recommended oil FORD SUPER DUTY 2009 2.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2009, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2009 2.GPages: 103, PDF Size: 0.75 MB

Page 5 of 103

Lubrication system

Extended oil change intervals can negatively affect engine performance,

fuel economy and engine life. Refer to the engine oil specification chart

located underEngine oil specificationsin theMaintenance and

Specificationschapter of this supplement.

On E-Series vehicles (6.0L engine),it is important to change the

engine oil at the recommended service intervals because oil viscosity is

important in maintaining the oil pressure required to actuate the fuel

injectors.

On F-Super Duty vehicles (6.4L engine),it is important to change

the engine oil at the recommended service intervals to maintain oil

viscosity with the addition of the diesel particulate filter (DPF).

Fast start glow plug system

The glow plug system consists of:

•eight glow plugs

•the glow plug control module (GPCM)

•engine oil temperature (EOT) sensor

•barometric pressure (BARO) sensor

The glow plug system is

electronically controlled by the

PCM. The GPCM energizes the glow

plugs immediately after the ignition

is placed in the ON position, then determines how long the glow plugs

will be on according to the EOT and BARO sensors. The required time

for the glow plugs to be energized decreases as the engine oil

temperature and barometric pressure increase.

Engine cooling system

The engine cooling system contains an engine oil cooler and an Exhaust

Gas Recirculation (EGR) cooler. The oil cooler’s function is to regulate

engine oil temperature. The EGR cooler function is to cool exhaust gases

before they are circulated back through the engine to reduce emissions.

Vehicles with diesel engines typically are used to carry heavy loads and

accumulate mileage rapidly. These two factors may cause the additives in

the coolant to “wear out” in a shorter time. Refer to the Special

Operating Conditions section for more information about coolant

additives and coolant change intervals. Operating the engine with

insufficient coolant and/or coolant additive can cause severe engine

damage.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Introduction

5

Page 11 of 103

STARTING THE ENGINE

Read all starting instructions carefully before you start your vehicle.

For temperatures below 32°F (0°C), the use of the correct grade engine

oil is essential for proper operation. Refer toEngine oil specifications

in theMaintenance and Specificationschapter for more information.

Your vehicle may be equipped with a cold weather starting strategy that

prevents severe engine damage by assisting in engine lubrication

warm-up. In extremely cold ambient temperatures, this strategy activates

and prevents the accelerator pedal from being used for 30 seconds after

starting the vehicle. By not allowing the accelerator pedal to be used, the

engine oil is allowed to properly lubricate the bearings preventing engine

damage due to lack of proper lubrication. After the 30 second warm-up

period, the accelerator pedal will be operational again as long as the

pedal is not being pressed when the 30 second time limit expires. When

starting the engine in extremely cold temperatures (-15°F [–26°C]), it is

recommended to allow the engine to idle for several minutes before

driving the vehicle.

If your vehicle is equipped with a manual transmission,make sure

the parking brake is fully set before you turn the key. Depress the clutch

pedal and place the gearshift in the neutral position. The clutch must be

fully depressed in order to operate the starter. Do not press the

accelerator during starting.

If your vehicle is equipped with an automatic transmission,ensure

the gearshift lever is in P (Park) and the parking brake is fully set before

you turn the key. Do not press the accelerator during starting.

Engine-driven cooling fan (fan clutch)

Your vehicle is equipped with an engine driven cooling fan drive (also

called a fan clutch). This fan drive changes the fan speed to match the

vehicle’s changing cooling air flow requirements. Fan speed, fan noise

level and fuel consumption all will increase based on the driving

conditions that include trailer towing, hill climbing, heavy loads, high

speed and high ambient temperature, individually or in combination. The

fan drive is designed to provide the minimum fan speed (and resulting

fan noise and fuel consumption) required to meet the ever changing

vehicle cooling air flow requirements. You will hear the amount of fan

noise increasing and decreasing as the engine power requirements and

vehicle driving conditions change as you drive. This is to be expected as

being normal to the operation of your vehicle. High levels of fan noise

might also be heard when your engine is first started, and should

normally decrease after driving for a short time.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Driving

11

Page 12 of 103

Cold weather starting

It is recommended that the engine block heater be used for starting

when the temperature is -10°F (-23°C) or colder. Refer toEngine block

heater (if equipped)in theDrivingchapter of theOwner’s Guide.

When operating in cold weather, use Motorcraft Cetane improvers or non

alcohol-based Cetane improvers from a reputable manufacturer.

Do not crank the engine for more than 10 seconds as starter damage

may occur. If the engine fails to start, turn the key to 3 (off) and wait

30 seconds before trying again.

WARNING:Do not use starting fluid, such as ether, in the air

intake system (see air filter decal). Such fluid could cause

immediate explosive damage to the engine and possible personal injury.

WARNING:Do not add gasoline, gasohol or alcohol to diesel

fuel. This practice creates a serious fire hazard and causes

engine performance problems.

1. Turn the key to on without turning the key to start.Do not start the

engineuntil the glow-plug pre-heat indicator

turns off.

2. When the glow plug pre-heat

indicator turns off, turn the key to

start, then release the key as soon

as the engine starts. The glow plugs

will continue to be activated for two minutes after the glow plug pre-heat

indicator

has turned off. If the engine is not started before the

glow plug activation time ends, the glow plugs will need to be reset by

turning the key to off.

3. After the engine starts,allow it to idle for about 15 seconds. This

is to protect the engine. Do not increase engine speed until the oil

pressure gauge indicates normal pressure.

ENGINE IDLE SHUTDOWN (IF EQUIPPED)

Your vehicle may be equipped with an engine idle shutdown system. This

system will automatically shut down your engine when it has been idling

in P (Park) or N (Neutral) for five minutes (parking brake set) or

15 minutes (parking brake not set). When the engine idle shutdown

process has started:

•A chime will sound and the message center will displayENGINE

TURNS OFF IN XX30 seconds prior to shutdown and begins

counting down to zero.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Driving

12

Page 13 of 103

•The timer can be reset by changing the position of the accelerator

pedal, brake pedal or the park brake within the final 30 seconds.

•When the timer reaches zero, the engine shuts down and the message

center will displayENGINE TURNED OFF.

•One minute after the engine has shut down, the electrical system will

simulate key off, even though the ignition is still in the on position,

initiating normal accessory delay period.

•The ignition must be moved to the off position to reset the system

before restarting the vehicle.

Note:The engine idle shutdown idle timer will not start if:

•The engine is operating in power take-off (PTO) mode.

•The engine coolant temperature is below 60°F (16°C).

•The exhaust emission control device (DPF) is regenerating.

STOPPING THE ENGINE

Turn the ignition to the OFF position.

On E-Series vehicles,

to prolong engine life (after extended high speed

or maximum GVW operation), it is recommended that a hot engine be idled

for 7–10 minutes which will allow the turbocharged engine to cool down.

On F-Super Duty vehicles,to prolong engine life (especially after

extended high speed, high ambient temperature, or high GVW/GCW

operation), it is recommended that a hot engine be idled for 3-5 minutes

which will allow the turbocharged engine to cool down.

COLD WEATHER OPERATION

Changing to a lighter grade engine oil also makes starting easier under

these conditions. Refer toEngine oil specificationsin theMaintenance

and Specificationschapter of this supplement.

At temperatures below 20°F (–7°C), number 2–D diesel fuel may thicken

enough to clog the fuel filter. Your vehicle is equipped with either an

FCM (E-Series) or an HFCM (F-Super Duty) which acts as a fuel

filter/water separator to keep the wax melted which will help prevent

fuel filter clogging. However, if the engine starts but stalls after a short

time and will not restart, the fuel filter(s) may be clogged. For best

results in cold weather, use Number 1–D diesel fuel or “winterized”

Number 2–D diesel fuel which has an additive to minimize wax

formation. If you have problems operating on biodiesel during cold

weather, you may need to use a diesel fuel with lower biodiesel content,

try another brand, or discontinue the use of biodiesel.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Driving

13

Page 14 of 103

Your vehicle is also equipped with a bypass relief valve, located in the

fuel tank pick-up boot, which provides fuel flow to the engine if the fuel

pickup should become plugged by ice or wax. To allow the bypass valve

to function and avoid engine fuel starvation, it is recommended that,

during cold weather operation 32°F (0°C) or below, the fuel level in your

tank should not be allowed to drop below

1�4full. This will help prevent

air from entering the fuel system and stalling the engine.

In cold weather below 32°F (0°C), the engine will slowly increase to a

higher idle speed if left idling in P (Park). As the engine warms-up, the

engine sound level will decrease due to the activation of PCM-controlled

sound reduction features.

If your vehicle is operated in a heavy snow storm or blowing snow

conditions, the engine air induction may become partially clogged with

snow and/or ice. If this occurs, the engine may experience a significant

reduction in power output. At the earliest opportunity, clear all the snow

and/or ice away from inside the air filter assembly. Take the top off the

assembly, leaving the air filter in, and remove any snow or ice.

In order to operate the engine in temperatures of 32°F (0°C) or lower,

read the following instructions:

•Make sure that the batteries are of sufficient size and are fully

charged. Check other electrical components to make sure they are in

optimum condition.

•Use Motorcraft Premium Gold Engine Coolant solution at the

concentration recommended to protect the engine against damage

from freezing.

•Try to keep the fuel tank full as much as possible at the end of

operation to prevent condensation in the fuel system.

•Make sure you use proper cold weather engine oil and that it is at its

proper level. Also, if necessary, make sure to follow the engine oil and

filter change schedule found under theSpecial operating conditions

section in thescheduled maintenance guideinformation.

•At temperatures of -10°F (-23°C) or below, it is recommended that

you use an engine block heater to improve cold engine starting.

•If operating in arctic temperatures of -20°F (-29°C) or lower, consult

your truck dealer for information about special cold weather

equipment and precautions.

Note:Idling in cold weather will not heat the engine to its normal

operating temperature. Long periods of idling in cold weather can cause

a buildup of heavy deposits of carbon and rust on valve stems causing

them to stick, which in turn, can cause valve train damage.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Driving

14

Page 35 of 103

BIODIESEL

Diesel fuel containing no more than 5% biodiesel may be used. To help

achieve acceptable engine performance and durability, it is important to

only use biodiesel of good quality in your diesel engine. At a minimum,

the biodiesel should comply with ASTM D6751 or an equivalent

specification.

Use of biodiesel in concentrations greater than 5% may cause damage to

your vehicles fuel system components such as fuel tank, fuel lines, fuel

pump, fuel sender and fuel injectors. Concentrations greater than 5% can

also cause fuel filter restrictions that may result in a lack of power and

or fuel pump and fuel injector failure.

Look for a label on the fuel pump to confirm the amount of biodiesel

contained in a diesel fuel. Biodiesel content is often indicated with the

letter “B” followed by the percent of biodiesel in the fuel. For example,

B5 indicates a fuel containing 5% biodiesel. Ask the service station

attendant to confirm the biodiesel content of a diesel fuel if you do not

see a label on the fuel pump.

Biodiesel should not be stored in the fuel tank for more than three

months. If your vehicle will be parked or stored for more than three

months, then your vehicle should be drained and filled with a diesel fuel

not containing biodiesel.

During cold weather, if you have problems operating on biodiesel, you

may need to use a diesel fuel with lower biodiesel content, try another

brand, or discontinue the use of biodiesel.

Biodiesel use may affect the recommended oil change intervals. Refer to

theSpecial Operating Conditionssection in theschedule

maintenance guidefor more information about oil change intervals and

other maintenance when operating on biodiesel.

Biodiesel fuel is a product that has been converted from renewable fuel

sources, including vegetable oil, animal fat and cooking oil. Raw or

refined vegetable oil, animal fat, cooking oil or recycled greases should

not be used.

Do not use home heating oil, agricultural fuel or any diesel fuel

not intended for highway use. Damage to the fuel injection

system, engine and exhaust catalyst can occur if an improper fuel

is used. Do not add gasoline, gasohol or alcohol to diesel fuel.

This practice creates a serious fire hazard and engine

performance problems.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

35

Page 36 of 103

FUEL REQUIREMENTS - CHOOSING THE RIGHT FUEL: VEHICLES

OPERATED WHERE ULTRA LOW SULFUR DIESEL FUEL IS NOT

REQUIRED

For a 6.4L engine to operate reliably on low sulfur or high sulfur diesel

fuel, the 6.4L engine must be a high sulfur configured engine or a ULSD

fuel-configured engine that has been retrofitted for high sulfur diesel fuel

use.

Use only a 6.4L diesel engine that has been configured for use

with high sulfur diesel fuel in markets with diesel fuel that has

sulfur content greater than 15 ppm. Using low sulfur diesel fuel

(16–500 ppm) or high sulfur diesel fuel (greater than 500 ppm) in

a 6.4L diesel engine designed to use only Ultra Low Sulfur Diesel

fuel increases the likelihood of engine oil dilution with fuel which

may lead to major engine damage. Engine damage from using the

improper type of fuel is not covered under your warranty.

Vehicles with 6.4L engines configured for use with high sulfur diesel fuel

will only be made available for sale in countries where ULSD fuel is not

available or mandated by the government. Vehicles originally sold in a

ULSD fuel market that are subsequently exported to non-ULSD fuel

markets will need to be retrofitted (at the customer’s expense) in order

to be reliably operated on non-ULSD fuel.

Vehicles equipped with a 6.0L engine that are operated in a market that

does not require ULSD fuel may be operated on higher sulfur fuel

without any engine fuel system or emissions-related concerns.

Number 1-D or winter blend number 2-D fuel is recommended at

temperatures below 20°F (-7°C) (seeCold weather operationin the

Drivingchapter of this supplement).

BIODIESEL

Diesel fuel containing no more than 5% biodiesel may be used. To help

achieve acceptable engine performance and durability, it is important to

only use biodiesel of good quality in your diesel engine. At a minimum,

the biodiesel should comply with ASTM D6751 or an equivalent

specification.

Use of biodiesel in concentrations greater than 5% may cause damage to

your vehicles fuel system components such as fuel tank, fuel lines, fuel

pump, fuel sender and fuel injectors. Concentrations greater than 5% can

also cause fuel filter restrictions that may result in a lack of power and

or fuel pump and fuel injector failure.

Look for a label on the fuel pump to confirm the amount of biodiesel

contained in a diesel fuel. Biodiesel content is often indicated with the

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

36

Page 37 of 103

letter “B” followed by the percent of biodiesel in the fuel. For example,

B5 indicates a fuel containing 5% biodiesel. Ask the service station

attendant to confirm the biodiesel content of a diesel fuel if you do not

see a label on the fuel pump.

Biodiesel should not be stored in the fuel tank for more than three

months. If your vehicle will be parked or stored for more than three

months, then your vehicle should be drained and filled with a diesel fuel

not containing biodiesel.

During cold weather, if you have problems operating on biodiesel, you

may need to use a diesel fuel with lower biodiesel content, try another

brand, or discontinue the use of biodiesel.

Biodiesel use may affect the recommended oil change intervals. Refer to

theSpecial Operating Conditionssection in theschedule

maintenance guidefor more information about oil change intervals and

other maintenance when operating on biodiesel.

Biodiesel fuel is a product that has been converted from renewable fuel

sources, including vegetable oil, animal fat and cooking oil. Raw or

refined vegetable oil, animal fat, cooking oil or recycled greases should

not be used.

Do not use home heating oil, agricultural fuel or any diesel fuel

not intended for highway use. Damage to the fuel injection

system, engine and exhaust catalyst can occur if an improper fuel

is used. Do not add gasoline, gasohol or alcohol to diesel fuel.

This practice creates a serious fire hazard and engine

performance problems.

Fuel quality

It should not be necessary to add any aftermarket additives to your fuel

tank if you use a properly formulated diesel fuel that meets the ASTM D

975 industry specification. Aftermarket additives can damage the injector

system or engine. Repairs to correct the effects of using an aftermarket

product in your fuel may not be covered by your warranty.

Do not blend used engine oil with diesel fuel under any

circumstances.Blending used oil with the fuel will significantly increase

your vehicle’s exhaust emissions and reduce engine life due to increased

internal wear.

Many of the world’s automakers approved the World-wide Fuel Charter

that recommends diesel fuel specifications to provide improved

performance and emission control system protection for your vehicle.

Diesel fuel that meets the World-wide Fuel Charter should be used when

available. Ask your fuel supplier about fuel that meets the World-wide

Fuel Charter.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

37

Page 44 of 103

Installation - both

The engine will not run properly if the fuel filter is not installed

in housing.

1. Install the new fuel filter and cap seal into the fuel filter housing.

Refer toMotorcraft Part Numberslater in this chapter for the fuel filter

part number.

2. Tighten cap onto fuel filter housing slowly, allowing fuel to soak into

the fuel filter element. Tighten cap until it contacts the housing.

Turn the ignition key to on for 30 seconds, then turn it to off. Do this a

total of six times in a row to purge any trapped air from the fuel system.

Replace the filter bowl O-ring with new seal (included in filter kit) every

time you service the filter.

After filter service, a no start or rough running engine may indicate that

air is entering the system through the filter bowl seal or drain. Make sure

the drain lever is pointing rearward and stowed against the HFCM case.

Using a fuel which has more than average impurities may require

the fuel filter to be replaced more frequently than the service

interval specifies.

ENGINE OIL

Checking the engine oil level

Because it is normal to add some oil between oil changes, check your

engine oil level each time you stop for fuel. To check the engine oil level

consistently and accurately, the following procedure is recommended:

1. Have engine at normal operating temperature (at least into the

NORMAL range on the engine coolant temperature gauge).

2. Park the vehicle on a level surface, then turn off the engine and open

the hood.

3. Allow at least20 minutesafter engine shutdown to ensure that the

oil contained in the upper parts of the engine has returned to the oil

pan.

4. Protecting yourself from engine heat, pull out the dipstick, wipe it

clean and reinsert fully.

5. Read oil level on both sides of dipstick and use highest level (reading)

for the actual engine oil level.

6. Maintain the oil level between MIN and MAX or the ADD and

OPERATING RANGE on the dipstick by adding oil as required. The

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

44

Page 45 of 103

distance from MIN to MAX or ADD to OPERATING RANGE on the

dipstick represents 2.0 quarts (1.9L). Do not overfill. If the oil level

exceeds MAX or OPERATING RANGE, oil consumption may result.

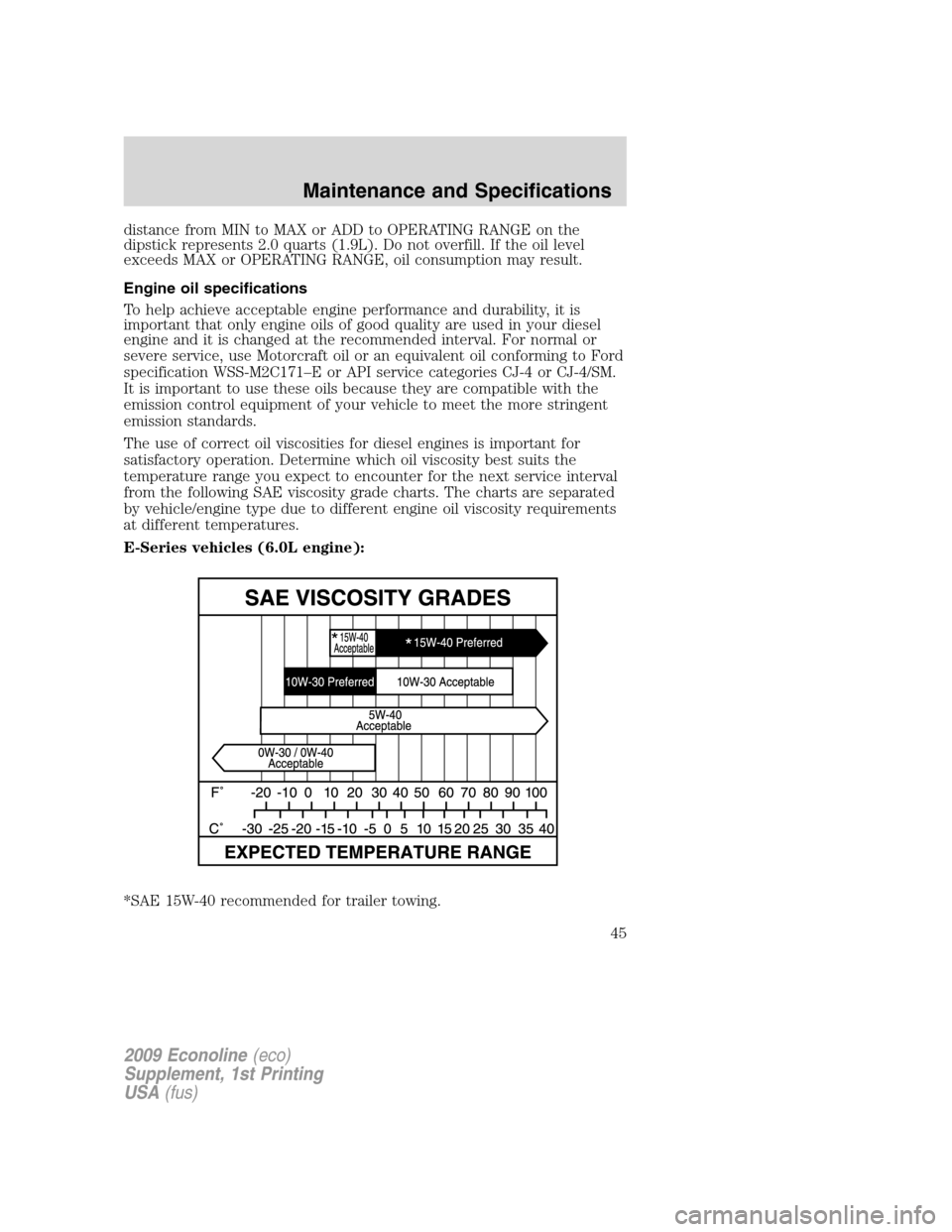

Engine oil specifications

To help achieve acceptable engine performance and durability, it is

important that only engine oils of good quality are used in your diesel

engine and it is changed at the recommended interval. For normal or

severe service, use Motorcraft oil or an equivalent oil conforming to Ford

specification WSS-M2C171–E or API service categories CJ-4 or CJ-4/SM.

It is important to use these oils because they are compatible with the

emission control equipment of your vehicle to meet the more stringent

emission standards.

The use of correct oil viscosities for diesel engines is important for

satisfactory operation. Determine which oil viscosity best suits the

temperature range you expect to encounter for the next service interval

from the following SAE viscosity grade charts. The charts are separated

by vehicle/engine type due to different engine oil viscosity requirements

at different temperatures.

E-Series vehicles (6.0L engine):

*SAE 15W-40 recommended for trailer towing.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

45