope, begin

winching slowly and steadily. Be sure the wire rope is winding evenly

and tightly around the drum. For assistance, the winched vehicle can be

slowly driven while being pulled by the winch.

Note:Avoid overheating of the winch motor. For extended winching,

stop at reasonable intervals to allow the winch motor to cool down.

What to look for under load

The wire rope must always spool onto the drum as indicated by the

drum rotation decal on the winch. As you power in, make sure the rope

winds evenly and tightly on the drum. This prevents the outer wrap from

drawing into the inner wraps, binding and damaging the rope. Avoid

shock loads by using the control switch intermittently to take up wire

2008 F-250/350/450/550(f23)

Supplement

USA(fus)

Driver Controls

12

Page 13 of 25

rope slack. During side pulls, the wire rope tends to stack up at one end

of the drum. This stack can become large enough to cause serious

damage to the winch. Line up pulls as straight as possible and stop

winching if the wire rope comes close to the tie rods or mounting plate.

Note:To fix an uneven stack, spool out that section of the rope and

reposition it to the opposite end of the drum; this will free up space for

continued winching.

15. For vehicle recovery, continue pulling until the vehicle is on stable

ground. If the vehicle is able to be driven, the winching operation is

complete.

16. Once recovery of the vehicle is complete, be sure to secure the

vehicle’s brakes and put the transmission in P (Park) (automatic

transmission) or 1 (First) (manual transmission). Release tension in the

wire rope.

17. Disconnect the wire rope from the anchor.

18. Rewind the wire rope. Control

the winch at all times and walk the

rope in without letting it slide

through your hands.

19. Disconnect the remote control from the control box and store it in a

clean dry place. Install the cap on the solenoid plug.

2008 F-250/350/450/550(f23)

Supplement

USA(fus)

Driver Controls

13

Page 14 of 25

How to spool under no load

Arrange the remote control lead so it cannot be caught in the winch.

Arrange the wire rope so it will not kink or tangle when spooled. Be sure

any wire rope already on the spooling drum is wound tightly and evenly

layered (unspool and tighten and layer evenly, if necessary). Keep the

wire rope under light tension and spool the wire rope back onto the

winch drum in even layers. Stop frequently to tighten and straighten the

layers as necessary. Repeat this process until the winch hook is the same

distance as the full length of the remote control from the winch. Attach

the hook strap, then walk the wire rope toward the fairlead, carefully

spooling in the remaining rope by pulsing the remote control switch.

Store the hook at the fairlead or tensioned to a suitable location to the

side.

If you do not have the hook strap, use a length of cord or something

similar.

To help prevent serious injury,neverput your fingers inside the

hook area as you are powering in.

Rigging techniques

Various winching situations will require unique winching techniques.

These could range from too little distance to achieve maximum pull

using straight line rigging, simply increasing pulling power or maintaining

a straight-line pulling situation.

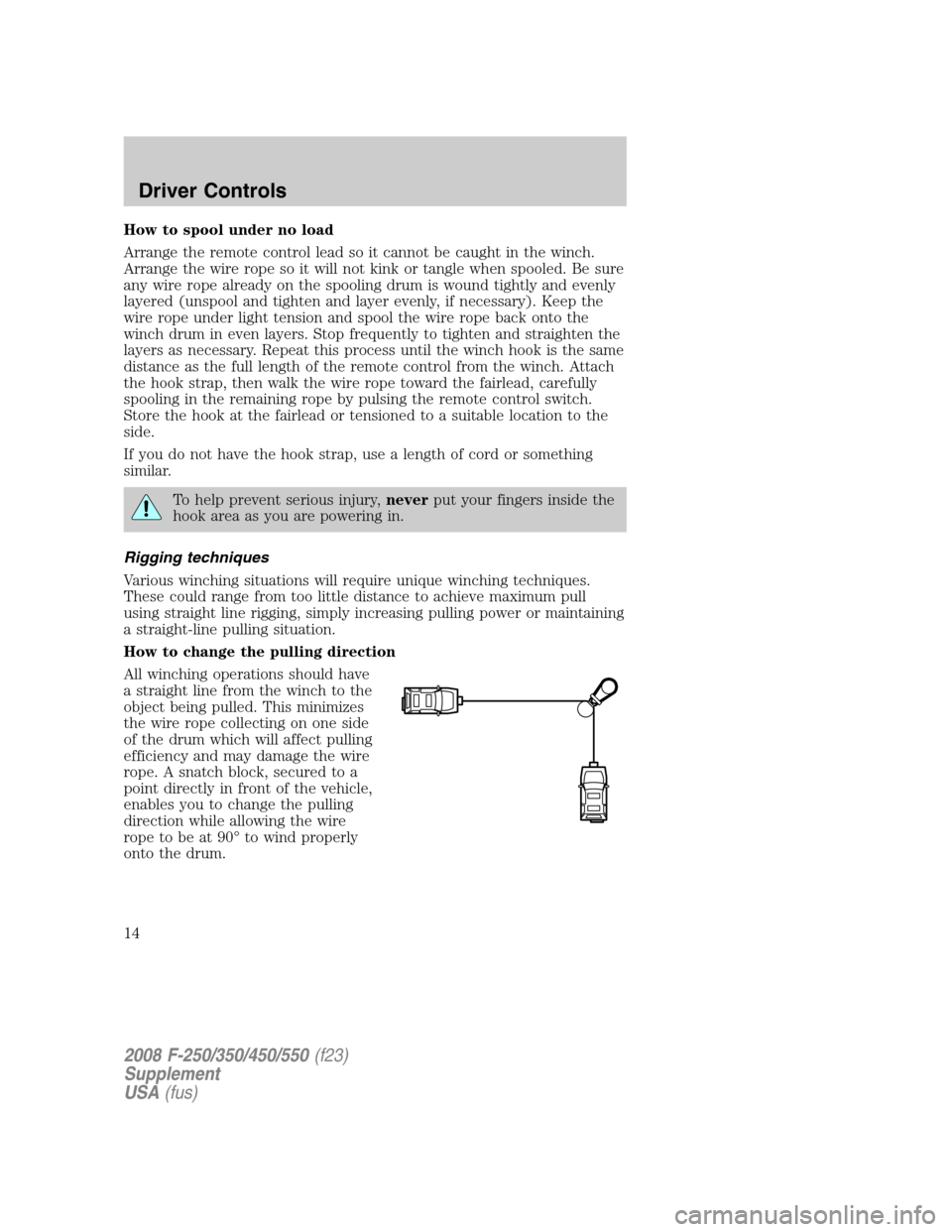

How to change the pulling direction

All winching operations should have

a straight line from the winch to the

object being pulled. This minimizes

the wire rope collecting on one side

of the drum which will affect pulling

efficiency and may damage the wire

rope. A snatch block, secured to a

point directly in front of the vehicle,

enables you to change the pulling

direction while allowing the wire

rope to be at 90° to wind properly

onto the drum.

2008 F-250/350/450/550(f23)

Supplement

USA(fus)

Driver Controls

14

Page 16 of 25

Triple line

Use the same techniques as a

double line.

Select a strong mounting location on your vehicle for the snatch block

and the clevis/D-shackle. Keep at a 90° angle between the winch and run

the wire rope to the first anchor point and through the snatch block.

Secure the rope back to the vehicle. Put the rope through the snatch

block and secure it with the clevis/D-shackle on the vehicle as close to

the winch as possible. Run the rope to the final anchor point.

Secure to the anchor point with a tree protector or choker chain. Attach the

clevis/D-shackle. Attach the clevis/D-shackle to the two ends of the protector/

chain, being careful not to overtighten (tighten and back off

1�2turn).

Secure the winch hook. While keeping the line near the ground, insert

the winch hook through the clevis/D-shackle. Check the anchor. Make

sure all connections are secured and free of debris before continuing

with the winching procedure.

Maintenance

•Inspect the wire rope before and after each winching operation. If the

wire rope has become kinked or frayed, it needs to be replaced. Be

sure to also inspect the winch hook and hook pin for signs of wear or

damage. Replace as necessary.

•

Keep winch, wire rope and switch control free from contaminants. Use a

clean rag or towel to remove any dirt and debris. If necessary, unwind the

winch completely (leaving a minimum of five wraps of rope on the drum)

and wipe it clean before rewinding it. Using a light oil on the rope and

winch hook can keep rust and corrosion from forming.

•Operating the winch for an extended period of time places an

additional load on your vehicle battery. Be sure to check and maintain

your battery and battery cables according to manufacturer guidelines.

Also, inspect the switch control and all electrical connections to be

certain they are clean and tight fitting.

•Inspect the remote control, if so equipped, for damage. Be sure to cap

the remote socket to prevent dirt and debris from entering the

connections. Store the remote control in a dry, protected area.

•No lubrication is required for the life of the winch.

2008 F-250/350/450/550(f23)

Supplement

USA(fus)

Driver Controls

16

Page 19 of 25

Dual action remote control suspension (if equipped)

To operate the system:

1. Push the red button to pressurize the system for a firmer ride.

2. Push the black buttons on the bleed valves for a softer ride. Separate

bleed valves allow independent adjustment of front and rear shocks.

Note:Do not operate the compressor for more than 30 seconds at a

time. Allow the compressor to cool down for one minute between

operations.

Note:Stop compressor operation when the arrow on the gauge reaches

maximum. Continuing to supply pressure will not make the shocks any

firmer and damage to the system will occur.

The following table is an example of typical settings for the suspension.

Setting Front Rear

High-speed firm ride 8 6

Slow-speed soft ride 2 2

Towing 5 8

2008 F-250/350/450/550(f23)

Supplement

USA(fus)

Driving

19