wheel FORD SUPER DUTY 2009 2.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2009, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2009 2.GPages: 418, PDF Size: 3.55 MB

Page 328 of 418

T-Type/Mini-Spare Tire Information (Harley Davidson only)

Your vehicle may be equipped with a temporary spare tire. This spare

tire is considered “temporary”. Replace the temporary spare with a tire

of the same size, speed rating, and load carrying capacity as the other

road tires as soon as possible.

When driving with the temporary spare tiredo not:

•Exceed 50 mph (80 km/h)

•Load the vehicle beyond maximum vehicle load rating listed on the

Safety Compliance Label

•Tow a trailer

•Use snow chains on the end of the vehicle with the temporary spare

tire

•Use more than one temporary spare tire at a time

Use of a temporary spare tire at any one wheel location can lead to

impairment of the following:

•Handling, stability and braking performance

•Comfort and noise

•Ground clearance and parking at curbs

•Winter weather driving capability

•Wet weather driving capability

Stopping and securing the vehicle

WARNING:To help prevent the vehicle from moving when you

change a tire, be sure the parking brake is set, then block (in

both directions) the wheel that is diagonally opposite to the tire being

changed.

Refer to the instruction sheet (located in the glove box) for detailed tire

change instructions.

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

328

Page 329 of 418

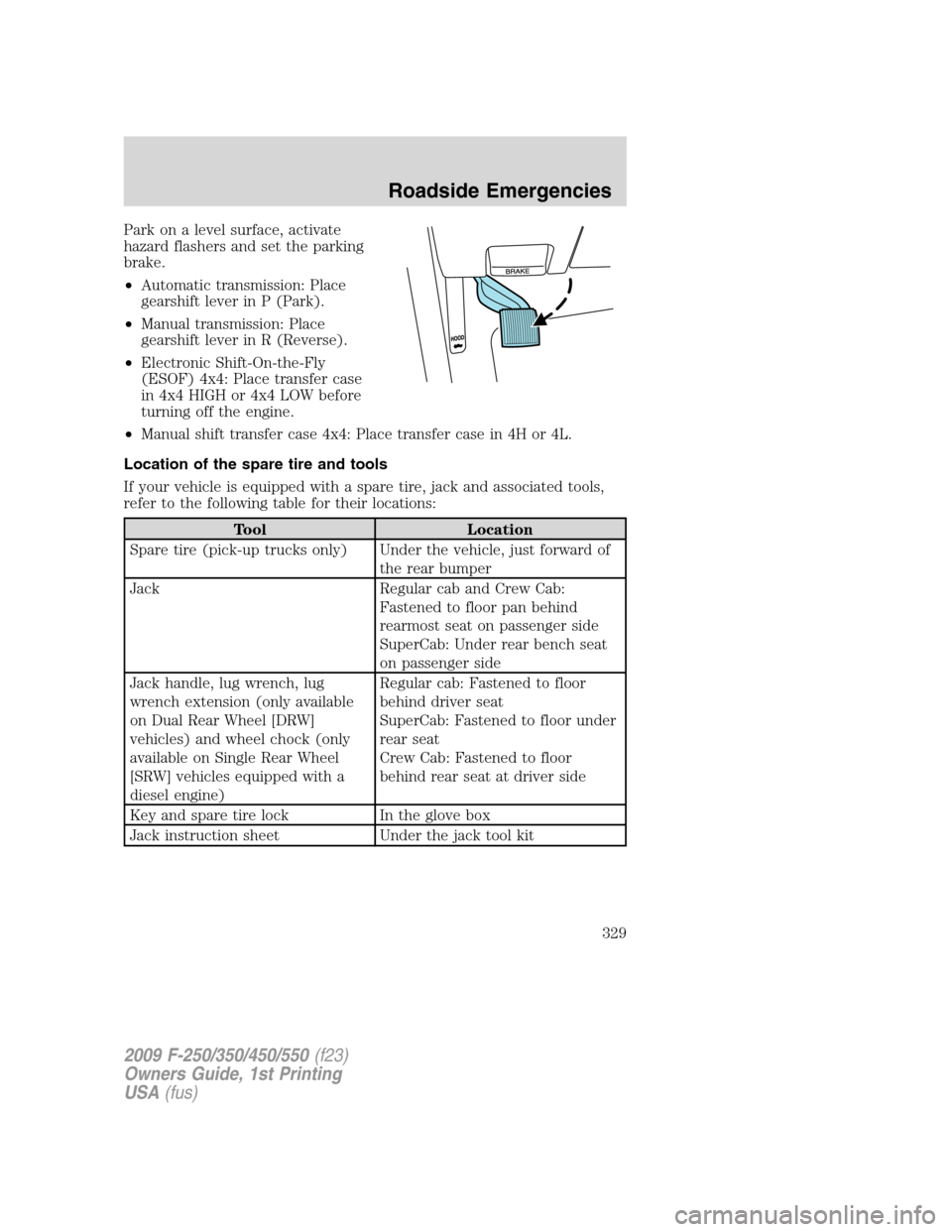

Park on a level surface, activate

hazard flashers and set the parking

brake.

•Automatic transmission: Place

gearshift lever in P (Park).

•Manual transmission: Place

gearshift lever in R (Reverse).

•Electronic Shift-On-the-Fly

(ESOF) 4x4: Place transfer case

in 4x4 HIGH or 4x4 LOW before

turning off the engine.

•Manual shift transfer case 4x4: Place transfer case in 4H or 4L.

Location of the spare tire and tools

If your vehicle is equipped with a spare tire, jack and associated tools,

refer to the following table for their locations:

Tool Location

Spare tire (pick-up trucks only) Under the vehicle, just forward of

the rear bumper

Jack Regular cab and Crew Cab:

Fastened to floor pan behind

rearmost seat on passenger side

SuperCab: Under rear bench seat

on passenger side

Jack handle, lug wrench, lug

wrench extension (only available

on Dual Rear Wheel [DRW]

vehicles) and wheel chock (only

available on Single Rear Wheel

[SRW] vehicles equipped with a

diesel engine)Regular cab: Fastened to floor

behind driver seat

SuperCab: Fastened to floor under

rear seat

Crew Cab: Fastened to floor

behind rear seat at driver side

Key and spare tire lock In the glove box

Jack instruction sheet Under the jack tool kit

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

329

Page 330 of 418

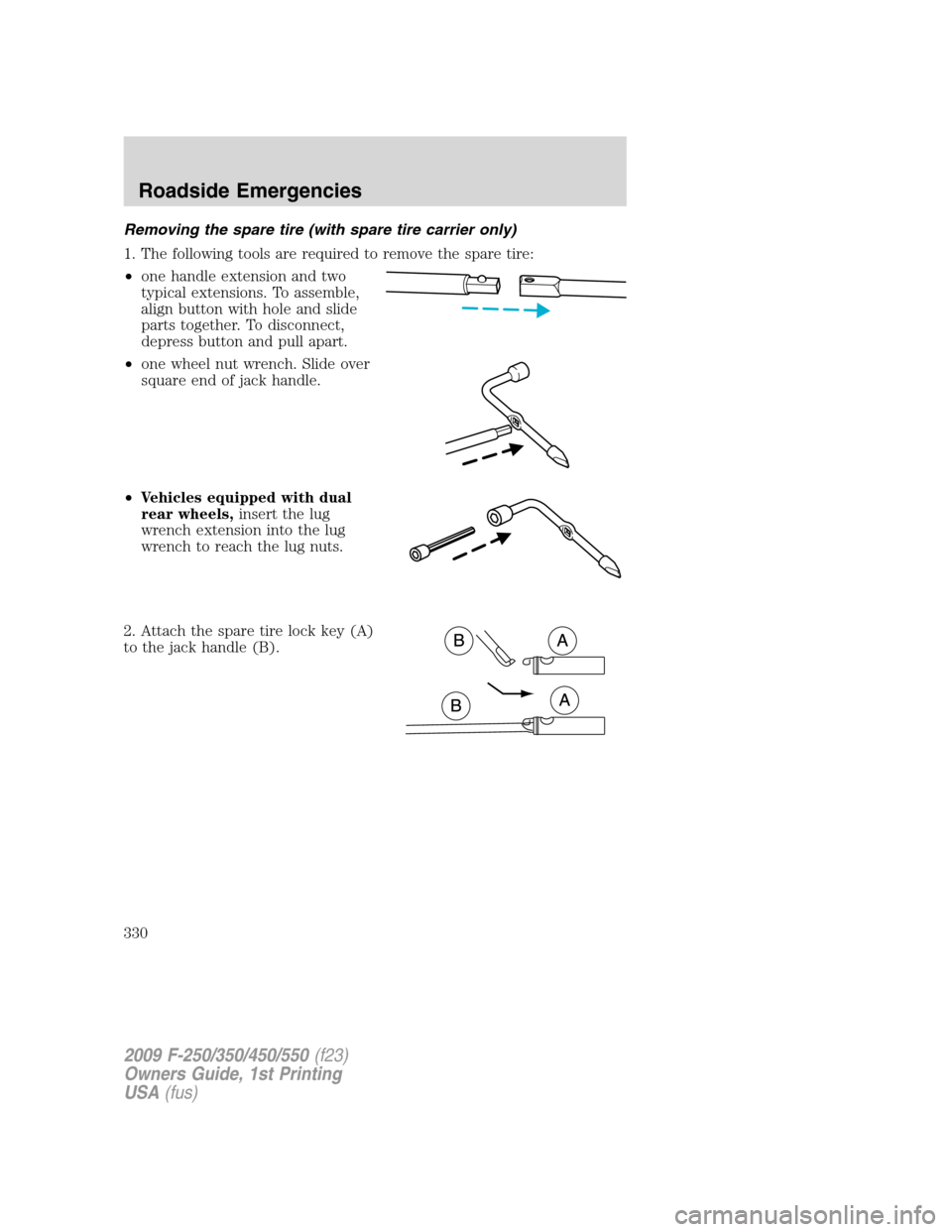

Removing the spare tire (with spare tire carrier only)

1. The following tools are required to remove the spare tire:

•one handle extension and two

typical extensions. To assemble,

align button with hole and slide

parts together. To disconnect,

depress button and pull apart.

•one wheel nut wrench. Slide over

square end of jack handle.

•Vehicles equipped with dual

rear wheels,insert the lug

wrench extension into the lug

wrench to reach the lug nuts.

2. Attach the spare tire lock key (A)

to the jack handle (B).

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

330

Page 331 of 418

3. Fully insert the jack handle (with

one extension) through the bumper

hole and into the guide tube. The

key and lock will engage with a

slight push and counterclockwise

turn. Some resistance will be felt

when turning the jack handle

assembly.

4. Turn the handle counterclockwise

and lower the spare tire until you

can slide the tire rearward and the

cable is slack.

5. Remove the retainer through the center of the wheel.

Tire change procedure

WARNING:When one of the rear wheels is off the ground, the

transmission alone will not prevent the vehicle from moving or

slipping off the jack, even if the transmission is in P (Park) (automatic

transmission) or R (Reverse) (manual transmission). To help prevent

the vehicle from moving when you change the tire, be sure that the

parking brake is set and the diagonally opposite wheel is blocked.

WARNING:To prevent the vehicle from moving when you

change a tire, be sure the parking brake is set, then block (in

both directions) the wheel that is diagonally opposite (other side and

end of the vehicle) to the tire being changed.

WARNING:If the vehicle slips off the jack, you or someone else

could be seriously injured.

WARNING:Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off the road to

avoid the danger of being hit when operating the jack or changing the

wheel.

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

331

Page 332 of 418

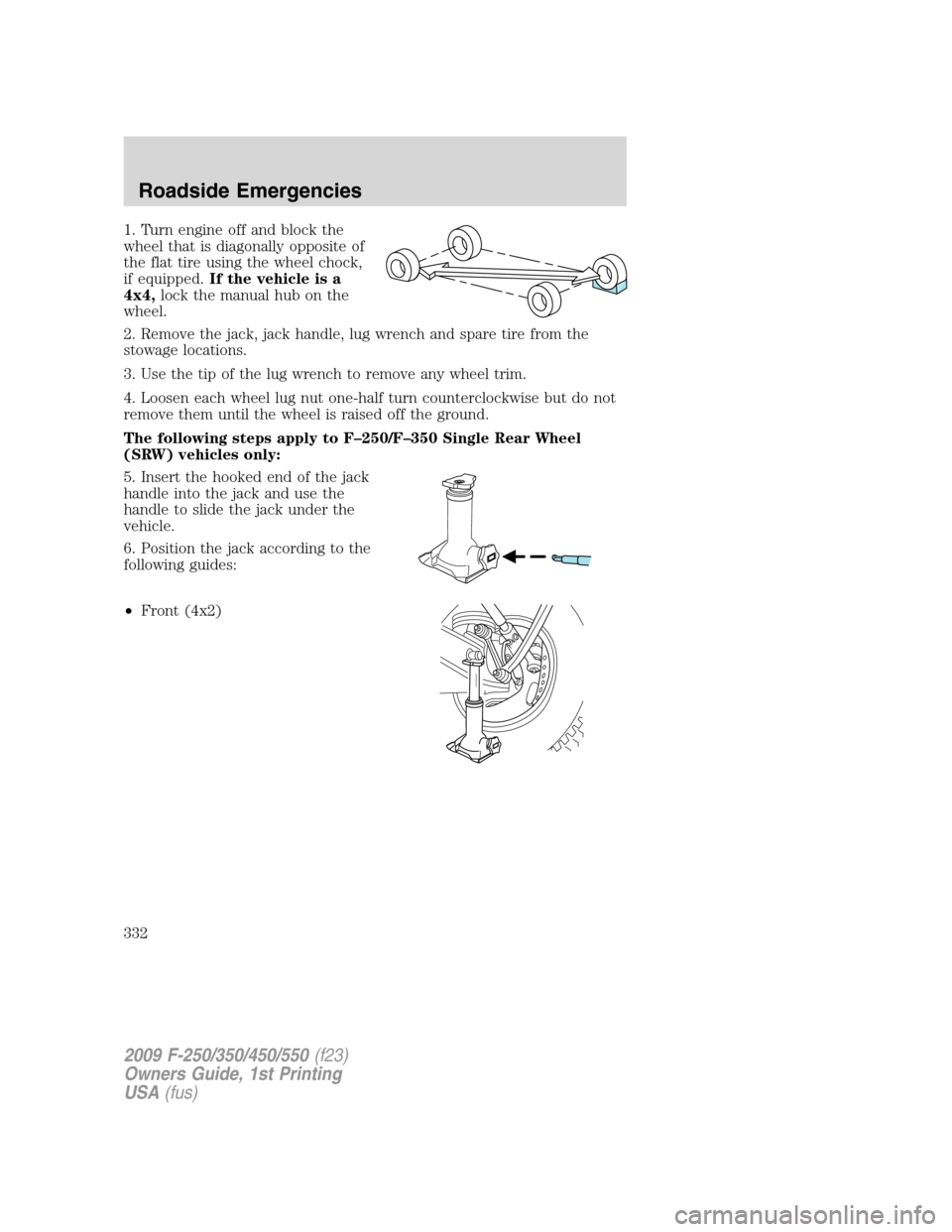

1. Turn engine off and block the

wheel that is diagonally opposite of

the flat tire using the wheel chock,

if equipped.If the vehicle is a

4x4,lock the manual hub on the

wheel.

2. Remove the jack, jack handle, lug wrench and spare tire from the

stowage locations.

3. Use the tip of the lug wrench to remove any wheel trim.

4. Loosen each wheel lug nut one-half turn counterclockwise but do not

remove them until the wheel is raised off the ground.

The following steps apply to F–250/F–350 Single Rear Wheel

(SRW) vehicles only:

5. Insert the hooked end of the jack

handle into the jack and use the

handle to slide the jack under the

vehicle.

6. Position the jack according to the

following guides:

•Front (4x2)

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

332

Page 334 of 418

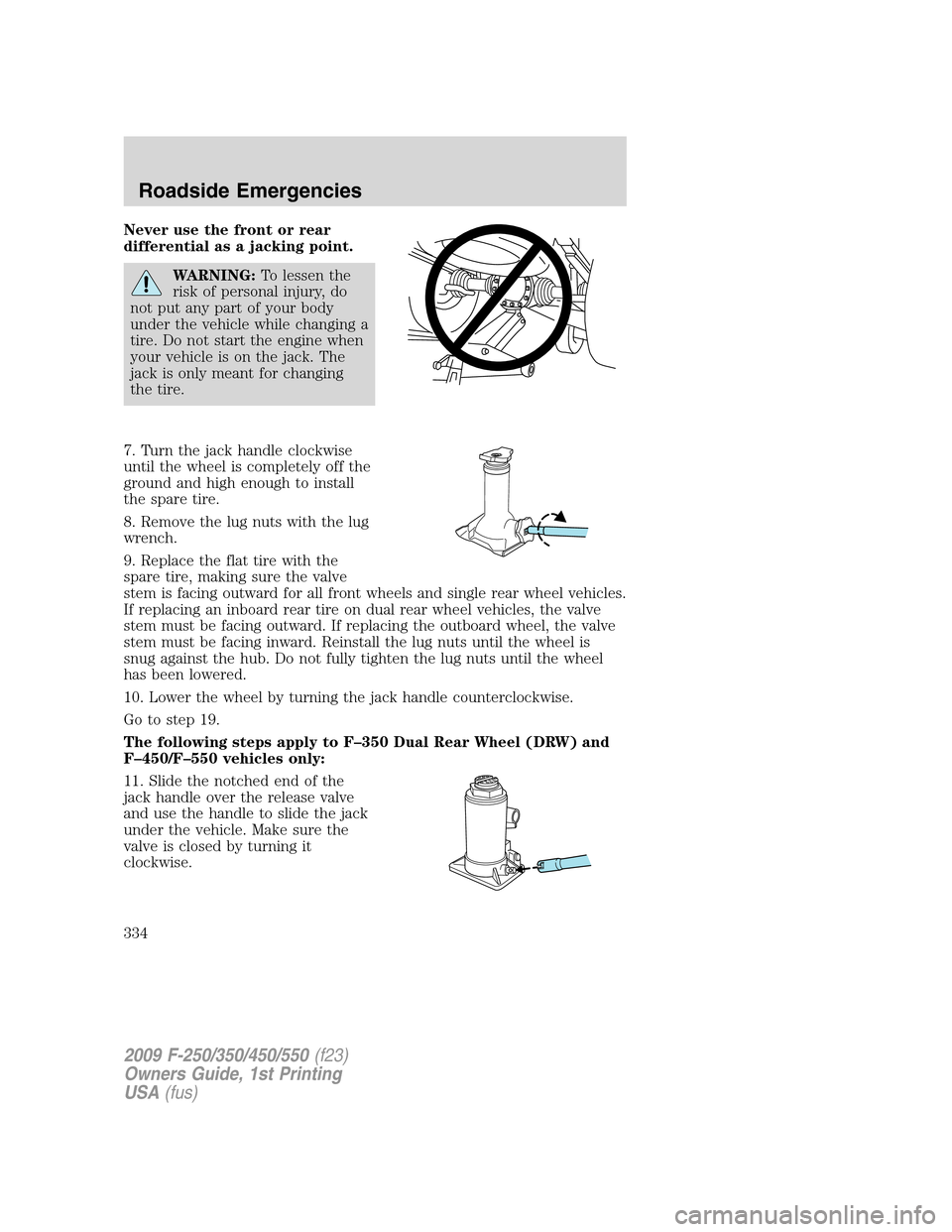

Never use the front or rear

differential as a jacking point.

WARNING:To lessen the

risk of personal injury, do

not put any part of your body

under the vehicle while changing a

tire. Do not start the engine when

your vehicle is on the jack. The

jack is only meant for changing

the tire.

7. Turn the jack handle clockwise

until the wheel is completely off the

ground and high enough to install

the spare tire.

8. Remove the lug nuts with the lug

wrench.

9. Replace the flat tire with the

spare tire, making sure the valve

stem is facing outward for all front wheels and single rear wheel vehicles.

If replacing an inboard rear tire on dual rear wheel vehicles, the valve

stem must be facing outward. If replacing the outboard wheel, the valve

stem must be facing inward. Reinstall the lug nuts until the wheel is

snug against the hub. Do not fully tighten the lug nuts until the wheel

has been lowered.

10. Lower the wheel by turning the jack handle counterclockwise.

Go to step 19.

The following steps apply to F–350 Dual Rear Wheel (DRW) and

F–450/F–550 vehicles only:

11. Slide the notched end of the

jack handle over the release valve

and use the handle to slide the jack

under the vehicle. Make sure the

valve is closed by turning it

clockwise.

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

334

Page 336 of 418

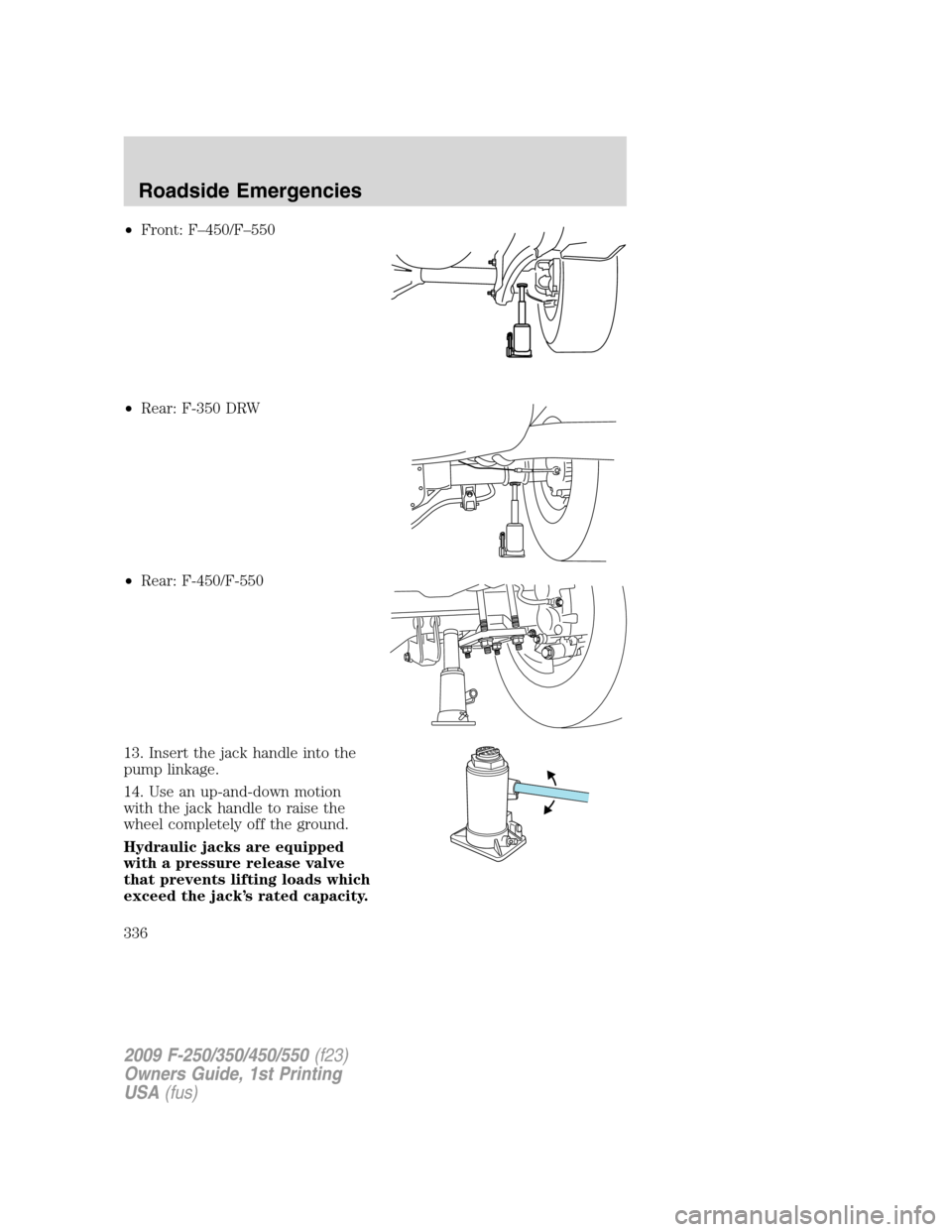

•Front: F–450/F–550

•Rear: F-350 DRW

•Rear: F-450/F-550

13. Insert the jack handle into the

pump linkage.

14. Use an up-and-down motion

with the jack handle to raise the

wheel completely off the ground.

Hydraulic jacks are equipped

with a pressure release valve

that prevents lifting loads which

exceed the jack’s rated capacity.

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

336

Page 337 of 418

15. Remove the lug nuts with the lug wrench.

16. Replace the flat tire with the spare tire, making sure the valve stem

is facing outward on all front an inboard rear wheels. If replacing the

outboard wheel, the valve stem must be facing inward. Reinstall the lug

nuts until the wheel is snug against the hub. Do not fully tighten the lug

nuts until the wheel has been lowered.

17. Lower the wheel by slowly turning the release valve

counterclockwise. Opening the release valve slowly will provide a more

controlled rate of descent.

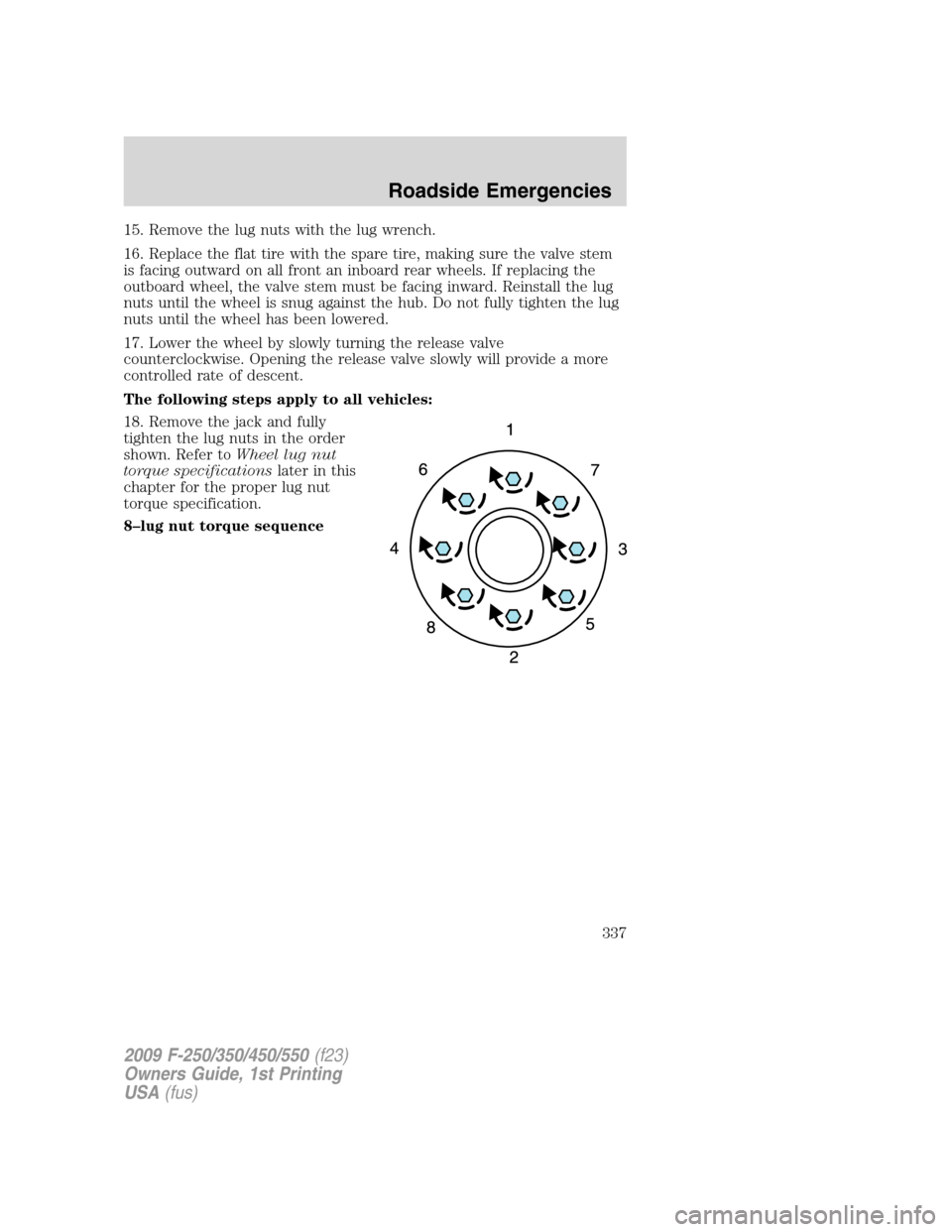

The following steps apply to all vehicles:

18. Remove the jack and fully

tighten the lug nuts in the order

shown. Refer toWheel lug nut

torque specificationslater in this

chapter for the proper lug nut

torque specification.

8–lug nut torque sequence

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

337

Page 338 of 418

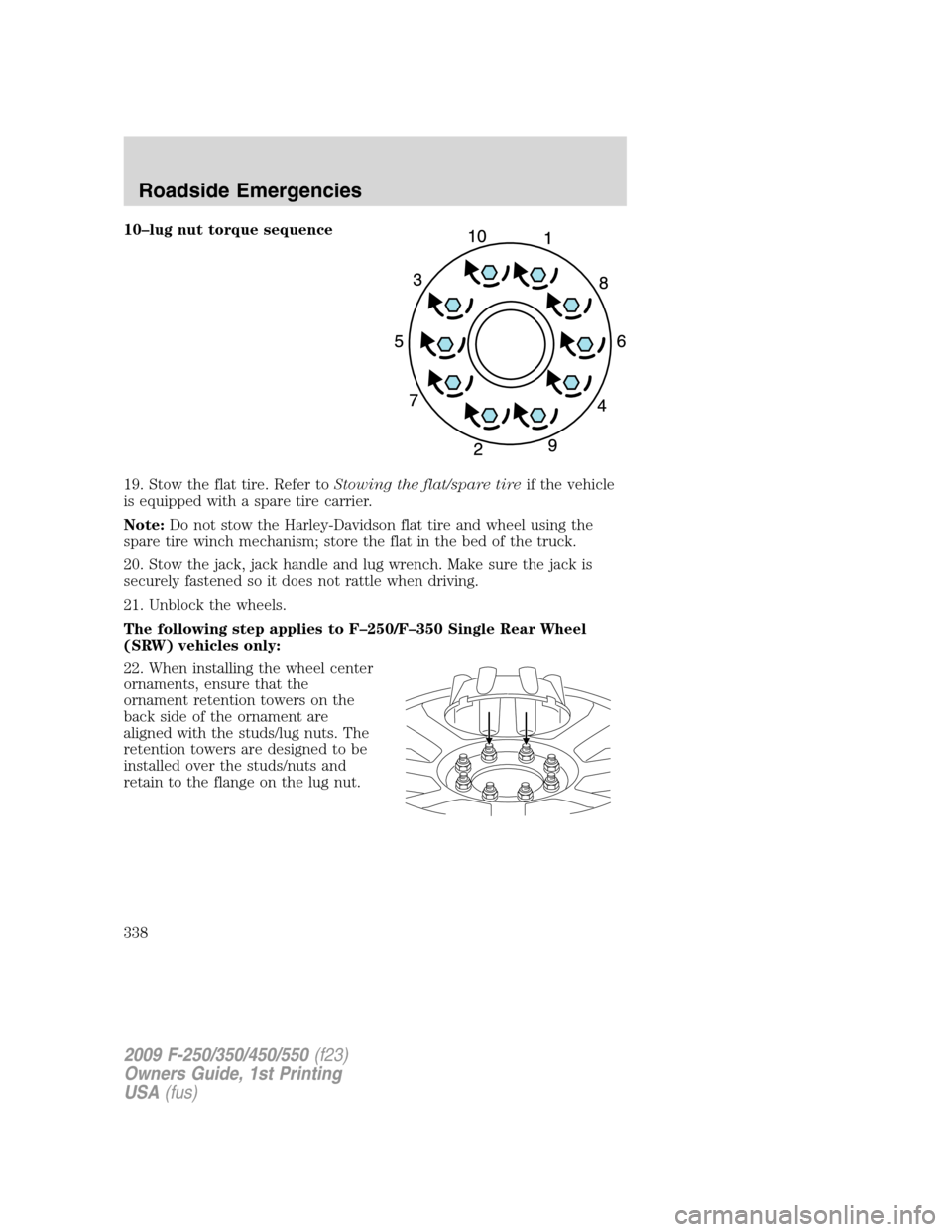

10–lug nut torque sequence

19. Stow the flat tire. Refer toStowing the flat/spare tireif the vehicle

is equipped with a spare tire carrier.

Note:Do not stow the Harley-Davidson flat tire and wheel using the

spare tire winch mechanism; store the flat in the bed of the truck.

20. Stow the jack, jack handle and lug wrench. Make sure the jack is

securely fastened so it does not rattle when driving.

21. Unblock the wheels.

The following step applies to F–250/F–350 Single Rear Wheel

(SRW) vehicles only:

22. When installing the wheel center

ornaments, ensure that the

ornament retention towers on the

back side of the ornament are

aligned with the studs/lug nuts. The

retention towers are designed to be

installed over the studs/nuts and

retain to the flange on the lug nut.

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

338

Page 339 of 418

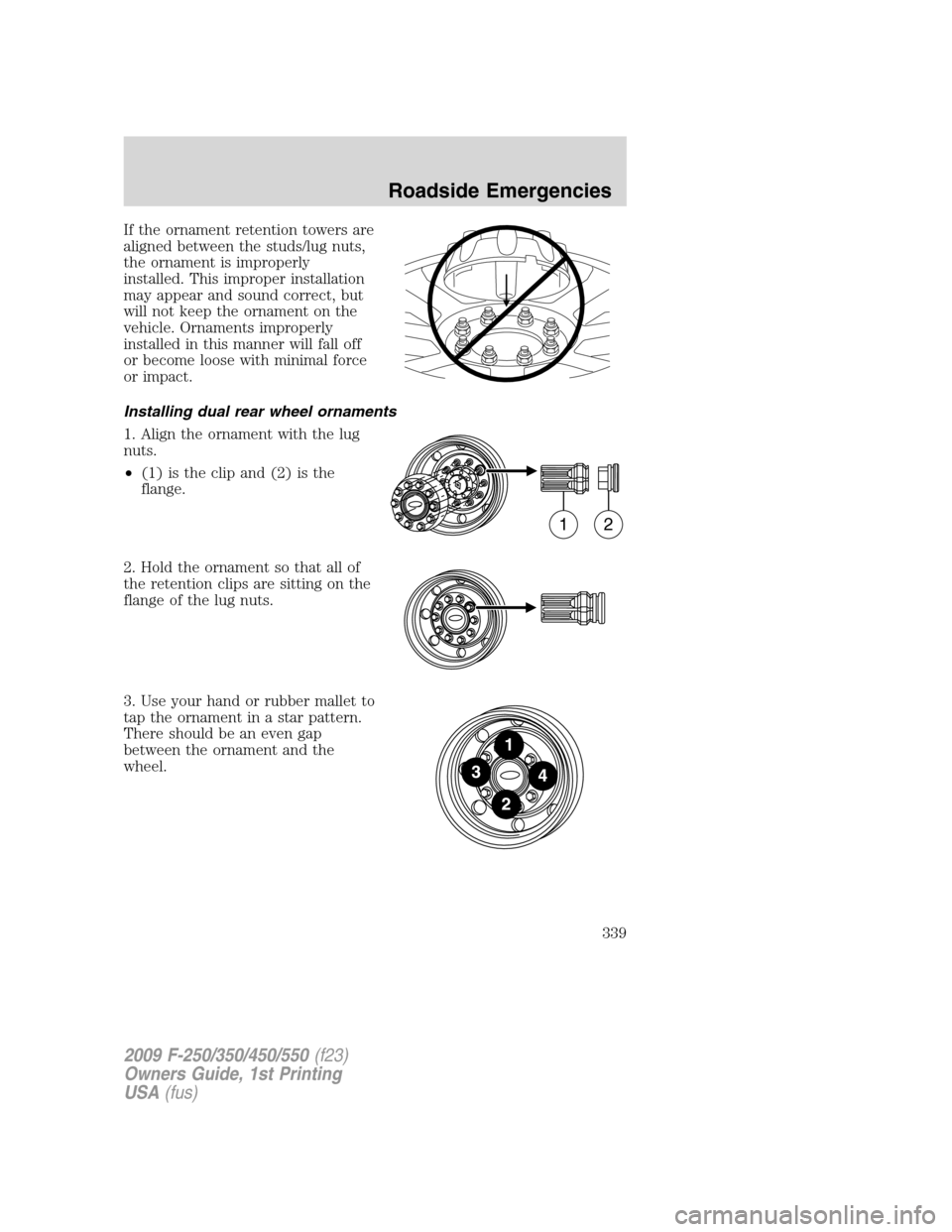

If the ornament retention towers are

aligned between the studs/lug nuts,

the ornament is improperly

installed. This improper installation

may appear and sound correct, but

will not keep the ornament on the

vehicle. Ornaments improperly

installed in this manner will fall off

or become loose with minimal force

or impact.

Installing dual rear wheel ornaments

1. Align the ornament with the lug

nuts.

•(1) is the clip and (2) is the

flange.

2. Hold the ornament so that all of

the retention clips are sitting on the

flange of the lug nuts.

3. Use your hand or rubber mallet to

tap the ornament in a star pattern.

There should be an even gap

between the ornament and the

wheel.

12

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

339